Optimization Evaluation of Quality Classification of Concrete with Recycled Coarse Aggregate

-

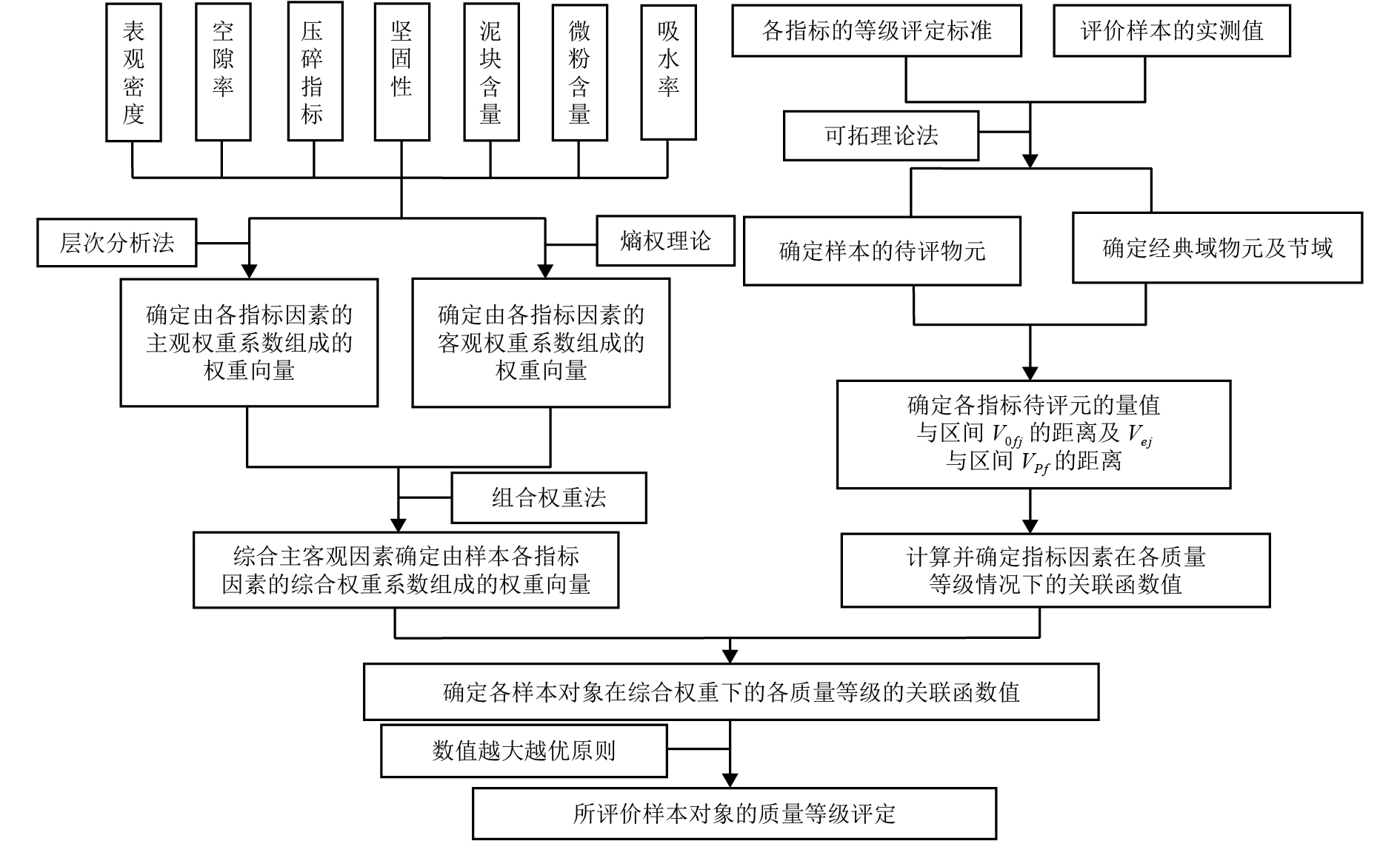

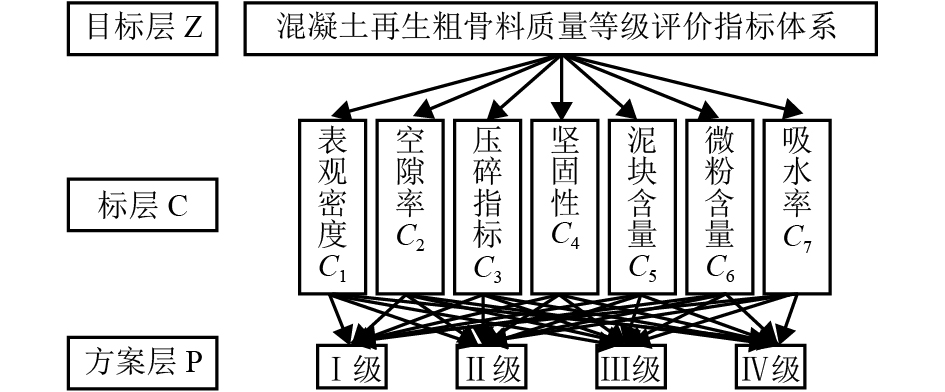

摘要: 为了克服再生骨料比选中主观、随意性等因素带来的误差,并确保对其质量作出科学合理选择,基于组合权重-可拓学理论,建立了混凝土再生粗骨料质量评价模型,根据《混凝土用再生骨料标准》确定评价指标体系和分类等级界限,利用层次分析法和熵权理论确定各指标的主、客观权重;依据可拓学理论求解不同等级下各个指标的样本关联度,然后结合组合权重法计算样本在不同等级下的关联函数值;按照数值越大越优原则进行质量等级评价,最后结合实例检验了评价方法的科学合理性. 研究结果表明:组合权重-可拓学理论综合评价法既能遵循规范单一因素法的评估步骤,还可以详细排序比较各项指标不同等级下的结果;通过实例计算出5组样本的质量等级分别为Ⅱ级、Ⅰ级、Ⅰ级、Ⅱ级、Ⅰ级,这与前人模糊理论评估结果一致;3种权重方法不仅计算出7项再生粗骨料性能指标的具体权重值,而且也能体现出各指标的相对重要性. 通过对再生骨料的质量优选研究,可以为再生混凝土的工程应用提供理论参考.Abstract: In order to overcome the errors caused by the subjective and discretionary factors of the recycled aggregate, select their quality scientifically and reasonably, a quality evaluation model for concrete with recycled coarse aggregate was established based on the combined weight-extension theory. According to the standard of concrete with recycled aggregate, the evaluation index system and limits of classification level were determined, the subjective and objective weights of each indexes were determined by the analytic hierarchy process (AHP) and entropy weight theory. The sample correlation degrees of each indexes under different levels were solved based on the extension theory, and then the correlation function values of the sample under different levels were calculated combined with the combination weight method. The quality grades were evaluated according to the principle that the bigger the number, the better the quality, finally, the scientificity of the evaluation method was tested by examples. The results show that: comprehensive evaluation method based on combined weight-extension theory not only follow the evaluation steps of the single factor method, but also can sort and compare the results under different levels of indicators; the quality grades of the five samples groups are calculated as II, I, I, II, and I, respectively, which are consistent with the evaluation results used by previous fuzzy theory; three weighting methods can not only calculate the specific weight values of seven performance indexes of the recycled coarse aggregate, but also can reflect the relative importance of each indexes. The study on the quality optimization of recycled coarse aggregate can provide a theoretical reference for the engineering application of recycled concrete.

-

表 1 层次分析法矩阵判断标度赋值

Table 1. Scales assignment of matrix in AHP

标度赋值 含义(重要性比较) 1 Xi 与 Xj 两元素具有同样重要性 3 Xi 与 Xj 两元素相比,Xi 稍重要 5 Xi 与 Xj 两元素相比,Xi 明显重要 7 Xi 与 Xj 两元素相比,Xi 极其重要 9 Xi 与 Xj 两元素相比,Xi 强烈重要 2、4、6、8 表示上述相邻判断标度赋值的中间值 说明:Xj 与 Xi 两元素相比时,标度取值为上述数值的倒数. 表 2 判断矩阵构造因素

Table 2. Structural factor of judgment matrix

元素 X1 X2 ··· Xj ··· Xn X1 a11 a12 ··· a1j ··· a1n X2 a21 a22 ··· a2j ··· a2n $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ Xi ai1 ai2 ··· aij ··· ain $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ Xn an1 an2 ··· anj ··· ann 表 3 判断矩阵的lRI数值汇总

Table 3. lRI of judment matrix

n lRI n lRI 1 0 6 1.24 2 0 7 1.32 3 0.58 8 1.41 4 0.90 9 1.45 5 1.12 10 1.40 表 4 混凝土再生粗骨料质量分级与评价指标

Table 4. Quality classification and evalution indexes of concrete with recycled coarse aggregate

指标 Ⅰ(优质) Ⅱ(良好) Ⅲ(合格) Ⅳ(不合格) C1/(kg•m–3) > 2 450 (2 350,2 450] (2 250,2 350] ≤2 250 C2/% < 47 [47,50) [50,53) ≥53 C3/% < 12 [12,20) [20,30) ≥30 C4/% < 5.0 [5.0,9.0) [9.0,15.0) ≥15.0 C5/% < 0.5 [0.5,0.7) [0.7,1.0) ≥1.0 C6/% < 1.0 [1.0,2.0) [2.0,3.0) ≥3.0 C7/% < 3.0 [3.0,5.0) [5.0,7.0) ≥7.0 表 5 混凝土再生粗骨料质量等级与适用范围

Table 5. Quality grades and scope of application of concrete with recycled coarse aggregate

质量等级 作用环境等级 工程种类 Ⅰ级 A-F 级 构筑物与非构筑物、建筑结构物与非结构物、预应力混凝土与路面 Ⅱ级 A-C 级 构筑物与非构筑物、建筑结构物与非结构物、预应力混凝土与路面 Ⅲ级 A-B 级 路基、路堤与绝缘障碍物 Ⅳ级 A-B 级 路堤与绝缘障碍物 表 6 样本实测值

Table 6. Actual measurement datas of the samples

样本 C1/(kg•m–3) C2/% C3/% C4/% C5/% C6/% C7/% S1 2 620 53 16.0 1.0 0.9 3.40 2.5 S2 2500 50 9.8 9.2 0.5 2.40 10.2 S3 2 435 44 23.1 1.4 1.0 0.18 4.9 S4 2 360 46 31.6 3.1 0.4 0.43 5.8 S5 2 300 53 17.5 12.0 0.7 1.40 9.0 表 7 修正补充后的再生粗骨料质量分级汇总

Table 7. Quality grades of concrete with recycled coarse aggregate after corrected

指标 Ⅰ级 Ⅱ级 Ⅲ级 Ⅳ级 (优质) (良好) (合格) (不合格) C1/

(kg•m–3)(2 450,

2 650](2 350,

2 450](2 250,

2 350][2 150,

2 250]C2/% [44,47) [47,50) [50,53) [53,56] C3/% [0,12) [12,20) [20,30) [30,40] C4/% [0,5) [5,9) [9,15) [15,20] C5/% [0,0.5) [0.5,0.7) [0.7,1.0) [1.0,1.5] C6/% [0,1.0) [1.0,2.0) [2.0,3.0) [3.0,4.0] C7/% [0,3.0) [3.0,5.0) [5.0,7.0) [7.0,11.0] 表 8 关联函数计算结果

Table 8. Calculation results of associative function

样本 等级 关联值 C1 C2 C3 C4 C5 C6 C7 S1 Ⅰ级 0.30 –0.667 0.20 0.40 0.40 0.80 –0.25 Ⅱ级 0.85 0.5 –0.333 0.80 0.25 0.70 0.167 Ⅲ级 0.90 0 0.20 0.889 –0.20 0.40 0.39 Ⅳ级 0.921 0 0.467 0.933 0.143 –2.0 0.643 S2 Ⅰ级 0.50 0.333 –0.289 0.313 0 0.467 0.90 Ⅱ级 0.25 0 0.183 0.021 0 0.20 0.867 Ⅲ级 0.50 0 0.51 –0.022 0.286 –0.333 –0.80 Ⅳ级 0.625 0.333 0.673 0.387 0.50 0.20 0.40 S3 Ⅰ级 0.065 0 0.396 0.56 0.5 0.36 0.279 Ⅱ级 0.075 1.0 0.155 0.72 0.375 0.82 –0.021 Ⅲ级 0.283 1.0 –0.225 0.844 0.667 0.91 0.02 Ⅳ级 0.4625 1.0 0.29 0.907 0 0.143 0.30 S4 Ⅰ级 0.30 –1.0 0.70 –1.583 0.333 0.83 0.35 Ⅱ级 –0.05 0.333 –0.05 0.38 0.20 0.57 0.133 Ⅲ级 0.045 0.667 0.16 0.656 0.429 0.785 –0.182 Ⅳ级 0.344 0.778 –0.235 0.793 0.60 0.857 0.1875 S5 Ⅰ级 0.50 0.667 0.239 0.467 0.222 0.222 0.75 Ⅱ级 0.25 0.50 –0.167 0.273 0 0.40 0.667 Ⅲ级 –0.50 0 0.125 –0.60 0 0.30 0.50 Ⅳ 0.25 0 0.417 0.273 0.30 0.533 1.0 表 9 再生粗骨料的各类权重计算结果

Table 9. Calculation results of various weights of concrete with recycled coarse aggregate

权重类型 权重 C1 C2 C3 C4 C5 C6 C7 主观 0.113 0.074 0.271 0.342 0.039 0.053 0.108 客观 0.123 0.172 0.096 0.219 0.137 0.123 0.131 组合 0.120 0.142 0.149 0.199 0.165 0.102 0.125 表 10 待评再生粗骨料在各等级下的综合关联度及综合评价结果

Table 10. Correlation degree and the comprehensive evaluation results of the RCA and the quality grades

样本 综合关联度 最大关联值 评定等级 Ⅰ级 Ⅱ级 Ⅲ级 Ⅳ级 S1 0.167 0 0.416 1 0.371 3 0.265 7 0.416 1 Ⅱ级 S2 0.386 7 0.190 2 0.044 8 0.352 5 0.386 7 Ⅰ级 S3 0.432 4 0.420 3 0.415 8 0.423 3 0.432 4 Ⅰ级 S4 – 0.133 4 0.417 2 0.382 6 0.384 4 0.417 2 Ⅱ级 S5 0.436 3 0.254 6 – 0.067 7 0.375 3 0.436 3 Ⅰ级 -

鲍学英,王起才,张磊. 基于灰色关联分析的再生混凝土粗骨料质量优选研究[J]. 硅酸盐通报,2014,33(4): 741-745.BAO Xueying, WANG Qicai, ZHANG Lei. Study on quality optimization of recycled aggregate coarse aggregate based on gray relational analysis[J]. Silicate Bulletin, 2014, 33(4): 741-745. 王江浩,耿欧,李富民. 再生粗骨料多种改性方法对混凝土抗压强度提升效果的试验[J]. 建筑科学与工程学报,2016,33(2): 91-97. doi: 10.3969/j.issn.1673-2049.2016.02.013WANG Jianghao, GENG Ou, LI Fumin. Experimental study on the effect of modified coarse aggregate modification method on compressive strength of concrete[J]. Journal of Building Science and Engineering, 2016, 33(2): 91-97. doi: 10.3969/j.issn.1673-2049.2016.02.013 刘书贤,魏晓刚,王伟,等. 再生粗骨料对再生混凝土性能的影响[J]. 建筑结构,2014,44(14): 17-20.LIU Shuxian, WEI Xiaogang, WANg Wei, et al. Effect of recycled coarse aggregate on properties of recycled concrete[J]. Building Structures, 2014, 44(14): 17-20. 肖建庄,林壮斌,朱军. 再生骨料级配对混凝土抗压强度的影响[J]. 四川大学学报(工程科学版),2014,46(4): 154-160.XIAO Jianzhuang, LIN Zhuangbin, ZHU Jun. Effect of recycled aggregate gradation on compressive strength of concrete[J]. Journal of Sichuan Univer sity (Engineering Science Edition), 2014, 46(4): 154-160. SAFIULLAH O, ELHEM G, GEORGE W. Relationships between recycled concrete aggregates characteristics and recycled aggregates concretes properties[J]. Construction and Building Materials, 2016, 108(1): 163-174. NICOLAS S, SANDRINE B, FRANÇOISE F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment[J]. Journal of Building Engineering, 2016, 5: 24-33. doi: 10.1016/j.jobe.2015.11.004 COMINGSTARFUL M, SHEMBIANG M. Enhancing mechanical properties of concrete prepared with coarse recycled aggregates[J]. The IES Journal Part A:Civil & Structural Engineering, 2015(3): 175-183. 吴瑾,朱磊,景宪航. 再生粗骨料的随机特性及分级方法研究[J]. 工程力学,2015,32(2): 97-104.WU Jin, ZHU Lei, JING Xianhang. Study on random characteristics and grading method of recycled coarse aggregate[J]. Engineering Mechanics, 2015, 32(2): 97-104. 罗素蓉,郑欣,黄海生. 再生粗骨料预处理及再生混凝土徐变试验研究[J]. 建筑材料学报,2016,19(2): 242-247. doi: 10.3969/j.issn.1007-9629.2016.02.006LUO Surong, ZHENG Xin, HUANG Haisheng. Preparation of recycled coarse aggregate and experimental study on creep of recycled concrete[J]. Journal of Building Materials, 2016, 19(2): 242-247. doi: 10.3969/j.issn.1007-9629.2016.02.006 鲍学英,王起才. 灰色聚类法在再生混凝土粗骨料质量等级评价中的应用[J]. 土木建筑与环境工程,2014,36(3): 112-117. doi: 10.11835/j.issn.1674-4764.2014.03.018BAO Xueying, WANG Qicai. Application of gray clustering method in quality evaluation of coarse aggregate of recycled concrete[J]. Civil Engineering and Environmental Engineering, 2014, 36(3): 112-117. doi: 10.11835/j.issn.1674-4764.2014.03.018 王思源,朱平华,姚荣,等. 再生混凝土粗骨料质量等级模糊综合评估方法[J]. 混凝土,2010(7): 87-89. doi: 10.3969/j.issn.1002-3550.2010.07.028WANG Siyuan, ZHU Pinghua, YAO Rong, et al. Fuzzy comprehensive evaluation method for quality grade of recycled concrete coarse aggregate[J]. Concrete, 2010(7): 87-89. doi: 10.3969/j.issn.1002-3550.2010.07.028 封金财,卢月园,朱平华. 混凝土用再生细骨料质量等级模糊综合评估方法[J]. 混凝土,2016(11): 126-129. doi: 10.3969/j.issn.1002-3550.2016.11.034FENG Jincai, LU Yueyuan, ZHU Pinghua. Fuzzy comprehensive evaluation method for quality grade of recycled fine aggregate for concrete[J]. Concrete, 2016(11): 126-129. doi: 10.3969/j.issn.1002-3550.2016.11.034 邓雪,李家铭,曾浩健,等. 层次分析法权重计算方法分析及其应用研究[J]. 数学的实践与认识,2012(7): 93-100. doi: 10.3969/j.issn.1000-0984.2012.07.012DENG Xue, LI Jiaming, ZENG Haojian, et al. Analysis and application of weight method for analytic hierarchy process[J]. Journal of Mathematics,Practice and Practice, 2012(7): 93-100. doi: 10.3969/j.issn.1000-0984.2012.07.012 王珂,郭进平,赵江平,等. 基于熵权理论的室内环境评价[J]. 中国安全科学学报,2017,17(7): 167-171.WANG Ke, GUO Jinping, ZHAO Jiangping, et al. Study on indoor environment evaluation based on entropy theory[J]. Journal of Chinese Society for Safety Science, 2017, 17(7): 167-171. 陶占盛,王新民,吴志强,等. 基于组合权重的汛期地质灾害预警预报模型[J]. 吉林大学学报(地球科学版),2014,44(6): 2010-2015.TAO Zhansheng, WANG Xinmin, WU Zhiqiang, et al. Evaluation model of geological disaster early warning and forecast based on combined weight[J]. Journal of Jilin University (Earth Science Edition), 2014, 44(6): 2010-2015. 薛晓辉,张军,姚广. 基于可拓学理论的黄土隧道围岩分级方法研究[J]. 地下空间与工程学报,2017,13(3): 651-657.Xue Xiaohui, ZHANG Jun, YAO Guang. Study on classification method of surrounding rock of loess tunnel based on extension theory[J]. Journal of Underground Space and Engineering, 2017, 13(3): 651-657. TOMOSAWA F. Recycling of concrete: the Japanese experience[C]//Proceeding of the 4th CANMET/ACI/JCI International Conference on Recent Advances in Concrete Technology. London: [s.n.], 1992: 221-237 British Standards Institution. BS 882 Specification for aggregates from natural sources for concrete[S]. London: British Standards Institution, 1992 American Society for Testing and Materials. ASTM D 2940-03 standard specification for graded aggrregate material for bases or sub-bases for highways or airports[S]. [S.l.]: America Society for Testing and Material, 2003 American Society for Testing and Materials. Standard specification for sizes of aggregate for road and bridge construction: ASTM D 448-03[S]. [S.l.]: America Society for Testing and Material, 2003 中华人民共和国住房和城乡建设部. 混凝土用再生粗骨料: GB/T25177—2010[S]. 北京: 中国标准出版社, 2010 苗壮. 再生粗骨料对再生混凝土力学与耐久性能影响的试验研究[D]. 哈尔滨: 哈尔滨工业大学, 2015 混凝土结构耐久性设计规范: GB/T 50476—2008[S]. 北京: 中国建筑工业出版社, 2009 李秋义, 全洪珠, 秦原. 混凝土再生骨料[M]. 北京: 中国建筑工业出版社, 2011: 1-169 孙艳云,郝伟. 信息熵未确知测度理论在混凝土再生粗骨料质量优选中的应用[J]. 土木建筑与环境工程,2017(5): 87-92. doi: 10.11835/j.issn.1005-2909.2017.05.021SUN Yanyun, HAO Wei. Application of information entropy unascertained measure theory in quality optimization of coarse aggregate concrete[J]. Civil Engineering and Environmental Engineering, 2017(5): 87-92. doi: 10.11835/j.issn.1005-2909.2017.05.021 -

下载:

下载: