Layout Optimization of Spatial Rigid Frame by Second-Order Effect Analysis

-

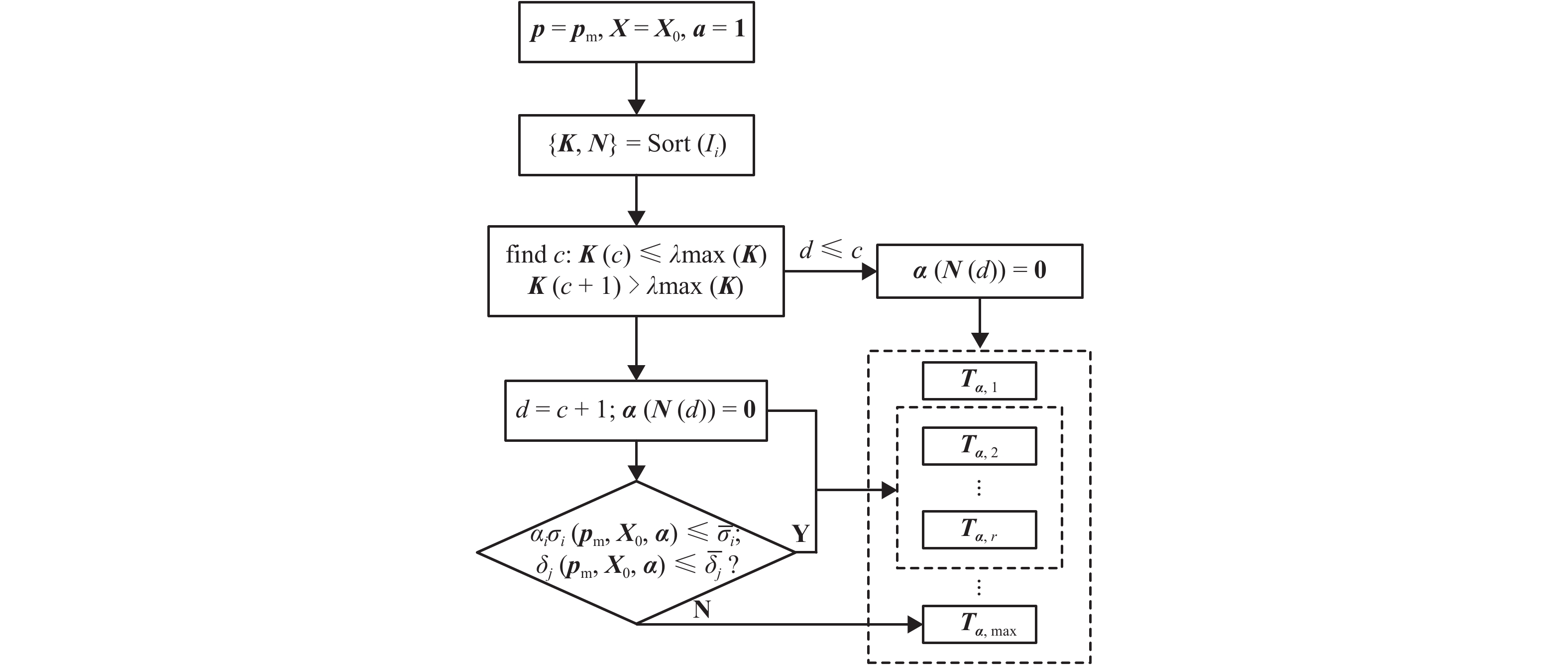

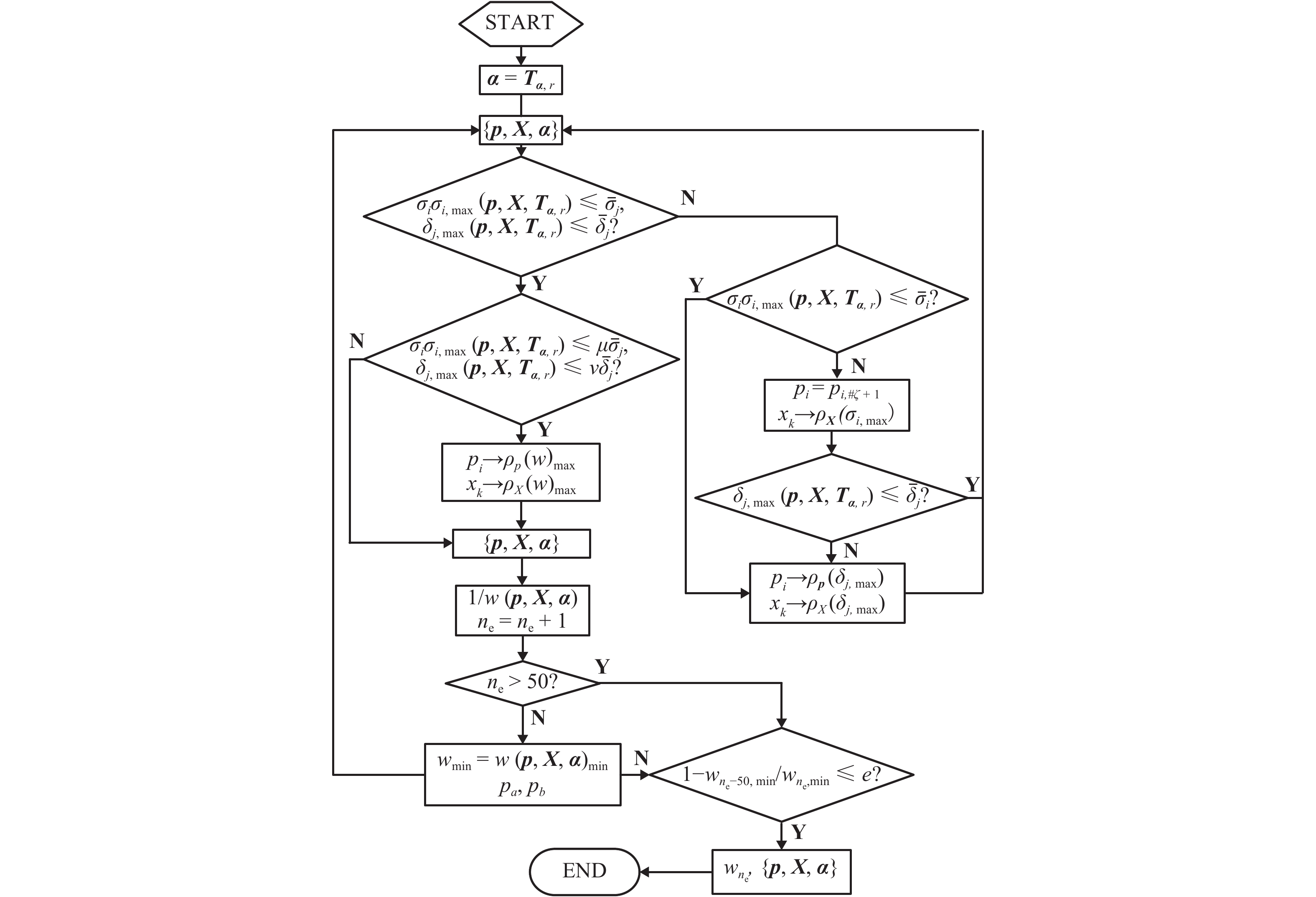

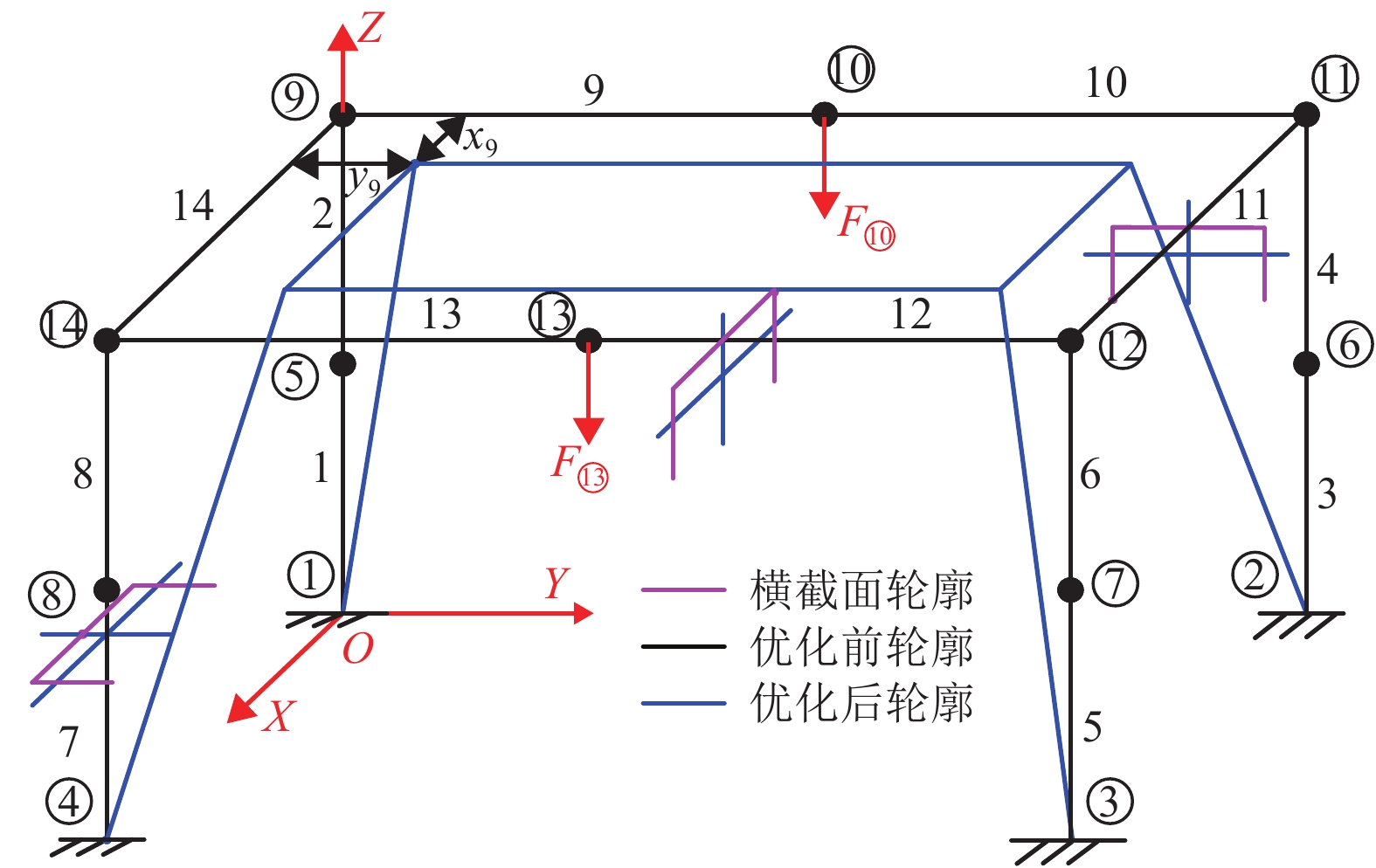

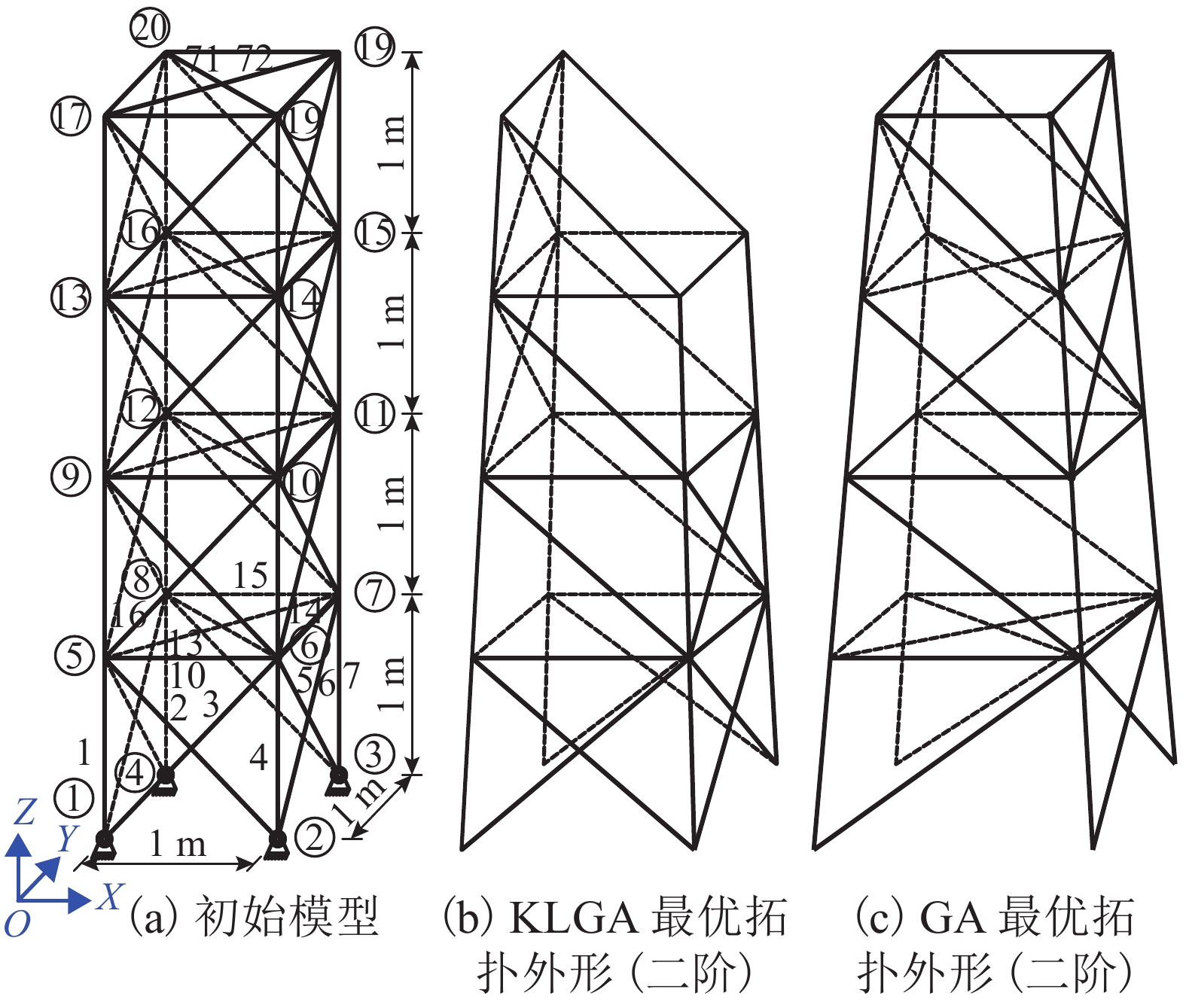

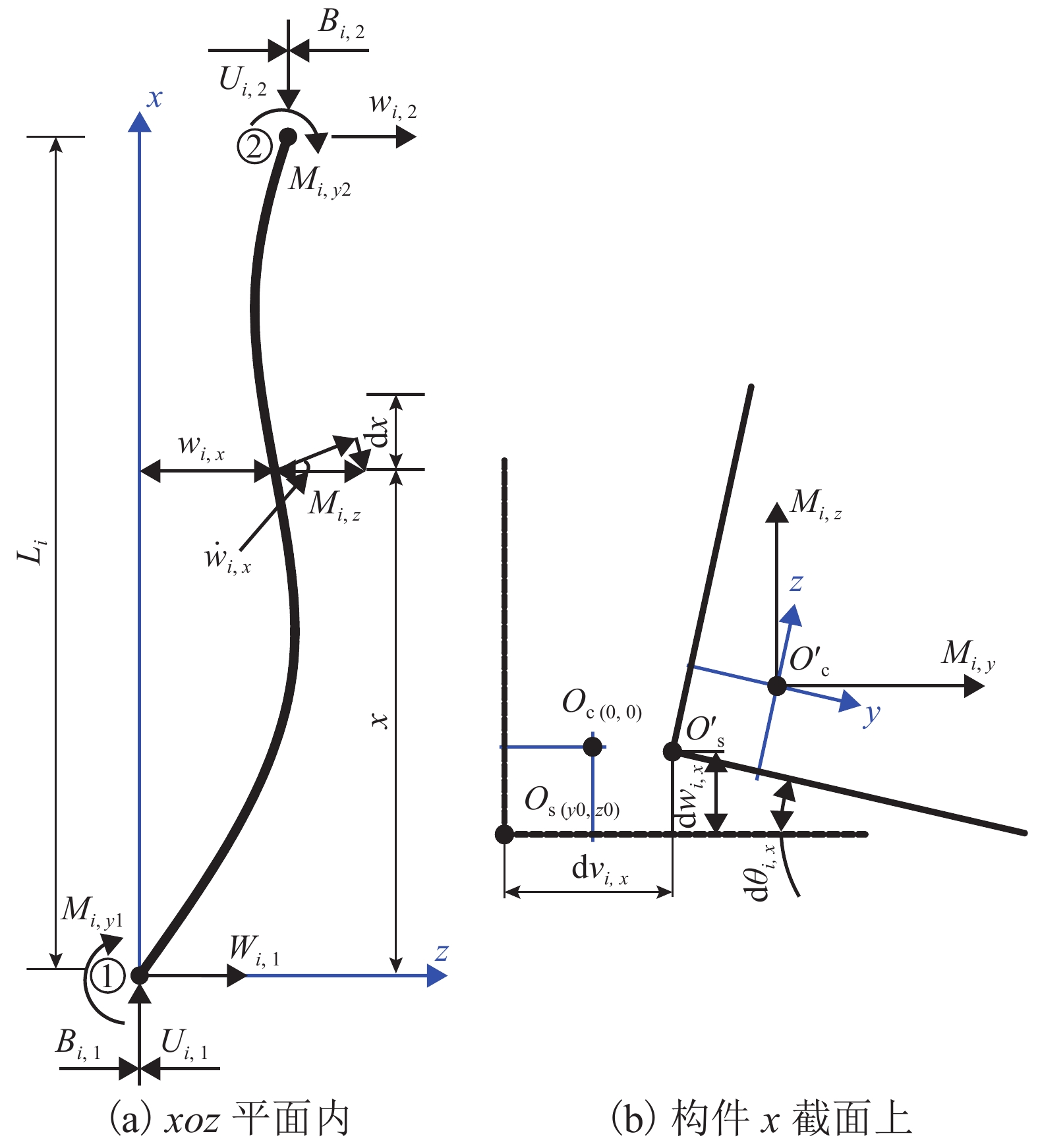

摘要: 针对三维空间刚架布局优化问题,以七自由度节点梁柱单元二阶弹性理论推导考虑构件几何非线性和截面翘曲变形的非线性刚度矩阵,通过整合梁柱单元非线性刚度矩阵对刚架结构进行整体的二阶弹性分析,建立满足刚架结构强度、刚度和稳定性要求的布局优化数值模型;并针对复杂刚架结构布局优化数值求解问题,改进遗传搜索算法(GA),提出可靠拓扑和引导型遗传算法双向控制方法(KLGA). 该方法一方面将拓扑变量从布局设计变量中分离,以构件重要度评定结构可靠拓扑变量组合,再与设计变量整合;另一方面将结构特有的引导信息加入算法中,为GA提供全局最优解的指引路径. 通过两种典型的刚架算例表明二阶效应模型和KLGA算法的可行性和有效性,例如算例2中基于二阶效应模型的KLGA得到的最优结构质量比GA减轻了24.5%,波动幅度从9.61%提升到1.39%,算法更加稳定.Abstract: In order to handle three-dimensional spatial frame layout optimization, nonlinear rigidity matrix of the beam-column element with seven degrees of freedom was deduced by second-order elastic theory, while the geometric nonlinearity and restrained torsional warping were considered. An overall second-order analysis for rigid-frame structure was conducted by integrating the nonlinear rigidity matrices of all beam-column elements. A numerical layout optimization model of spatial rigid frame was built, which was able to satisfy the requirements for structural strength, stiffness and stability. In order to solve the numerical model, a two-way control method of reliable topology and guided genetic algorithm (KLGA) was proposed based on the improvement of the genetic algorithm (GA). In one respect, this method enables the separation of the topological variables from the layout design variables, and then integrates them after evaluating the reliable topological variable combinations based on component importance. In addition, the guidance information of structure was added in the algorithm to guide the path of global optimal solution for GA. Finally, two typical examples of rigid frame structure are presented to validate the feasibility and effectiveness of the second-order effect model and optimization method KLGA. For example, in the second-order effect model of example 2, the optimal structural mass acquired by KLGA is 24.5% less than that of GA, and its range of fluctuation promotes from 9.61% to 1.39%, indicating the stability of KLGA.

-

表 1 槽钢框架布局优化变量信息

Table 1. Layout optimization variables of channel frame

项目 描述 单元分组 e1 = {1,3,5,7,2,4,6,8};

e2 = {9,10,12,13};e3 = {11,14}截面型号 a类槽钢:5#,6.3#,8#,10#,12#,14#,16#,

18#,20#,22#,25#,28#,30#,32#,36#,40#设计变量 型号拓扑变量:p①~p⑭;α①~α⑭;

位置设计变量:x⑨∈[0,400];

x⑭ = x⑨;y⑨∈[0,600];y⑪ = y⑨表 2 槽钢框架布局优化结果

Table 2. Layout optimization results of channel frame

分组号 单元号 初始模型 优化结果GA/KLGA 线弹性约束 二阶效应约束 线弹性约束 二阶效应约束 1 e1 40#(42.337) 40#(45.593) 14# 14# 2 e2 40#(12.271) 40#(13.214) 22# 22# 3 e3 40#(6.076) 40#(6.543) 5# 5# 4 x⑨/mm 0 0 212.50 212.50 5 y⑨/mm 0 0 318.75 318.75 下挠位移/mm 8.221 8.854 9.808 10.788 最大应力/MPa 42.337 45.593 150.652 158.501 结构重量/kg 1 131.072 1 131.072 308.103 308.103 表 3 格构式刚架优化变量信息

Table 3. Layout optimization variables of latticed column

项目 描述 对称单元 {1,10},···,{55,64};{2,8},···,{56,62};

{3,9},···,{57,63};{4,7},···,{58,61};

{5,6},···,{59,60};{11,12},···,{65,66};

{13,15},···,{67,69};{17,18},···,{71,72}截面型号 缀条:{20,25,30,36,40,45,50,56}*3;

肢脚:{63,70,75,80,90,100,110,125}*8设计变量 型号拓扑变量:p①~p  ;α①~α

;α①~α ;

;

节点位置/mm:1 000 ≤ x③,y③ ≤ 1 600注:截面型号表示为等边角钢宽度*厚度,如56*3表示

角钢宽度56 mm、厚度3 mm.表 4 格构式刚架结构布局优化结果

Table 4. Layout optimization results of latticed rigid structure

分组号 单元号 初始模型 优化结果(GA) 优化结果(KLGA) 线弹性约束 二阶效应约束 线弹性约束 二阶效应约束 线弹性约束 二阶效应约束 1 1,10 125*8(11.70) 125*8(12.20) 75*8 63*8 63*8 70*8 2 2,8 56*3(22.19) 56*3(23.71) 25*3 — — — 续 表 4

Continue Tab. 4分组号 单元号 初始模型 优化结果(GA) 优化结果(KLGA) 线弹性约束 二阶效应约束 线弹性约束 二阶效应约束 线弹性约束 二阶效应约束 3 3,9 56*3(12.77) 56*3(14.16) — 30*3 20*3 25*3 4 4,7 125*8(21.57) 125*8(22.49) 70*8 63*8 90*8 70*8 5 5,6 56*3(7.85) 56*3(8.51) — 40*3 45*3 50*3 6 11,12 56*3(3.62) 56*3(3.91) 30*3 — — — 7 13,15 56*3(8.16) 56*3(8.58) 45*3 20*3 20*3 30*3 8 14 56*3(4.56) 56*3(5.08) 30*3 40*3 45*3 25*3 9 16 56*3(1.71) 56*3(2.19) 50*3 20*3 30*3 25*3 10 17,18 56*3(5.76) 56*3(5.98) — 30*3 — — 11 19,28 125*8(10.41) 125*8(11.52) 63*8 63*8 63*8 110*8 12 20,26 56*3(23.41) 56*3(24.99) — 36*3 25*3 45*3 13 21,27 56*3(14.64) 56*3(16.17) 40*3 — — — 14 22,25 125*8(11.63) 125*8(12.53) 63*8 90*8 63*8 90*8 15 23,24 56*3(4.42) 56*3(4.76) 25*3 — 40*3 36*3 16 29,30 56*3(4.16) 56*3(4.44) 20*3 — — — 17 31,33 56*3(6.87) 56*3(7.20) 36*3 40*3 20*3 25*3 18 32 56*3(2.35) 56*3(2.66) 30*3 30*3 30*3 30*3 19 34 56*3(3.91) 56*3(4.16) 30*3 36*3 40*3 25*3 20 35,36 56*3(4.91) 56*3(5.08) 40*3 — — — 21 37,46 125*8(15.46) 125*8(15.92) 70*8 63*8 63*8 63*8 22 38,44 56*3(22.62) 56*3(24.14) — 20*3 — — 23 39,45 56*3(14.13) 56*3(15.61) 20*3 30*3 25*3 30*3 24 40,43 125*8(7.98) 125*8(8.55) 75*8 75*8 75*8 63*8 25 41,42 56*3(3.04) 56*3(3.24) 25*3 36*3 36*3 — 26 47,48 56*3(5.89) 56*3(6.02) — 50*3 20*3 40*3 27 49,51 56*3(8.03) 56*3(8.47) 45*3 — 40*3 25*3 28 50 56*3(0.18) 56*3(0.23) 50*3 — 50*3 30*3 29 52 56*3(5.80) 56*3(5.93) 30*3 20*3 36*3 40*3 30 53,54 56*3(5.40) 56*3(5.61) 20*3 30*3 — — 31 55,64 125*8(20.11) 125*8(20.13) 70*8 75*8 100*8 75*8 32 56,62 56*3(25.25) 56*3(25.95) 45*3 — 20*3 36*3 33 57,63 56*3(12.65) 56*3(14.01) — 36*3 — — 34 58,61 125*8(2.80) 125*8(2.96) 70*8 70*8 — — 35 59,60 56*3(0.72) 56*3(0.73) 40*3 36*3 — — 36 65,66 56*3(7.75) 56*3(7.79) 36*3 30*3 36*3 30*3 37 67,69 56*3(11.71) 56*3(12.75) 20*3 25*3 — — 38 68 56*3(1.45) 56*3(1.64) 45*3 45*3 — — 39 70 56*3(6.04) 56*3(6.21) 50*3 45*3 36*3 45*3 40 71,72 56*3(4.00) 56*3(4.43) 20*3 — — — 43 x③/mm 0 0 243.75 337.5 468.75 56.25 44 y③/mm 0 0 262.5 75 18.75 56.25 最大约束位移/mm 1.72 1.85 3.96 3.15 2.18 3.93 最大约束应力/MPa 25.25 25.95 113.54 106.03 151.52 156.59 w/kg 427.34 427.34 216.32 228.46 184.67 179.90 迭代次数 — — 65 86 122 109 注:“—”代表优化中被删除的项目(节点或构件);初始模型目录下括号内为构件上的最大应力;截面型号表示为等

边角钢宽度*厚度,如56*3表示角钢宽度56 mm、厚度3 mm. -

王毅,姚卫星. 桁架结构布局优化的并行子空间方法[J]. 工程设计学报,2015,22(3): 256-261. doi: 10.3785/j.issn.1006-754X.2015.03.009WANG Yi, YAO Weixing. Concurrent subspace optimization for layout design of trusses[J]. Chinese Journal of Engineering Design, 2015, 22(3): 256-261. doi: 10.3785/j.issn.1006-754X.2015.03.009 SHI Lianshuan, WANG Yuefang, SUN Huanchun. Approach for layout optimization of truss structures with discrete variables under dynamic stress,displacement and stability constraints[J]. Applied Mathematics and Mechanics, 2006, 27(5): 593-599. doi: 10.1007/s10483-006-0504-y GHOLIZADEH S. Layout optimization of truss structures by hybridizing cellular automata and particle swarm optimization[J]. Computers and Structures, 2013, 125: 86-99. doi: 10.1016/j.compstruc.2013.04.024 HOOSHMAND A, CAMPBELL M I. Truss layout design and optimization using a generative synthesis approach[J]. Computers and Structures, 2016, 163: 1-28. doi: 10.1016/j.compstruc.2015.09.010 AHRARI A, DEB K. An improved fully stressed design evolution strategy for layout optimization of truss structures[J]. Computers and Structures, 2016, 164: 127-144. doi: 10.1016/j.compstruc.2015.11.009 AHRARI A, ATAI A. Fully stressed design evolution strategy for shape and size optimization of truss structures[J]. Computers and Structures, 2013, 123: 58-67. doi: 10.1016/j.compstruc.2013.04.013 GAO Ge, LIU Zhenyu, LI Yaobin, et al. A new method to generate the ground structure in truss topology optimization[J]. Engineering Optimization, 2017, 49(2): 235-251. doi: 10.1080/0305215X.2016.1169050 STOLPE M. Truss topology optimization with discrete design variables by outer approximation[J]. Global Optimization, 2015, 61: 139-163. doi: 10.1007/s10898-014-0142-x 肖阿阳. 基于演化算法的杆系结构拓扑与布局优化设计研究[D]. 哈尔滨: 哈尔滨工业大学, 2014. 童根树. 钢结构的平面外稳定性[M]. 修订版. 北京: 中国建筑工业出版社, 2012: 107-108. 中华人民共和国住房与城乡建设部. 钢结构设计规范: GB 50017—2003[S]. 北京: 中国计划出版社, 2003. AISC Committee. Specification for structural steel buildings: ANSI/AISC360—05[S]. Chicago: AISC B. D, 2005. CEN. Eurocode 3: Design of Steel Structures: BS EN 1993-1-1[S]. Brussels: BSI, 2003. ALWIS W A M, WANG C M. Wangner term in flexural-torsional buckling of thin-walled open-profile columns[J]. Engineering Structures, 1996, 18(2): 125-132. doi: 10.1016/0141-0296(95)00112-3 刘坚. 钢结构高等分析的二阶非弹性理论与应用[M]. 北京: 科学出版社, 2011: 147–158. 朱朝艳,刘斌,张延年,等. 复合形遗传算法在离散变量桁架结构拓扑优化中的应用[J]. 四川大学学报(工程科学版),2004,36(5): 6-10. doi: 10.3969/j.issn.1009-3087.2004.05.002ZHU Chaoyan, LIU Bin, ZHANG Yannian, et al. Application of complex genetic algorithm to discrete topology optimization of truss structure[J]. Journal of Sichuan University (Engineering Science Edition), 2004, 36(5): 6-10. doi: 10.3969/j.issn.1009-3087.2004.05.002 -

下载:

下载: