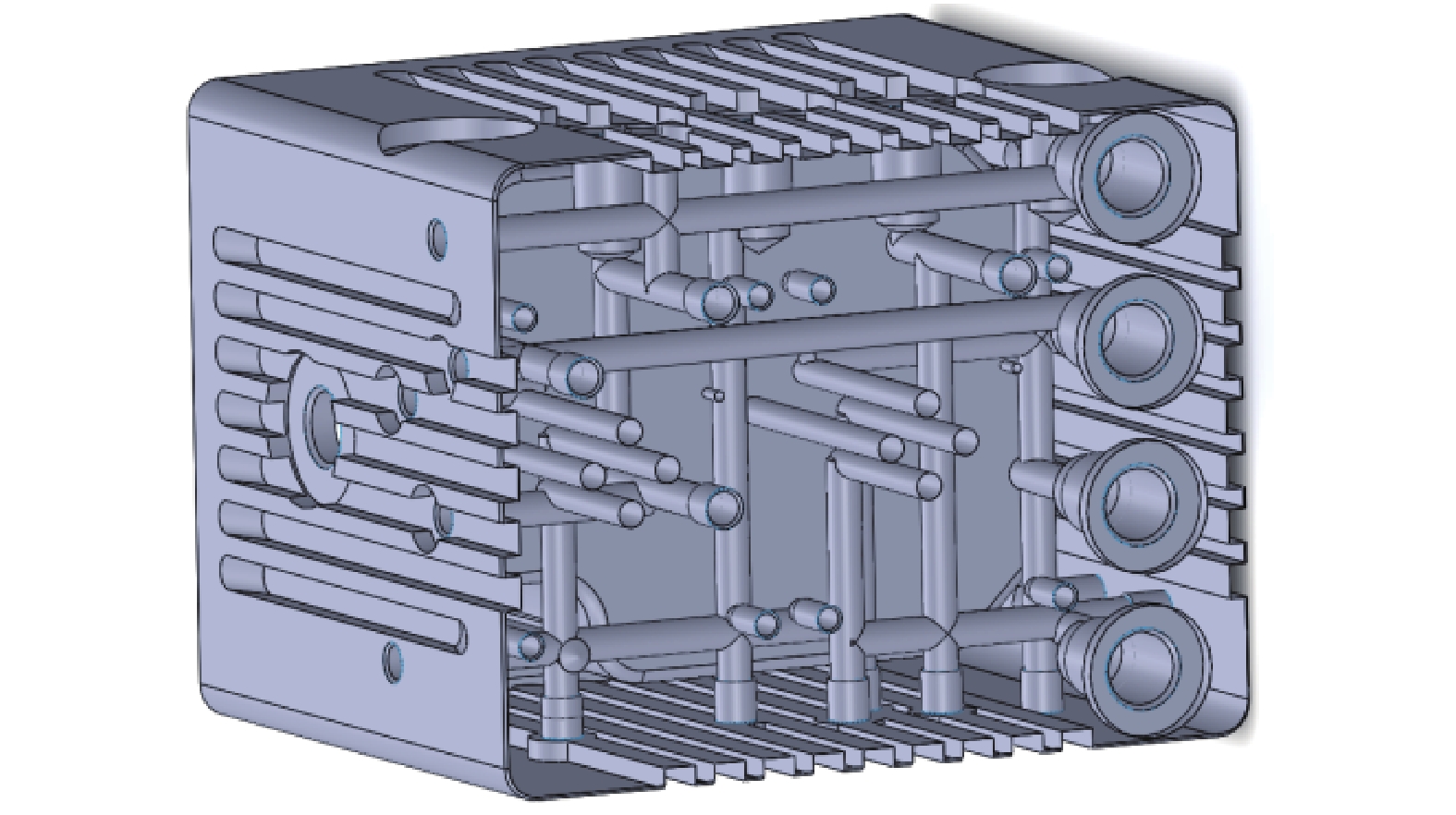

Flow Field Analysis and Optimization for Internal Channel of Hydraulic Manifold Block in Lower Extremity Exoskeleton Robot

-

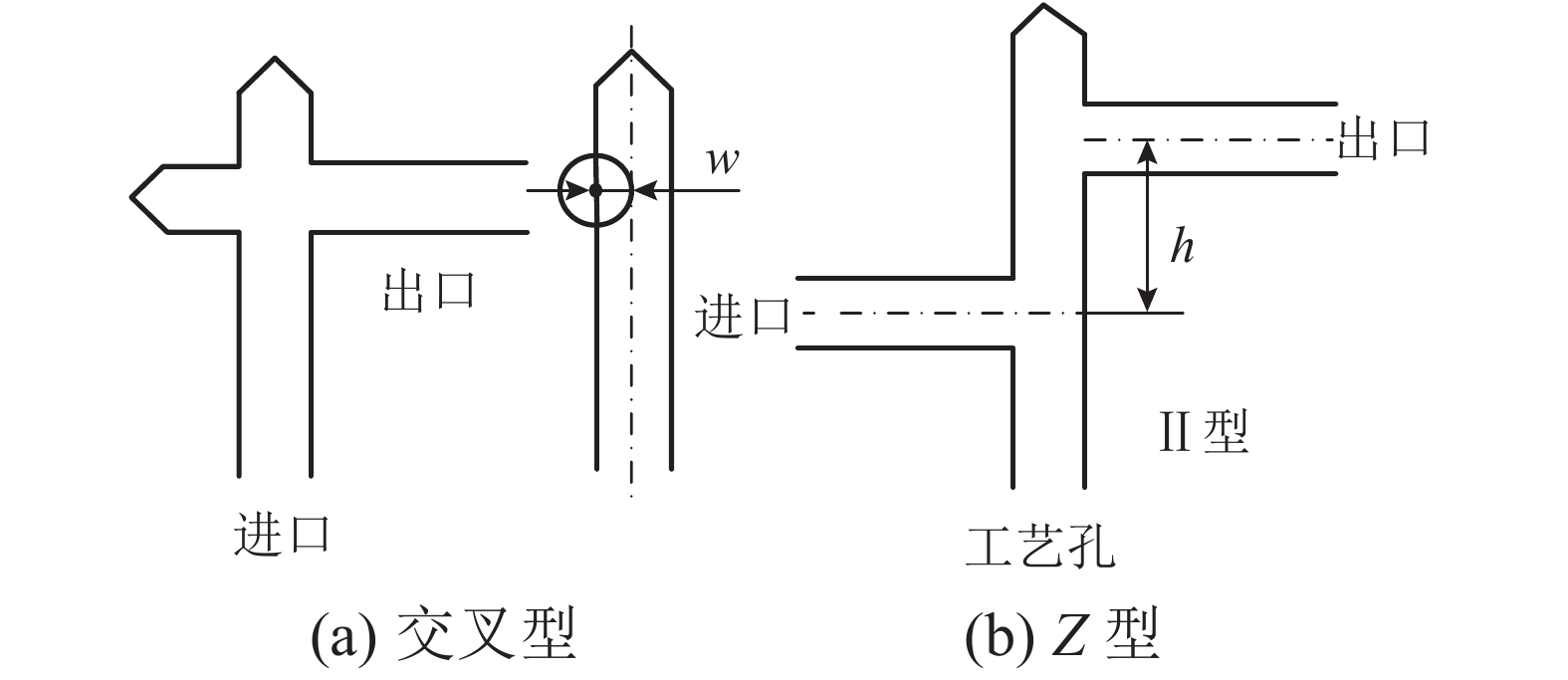

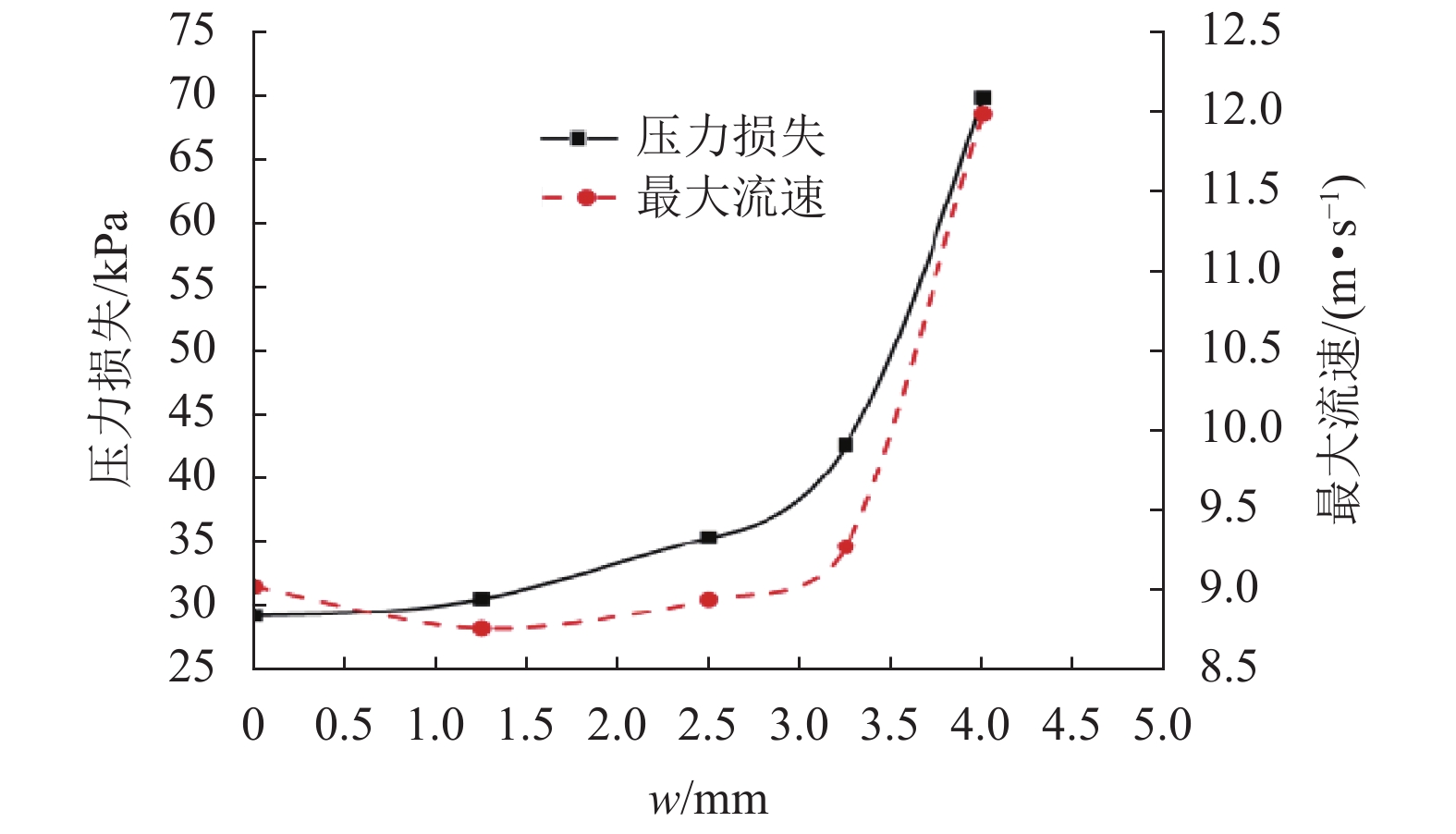

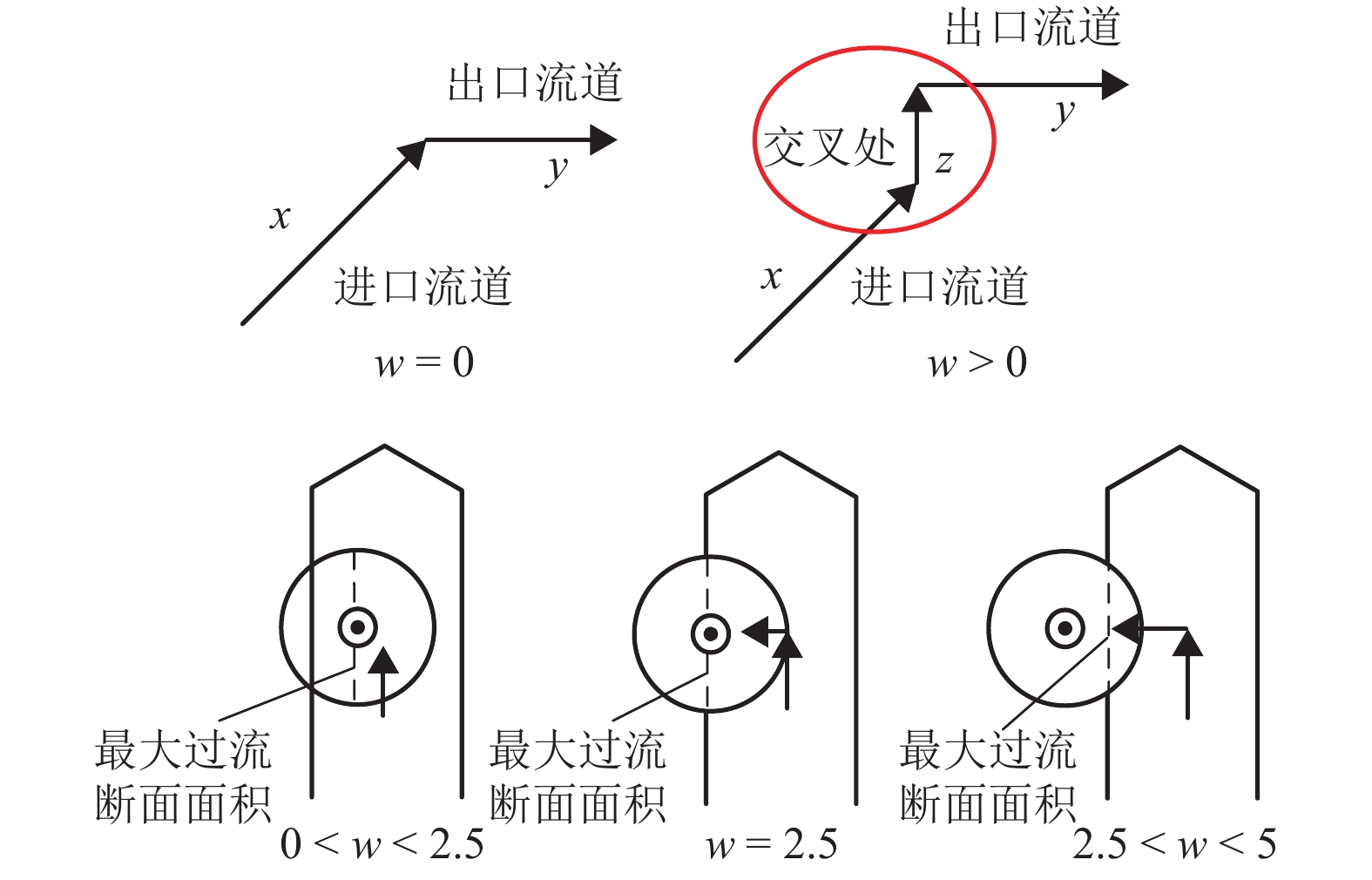

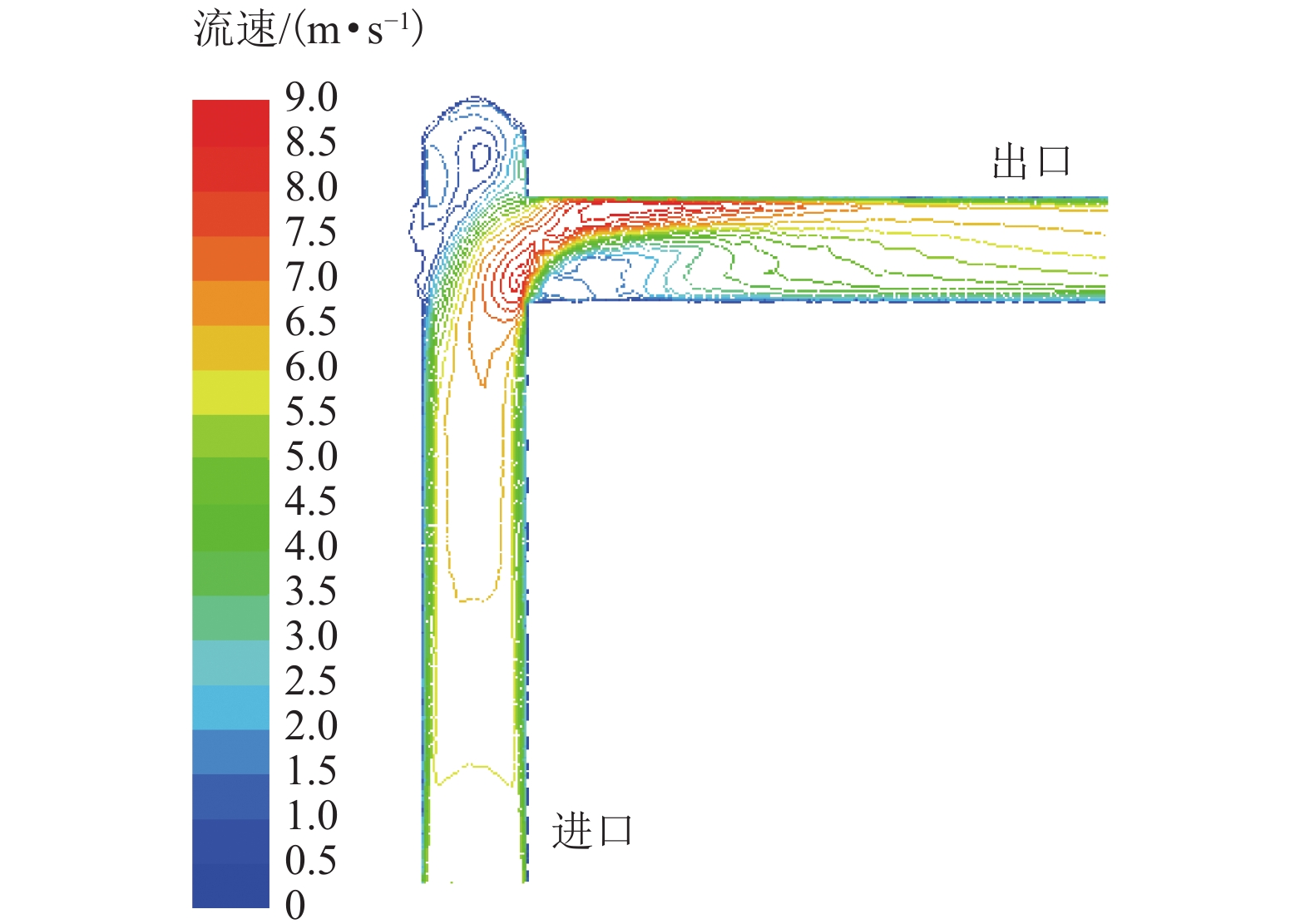

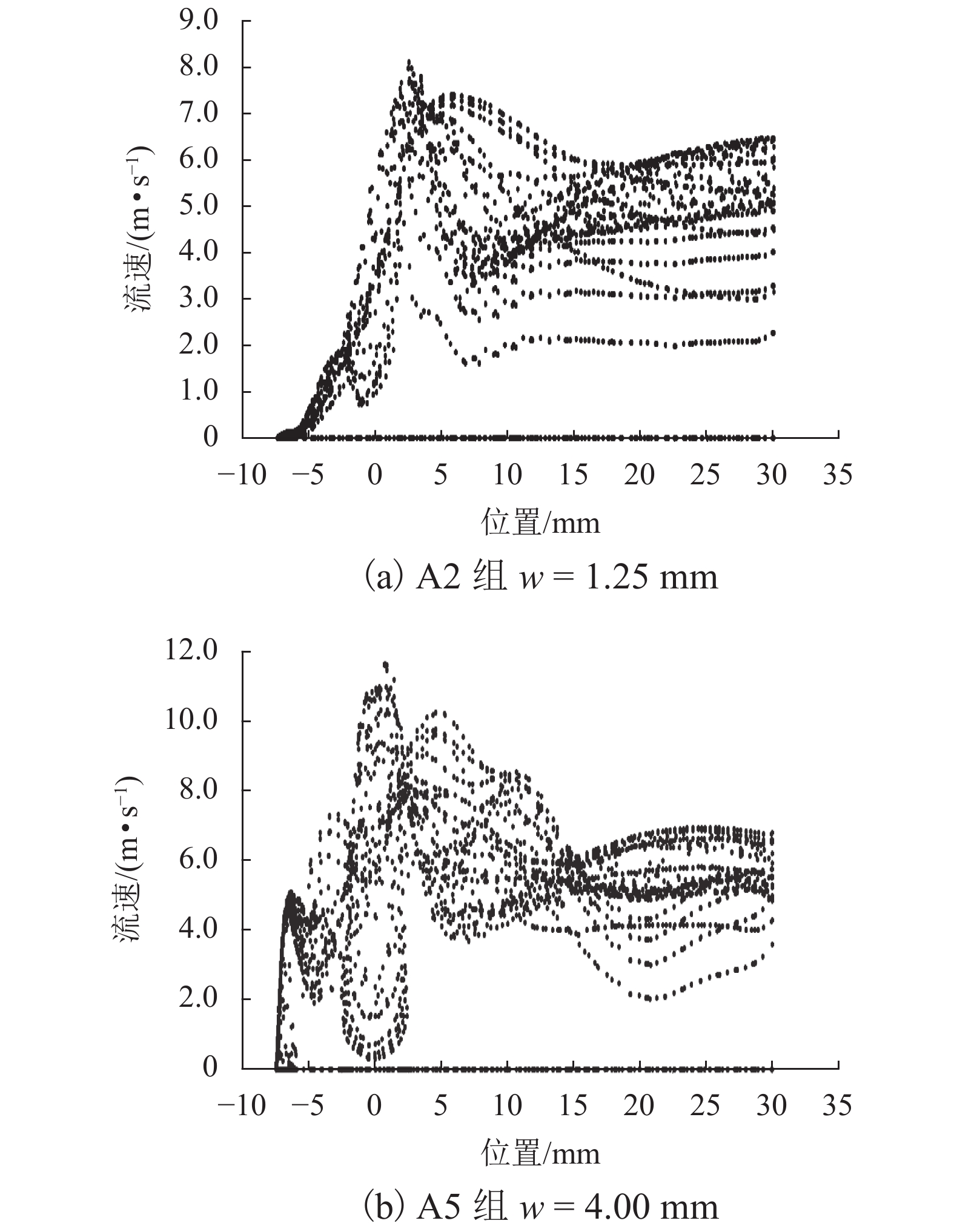

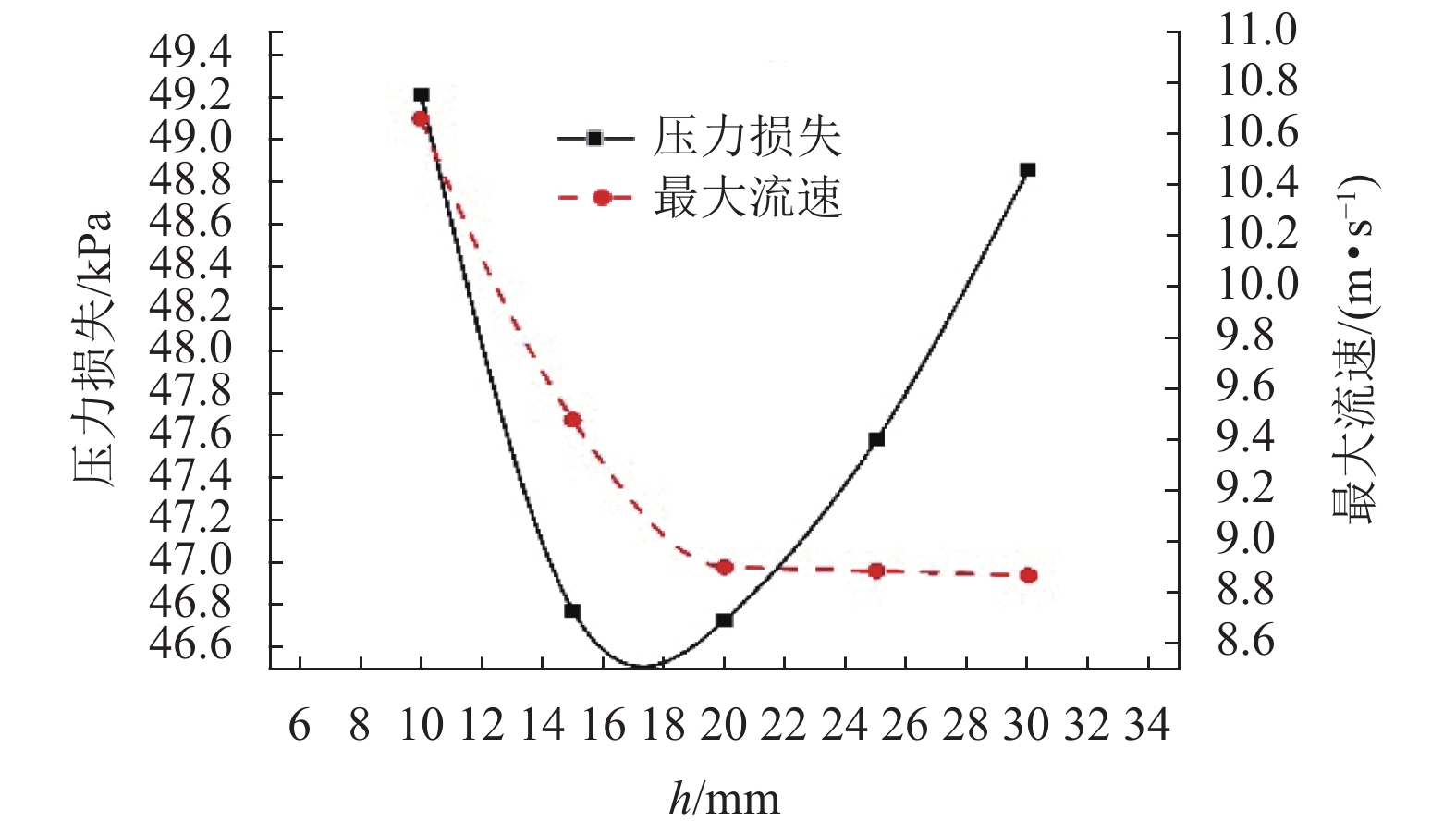

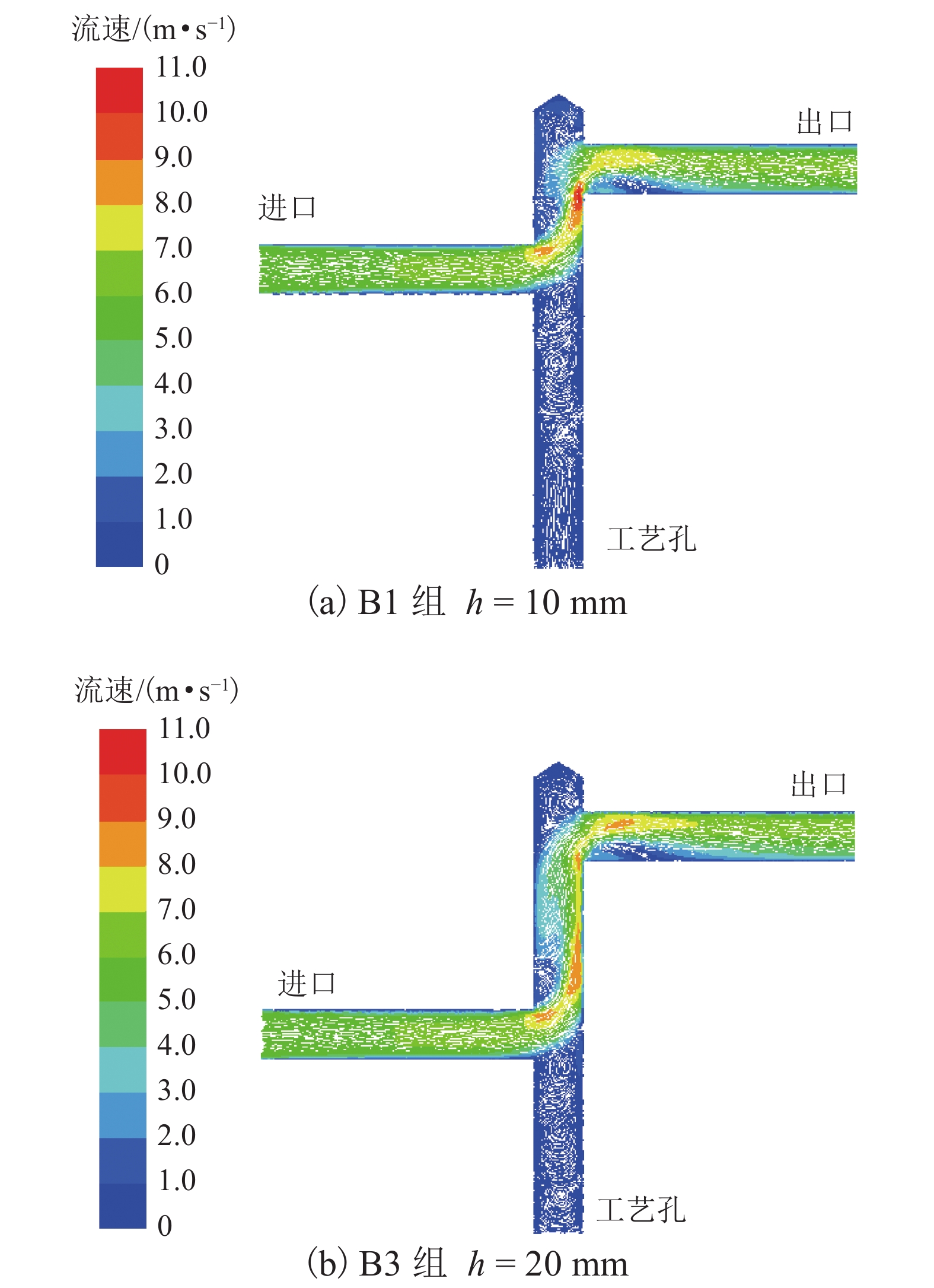

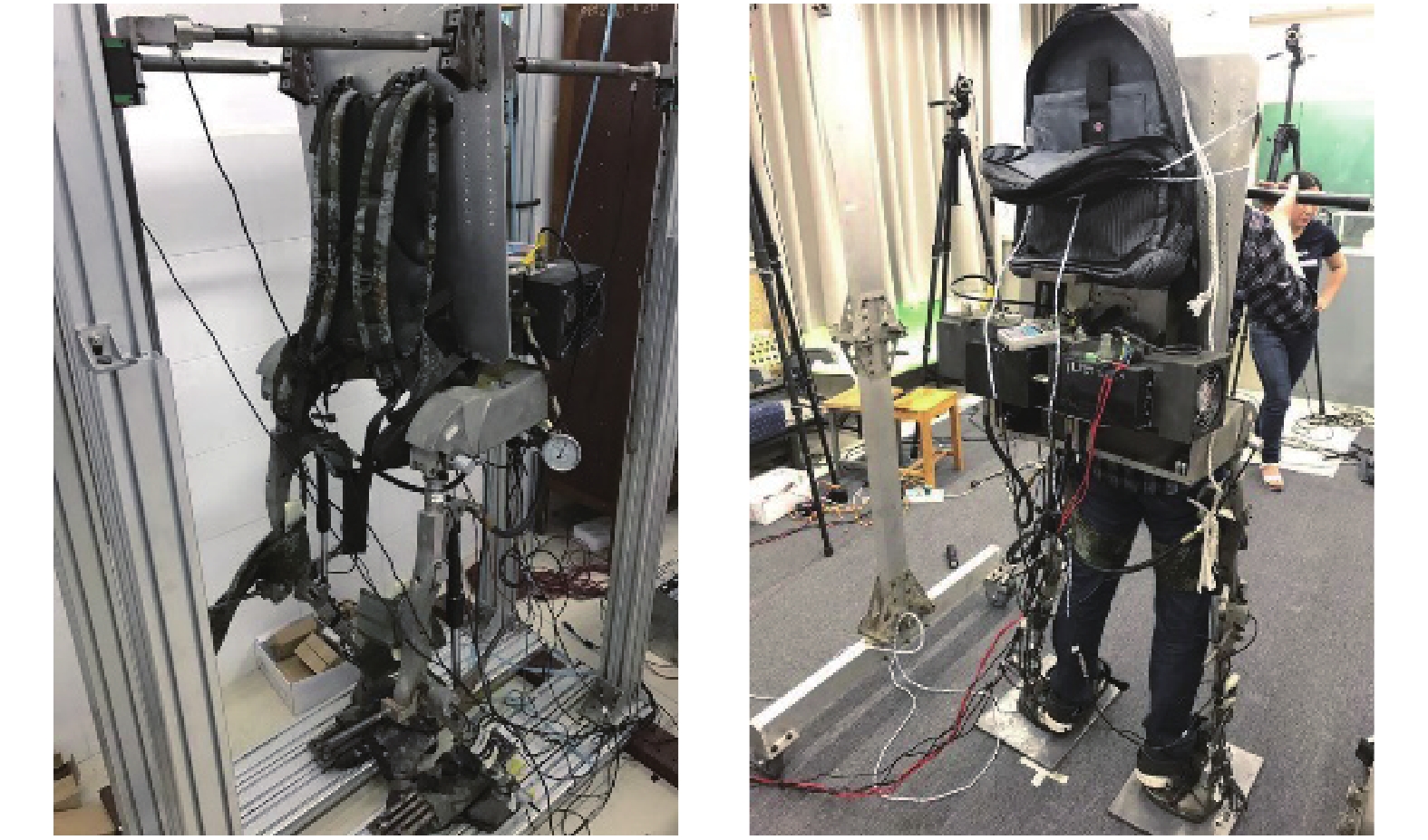

摘要: 为了研究负重型外骨骼液压动力单元温升及噪声过大的问题,利用ANSYS Fluent软件对负重型外骨骼液压阀块内部流道主要组成部分Z型流道和交叉流道进行计算流体动力学仿真,分别设计了5组不同尺寸的仿真试验,分析不同流道尺寸下流体速度稳定性与压力损失变化情况. 仿真试验表明,对于流道直径为5 mm的外骨骼动力单元液压阀块交叉流道压力损失随着进出口流道偏心距的增大而增大,流体速度在偏心距为 1.25 mm时稳定性最好;Z型流道压力损失在进出口流道之间的距离为 17 mm时达到最小,流体速度随着该距离的增大其稳定性上升. 优化过后的样机试验表明,液压阀块最大温度下降了3.3 ℃,最大噪声下降了7.6 dB.Abstract: In order to deal with the excessive temperature rise and noise of the hydraulic power unit in the lower extremity exoskeleton robot, ANSYS Fluent software was used for the simulation tests of Z-channel and cross-channel, which are the main components of internal flow channel of the hydraulic manifold block. Furthermore, 5 groups of simulation test with different sizes are designed to analyze how the stability of flow velocity and pressure loss change with channel dimension. The simulation test shows that when the channel diameter is 5 mm, the pressure loss of the cross-channel increases with eccentricity between the inlet and outlet; and the stability of flow velocity is the best when eccentricity is 1.25 mm. The pressure loss of Z-channel reaches the minimum when the distance between inlet and outlet is 17 mm, and the stability of fluid velocity increases with the distance. The optimized prototype test shows that the maximum temperature of the hydraulic manifold block was decreased by 3.3 ℃ and the maximum noise was decreased by 7.6 dB.

-

表 1 交叉型流道仿真结果

Table 1. Simulations results of cross-channel

分组 w/mm 压力损失/Pa 最大流速/(m•s–1) A1 0.00 29 069 9.009 A2 1.25 30 411 8.742 A3 2.50 35 210 8.930 A4 3.25 42 513 9.260 A5 4.00 69 917 11.992 表 2 Z型流道仿真结果

Table 2. Simulations results of Z-channel

分组 h/mm 压力损失/Pa 最大流速/(m•s–1) B1 10 49 208 10.661 B2 15 46 775 9.478 B3 20 46 729 8.900 B4 25 47 582 8.884 B5 30 48 856 8.866 表 3 样机试验结果

Table 3. Test results of prototypes

动力单元 30 min 时温度/℃ 最大噪音/dB 旧 55.8 73.4 新 52.5 65.8 -

STEGER R, KIM S H, KAZEROONI H. Control scheme and networked control architecture for the Berkeley lower extremity exoskeleton (BLEEX)[C]// IEEE International Conference on Robotics and Automation. [S.l.]: IEEE, 2006: 3469-3476 ZOSS A B, KAZEROONI H, CHU A. Biomechanical design of the Berkeley lower extremity exoskeleton (BLEEX)[J]. IEEE/ASME Transactions on Mechatronics, 2006, 11(2): 128-138. doi: 10.1109/TMECH.2006.871087 周加永,张昂,莫新民,等. 液压驱动型负重外骨骼机器人液压系统设计[J]. 机床与液压,2016(21): 30-34. doi: 10.3969/j.issn.1001-3881.2016.21.007ZHOU Jiayong, ZHANG Ang, MO Xinmin, et al . Hydraulic system design of hydraulic-driven load exoskeleton robot[J]. Machine Tool & Hydraulics, 2016(21): 30-34. doi: 10.3969/j.issn.1001-3881.2016.21.007 AMUNDSON K, RAADE J, HARDING N, et al. Hybrid hydraulic-electric power unit for field and service robots[C]// IEEE/RSJ International Conference on Intelligent Robots and Systems. [S.l.]: IEEE, 2005: 3453-3458 WANG Zhixin. Raytheon launched XOS2 second-generation exoskeleton device[J]. Light Weapons, 2010, 24: 44. GHAN J, STEGER R, KAZEROONI H. Control and system identification for the Berkeley lower extremity exoskeleton (BLEEX)[J]. Advanced Robotics, 2006, 20(9): 989-1014. doi: 10.1163/156855306778394012 王超,王玉林,宋慧新. 人体助力行走机器人关键技术分析[J]. 车辆与动力技术,2014,1(1): 53-57.WANG Chao, WANG Yulin, SONG Huixin. Key technologies analysis of human stepped power assist device[J]. Vehicle & Power Technology, 2014, 1(1): 53-57. 高殿荣,王益群. 液压集成块内弯曲流道流场数值计算与分析[J]. 机床与液压,2001(6): 34-35. doi: 10.3969/j.issn.1001-3881.2001.06.014GAO Dianrong, WANG Yiqun. Numerical calculation and analysis of curved flow field in hydraulic integration block[J]. Machine Tool & Hydraulics, 2001(6): 34-35. doi: 10.3969/j.issn.1001-3881.2001.06.014 林义忠,陈丽莉,张忠南. 液压集成块典型转弯孔道流场仿真分析[J]. 机床与液压,2012(5): 134-137. doi: 10.3969/j.issn.1001-3881.2012.05.042LIN Yizhong, CHEN Lili, ZHANG Zhongnan. Simulation and analysis of flow field of typical turning channel inside hydraulic manifold block[J]. Machine Tool & Hydraulics, 2012(5): 134-137. doi: 10.3969/j.issn.1001-3881.2012.05.042 林义忠,唐忠盛,黄光永,等. 液压集成块直角孔道局部压力损失的仿真及实验研究[J]. 机床与液压,2012(23): 38-41. doi: 10.3969/j.issn.1001-3881.2012.23.010LIN Yizhong, TANG Zhongsheng, HUANG Guangyong, et al. Simulation and experimental study of local pressure loss at right angle channel inside hydraulic manifold blocks[J]. Machine Tool & Hydraulics, 2012(23): 38-41. doi: 10.3969/j.issn.1001-3881.2012.23.010 吴正坤,赵毅红,吕宵宵,等. 基于Fluent液压集成块内部流场数据仿真[J]. 机械工程与自动化,2014(6): 76-77,80. doi: 10.3969/j.issn.1672-6413.2014.06.031WU Zhengkun, ZHAO Yihong, LÜ Xiaoxiao, et al. Fluent-based numerical simulation of internal flow field of hydraulic manifold[J]. Mechanical Engineering and Automation, 2014(6): 76-77,80. doi: 10.3969/j.issn.1672-6413.2014.06.031 付永领, 阳加远, 朱德明. 基于Fluent的电液泵流场与温度场有限元分析[J]. 北京航空航天大学学报, 2017, 43(8): 1647-1653FU Yongling, YANG Jiayuan, ZHU Deming. Finite element analysis of flow field and temperature field of electro-hydraulic pump by Fluent[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(8): 1647-1653 吴健兴,路芳,吴昌锋. 基于CFD的液压多路阀阀后压力补偿回路流道流场仿真研究[J]. 液压气动与密封,2017,37(5): 6-7, 12. doi: 10.3969/j.issn.1008-0813.2017.05.002WU Jianxing, LU Fang, WU Changfeng. Research on the flow-channel's flow-field of the pressure-compensated circuit for the load sensitive multi-way valve based on CFD[J]. Hydraulics Pneumatics & Seals, 2017, 37(5): 6-7, 12. doi: 10.3969/j.issn.1008-0813.2017.05.002 侯占勇,胡军科,周创辉. 混凝土泵高低压切换阀典型管网液流特性[J]. 长安大学学报(自然科学版),2014(6): 168-174. doi: 10.3969/j.issn.1671-8879.2014.06.025HOU Zhanyong, HU Junke, ZHOU Chuanghui. Flowing characteristics of typical pipeline network of pressure switching valve block in concrete pump[J]. Journal of Chang'an University (Natural Science Edition), 2014(6): 168-174. doi: 10.3969/j.issn.1671-8879.2014.06.025 田瑞峰, 刘平安. 传热与流体流动的数值计算[M]. 哈尔滨: 哈尔滨工程大学出版社, 2015: 211-234 任国志. 某船舶操舵系统液压噪声控制的理论建模与仿真研究[D]. 武汉: 华中科技大学, 2006 -

下载:

下载: