Theoretical Model and Performance Tests of Rotational Eddy Current Dampers with Cable

-

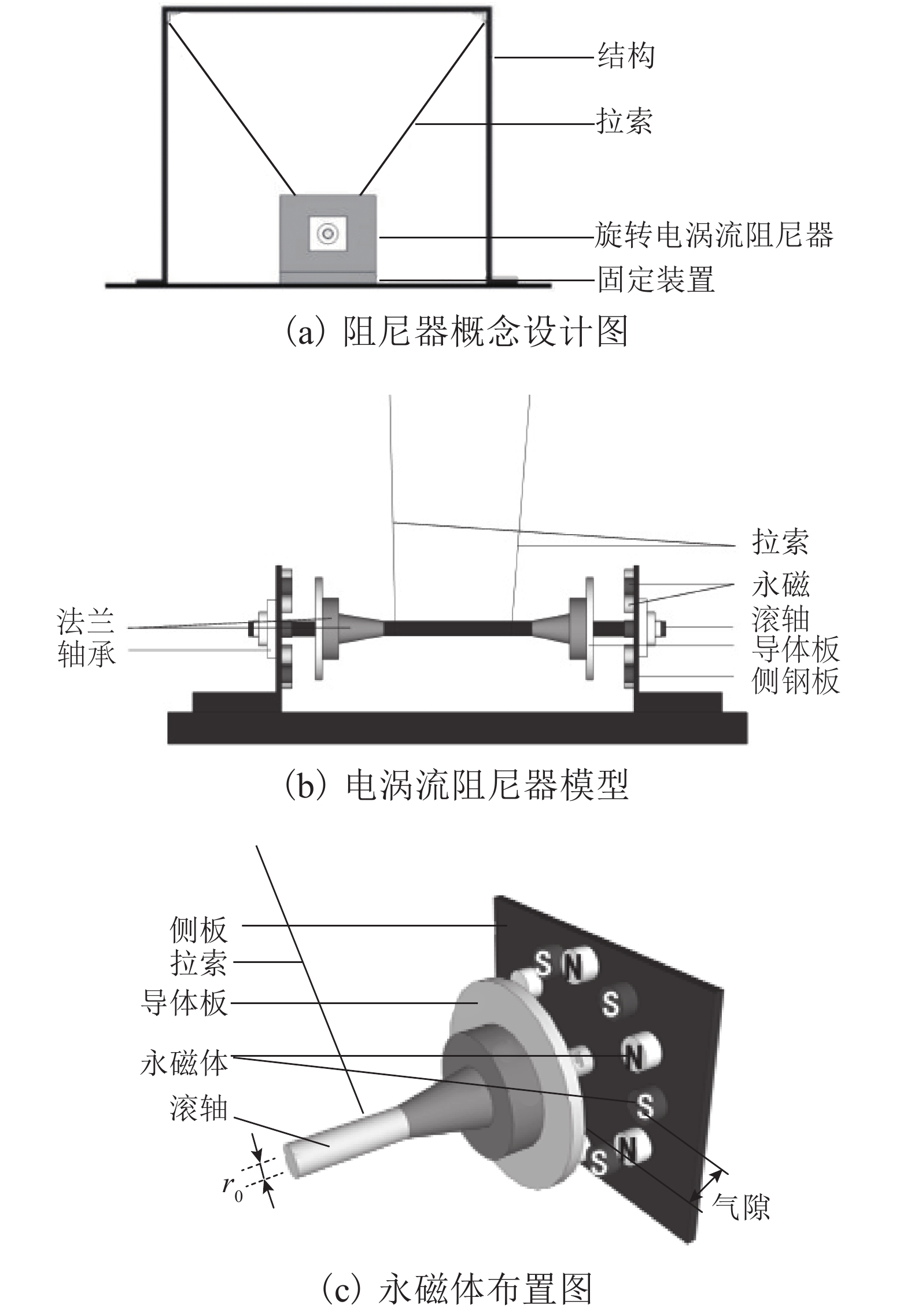

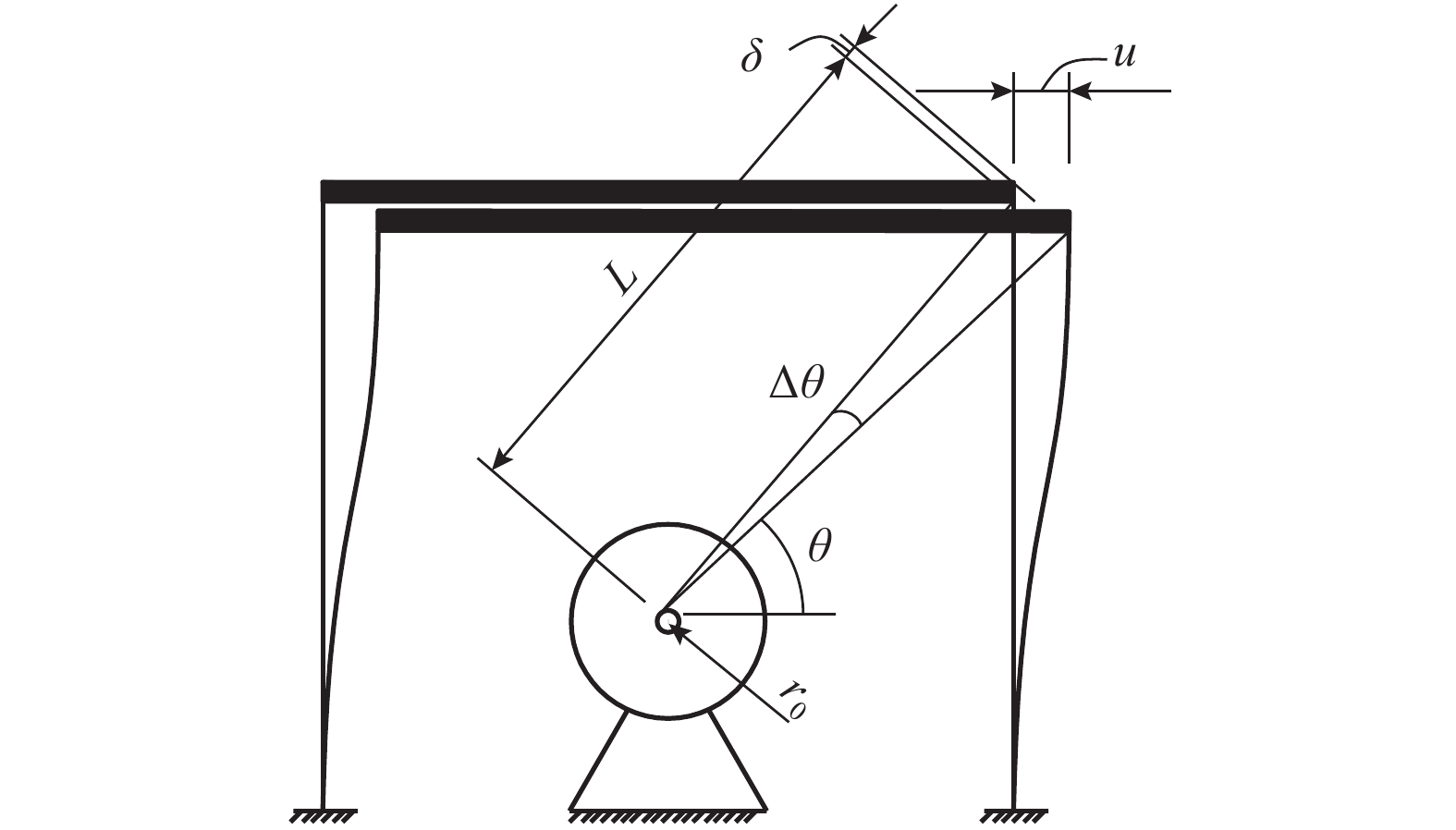

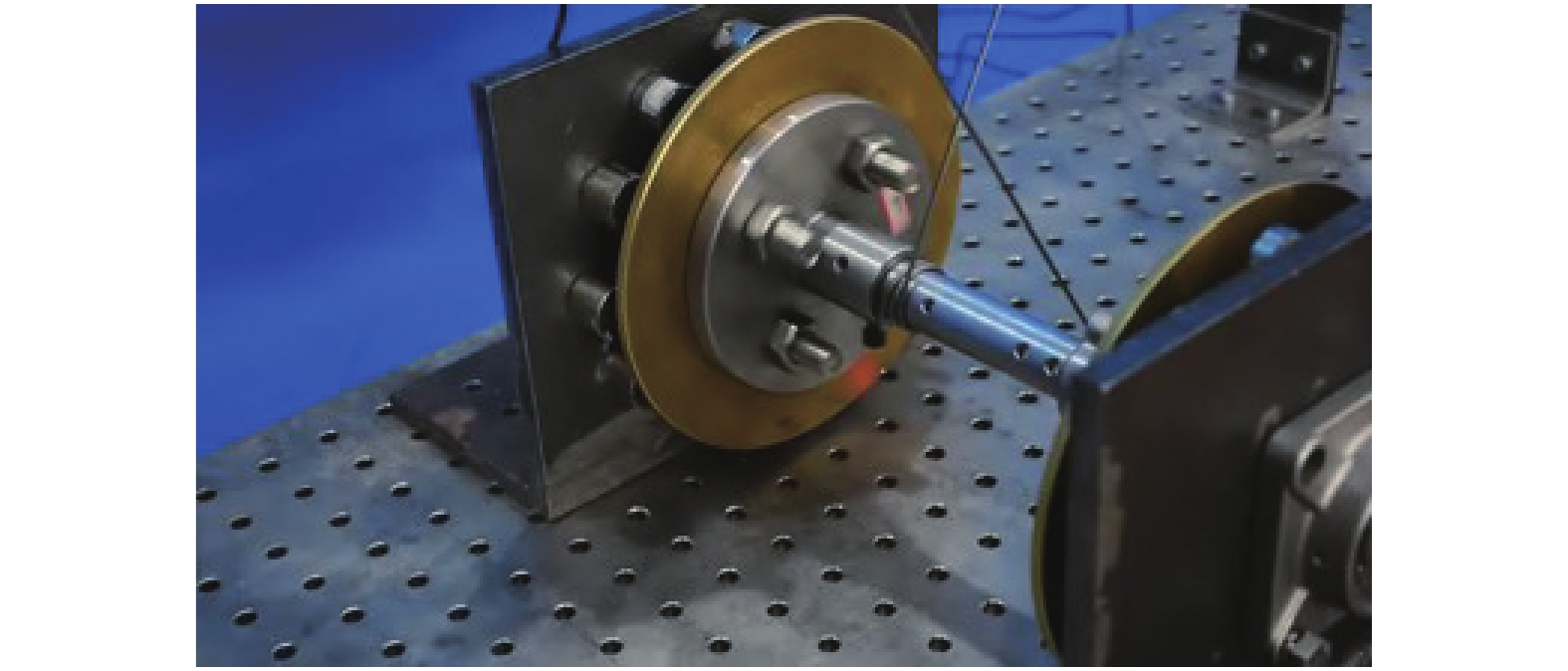

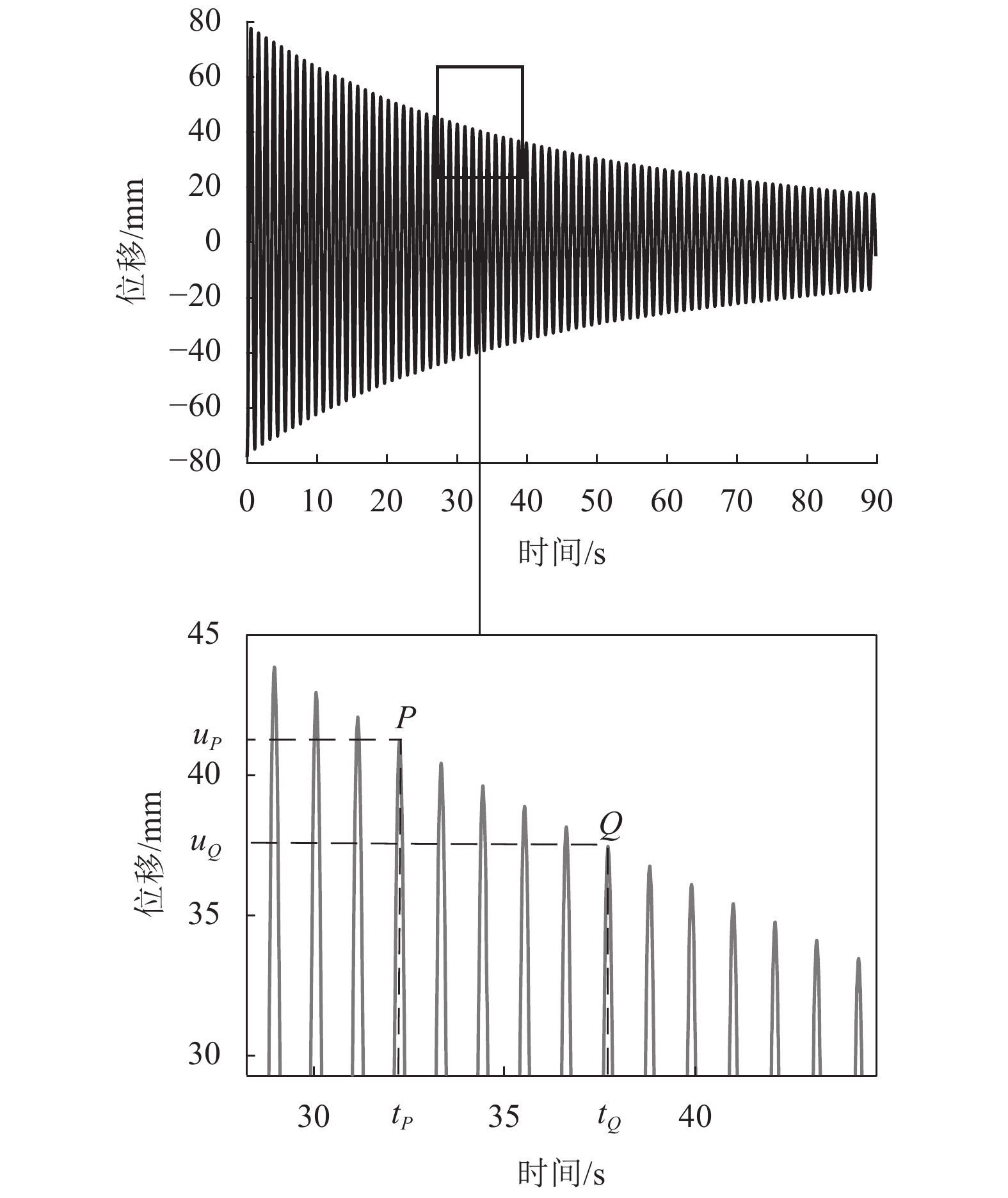

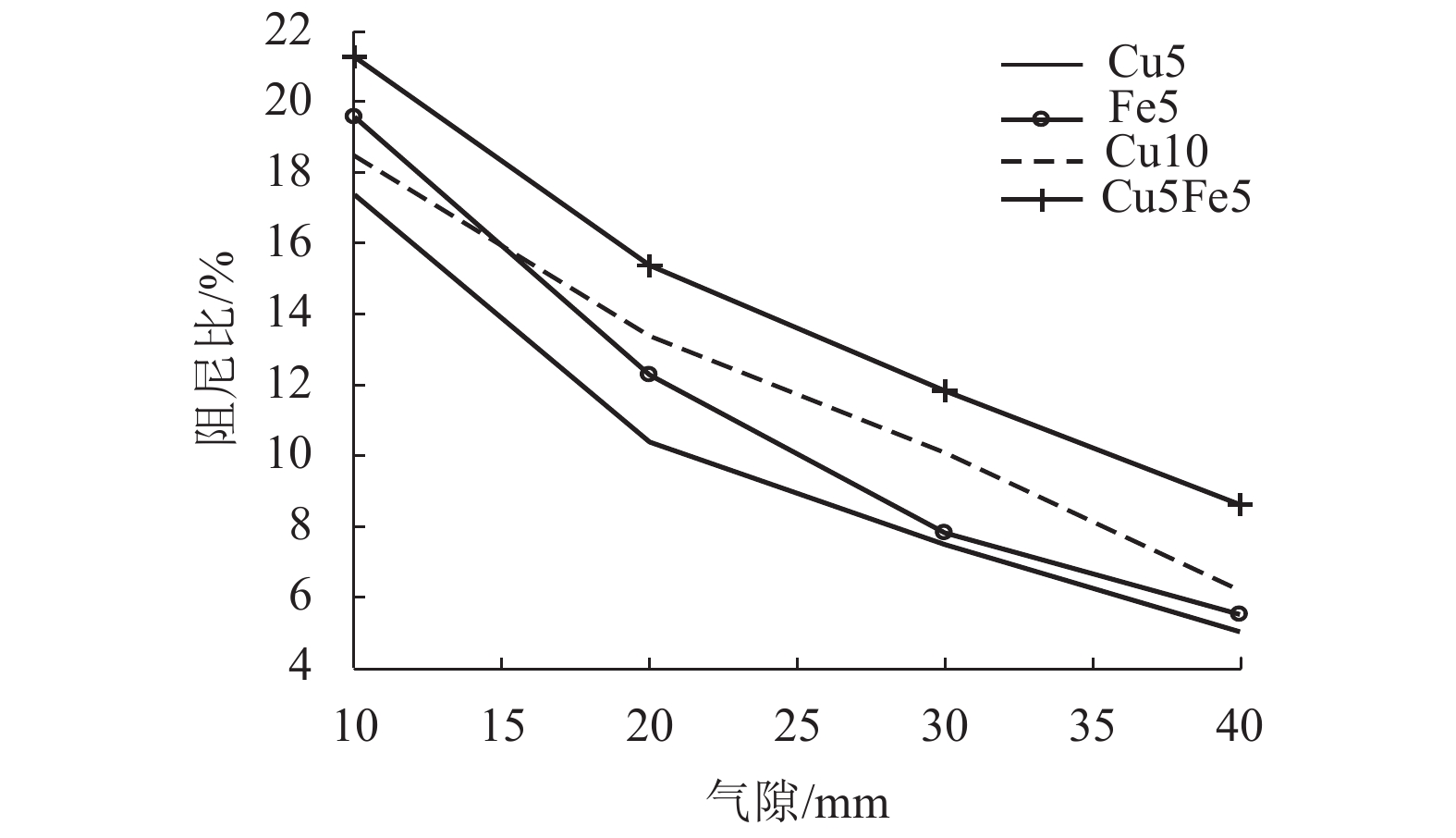

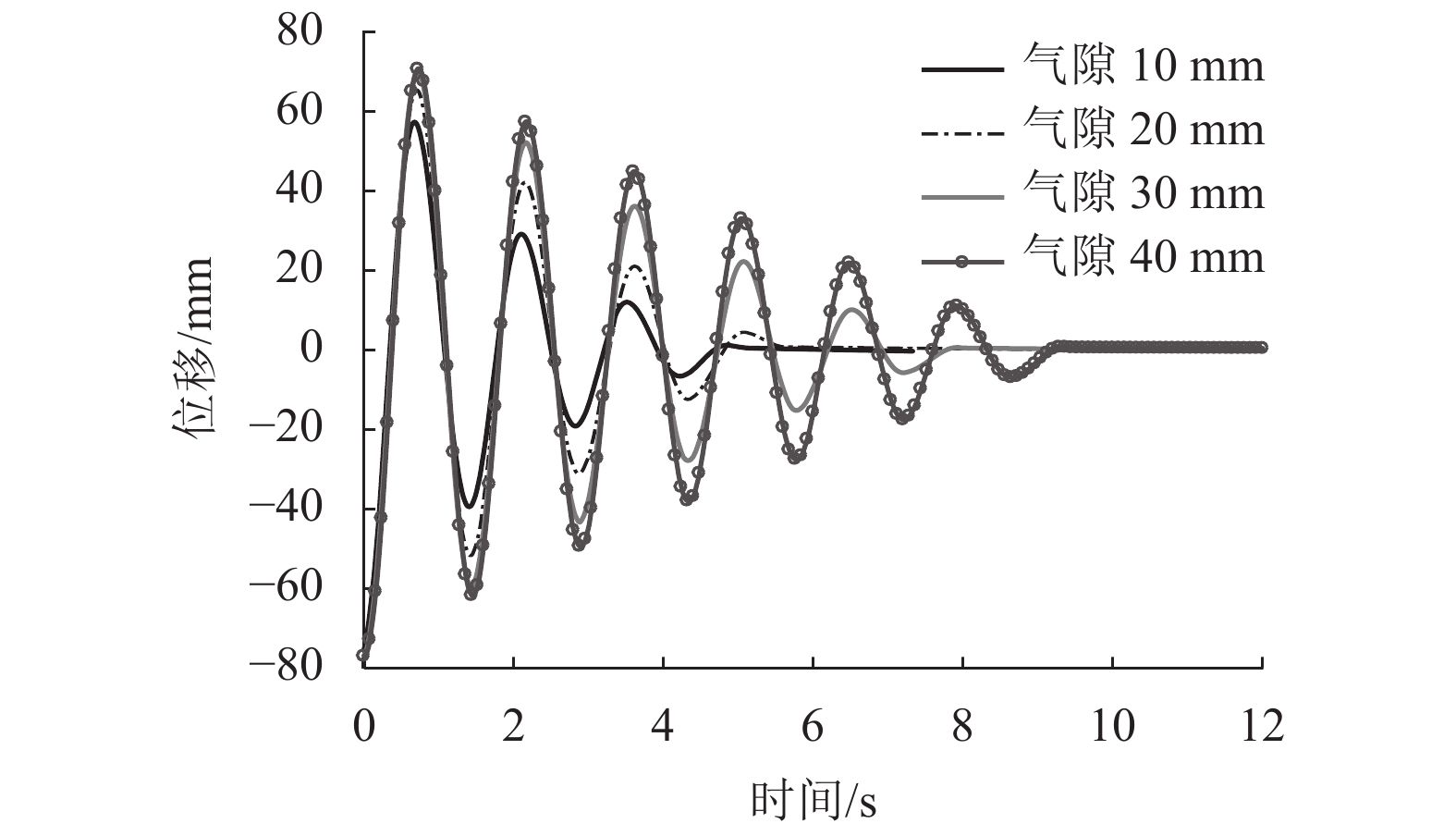

摘要: 提出一种新型的拉索式旋转电涡流减震系统,该系统由惯容器、弹簧和阻尼单元组成. 为验证该减震系统的减震机理,建立了装配阻尼器的单层框架力学模型,分别进行了单层框架、导体盘为5 mm铜板、10 mm铜板、5 mm铁板、5 mm铜板与5 mm铁板复合时的惯容器和不同材质的导体盘在10、20、30、40 mm气隙下带电涡流阻尼器的振动测试,以分析导体盘与永磁体间的气隙大小、导体盘材质和导体盘厚度对阻尼器附加阻尼比的影响. 试验结果表明:在铜板后附加铁板,阻尼增加至铜板的1.9倍、铁板的1.4倍,可最大化增加阻尼;气隙是影响电涡流阻尼的关键因素,当气隙增大时,阻尼比会迅速减小,调节气隙大小是改变结构附加阻尼比最有效和最容易的方法;阻尼器提供的阻尼比最大可达15.40%,证实了该阻尼器具有较强的耗能能力.Abstract: A novel rotational eddy current damper with cable is proposed, which is composed of inerter, spring and damping elements. In order to validate the mechanism for vibration mitigation, a mechanical model of a single-layer frame equipped with the damper is built. A series of vibration tests are carried out in terms of the frame, inerter and eddy current damper to analyze the impacts of air gap dimension between the conductor plate and permanent magnet, the material and thickness of the conductor plate on additional damping ratio. The conductor plates used in the tests include copper plates with the thickness of 5 mm or 10 mm, iron plate with the thickness of 5 mm, and a composite plate made up of a 5 mm thick copper plate and a 5 mm thick iron plate. In the vibration test, the conductor plates of different materials work in the air gaps of 10 mm, 20 mm, 30 mm, 40 mm. The test results show that the iron plate is added after the copper plate, and the damping is increased to 1.9 times and 1.4 times when the copper plate and iron plate are used alone. The air gap is a critical factor affecting the eddy current damping. When the air gap increases, the damping ratio will decrease rapidly. Adjusting the air gap dimension is the most effective and easiest method to change the damping ratio. The maximum damping ratio provided by the damper is 15.40%, which proves that it has a strong energy dissipation ability.

-

Key words:

- inerter /

- eddy current damper /

- damping ratio /

- free vibration test

-

表 1 框架及拉索式旋转电涡流阻尼器的结构参数

Table 1. Parameters of test frame and rotational eddy current dampers

部件 参数说明 框架楼板 长 834 mm,宽 390 mm,厚 10 mm,Q235 框架柱 截面 5 mm × 60 mm,高 1 000 mm,Q235 永磁体 厚度 20 mm,直径 25 mm,剩磁 Br = 1.2 T 磁极数 单侧 12个 导体板 厚度 5、10 mm,直径 190 mm 固定侧板 240 mm × 200 mm × 12 mm 气隙 10、20、30、40 mm 钢绞线 直径 2 mm,最大承重 294 kg 表 2 工况参数表

Table 2. Condition parameters

编号 工况名 编号 工况名 1 Cu5-g-20 12 Fe5-d-10 2 Fe5-g-20 13 Cu10-d-40 3 Cu10-g-20 14 Cu10-d-30 4 Cu5Fe5-g-20 15 Cu10-d-20 5 Cu5-d-40 16 Cu10-d-10 6 Cu5-d-30 17 Cu5Fe5-d-40 7 Cu5-d-20 18 Cu5Fe5-d-30 8 Cu5-d-10 19 Cu5Fe5-d-20 9 Fe5-d-40 20 Cu5Fe5-d-10 10 Fe5-d-30 21 单层框架 11 Fe5-d-20 表 3 自由振动测试结果

Table 3. Test results in free vibration

工况 固有圆频率

/(rad·s−1)阻尼比

/%电涡流效应

提供的阻尼比/%纯框架 5.882 0.509 — Cu5-g-20 4.720 4.950 — Cu5-d-20 4.900 10.400 5.450 Fe5-g-20 4.640 4.630 — Fe5-d-20 4.910 12.300 7.670 Cu10-g-20 3.900 4.790 — Cu10-d-20 4.510 13.400 8.610 Cu5Fe5-g-20 4.150 4.860 — Cu5Fe5-d-20 4.240 15.400 10.540 注:—表示无电涡流阻尼效应. -

梅真,郭子雄,侯炜,等. 随机地震动下粘滞阻尼减震结构振动台试验研究[J]. 西南交通大学学报,2018,53(5): 989-999. doi: 10.3969/j.issn.0258-2724.2018.05.016MEI Zhen, GUO Zixiong, HOU Wei, et al. Shaking table test of model structure with viscous dampers subjected to random earthquake ground motions[J]. Journal of Southwest Jiaotong University, 2018, 53(5): 989-999. doi: 10.3969/j.issn.0258-2724.2018.05.016 JSSI. Report of response-controlled buildings[R]. Tokyo: Japan Society of Seismic Isolation (JSSI) Investigation Committee, 2012. CAO M, TANG H, FUNAKI N, et al. Study on a real 8F steel building with oil damper damaged during the 2011 Great East Japan Earthquake[C]//15th World Conference on Earthquake Engineering. Lisbon: [s.n.], 2012: 1-10. KIENHOLZ D A, PENDLETON S C, RICHARDS K E, et al. Demonstration of solar array vibration suppression[C]//Proceedings of SPIE Conference on Smart Structures and Materials. Orlando: [s.n.], 1994, 2193: 59-73. LAROSE G L, LARSEN A, SVENSSON E. Modelling of tuned mass dampers for wind-tunnel tests on a full-bridge aeroelastic model[J]. Journal of Wind Engineering and Industrial Aerodynamics, 1995, 54: 427-437. 方重,吴和霖,楼梦麟. 电磁涡流耗能调谐质量阻尼器研制与性能试验[J]. 同济大学学报(自然科学版),2001,29(6): 752-756.FANG Chong, WU Helin, LOU Menglin. Development of electromagnetism vortex flow energy dissipation TMD devices and test study on its property[J]. Journal of Tongji University (Natural Science), 2001, 29(6): 752-756. 陈政清,黄智文. 一种板式电涡流阻尼器的有限元模拟及试验分析[J]. 合肥工业大学学报(自然科学版),2016,39(4): 499-502. doi: 10.3969/j.issn.1003-5060.2016.04.014CHEN Zhengqing, HUANG Zhiwen. Finite element simulation and experimental test of a plane-type eddy current damper[J]. Journal of Hefei University of Technology (Science and Technology), 2016, 39(4): 499-502. doi: 10.3969/j.issn.1003-5060.2016.04.014 祝长生. 转子系统径向电涡流阻尼器[J]. 中国机械工程,2007,18(19): 2269-2272. doi: 10.3321/j.issn:1004-132x.2007.19.001ZHU Changsheng. A journal eddy current damper for rotor systems[J]. China Mechanical Engineering, 2007, 18(19): 2269-2272. doi: 10.3321/j.issn:1004-132x.2007.19.001 祝长生. 时变磁场下径向电涡流阻尼器的动力特性[J]. 机械工程学报,2009,45(8): 31-36.ZHU Changsheng. Dynamic performance of a radial eddy current damper under variable-time magnetic field[J]. Journal of Mechanical Engineering, 2009, 45(8): 31-36. VAR BEEK T A, PLUK K J W, JANSEN J W, et al. Optimization and measurement of eddy current damping applied in a tuned mass damper[C]//2014 International Conference on Electrical Machines (ICEM). [S.l.]: IEEE, 2014: 609-615. -

下载:

下载: