Structural Dynamic Characteristics of Force-Measurement System for Impulse Wind Tunnel

-

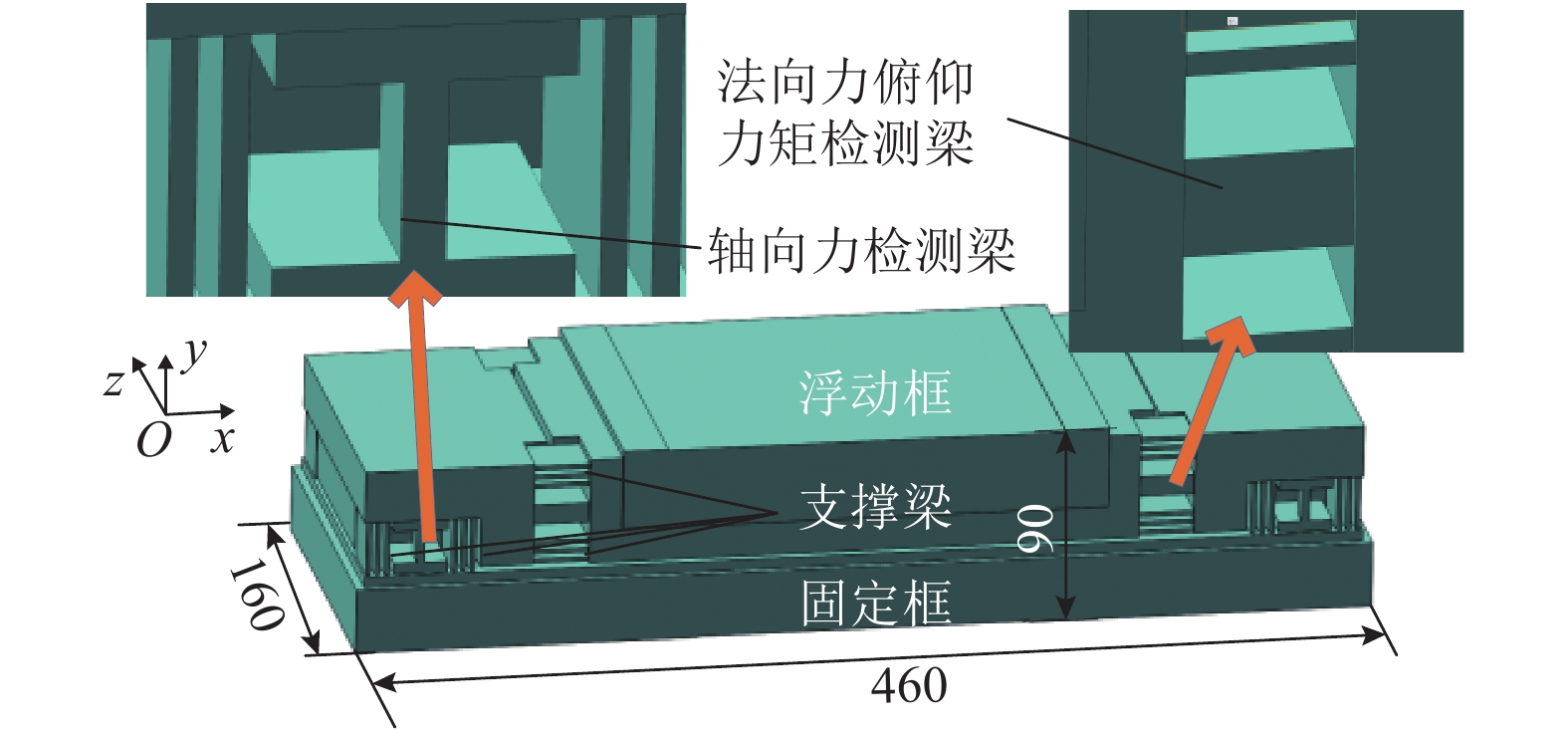

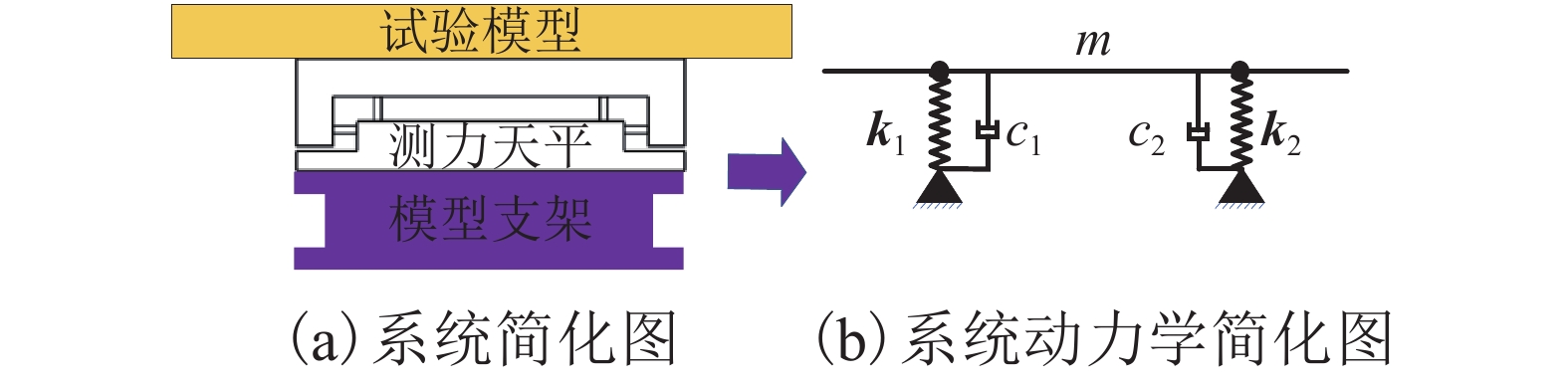

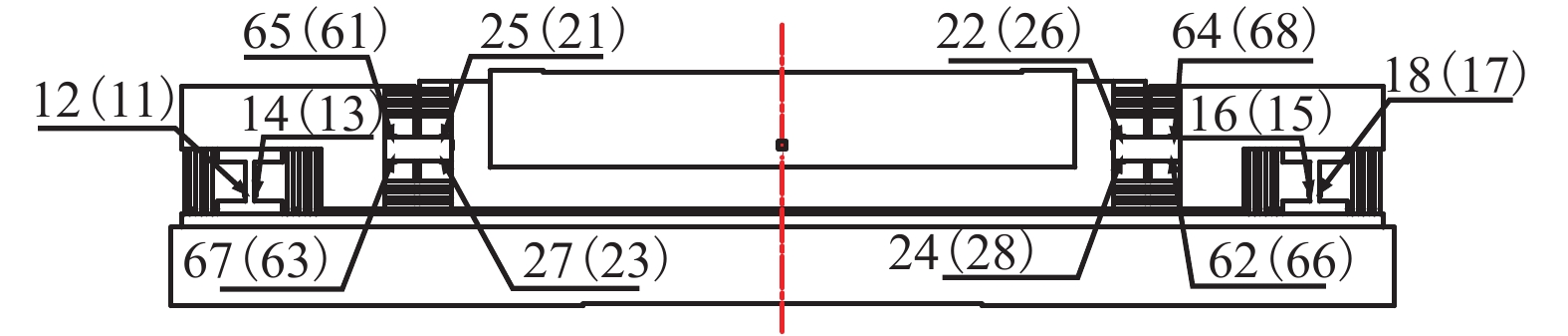

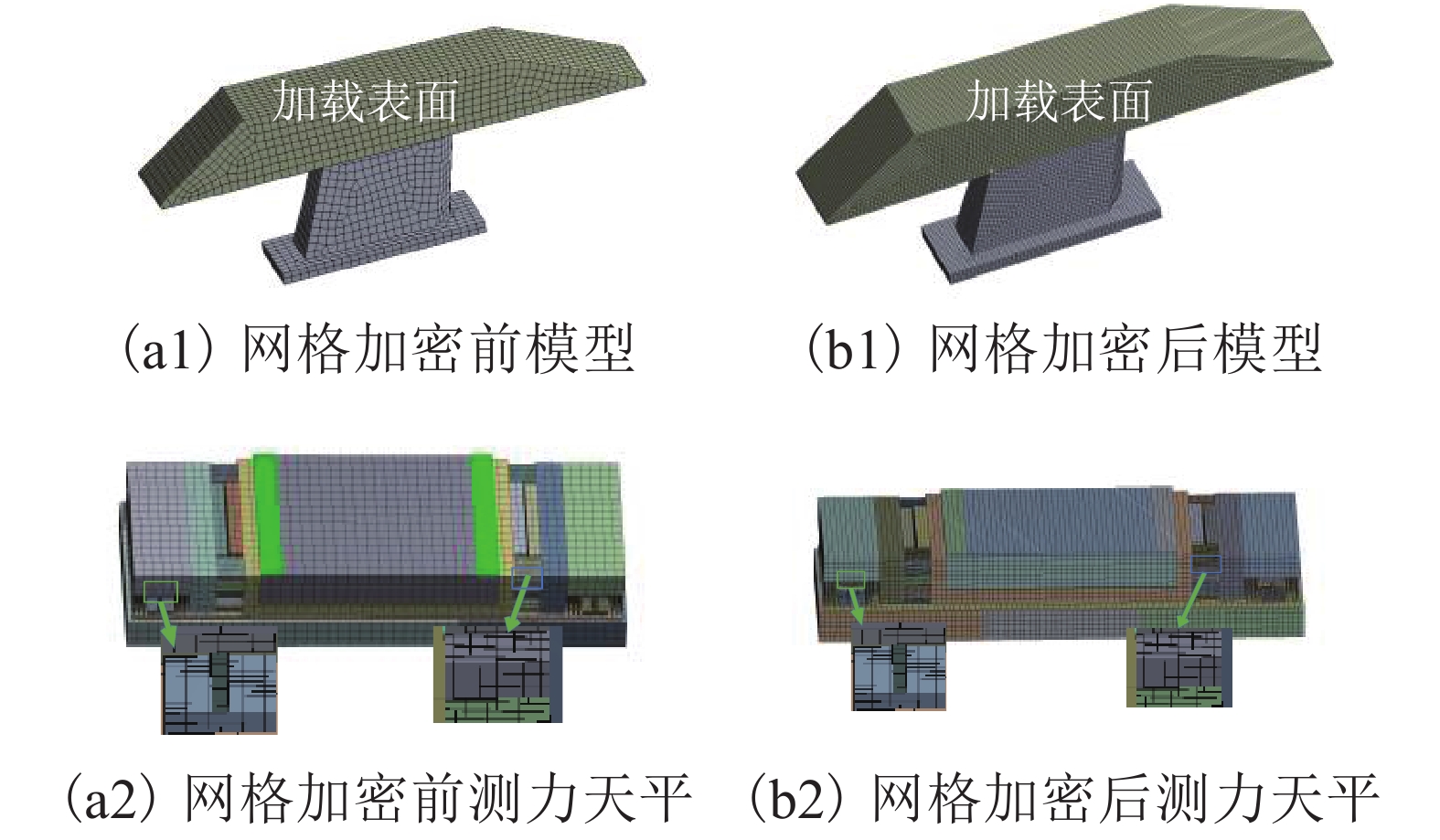

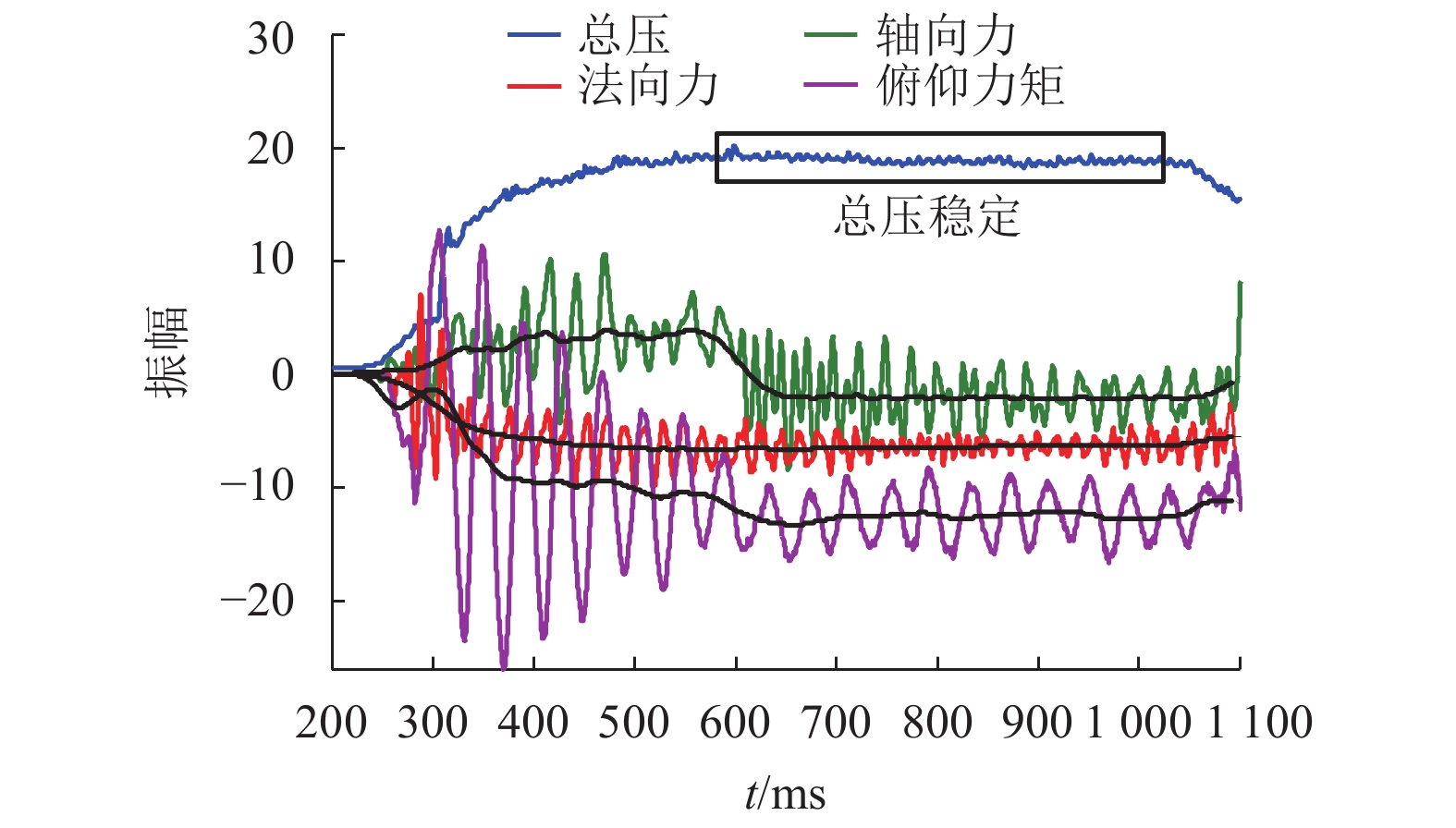

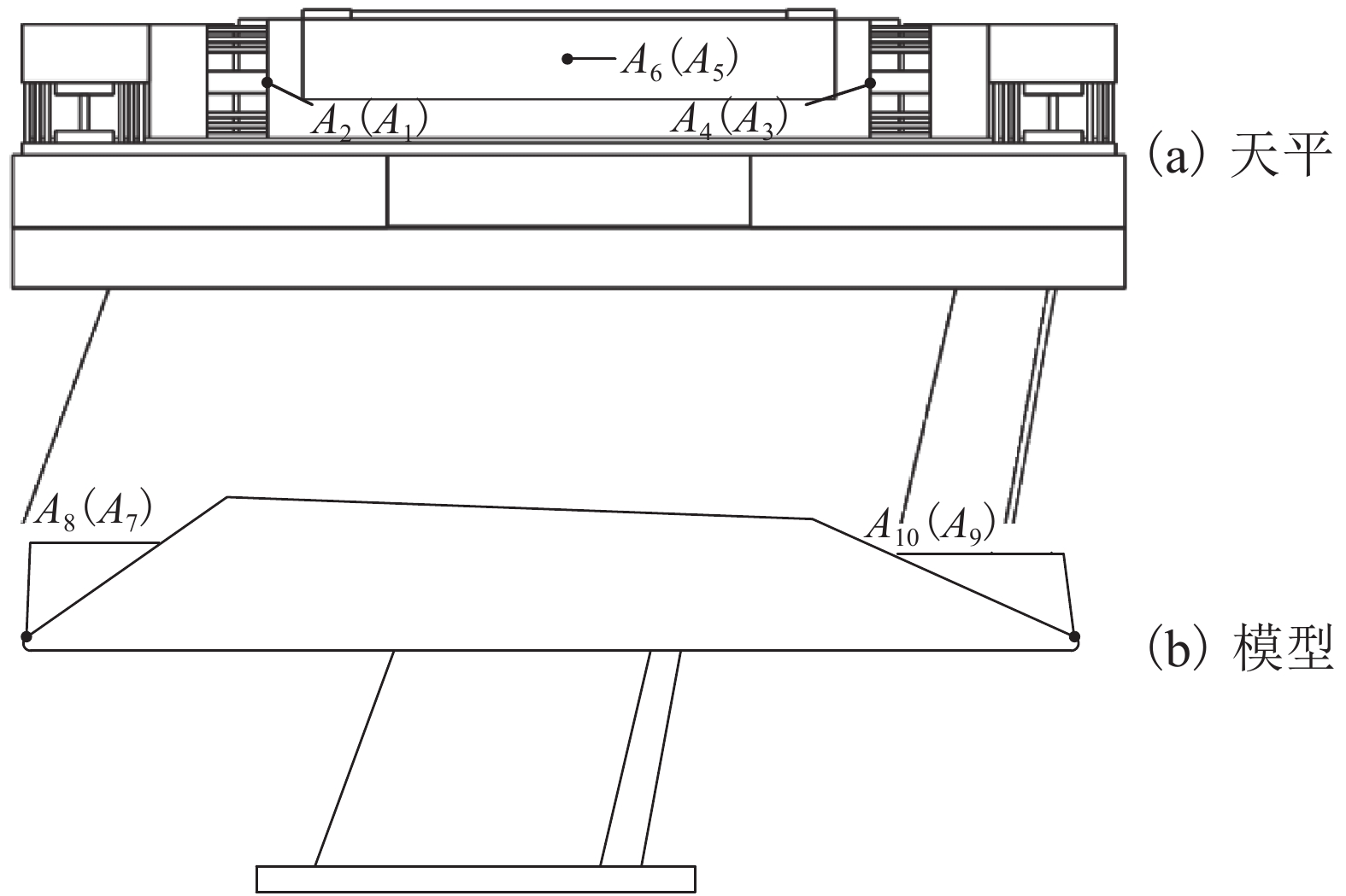

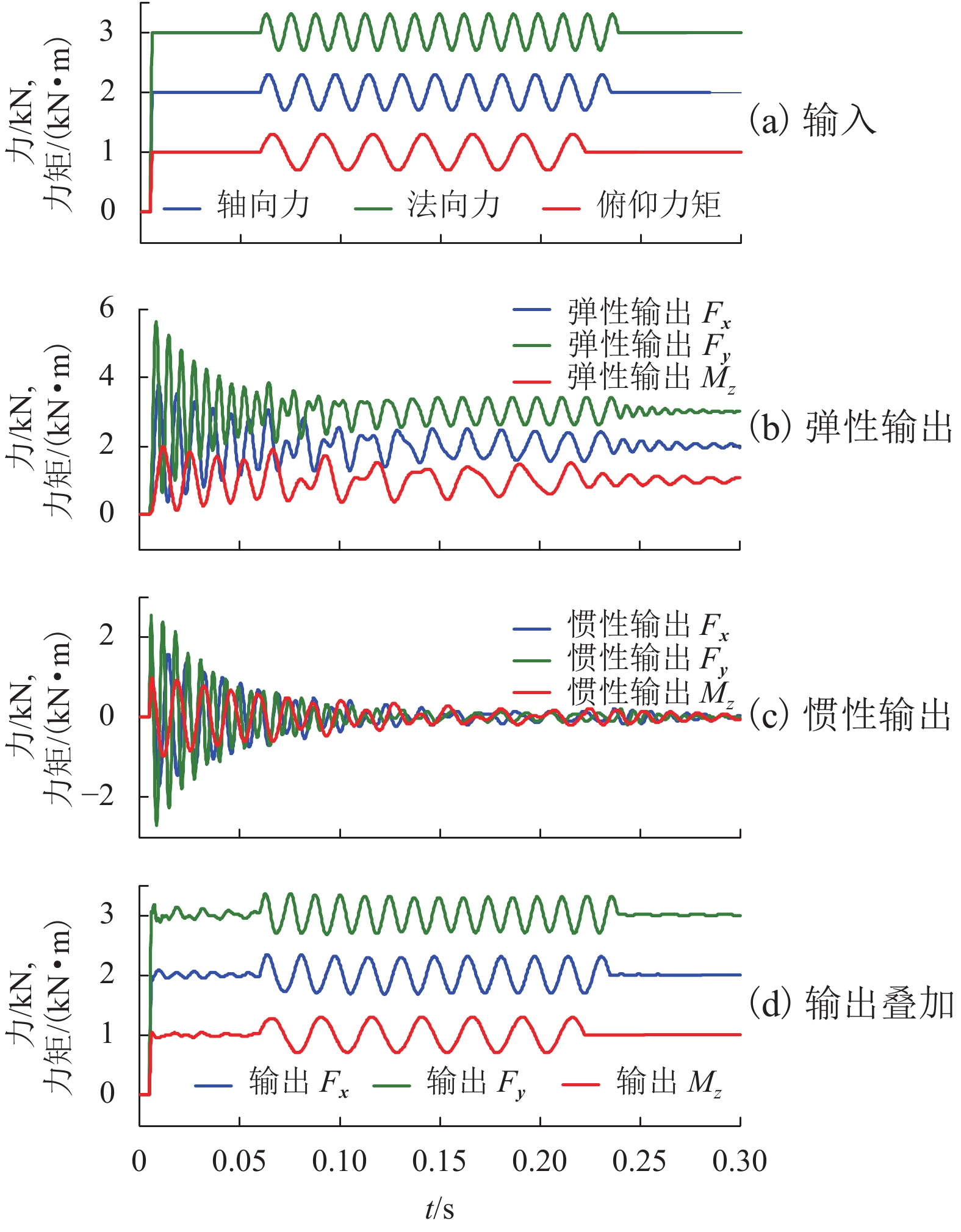

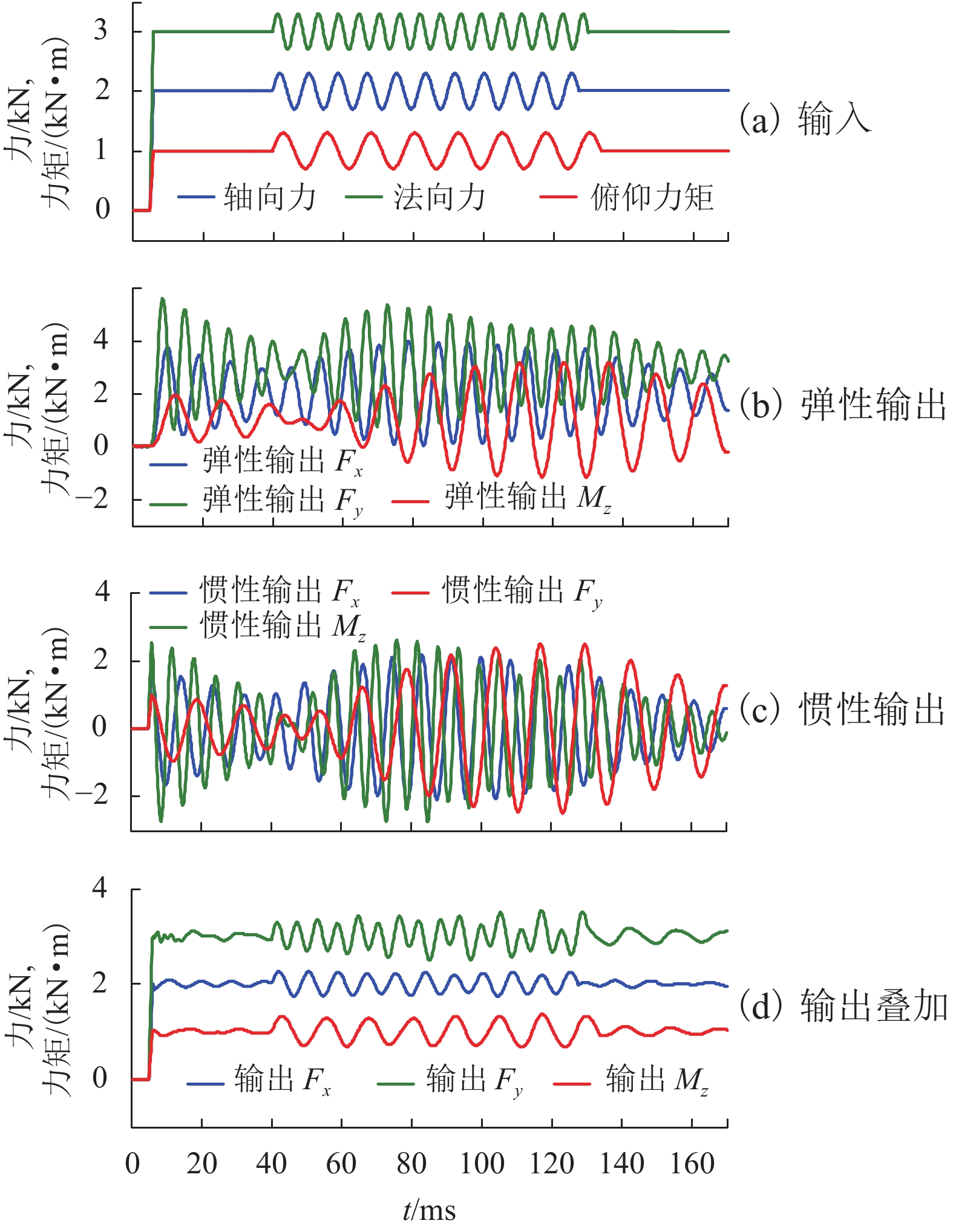

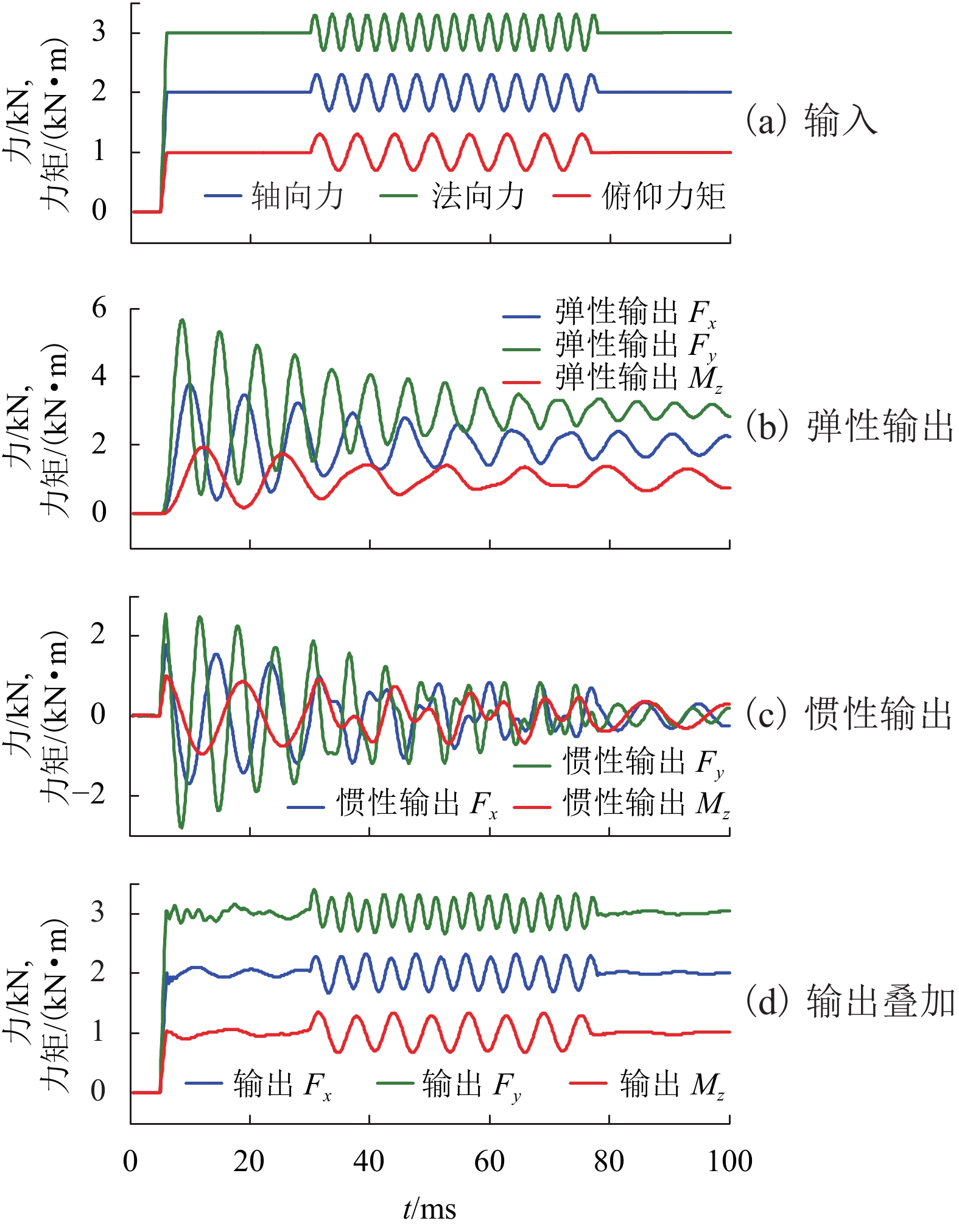

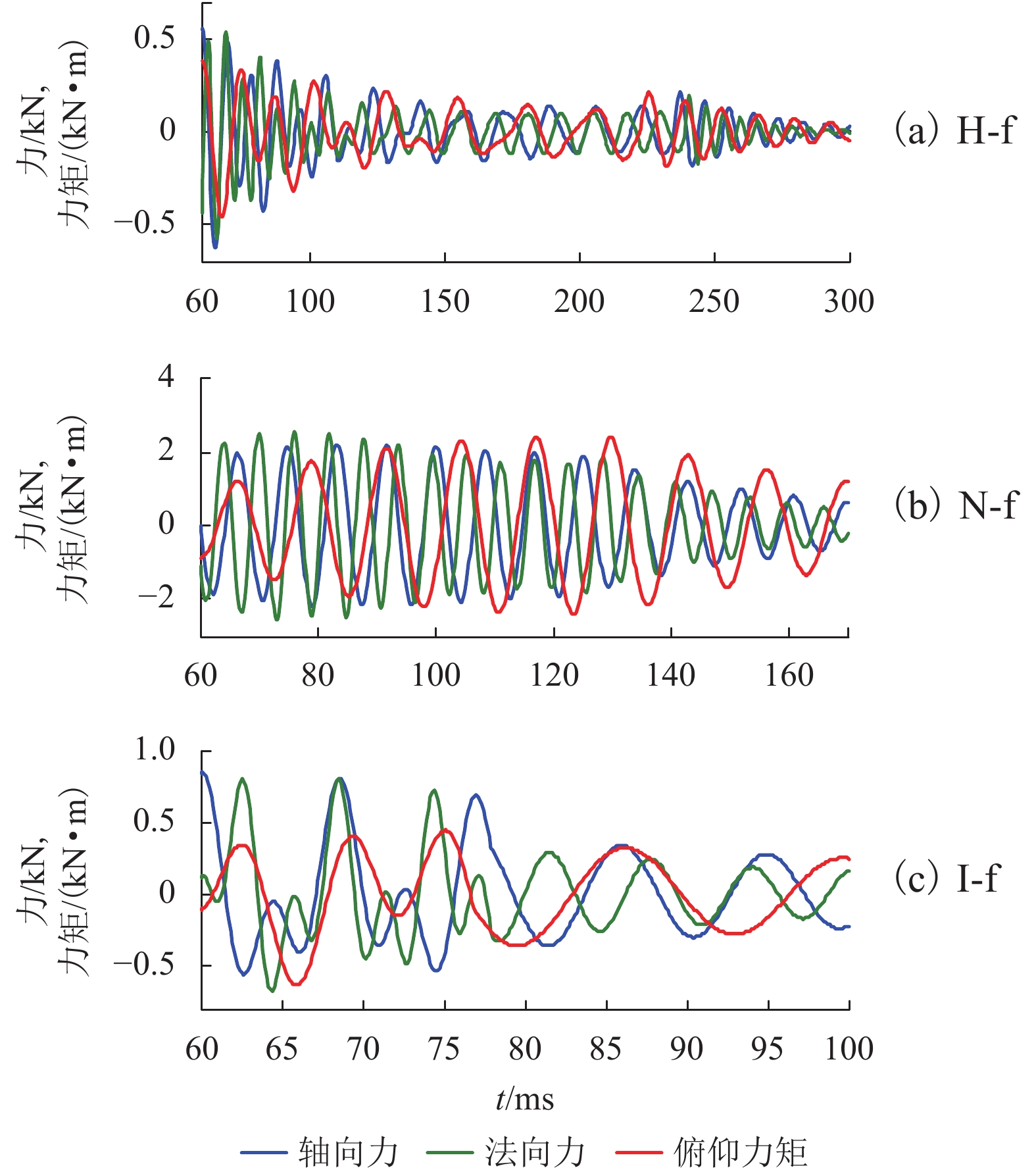

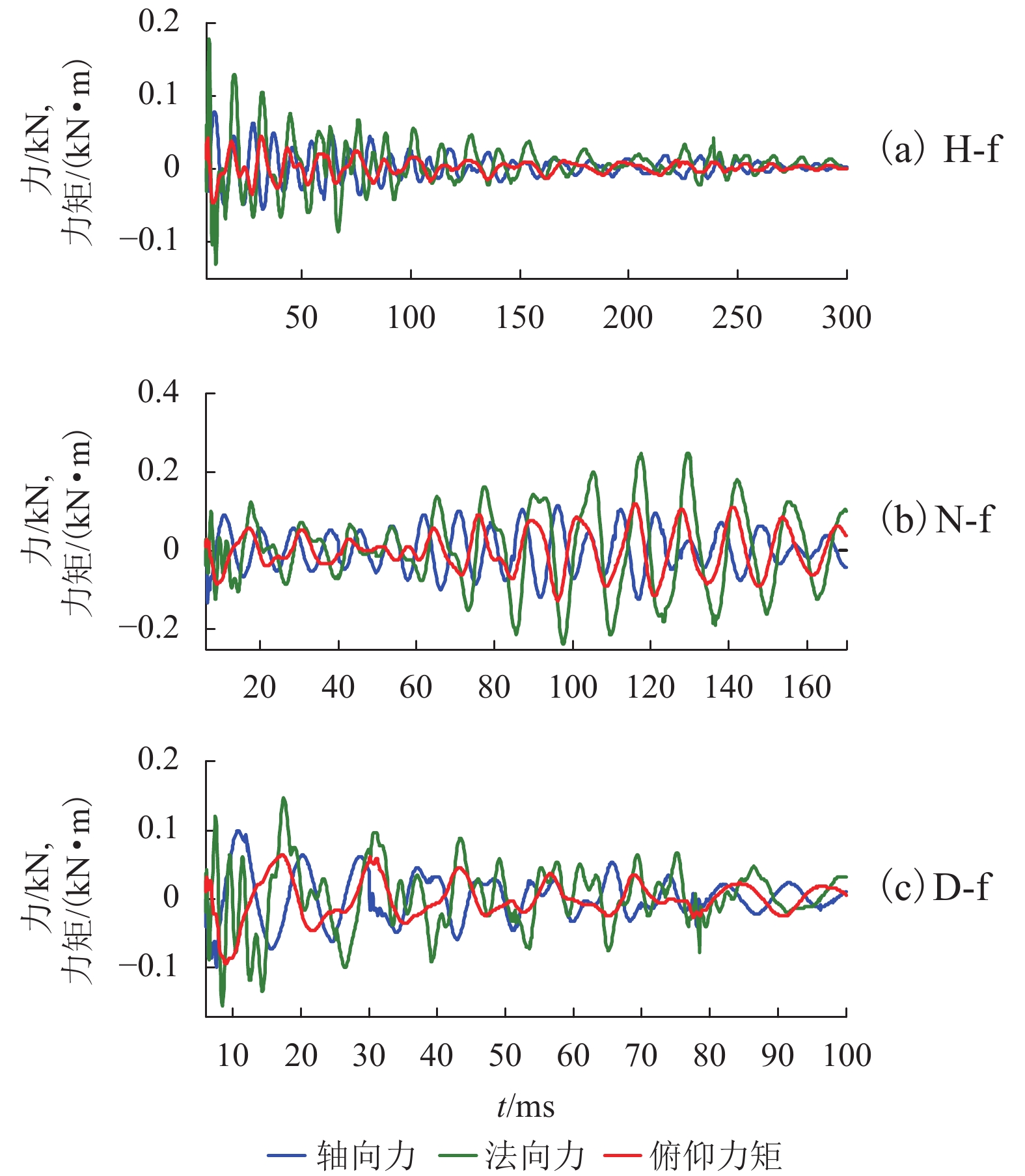

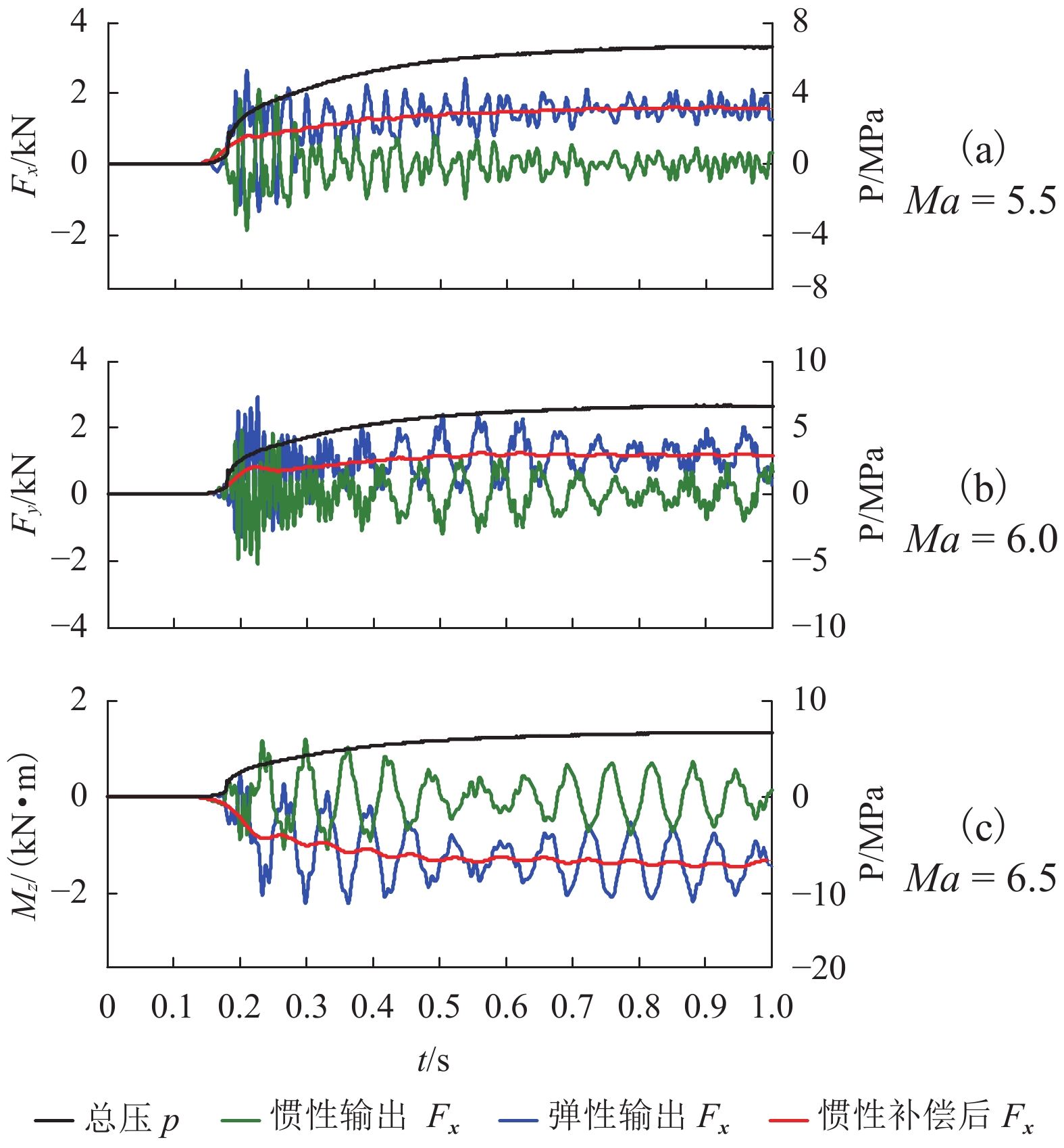

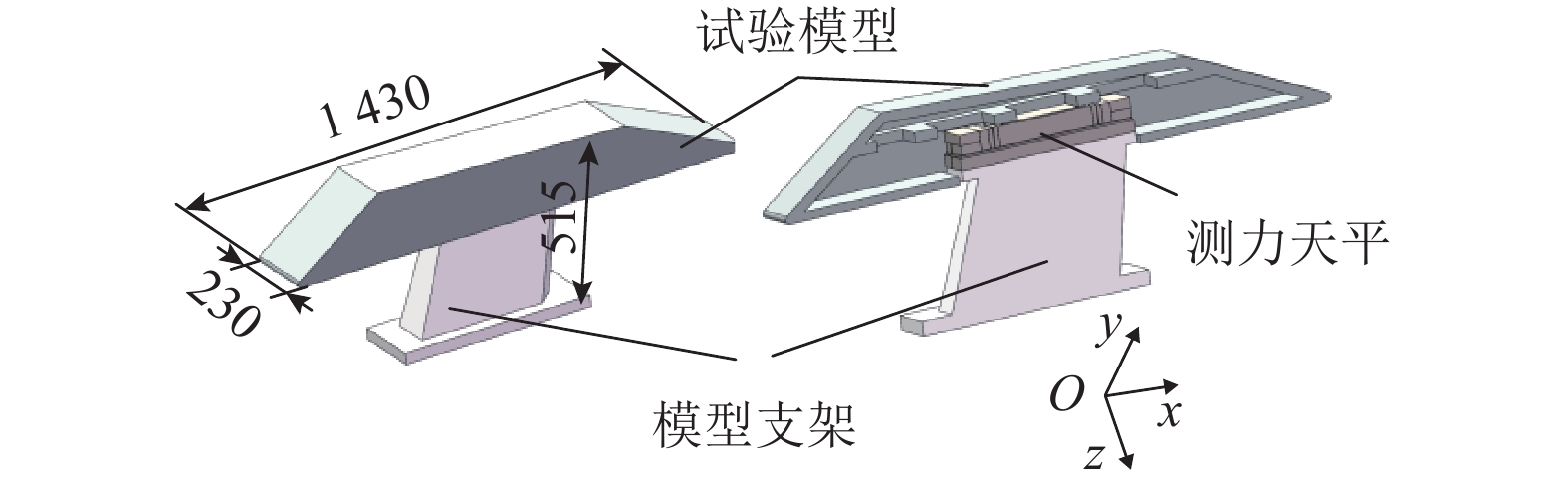

摘要: 脉冲风洞试验过程时,试验气流引起测力系统强烈振动对测试结果产生严重干扰. 为解决测力系统振动对测力结果干扰的问题,首先根据测力系统结构特点建立了相应的动力学模型;其次,对其进行了虚拟标定和模态分析;第三,对测力系统进行了瞬态分析和惯性补偿,获得了相应的瞬态输出;最后,对测力系统进行了风洞试验,分别获得了相应的弹性输出结果和惯性输出结果. 分析和试验结果表明:惯性补偿后,测力系统均值测量精度略有提高,瞬态测量精度大幅提高;惯性补偿后瞬态测量精度最低为87.4%,出现在测力系统共振时,其他状态下,瞬态测量精度超过91%;惯性补偿后的测力系统输出结果振动基本消失,说明惯性补偿方法能够消除振动对输出结果的干扰.Abstract: During testing in impulse wind tunnel, vibrations of the force-measurement system (FMS) caused by airflow will greatly tamper measurement results. To solve this issue, firstly the dynamic model of the FMS was constructed according to its structural characteristics. Then, the virtual calibration and modal analysis were carried out. Thirdly, the transient analysis and inertia compensation were processed to obtain the response of the FMS. Finally, the force measurement tests was conducted in the impulse wind tunnel, and both the elastic and inertia outputs were obtained in tests. Results show that after inertia compensation, the mean measurement accuracy were improved, and the transient measurement accuracy were improved significantly. When there was resonance, the lowest transient measurement accuracy was 87.4% after inertia compensation. In the other cases, the transient measurement accuracy exceeded 91%. Vibrations on the output curves of the FMS were virtually smoothed after inertia compensation, demonstrating that inertia compensation can eliminate the disturbance in the outputs.

-

Key words:

- FMS /

- virtual calibration /

- transient simulation /

- inertia compensation /

- measurement accuracy

-

表 1 测力系统模态参数

Table 1. Mode parameters of FMS

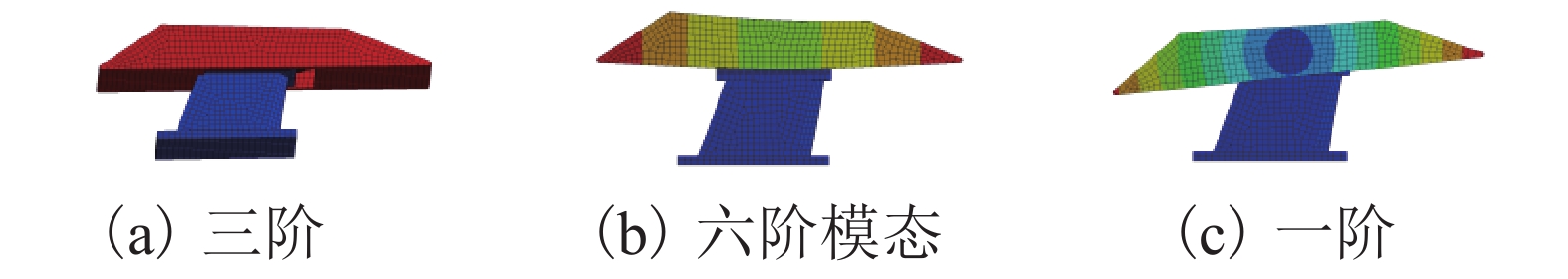

阶数 频率 振型描述 阶数 频率 振型描述 1 80.65 绕 z 轴旋转 3 120.99 沿 x 轴振动 6 172.64 沿 y 轴振动 表 2 测力系统各分量均值测量精度

Table 2. Mean measurement accuracy of FMS in each component

% 加载频率 惯性补偿 Fx Fy Mz H-f 前 99.527 99.508 99.077 后 99.653 99.71 99.195 N-f 前 99.305 99.391 99.088 后 99.69 99.775 99.319 D-f 前 99.151 99.253 98.889 后 99.724 99.787 99.450 表 3 测力系统瞬态测量精度最小值

Table 3. Minimum values in measurement accuracy of FMS

% 分量 H-f N-f D-f Fx 96.136 93.284 95.004 Fy 93.462 91.678 92.292 Mz 95.644 87.388 93.616 -

STALKER R J. A study of the free-piston shock tunnel[J]. AIAA Journal, 1967, 5(12): 2160-2165. PATE S R, SILM L G, STALLINGS D W, et al. Development of an MHD-augmented,high enthalpy,shock tunnel facility[J]. AIAA Journal, 1974, 12(3): 289-297. doi: 10.2514/3.49223 OLIVIER H, GROENIG H, BOZEC A L. Hypersonic model testing in a shock tunnel[J]. AIAA Journal, 1995, 33(2): 262-265. doi: 10.2514/3.12429 ROBINSON M J, MEE D J, TSAI C Y, et al. Three-component force measurements on a large scramjet in a shock tunnel[J]. Journal of Spacecraft & Rockets, 2004, 41(3): 416-425. SCHULTZ I A, GOLDENSTEIN C S, STRAND C L, et al. Hypersonic scramjet testing via diode laser absorption in a reflected shock tunnel[J]. Journal of Propulsion & Power, 2014, 30(6): 1586-1594. TANNO H, KOMURO T, SATO K, et al. Aerodynamic force measurement technique with accelerometers in the impulsive facility HIEST[M]//Shock Waves. Berlin: Springer, 2009: 471-476. TANNO H, KOMURO T, TAKAHASHI M, et al. Unsteady force measurement technique in shock tubes[J]. Review of Sci-entific Instruments, 2004, 75(2): 532-536. doi: 10.1063/1.1641156 SINGH P, MENEZES V, IRIMPAN K J, et al. Impulse force bal-ance for ultrashort duration hypersonic test facili-ties[DB/OL]. (2015-5-24)[2017-08-18]. https://www.hindawi.com/journals/sv/2015/803253/. SINGH P, TRIVEDI S, MENEZES V, et al. Dynamic calibration and validation of an accelerometer force balance for hypersonic lifting models[J]. The Scientific World Journal, 2014, 2014(6): 813759. TRIVEDI S, MENEZES V. Measurement of yaw,pitch and ide-force on a lifting model in a hypersonic shock tunnel[J]. Measurement, 2012, 45(7): 1755-1764. doi: 10.1016/j.measurement.2012.04.008 SATHEESH K, JAGADEESH G. Analysis of an internally mount-able accelerometer balance system for use with non-isotropic models in shock tunnels[J]. Measurement, 2009, 42(6): 856-862. doi: 10.1016/j.measurement.2009.01.010 SARAVANAN S, JAGADEESH G, REDDY K P J. Aerodynamic force measurement using 3-component accelerometer force balance system in a hypersonic shock tunnel[J]. Shock Waves, 2009, 18(6): 425-435. doi: 10.1007/s00193-008-0172-8 SMITH A L, MEE D J, DANIEL W J T, et al. Design,modelling and analysis of a six component force balance for hypervelocity wind tunnel testing[J]. Computers & Structures, 2001, 79(11): 1077-1088. LAURENCE S J, HORNUNG H G. Image-based force and mo-ment measurement in hypersonic facilities[J]. Experiments in Fluids, 2009, 46(2): 343-353. doi: 10.1007/s00348-008-0565-6 LAURENCE S J, KARL S. An improved visualization-based force-measurement technique for short-duration hypersonic facilities[J]. Experiments in Fluids, 2010, 48(6): 949-965. doi: 10.1007/s00348-009-0780-9 刘洪山,徐翔,姜华. 应力波天平在国内激波风洞上的应用[J]. 实验流体力学,2006,20(1): 36-39. doi: 10.3969/j.issn.1672-9897.2006.01.009LIU Hongshan, XU Xiang, JIANG Hua, et al. The application of the stress wave force balance in shock tunnel[J]. Journal of Experiments in Fluid Mechanics, 2006, 20(1): 36-39. doi: 10.3969/j.issn.1672-9897.2006.01.009 WANG Yunpeng, LIU Y, LUO C, et al. Force measurement using strain-gauge balance in a shock tunnel with long test duration[J]. Review of Scientific Instruments, 2016, 87(5): 1068. WANG Y, LIU Y, JIANG Z. Design of a pulse-type strain gauge balance for a long-test-duration hypersonic shock tunnel[J]. Shock Waves, 2016, 26(6): 1-10. 贺伟,童泽润,李宏斌. 单模块超燃发动机推力测量天平研制[J]. 航空动力学报,2006,20(1): 36-39. doi: 10.3969/j.issn.1000-8055.2006.01.007HE Wei, TONG Zerun, LI Hongbin. Investigation of thrust balance for the single module scramjet[J]. Journal of Aerospace Power, 2006, 20(1): 36-39. doi: 10.3969/j.issn.1000-8055.2006.01.007 王锋,贺伟,毛鹏飞,等. 脉冲风洞测力系统建模与载荷辨识方法研究[J]. 振动与冲击,2015,34(1): 94-103.WANG Feng, HE Wei, MAO Pengfei, et al. Dynamic modeling of testing system in impulse facilities and load identification method[J]. Journal of Vibration and Shock, 2015, 34(1): 94-103. 程忠宇,陈宏,张琦. 多加速度计振动分离惯性补偿测力技术[J]. 流体力学实验与测量,1999,13(4): 57-61. doi: 10.3969/j.issn.1672-9897.1999.04.012CHENG Zhongyu, CHEN Hong, ZHANG Qi. Inertia compensation technology based on multi-accelerometer vibration separating[J]. Experiments and Measurements in Fluid Mechanics, 1999, 13(4): 57-61. doi: 10.3969/j.issn.1672-9897.1999.04.012 -

下载:

下载: