Analysis of Flow Characteristics of Asymmetric Cam-Rotor Double Stator Pump

-

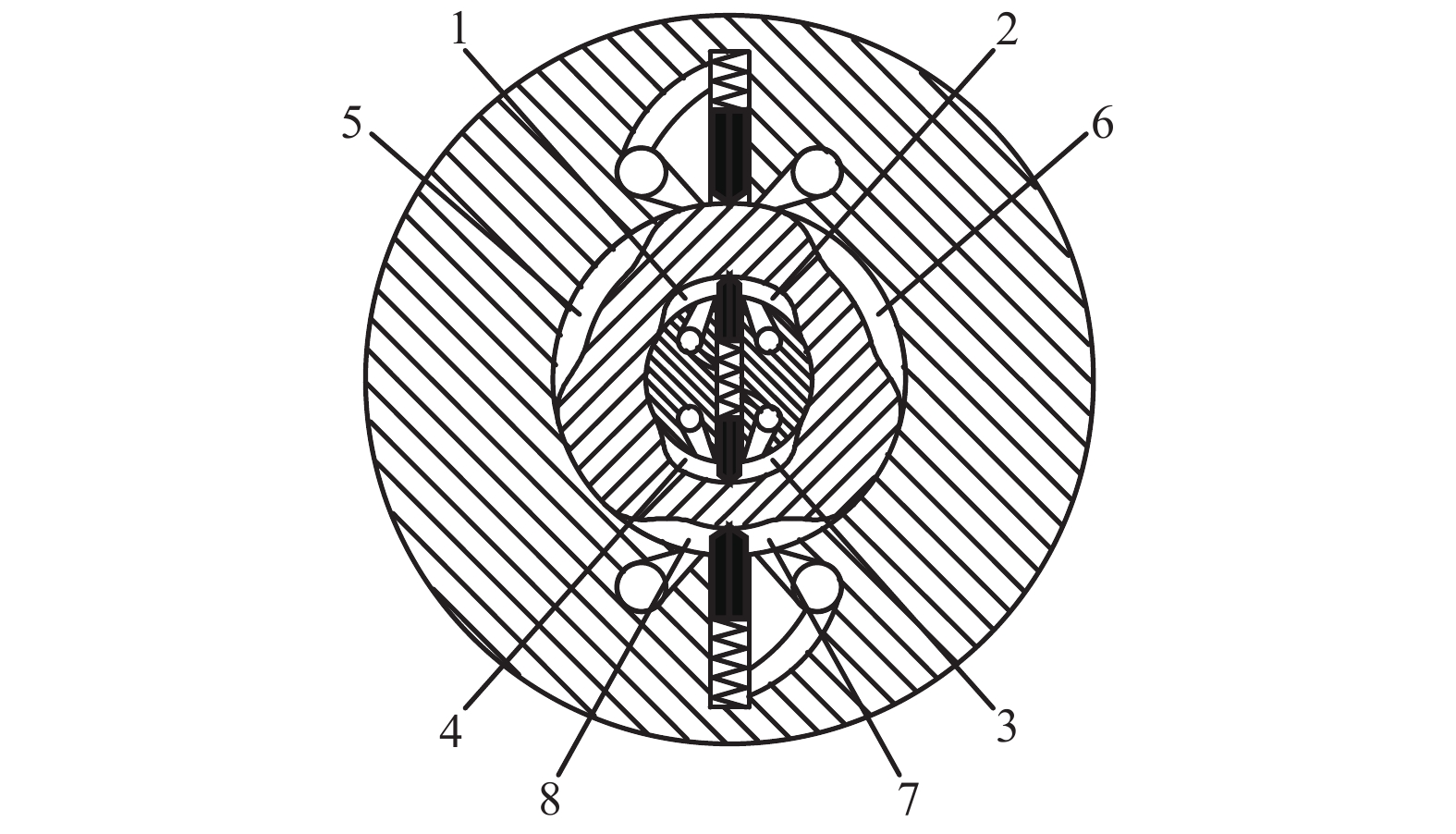

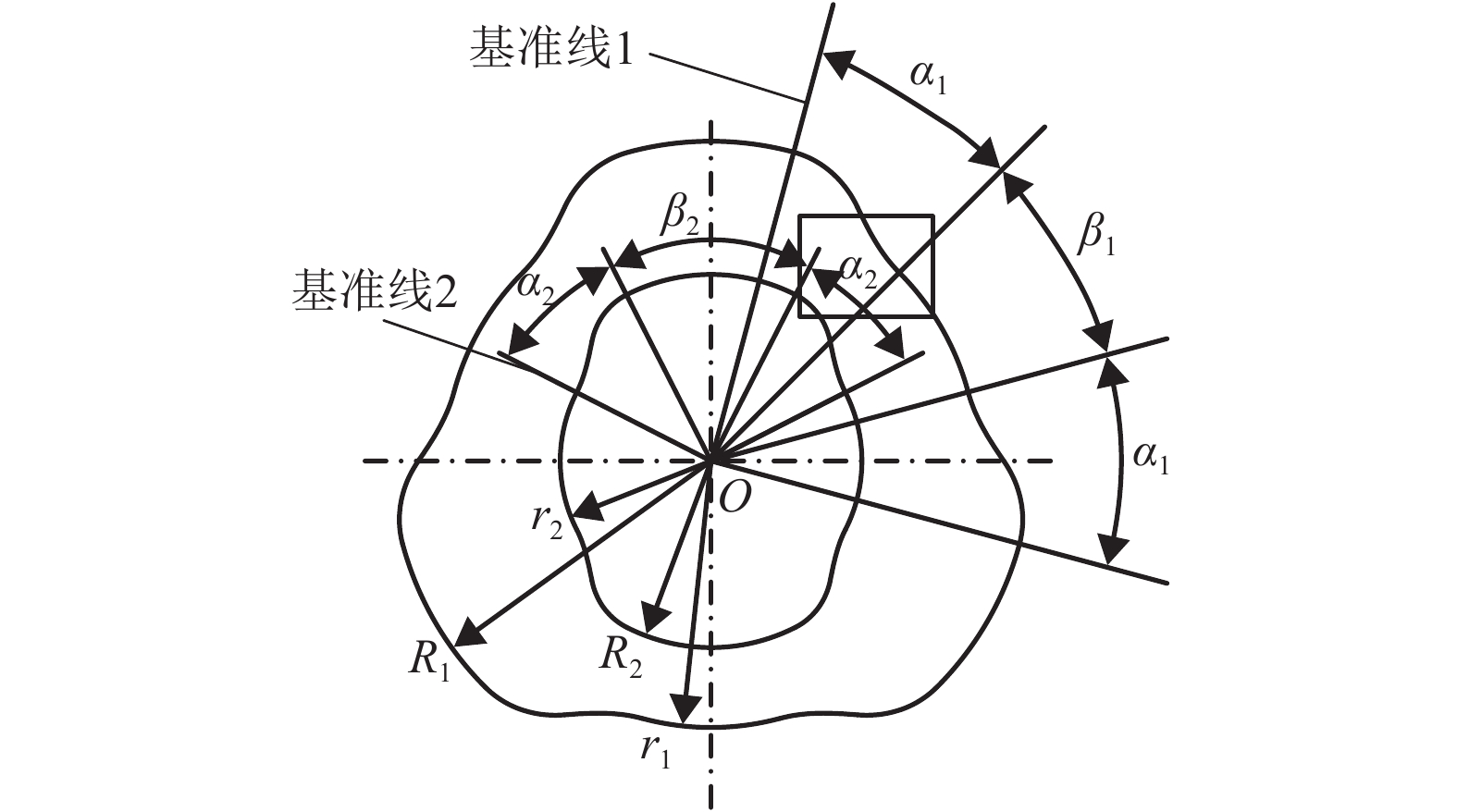

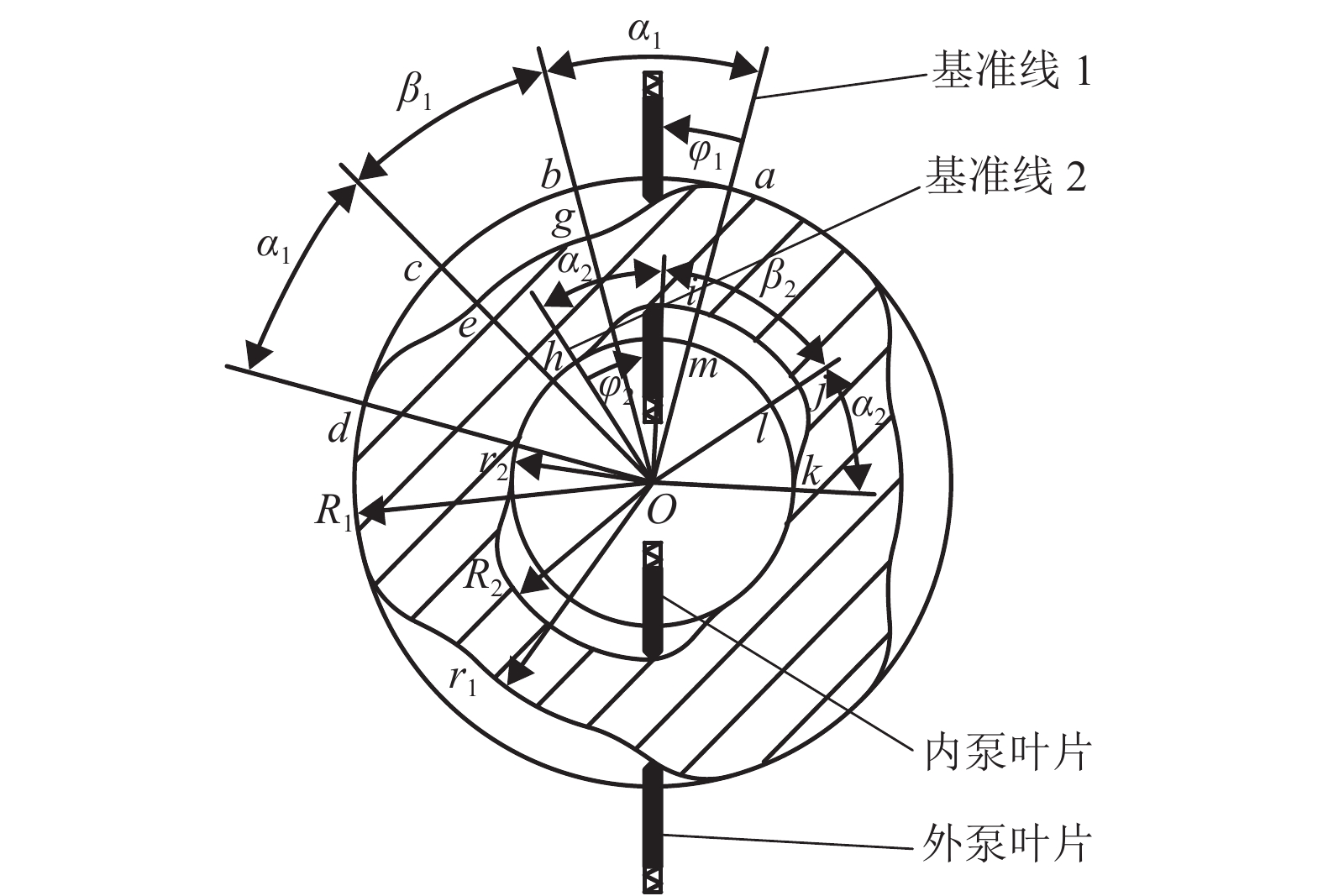

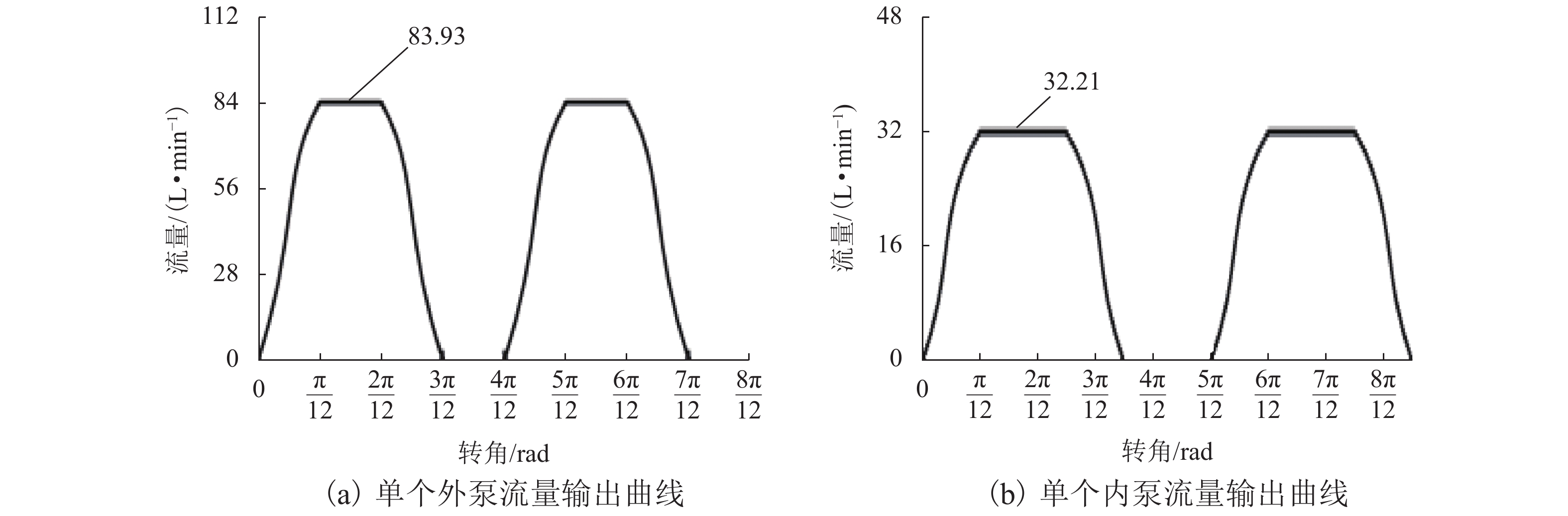

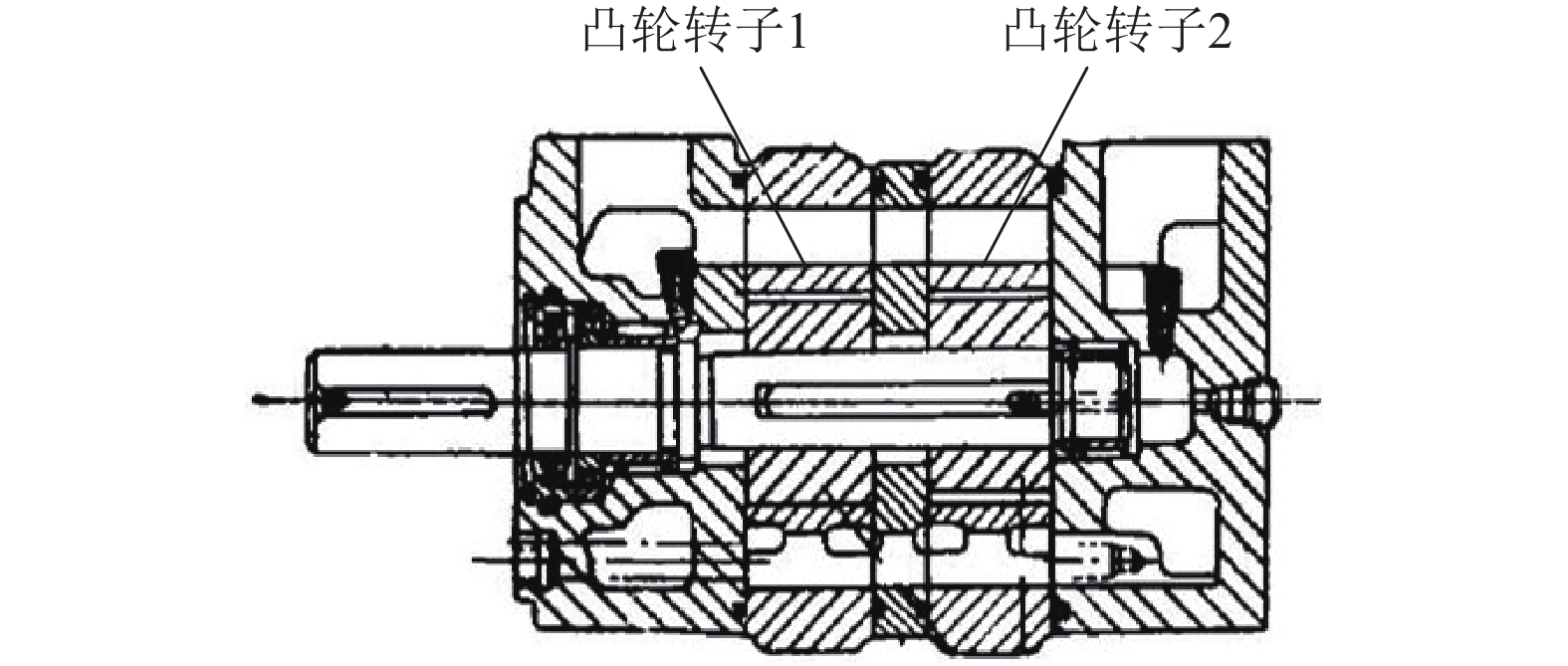

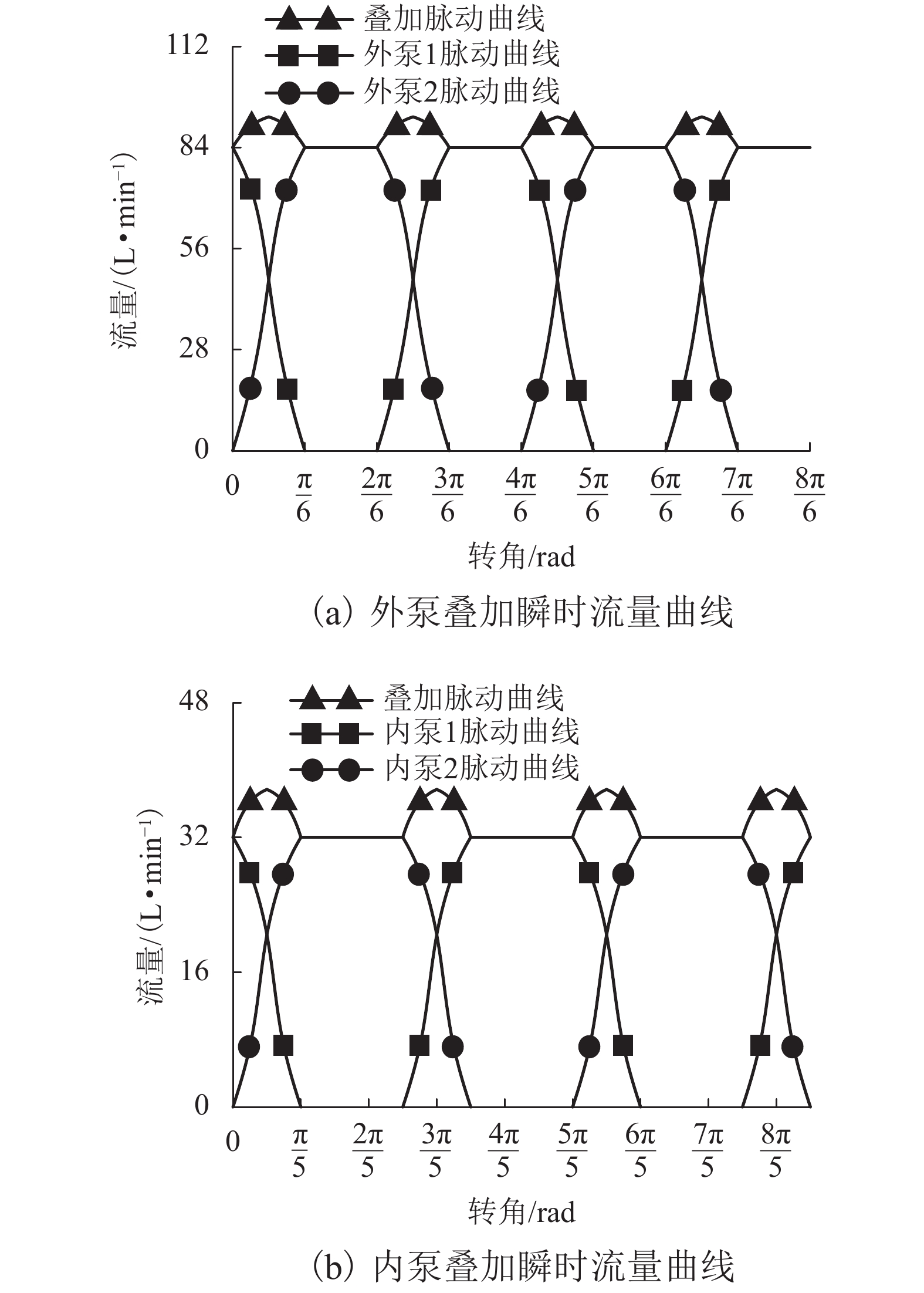

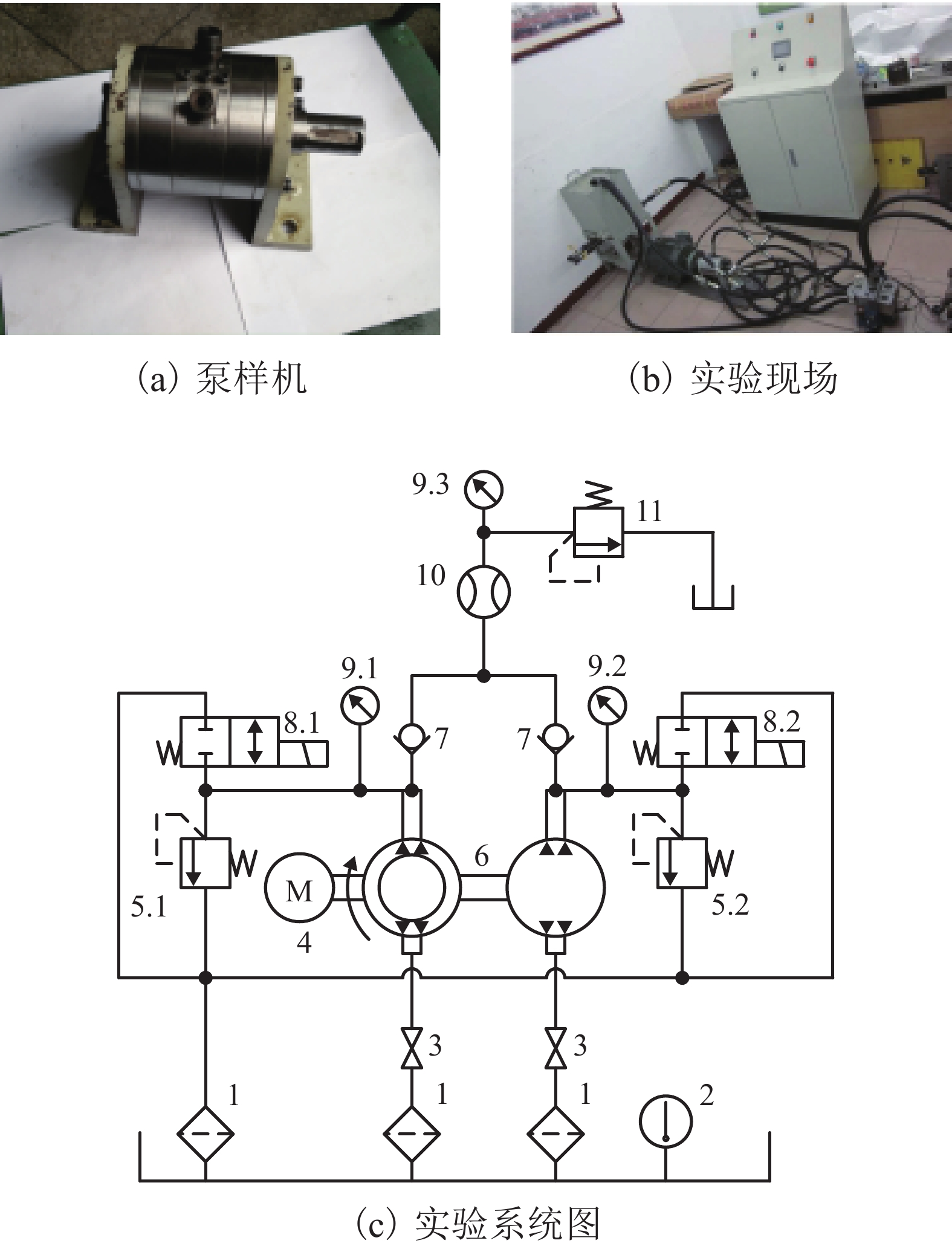

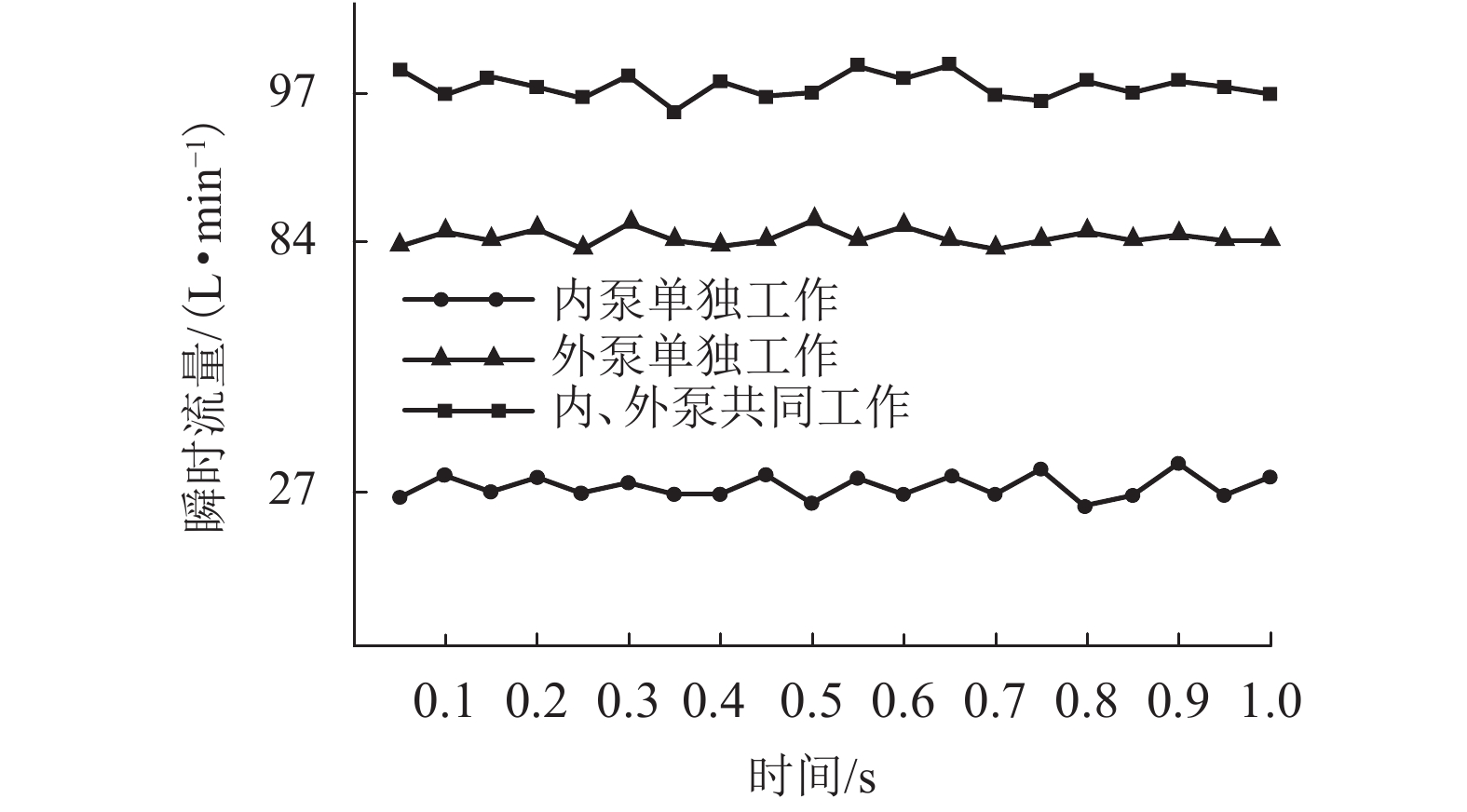

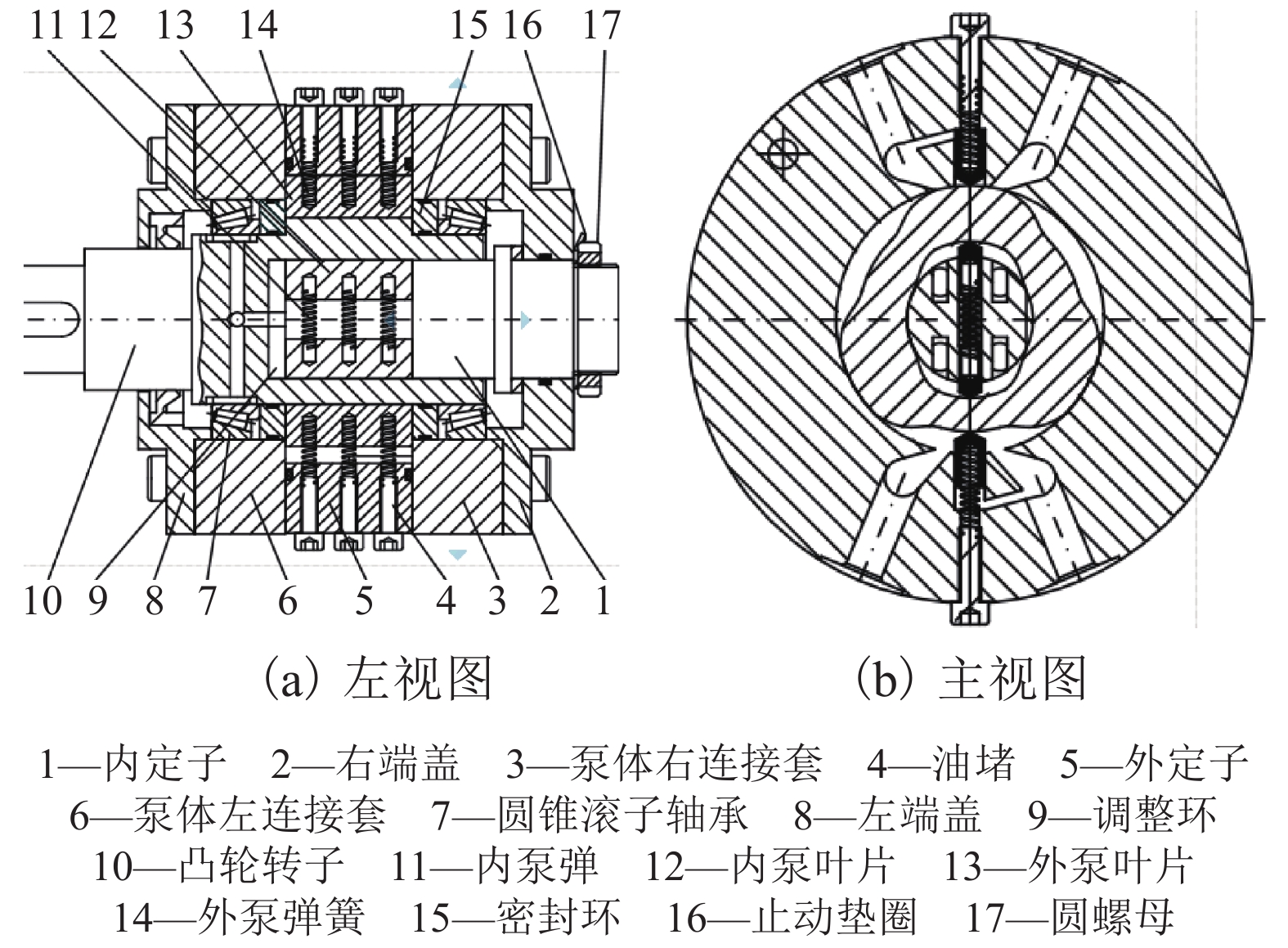

摘要: 针对传统液压泵的不足,研制了一种新型非对称式凸轮转子型双定子叶片泵. 该泵将凸轮转子型叶片泵的结构和双定子的思想相结合,在泵的壳体内设置了内外两个定子和一个转子,其中转子内外凸起数不同,使该泵可输出多级定流量,也能够同时对多个系统供油. 阐述了泵的工作原理与特点,通过非对称式凸轮转子型双定子叶片泵内部结构的分析,归纳出凸轮转子在不同转角下内外泵的理论流量,进而得到泵在不同工作方式下的瞬时流量. 搭建了非对称式凸轮转子型双定子叶片泵试验平台,试验结果表明:与传统的对称式双凸起凸轮转子型叶片泵相比,非对称式凸轮转子型叶片泵的流量脉动更小,大约降低了2%左右,试验结果与理论分析基本一致,验证了理论分析的正确性.Abstract: A new type of asymmetric cam-rotor double-stator vane pump was developed to deal with the shortcomings of traditional hydraulic pumps. Two inner and outer stators and one rotor are arranged in the casing of the vane pump, in which the numbers of protrusions inside and outside the rotor are different, so that the vane pump can output multi-stage constant flow, and simultaneously supply oil to multiple systems. The operation principle and characteristics of the vane pump are explained . Through the analysis on the internal structure of the vane pump, the theoretical flow of the inner and outer pumps of the cam rotor at different rotation angles is deduced, and then the instantaneous flow of the vane pump in different working modes is obtained. A test platform for the asymmetric cam-rotor double-stator vane pump was built. The test results show that the flow pulsation of the asymmetric cam-rotor vane pump is 2% less than that of the conventional symmetric vane pump with double convex cams. The test results are basically consistent with the theoretical analysis, which verifies the correctness of the theoretical analysis.

-

Key words:

- asymmetric type /

- double-stator pump /

- cam rotor /

- flow pulsation /

- coefficient of inhomogeneity

-

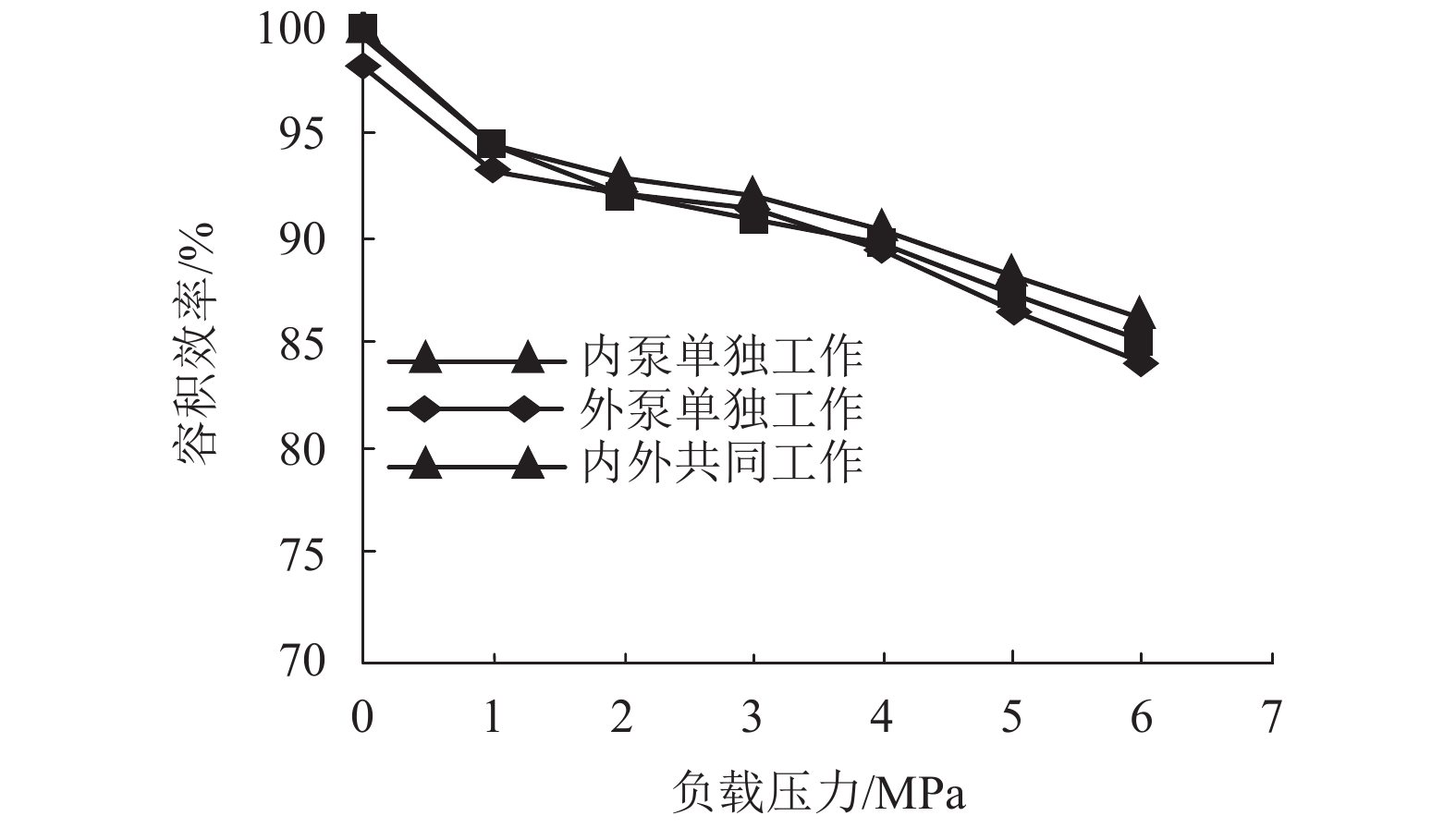

表 1 内泵单独工作时容积效率实验测量数据

Table 1. Test data of volumetric efficiency with single operation of internal pump

工作压力

/MPa额定转速

/(r•min−1)理论流量

/(L•min−1)实际流量

/(L•min−1)容积效

率/%1 1 440 31.56 29.63 93.88 2 1 440 31.56 29.28 92.79 3 1 440 31.56 28.87 91.47 4 1 440 31.56 28.27 89.56 5 1 440 31.56 27.29 86.48 6 1 440 31.56 26.55 84.11 表 3 内外泵联合工作时容积效率实验测量数据

Table 3. Test data of volumetric efficiency with joint operation of internal and external pumps

工作压力

/MPa额定转速

/(r•min−1)理论流量

/(L•min−1)实际流量

/(L•min−1)容积效

率/%1 1 440 112.99 106.25 94.11 2 1 440 112.99 104.93 92.87 3 1 440 112.99 103.45 91.56 4 1 440 112.99 101.67 89.98 5 1 440 112.99 98.99 87.61 6 1 440 112.99 96.58 85.48 表 2 外泵单独工作时容积效率实验测量数据

Table 2. Test data of volumetric efficiency with single operation of external pump

工作压力/MPa 额定转速/(r•min−1) 理论流量/(L•min−1) 实际流量/(L•min−1) 容积效率/% 1 1 440 81.43 76.77 94.11 2 1 440 81.43 75.85 92.87 3 1 440 81.43 74.95 91.56 4 1 440 81.43 73.38 89.98 5 1 440 81.43 72.13 87.61 6 1 440 81.43 70.49 85.48 -

张笃增. 现代液压技术在机械自动化生产中的应用[J]. 机电信息,2013(21): 96-97.ZHANG Duzeng. Modern hydraulic technology in the mechanical automation of production applications[J]. Electrical and Mechanical Information, 2013(21): 96-97. 付红光,范孝杰. 液压系统在矿山机械中的应用[J]. 科技与企业,2013(21): 344-355.Fu Hongguang, Fan Xiaojie. Application of hydraulic system in mining machinery[J]. Technology and Enterprise, 2013(21): 344-355. 彭熙伟,陈建萍. 液压技术的发展动向[J]. 液压与气动,2007(3): 1-5. doi: 10.3969/j.issn.1000-4858.2007.03.001PENG Xiwei, CHEN Jianping. The future trends of hydraulics[J]. Hydraulic & Pneumatics, 2007(3): 1-5. doi: 10.3969/j.issn.1000-4858.2007.03.001 许仰曾. 我国液压工业与技术的发展现状与展望的战略思考[J]. 液压气动与密封,2010(8): 1-5. doi: 10.3969/j.issn.1008-0813.2010.08.001XU Yangzeng. Strategy thinking on development of hydraulic industry and its technology[J]. Hydraulics Pneumatics & Seals, 2010(8): 1-5. doi: 10.3969/j.issn.1008-0813.2010.08.001 路甬祥. 流体传动与控制技术的历史进展与发展[J]. 机械工程学报,2001,37(10): 1-9. doi: 10.3321/j.issn:0577-6686.2001.10.001LU Yongxiang. Historical progress and development of fluid transmission and control technology[J]. Journal of Mechanical Engineering, 2001, 37(10): 1-9. doi: 10.3321/j.issn:0577-6686.2001.10.001 王忠楗. TYB型凸轮转子叶片泵[J]. 机床与液压,1982(6): 13-33.WANG Zhongjian. TYB cam rotor vane pump[J]. Machine Tool and Hydraulics, 1982(6): 13-33. 张或定. 凸轮转子式叶片泵[J]. 液压与气动,1977(2): 27-29.ZHANG Huoding. Cam rotor blade pump[J]. Hydraulic & Pneumatics, 1977(2): 27-29. 林信彰. 提高凸轮转子叶片泵的工作寿命[J]. 中国机械工程,1994(1): 41-43. doi: 10.3321/j.issn:1004-132X.1994.01.016LIN Xinzhang. Improve the working life of cam rotor blade pump[J]. China Mechanical Engineering, 1994(1): 41-43. doi: 10.3321/j.issn:1004-132X.1994.01.016 林信彰,薛昭明. 低噪声、高性能凸轮转子叶片泵的研究[J]. 福州大学学报,1983(3): 73-84.LIN Xinzhang, XUE Zhaoming. A study of the cam-rotor vane pump featured by low noise and optimum performance[J]. Journal of Fuzhou University, 1983(3): 73-84. 林信彰. 凸轮转子叶片马达的研究[J]. 福州大学学报(自然科学版),1995,23(2): 59-64.LIN Xinzhang. The research of cam-rotor vane motor[J]. Journal of Fuzhou University (Natural Science Edition), 1995, 23(2): 59-64. 邱永榴,陈楚琳. 凸轮转子式叶片泵的流量和叶片马达的转矩问题分析[J]. 机床与液压,1978(2): 3-17.QIU Yongju, CHEN Chulin. Analysis of the flow of cam rotor vane pump and torque of vane motor[J]. Machine Tool & Hydraulics, 1978(2): 3-17. 雷亚勇,吴晓明,陈春明. 双作用叶片泵噪声的产生机理和降噪分析[J]. 机床与液压,2007,35(1): 145-147. doi: 10.3969/j.issn.1001-3881.2007.01.048LEI Yayong, WU Xiaoming, CHEN Chunming. Discussion on noise problems for double-acting vane pump[J]. Machine tool & Hydraulics, 2007, 35(1): 145-147. doi: 10.3969/j.issn.1001-3881.2007.01.048 叶仲和,钟汉桥,林信彰. 正偏置式凸轮转子叶片泵的最佳参数[J]. 福州大学学报(自然科学版),1999,27(2): 57-61.YE Zhonghe, ZHONG Hanqiao, LIN Xinzhang. Optimum parameters of positive bias cam rotor vane pump[J]. Journal of Fuzhou University (Natural Science Edition), 1999, 27(2): 57-61. 赵超. 双作用双定子凸轮转子型叶片泵的理论分析与研究[D]. 秦皇岛: 燕山大学, 2012. 郑澈. 采用奇数叶片的变量双作用叶片泵径向力研究[J]. 液压与气动,2004(8): 42-44. doi: 10.3969/j.issn.1000-4858.2004.08.016ZHENG Che. Research on the radial force by double action variable vane pump of odd number vane[J]. Chinese Hydralics & Pneumatics, 2004(8): 42-44. doi: 10.3969/j.issn.1000-4858.2004.08.016 王马林,唐坤,郝跃跃,等. 新型双作用式叶片泵的理论研究[J]. 机械,2012,39(10): 68-70. doi: 10.3969/j.issn.1000-033X.2012.10.032WANG Malin, TANG Kun, HAO Yueyue, et al. Theory of new double acting variable vane pump[J]. Mechanical, 2012, 39(10): 68-70. doi: 10.3969/j.issn.1000-033X.2012.10.032 李义,袁圆,陈超,等. 双作用式变量叶片泵理论研究[J]. 煤矿机械,2011,32(2): 42-43. doi: 10.3969/j.issn.1003-0794.2011.02.018LI Yi, YUAN Yuan, CHEN Chao, et al. Theory of double acting variable pump[J]. Coal Mine Machinery, 2011, 32(2): 42-43. doi: 10.3969/j.issn.1003-0794.2011.02.018 张或定. 凸轮转子型叶片泵和叶片马达的结构与计算[J]. 机床与液压,1977(2): 42-53.ZHANG Huoding. Structure and calculation of vane rotor blade and vane motor[J]. Machine Tools & Hydraulics, 1977(2): 42-53. 王天祥,何利民,任吉娟. 刚性转子式叶片泵最佳过渡曲线的研究[J]. 流体机械,2006(3): 25-27,78.WANG Tianxiang, HE Limin, REN Jijuan. Study on the optimal transitional curve of stator for rigid rotator model vane pump[J]. Fluid Machinery, 2006(3): 25-27,78. 闻德生. 液压元件的创新与发展[M]. 北京: 航空工业出版社, 2009: 375-383. 黎克英, 陆祥生. 叶片式液压泵和马达[M]. 北京: 机械工业出版社, 1993: 5-18. 那成烈. 论凸轮转子叶片泵的过渡曲线[J]. 甘肃工业大学学报,1981(1): 34-52.NA Chenglie. On the transition curve of cam rotor blade[J]. Journal of Gansu Polytechnic University, 1981(1): 34-52. 王益群,张伟. 流体传动及控制技术的评述[J]. 机械工程学报,2003,39(10): 95-99. doi: 10.3321/j.issn:0577-6686.2003.10.016WANG Yiqun, ZHANG Wei. Summary of fluid power transmission and contral technology[J]. Journal of Mechanical Engineering, 2003, 39(10): 95-99. doi: 10.3321/j.issn:0577-6686.2003.10.016 -

下载:

下载: