Influence of Ca Content on Ultra-High Cycle Fatigue Fracture Behavior of AMCa Magnesium Alloy

-

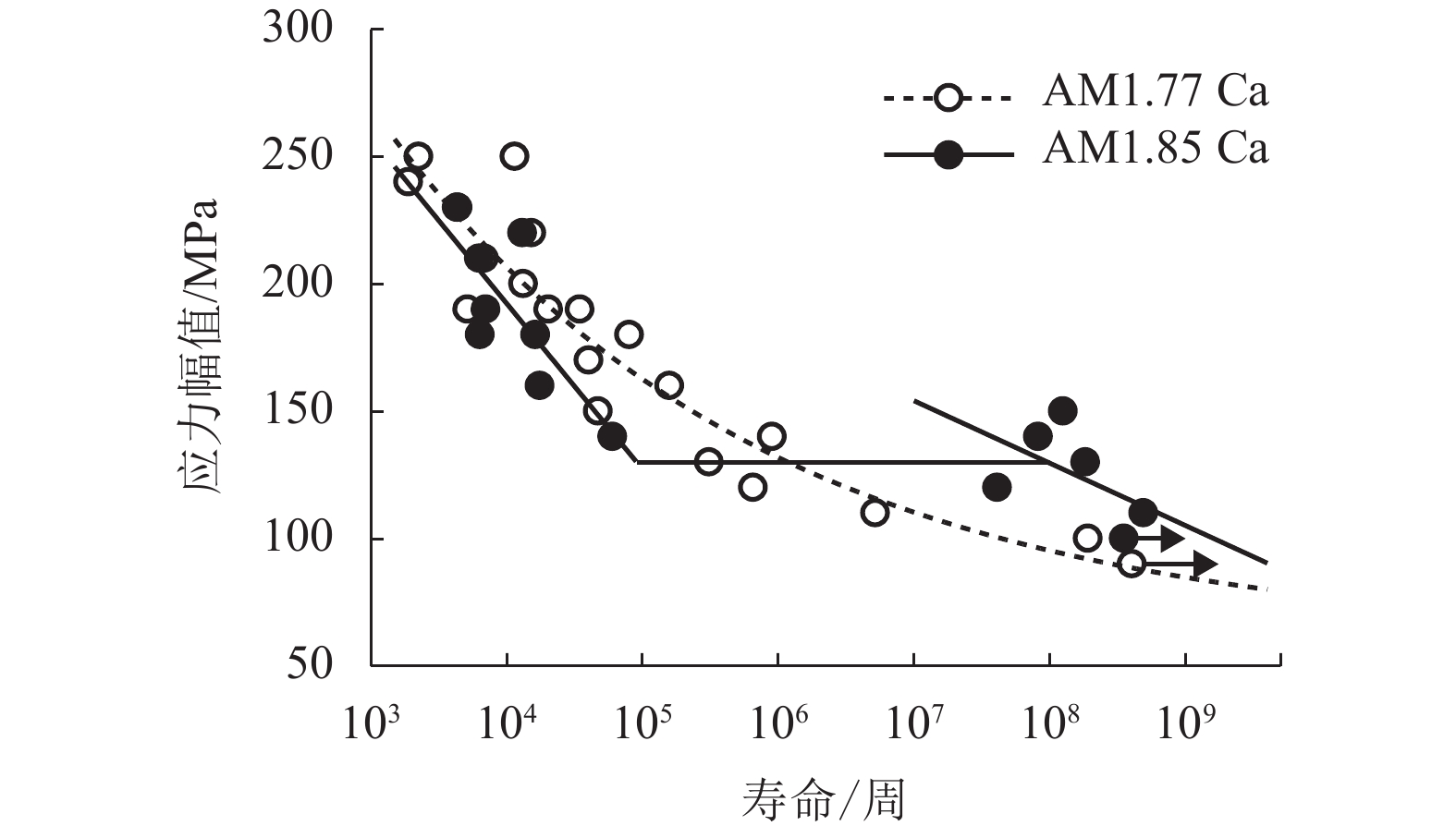

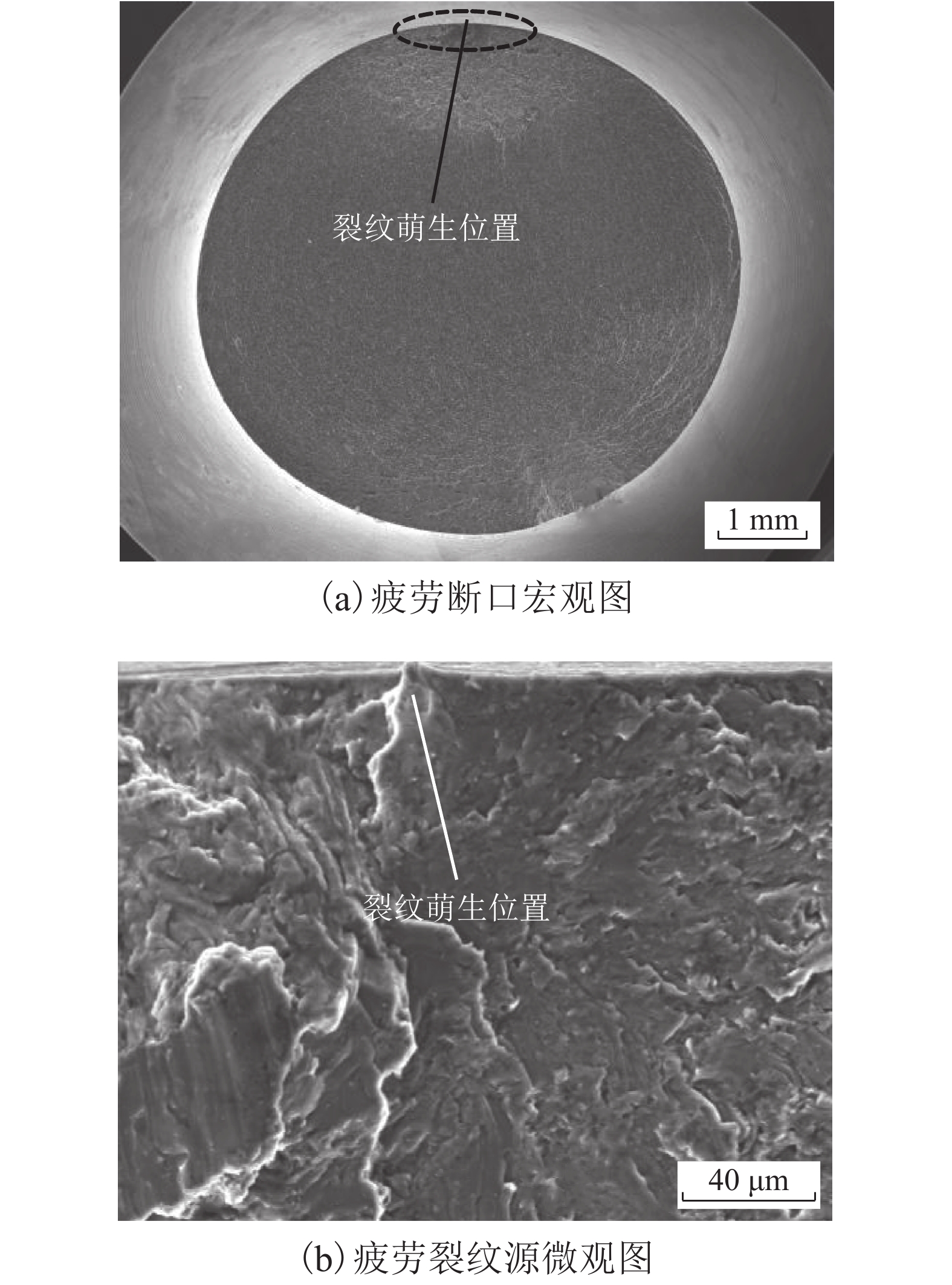

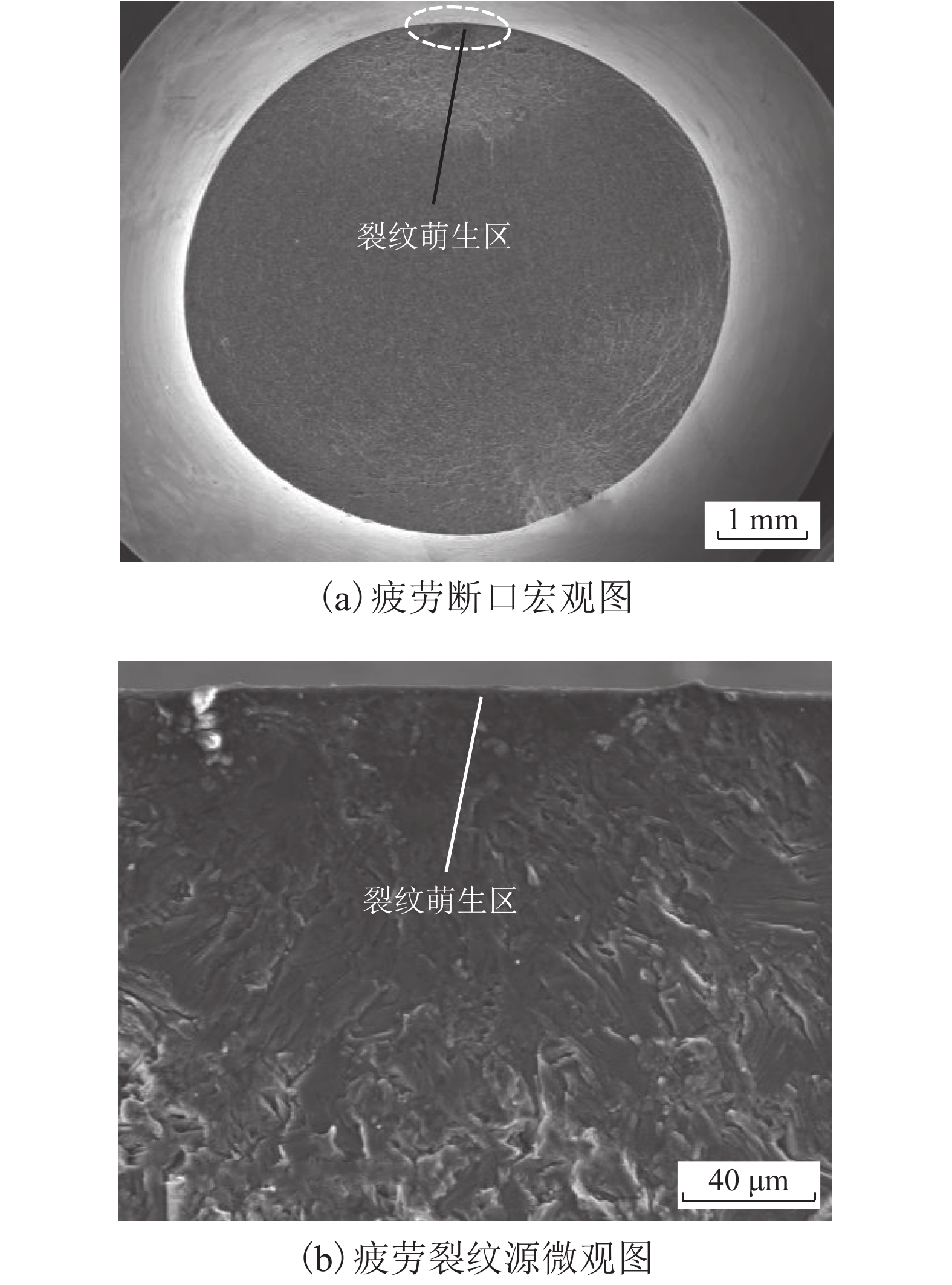

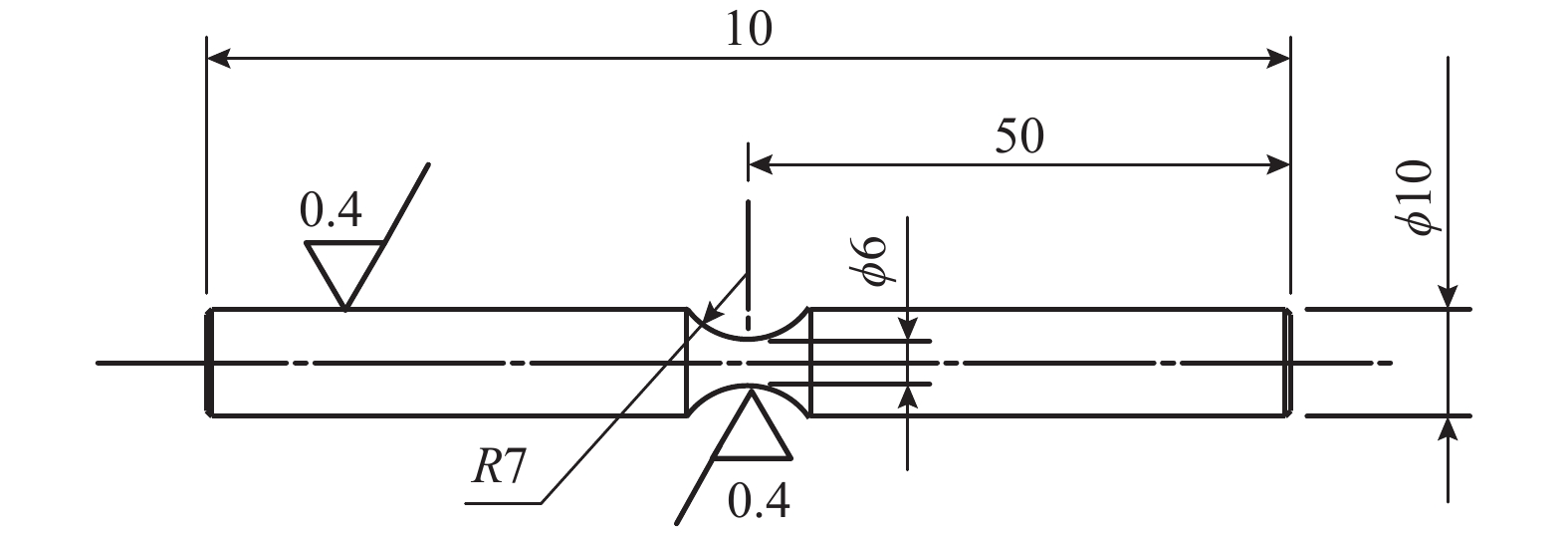

摘要: 为了阐明Ca含量对镁合金疲劳性能的影响,采用旋转弯曲疲劳试验机对两种AMCa镁合金进行超高周疲劳实验,并利用扫描电子显微镜SEM (scanning electron microscope)和X射线能谱仪EDS (X-ray energy dispersive spectroscopy)观察疲劳试样的断口形貌,分析了两种镁合金疲劳S-N(疲劳应力-疲劳寿命)曲线特性和疲劳断裂行为,讨论了Ca元素含量增加对镁合金疲劳寿命和疲劳裂纹萌生机制的影响. 结果表明,AM1.77 Ca镁合金S-N曲线没有传统的疲劳极限,呈现曲线连续下降趋势;AM1.85 Ca镁合金具有双S-N曲线特性,在130 MPa左右出现转折点;Ca元素含量增加导致镁合金产生微观结构缺陷,使材料的疲劳裂纹萌生模式从AM1.77 Ca镁合金的表面萌生模式转变为AM1.85 Ca镁合金的两种疲劳裂纹萌生模式,即表面萌生和次表面萌生模式,这种转变对材料抗疲劳性能的提升不利.Abstract: In order to investigate the effect of Ca content on the fatigue properties of magnesium alloys, the ultra-high cycle fatigue tests were carried out for two AMCa magnesium alloys using a rotating bending fatigue machine. The fracture morphologies of the fatigue specimens were observed by using scanning electron microscopy (SEM) and X-ray energy dispersive spectroscopy (EDS). Based on the experimental results, the fatigue S-N (fatigue strength-fatigue life) curves features and the fatigue fracture behavior were analyzed. Then, the influence of the Ca content on the fatigue life and fatigue crack initiation mechanism was discussed. The results indicate that the S-N curve of the AM1.77 Ca magnesium alloy shows a trend of continuous decline without a traditional fatigue limit, and the AM1.85 Ca magnesium alloy shows double S-N curve characteristics with a turning point around 130 MPa. The fatigue crack initiation mode is the surface initiation mode for the AM1.77 Ca magnesium alloy. However, the AM1.85 Ca magnesium alloy has two types of fatigue crack initiation modes, namely, the surface initiation mode and sub-surface initiation mode, which is due to the increase in the Ca content. The change that AM1.85 Ca magnesium alloy has two types of fatigue crack initiation modes is not conducive to improve the anti-fatigue performance.

-

表 1 实验材料的化学成分

Table 1. Chemical composition of experimental material

材料 Al Zn Mn Si Cu Fe Ni Ca Mg AM1.77 Ca 6.790 0.003 0.25 0.04 0.002 0.006 <0.001 1.770 余量 AM1.85 Ca 5.950 0.021 0.21 0.02 0.001 0.001 <0.001 1.850 余量 表 2 实验材料的力学性能参数

Table 2. Mechanical properties of experimental material

材料 抗拉强度/MPa 屈服强度/MPa 伸长率/% 硬度/HV AM1.77 Ca 299 215 12 60.5 AM1.85 Ca 308 250 10 75.2 -

PLATUS D L, KOJIMA Y. Platform science and technology for advanced magnesium alloy[J]. Materials Science Forum, 2000, 350-351(7): 3-20. FRIEDRICH H, SCHUMANN S. Research for a new age of magnesium in the automotive industry[J]. Journal of Materials Processing Technology, 2001, 117(3): 276-281. doi: 10.1016/S0924-0136(01)00780-4 唐靖林,曾大本. 镁合金的应用发展现状[J]. 机械工人:热加工,2002(9): 32-35.TANG Jinglin, ZENG Daben. The applications and development of magnesium alloys[J]. Machinist Metal Forming, 2002(9): 32-35. 王渠东,丁文江. 镁合金研究开发现状与展望[J]. 世界有色金属,2004(7): 8-11.WANG Qudong, DING Wenjiang. The development situation and prospect of magnesium alloys[J]. World Nonferrous Metals, 2004(7): 8-11. 翟春泉,曾小勤,丁文江,等. 镁合金的开发与应用[J]. 机械工程材料,2001,25(1): 6-10. doi: 10.3969/j.issn.1000-3738.2001.01.004ZHAI Chunquan, ZENG Xiaoqin, DING Wenjiang, et al. Development and application of magnesium alloys in China[J]. Materials for Mechanical Engineering, 2001, 25(1): 6-10. doi: 10.3969/j.issn.1000-3738.2001.01.004 KONDORI B, MAHMUDI R. Effect of Ca additions on the microstructure,thermal stability and mechanical properties of a cast AM60 magnesium alloy[J]. Materials Science and Engineering A, 2010, 527(7): 2014-2021. 樊昱,吴国华,高洪涛,等. Ca对镁合金组织、力学性能和腐蚀性能的影响[J]. 中国有色金属学报,2005,15(2): 210-216. doi: 10.3321/j.issn:1004-0609.2005.02.007FAN Yu, WU Guohua, GAO Hongtao, et al. Effect of Ca on microstructure,mechanical properties and corrosion resistance of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 210-216. doi: 10.3321/j.issn:1004-0609.2005.02.007 WANG Q D, CHEN W Z, ZENG X Q, et al. Effects of Ca addition on the microstructure and mechanical properties of AZ91magnesium alloy[J]. Journal of Materials Science, 2001, 36(12): 3035-3040. doi: 10.1023/A:1017927109291 LI P J, TANG B, KANDALOVA E G. Microstructure and properties of AZ91D alloy with Ca additions[J]. Materials Letters, 2005, 59(6): 671-675. doi: 10.1016/j.matlet.2004.11.006 MASAKI K, OCHI Y, KAKIUCHI T, et al. High cycle fatigue property of extruded non-combustible Mg alloy AM602[J]. Materials Transactions, 2008, 49(5): 1148-1156. doi: 10.2320/matertrans.MC2007108 PETERSON R E. Stress concentration design factors[M]. [S.l.]: Wiley, 1953: 28 张艳斌,鲁连涛,薛弼一. 喷丸处理对6151-T6铝合金旋转弯曲疲劳性能的影响[J]. 材料工程,2014(4): 73-78. doi: 10.11868/j.issn.1001-4381.2014.11.013ZHANG Yanbin, LU Liantao, XUE Biyi. Effect of shot-peening on fatigue behavior of 6151-T6 aluminum alloy under rotating bending[J]. Journal of Materials Engineering, 2014(4): 73-78. doi: 10.11868/j.issn.1001-4381.2014.11.013 YANG F, YIN S M, LI S X, et al. Crack initiation mechanism of extruded AZ31 magnesium alloy in the very high cycle fatigue regime[J]. Materials Science and Engineering A, 2008, 491(1/2): 131-136. 鲁连涛,李伟,张继旺,等. GCr15钢旋转弯曲超长寿命疲劳性能分析[J]. 金属学报,2009,45(1): 73-78. doi: 10.3321/j.issn:0412-1961.2009.01.012LU Liantao, LI Wei, ZHANG Jiwang, et al. Analysis of rotary bending gigacycle fatigue properties of bearing steel GGr15[J]. Acta Metallurgica Sinica, 2009, 45(1): 73-78. doi: 10.3321/j.issn:0412-1961.2009.01.012 -

下载:

下载: