Flexural Behavior of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer under Hydrothermal Environment

-

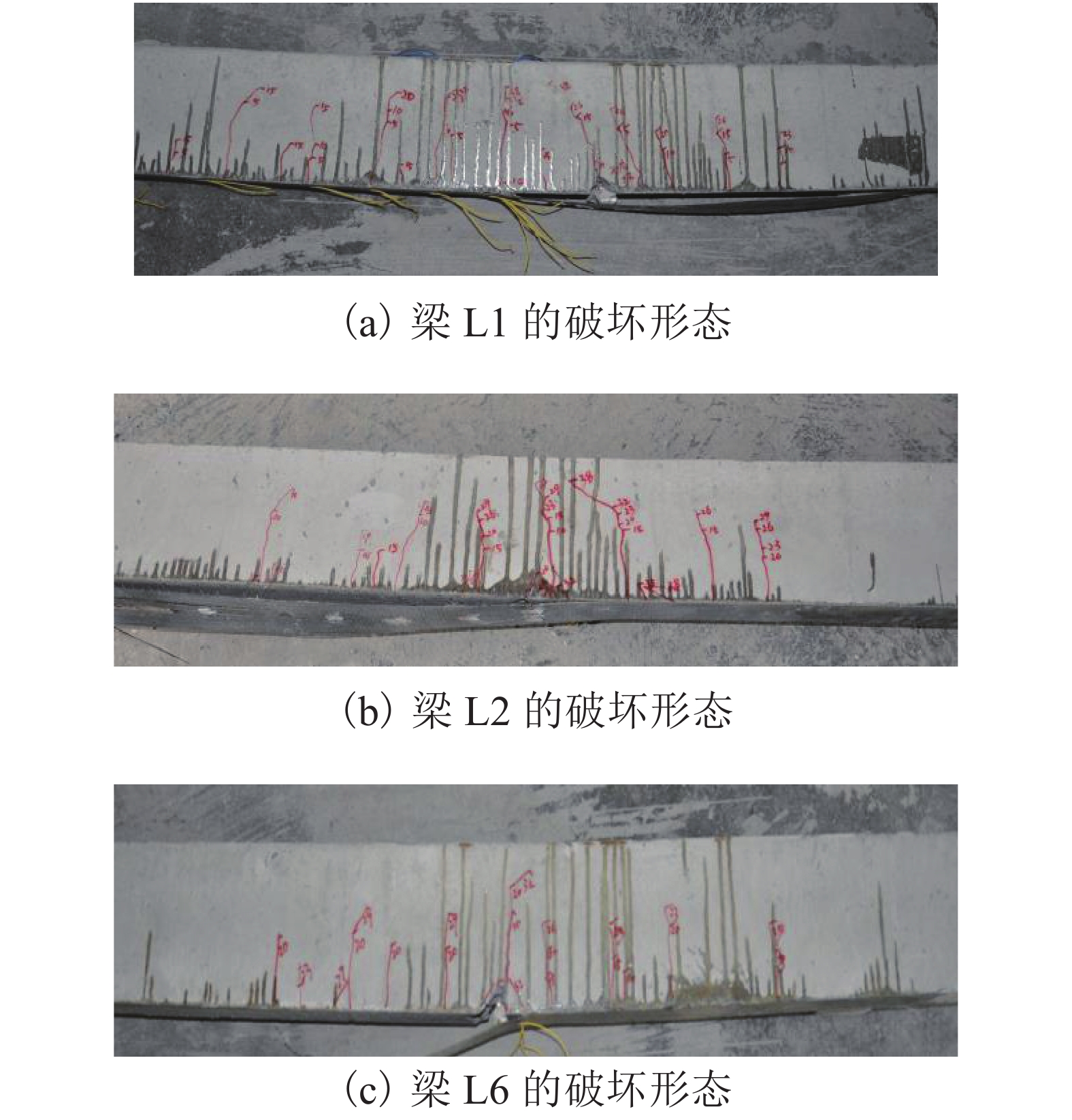

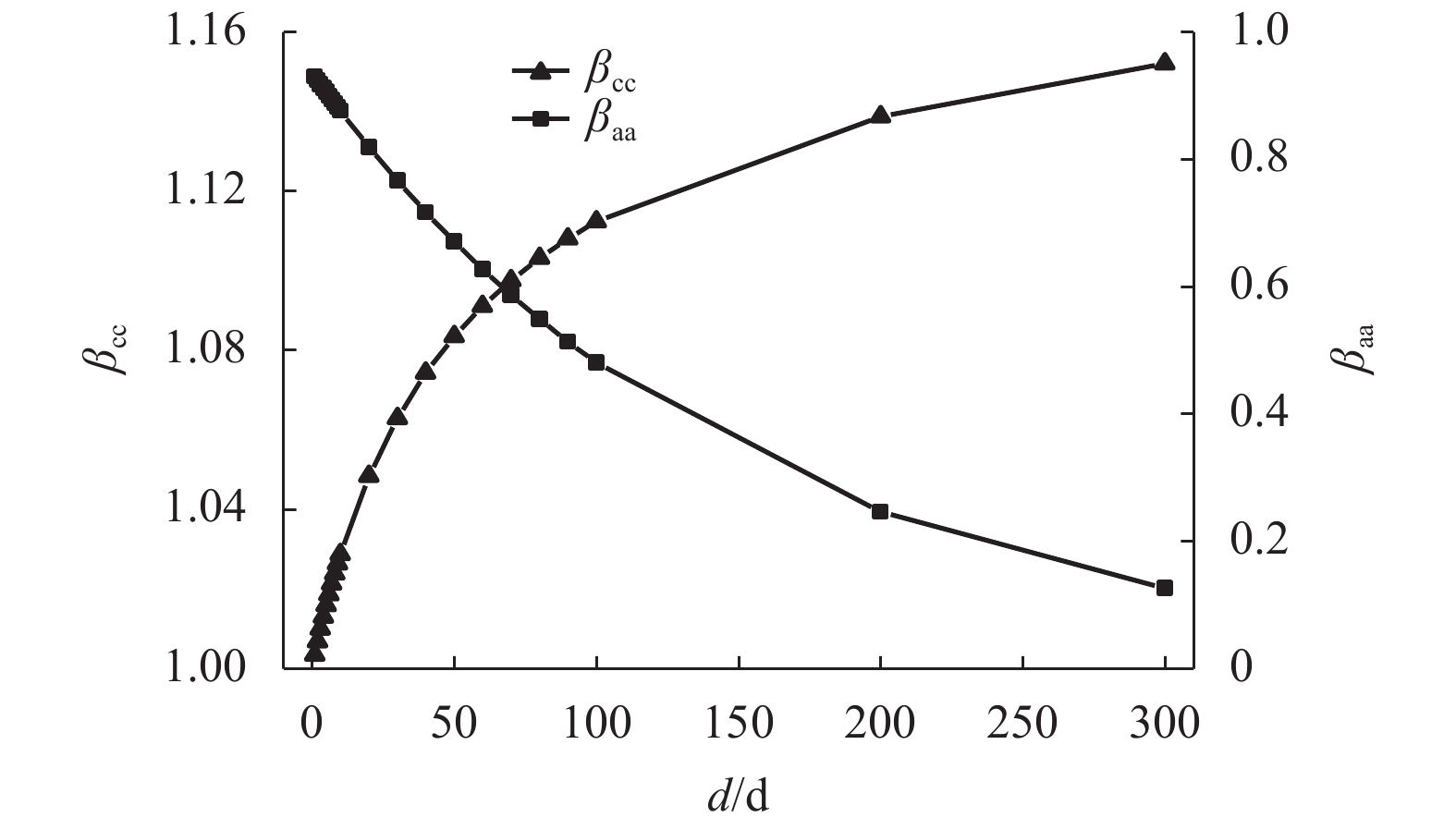

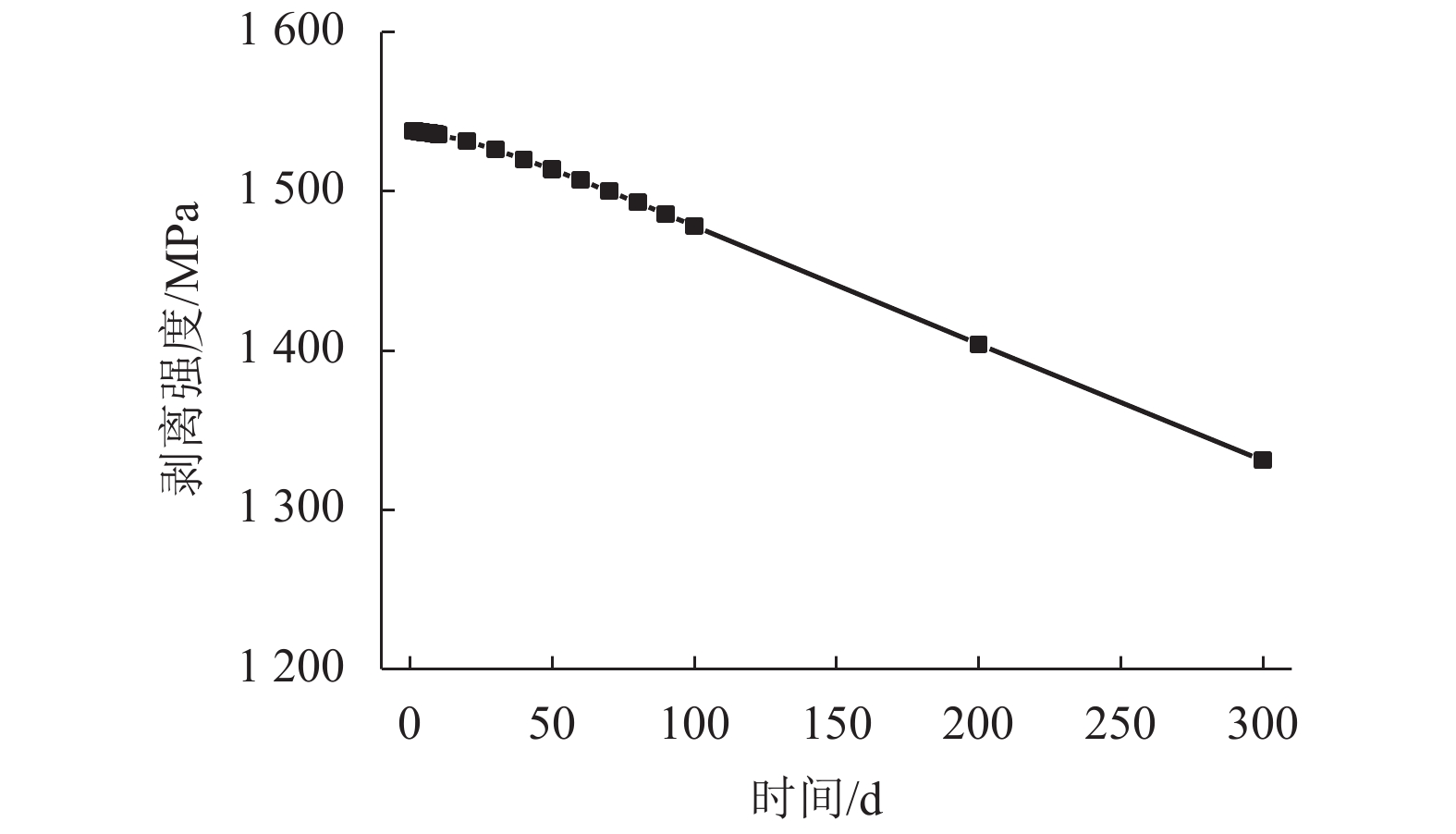

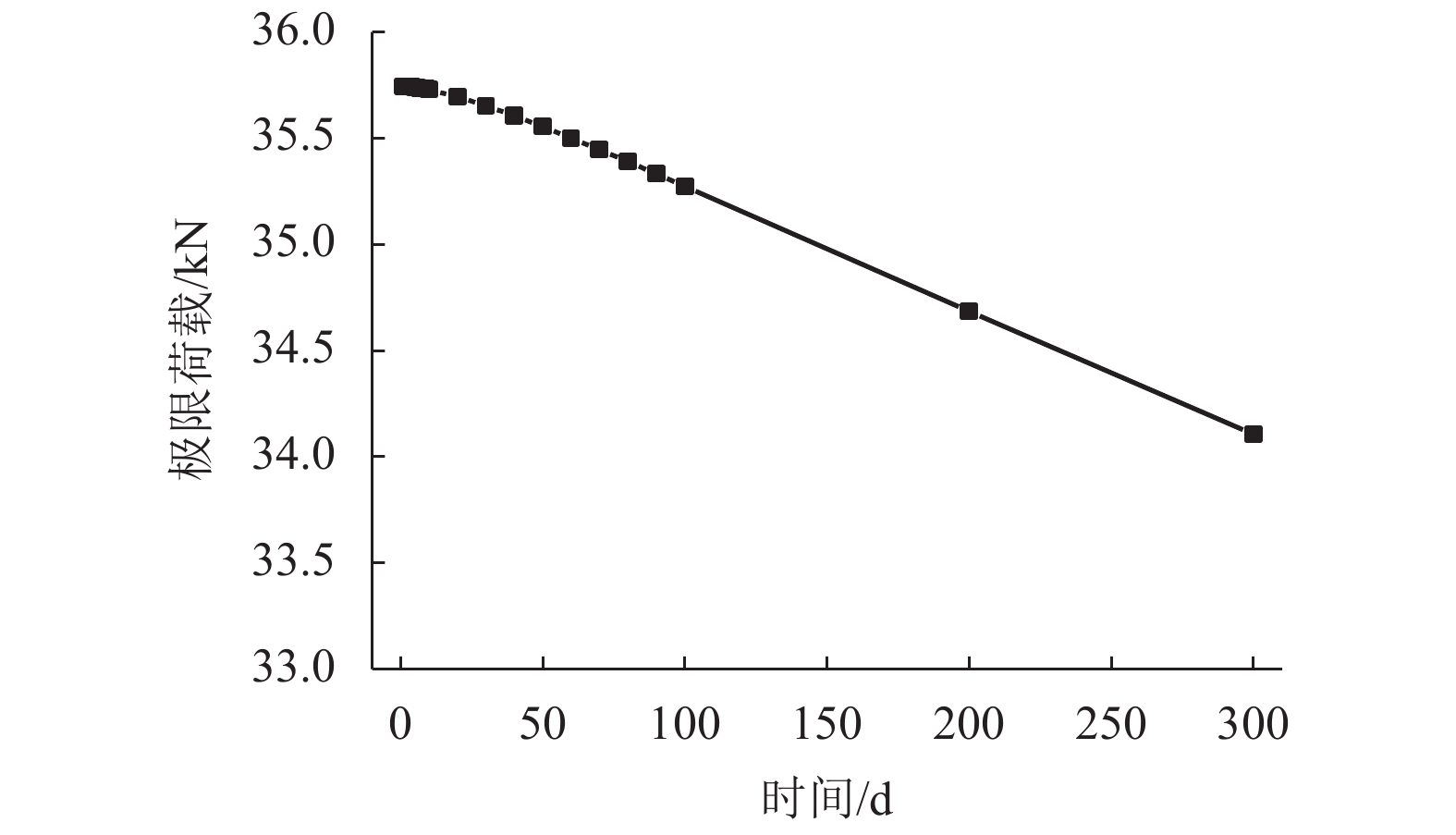

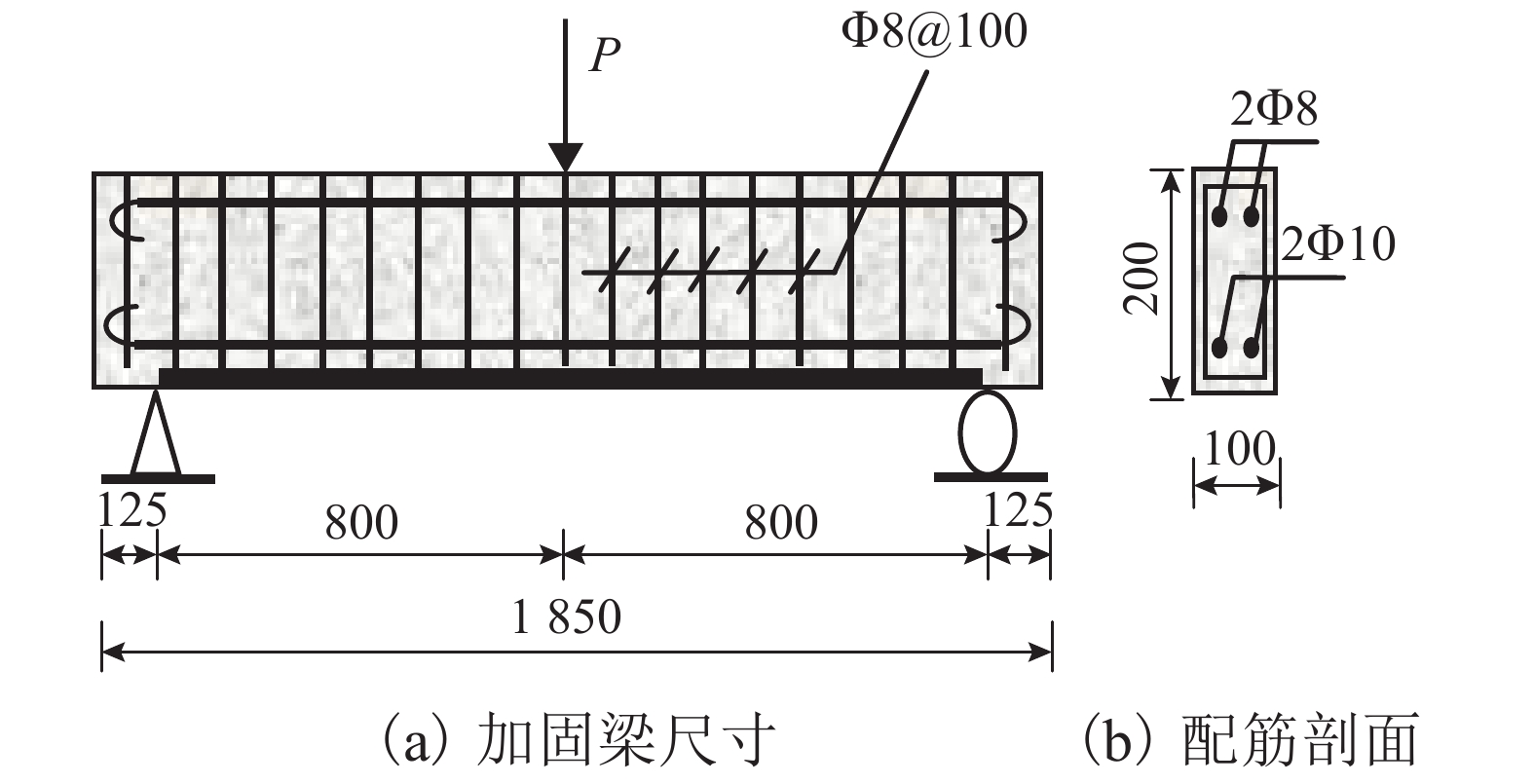

摘要: 为研究湿热环境下碳纤维增强复合材料(CFRP)加固钢筋混凝土结构的耐久性问题,采用6根湿热环境下CFRP加固的钢筋混凝土梁进行抗弯性能试验,研究在湿热环境下CFRP加固钢筋混凝土梁的破坏形态、承载力、挠度和裂缝等;根据环氧树脂老化的化学反应微分方程和反应速度的指数定律,给出环氧树脂胶层弹性模量的衰减模型;从混凝土和环氧树脂胶层的力学性能出发,提出湿热环境下CFRP加固钢筋混凝土结构后CFRP剥离时的强度计算公式,推导湿热环境作用下CFRP加固钢筋混凝土梁的抗弯承载力计算公式. 研究结果表明:随着湿热环境作用时间的增加,加固梁的抗弯承载力逐渐减小,CFRP剥离破坏由混凝土控制逐渐转换为由环氧树脂胶层控制;随着湿热环境作用的持续,混凝土裂缝数量减小、裂缝宽度增加但挠度减小,加固梁的损伤增大且脆性增加;加固梁的屈服曲率、极限曲率和曲率延性系数均减小,加固梁的延性变差且CFRP剥离破坏时的脆性和离散性增强;试验与理论计算的对比表明,在湿热环境作用下加固梁发生CFRP剥离破坏时,CFRP极限应变的理论值与试验值误差在20%以内,抗弯承载力的理论值与试验值误差在11%以内.Abstract: To study the durability of concrete structure strengthened with CFRP(carbon fiber reinforced polymer) under hydrothermal environment, six concrete beams strengthened with CFRP under warm and moisture conditions were used for flexural behavior experiment; the failure mode, bearing capacity, deflection and crack were studied by the experiment. Based on differential equations of chemical reactions and exponential law of reaction rate for epoxy resin aging, the attenuation model of elastic modulus was given for epoxy resin under warm and moisture conditions. From the mechanical properties of concrete and epoxy resin, theoretical formula of CFRP peel strength was given for concrete beams strengthened with CFRP under hydrothermal environment, and the flexural capacity formula was also put forward. The results show that the flexural capacity of strengthened concrete beams decrease exposed to environmental conditions, and peeling failure of CFRP is gradually transferring from the interface region of concrete side to the interface region of CFRP side. As the environmental effect continues, the number of cracks and deflection reduce while the crack width increases, which show that both damage and brittleness of strengthened beam increases. The yield curvature, ultimate curvature and curvature ductility factor of the strengthened beam reduce, and it indicates that the ductility of the strengthened beam deteriorates, but the brittleness and dispersion of the CFRP peeling failure increase. The comparison between the experimental and theoretical analysis shows that the relative error of the theoretical and the experimental value is smaller than 20% for CFRP ultimate strain, and the relative error is smaller than 11% for flexural capacity.

-

Key words:

- carbon fiber reinforced polymer sheet /

- peeling /

- hydrothermal environment /

- epoxy resin /

- reaction rate

-

表 1 钢筋的实测力学性能

Table 1. Mechanical property of steel

类别 型号 屈服强度/MPa 极限强度/MPa 延伸率% 弹性模量/GPa 塑性模量/GPa 受拉纵筋 Ф10 333.3 506.5 34.6 204 7.18 架立钢筋和箍筋 Ф8 310.0 500.0 23.0 194 — 表 2 CFRP的力学性能

Table 2. Mechanical property of CFRP

规格 理论厚度/mm 抗拉强度/MPa 弹性模量/GPa 伸长率/% WF300 0.167 3 609 243.0 1.71 表 3 环氧树脂粘结剂的力学性能

Table 3. Mechanical property of epoxy resin

MPa 规格 弹性模量 拉伸强度 压缩强度 剪切强度 弯曲强度 JGN-II ≥ 2 500 ≥ 40 ≥ 70 ≥ 14 ≥ 50 表 4 试验梁参数

Table 4. Parameters of experimental beams

试验梁编号 混凝土 配筋 粘贴层数/层 试验环境 环境作用时间/d L1 C30 2Φ10 1 正常 0 L2 C30 2Ф10 1 湿热 5 L3 C30 2Ф10 1 湿热 10 L4 C30 2Ф10 1 湿热 15 L5 C30 2Ф10 1 湿热 30 L6 C30 2Ф10 1 湿热 60 表 5 承载力试验结果

Table 5. Experimental results

试验梁

编号试验

环境环境用

时间/d开裂荷载/kN 与 L1 的

比值/%屈服荷载/kN 与 L1 的

比值/%极限荷载/kN 与 L1 的

比值/%CFRP极限

应变/× 10−6与 L1 的

比值/%破坏形态 L1 正常 0 8.80 100 26.73 100 40.01 100 6 926 100 中部裂缝

处剥离L2 湿热 5 8.90 101 24.96 94 40.42 101 6 527 94 L3 湿热 10 10.59 120 24.10 90 39.62 99 6 061 88 L4 湿热 15 10.82 123 22.99 86 39.29 98 6 018 87 L5 湿热 30 9.54 108 23.10 87 38.51 96 5 733 83 L6 湿热 60 7.30 83 22.71 85 37.20 93 5 150 74 表 6 裂缝与挠度试验结果

Table 6. Experimental results of crack and deflection

试验梁

编号试验

环境环境作用

时间/d裂缝

数量与 L1 的

比值/%平均裂缝

间距/mm与 L1 的

比值/%最大裂缝

宽度/mm与 L1 的

比值/%极限挠度/mm 与 L1 的

比值/%L1 正常 0 11 100 96.8 100 0.86 100 12.36 100 L2 湿热 5 11 100 86.4 89 0.91 106 11.91 96 L3 湿热 10 10 91 89.6 93 0.95 110 11.83 96 L4 湿热 15 10 91 98.4 102 1.04 121 10.05 81 L5 湿热 30 9 82 106.2 110 1.12 130 9.91 80 L6 湿热 60 9 82 101.5 105 1.17 136 8.46 68 表 7 曲率延性

Table 7. Experimental results of curvature ductility

试验梁

编号试验

环境环境作用

时间/d屈服曲率

/(× 10−6•mm−1)与 L1 的

比值/%极限曲率

/(× 10−6•mm−1)与 L1 的

比值/%曲率延性

系数与 L1 的

比值/%L1 正常 0 14.88 100 58.25 100 3.91 100 L2 湿热 5 14.84 99.7 53.02 91.0 3.57 91.3 L3 湿热 10 14.89 100 50.58 86.8 3.40 87.0 L4 湿热 15 14.72 98.9 53.48 91.8 3.63 92.8 L5 湿热 30 14.71 98.9 52.79 90.6 3.59 91.8 L6 湿热 60 14.67 98.6 49.62 85.2 3.38 86.4 表 8 弹性模量衰减与时间的关系

Table 8. Relationship between βaa and d

d/d 0 5 10 15 30 60 βaa 1.00 0.90 0.85 0.80 0.75 0.66 表 9 理论值与试验值的比较

Table 9. Comparison between theoretical and experimental values

试验梁编号 试验环境 环境作用时间/d CFRP 极限应变/× 10−6 极限荷载/kN 试验值 理论值 比值/% 试验值 理论值 比值/% L1 正常 0 6 926 6 362 92 40.01 35.81 90 L2 湿热 5 6 527 6 322 97 40.42 35.73 89 L3 湿热 10 6 061 6 319 104 39.62 35.72 90 L4 湿热 15 6 018 6 311 105 39.29 35.71 91 L5 湿热 30 5 733 6 280 110 38.51 36.65 95 L6 湿热 60 5 150 6 200 120 37.20 35.50 95 -

刘超越. 荷载/湿热环境作用下粘贴CFRP加固钢筋砼梁的耐久性研究[D]. 重庆: 重庆交通大学, 2016 任慧韬,胡安妮,姚谦峰. 湿热环境对FRP加固混凝土结构耐久性能的影响[J]. 哈尔滨工业大学学报,2006,38(11): 1996-1999. doi: 10.3321/j.issn:0367-6234.2006.11.045REN Huitao, HU Anni, YAO Qianfeng. The influence of wet-thermal condition on durability behavior of concrete structures strengthened by FRP[J]. Journal of Harbin Institute of Technology, 2006, 38(11): 1996-1999. doi: 10.3321/j.issn:0367-6234.2006.11.045 任慧韬,胡安妮,姚谦峰. 纤维增强聚合物加固混凝土结构耐久性能研究[J]. 大连理工大学学报,2005,45(6): 847-852. doi: 10.3321/j.issn:1000-8608.2005.06.015REN Huitao, HU Anni, YAO Qianfeng. Research on durability of concrete structures strengthened with FRP laminates[J]. Journal of Dalian University of Technology, 2005, 45(6): 847-852. doi: 10.3321/j.issn:1000-8608.2005.06.015 AU C, BUYUKOZTURK O. Peel and shear fracture characterization of debonding in FRP plated concrete affected by moisture[J]. Journal of Composites for Construction, 2006, 10(1): 35-47. doi: 10.1061/(ASCE)1090-0268(2006)10:1(35) OUYANG Zhengyu, WAN Baolin. Nonlinear deterioration model for bond interfacial fracture energy of FRP-concrete joints in moist environments[J]. Journal of Composites for Construction, 2009, 13(1): 53-63. doi: 10.1061/(ASCE)1090-0268(2009)13:1(53) DAI J G, YOKOTA H, IWANAMI M, et al. Experimental investigation of the influence of moisture on the bond behavior of FRP to concrete interfaces[J]. Journal of Composites for Construction, 2010, 14(6): 834-844. doi: 10.1061/(ASCE)CC.1943-5614.0000142 ZHANG Pu, WU Gang, ZHU Hong, et al. Mechanical performance of the wet-bond interface between FRP plates and cast-in-place concrete[J]. Journal of Composites for Construction, 2014, 18(6): 04014016-1-04014016-9. doi: 10.1061/(ASCE)CC.1943-5614.0000472 STRATFORD T J, BISBY L A. Effect of warm temperatures on externally bonded FRP strengthening[J]. Journal of Composites for Construction, 2012, 16(3): 235-244. doi: 10.1061/(ASCE)CC.1943-5614.0000260 JAIPURIAR A, FLOOD J P, BAKIS C E, et al. Glassy-rubbery transition behavior of epoxy resins used in FRP structural strengthening systems[C]//The 5th International Conference on FRP Composites in Civil Engineering. Berlin: Springer, 2011: 10-25. 郑小红. 湿热环境下CFL-混凝土界面粘结-滑移机理研究[D]. 广州: 华南理工大学, 2014 宋亮辉. 湿热环境下FRP-混凝土界面粘结性能的耐久性试验研究[D]. 广州: 广东工业大学, 2016 BETONBAN. Fib model code for concrete structures: 2010 CEB-FIP[S]. Berlin: Wilhelm Ernst & Sohn, 2013 BILOTTA A, FAELLA C, MARTINELLI E, et al. Indirect identification method of bilinear interface laws for FRP bonded on a concrete substrate[J]. Journal of Composites for Construction, 2012, 16(2): 171-184. doi: 10.1061/(ASCE)CC.1943-5614.0000253 SHRESTHA J, UEDA T, ZHANG D. Durability of FRP concrete bonds and its constituent properties under the influence of moisture conditions[J]. Journal of Materials in Civil Engineering, 2015, 27(2): A4014009-1-A4014009-14. DAI J G, GAO W Y, TENG J G. Bond-slip model for FRP laminates externally bonded to concrete at elevated temperature[J]. Journal of Composites for Construction, 2013, 17(2): 217-228. doi: 10.1061/(ASCE)CC.1943-5614.0000337 OBAIDAT Y T, HEYDEN S, DAHLBLOM O. Evaluation of parameters of bond action between FRP and concrete[J]. Journal of Composites for Construction, 2013, 17(5): 626-635. doi: 10.1061/(ASCE)CC.1943-5614.0000378 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2011 宋文娟. 玻纤增强环氧树脂复合材料耐海水腐蚀行为与寿命预测[D]. 哈尔滨: 哈尔滨工业大学, 2014 苗蓉丽, 闫素云,殷胜昔,等. 两种环氧树脂灌封料使用寿命研究[J]. 航空兵器,2006(2): 53-55. doi: 10.3969/j.issn.1673-5048.2006.02.015MIAO Rongli, YAN Suyun, YIN Shengxi, et al. Study on the life of two kinds of epoxy resin[J]. Aero Weaponry, 2006(2): 53-55. doi: 10.3969/j.issn.1673-5048.2006.02.015 吕小军,张琦,马兆庆,等. 湿热老化对碳纤维/环氧树脂基复合材料力学性能影响研究[J]. 材料工程,2005(11): 50-53. doi: 10.3969/j.issn.1001-4381.2005.11.014LÜ Xiaojun, ZHANG Qi, MA Zhaoqing, et al. Study of hydro thermal aging effect on mechanical properties of carbon fiber/epoxy resin composites[J]. Journal of Materials Engineering, 2005(11): 50-53. doi: 10.3969/j.issn.1001-4381.2005.11.014 AYDIN H, GRAYINA R J, VISINTIN P. Durability of adhesively bonded FRP-to-concrete joints[J]. Journal of Composites for Construction, 2016, 20(5): 04016016-1-04016016-19. TOUTANJI H, HAN M, GHORBEL E. Interfacial bond strength characteristics of FRP and RC substrate[J]. Journal of Composites for Construction, 2015, 16(1): 35-46. TOUTANJI H, SAXENA P, ZHAO L, et al. Prediction of interfacial bond failure of FRP:concrete surface[J]. Journal of Composites for Construction, 2007, 11(4): 427-436. doi: 10.1061/(ASCE)1090-0268(2007)11:4(427) 四川省住房和城乡建设厅. 混凝土结构加固设计规范: GB 50367—2013[S]. 北京: 中国建筑工业出版社, 2014 -

下载:

下载: