Effect of Transverse Deflection on Force State of Prestressed Concrete Trough Girders with Asymmetric Cross-Section

-

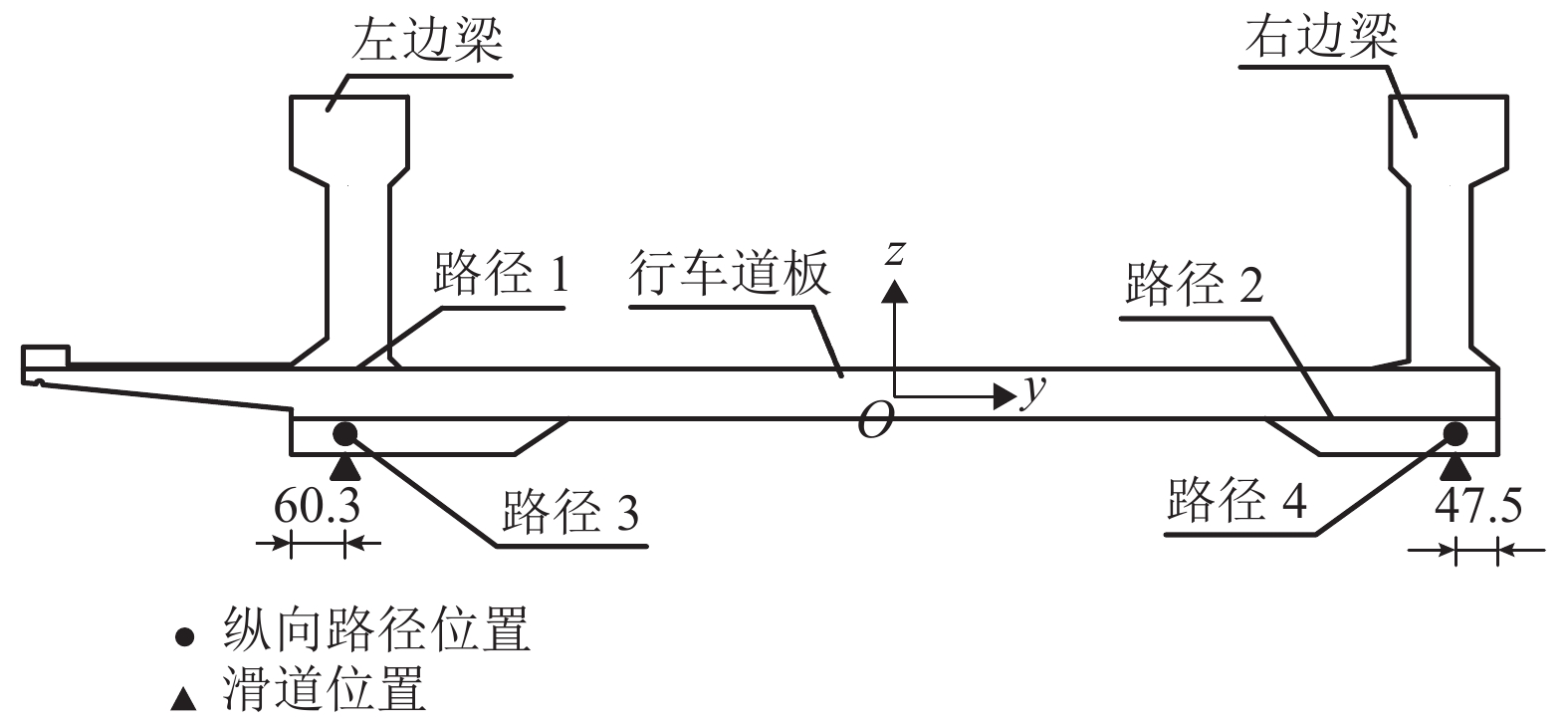

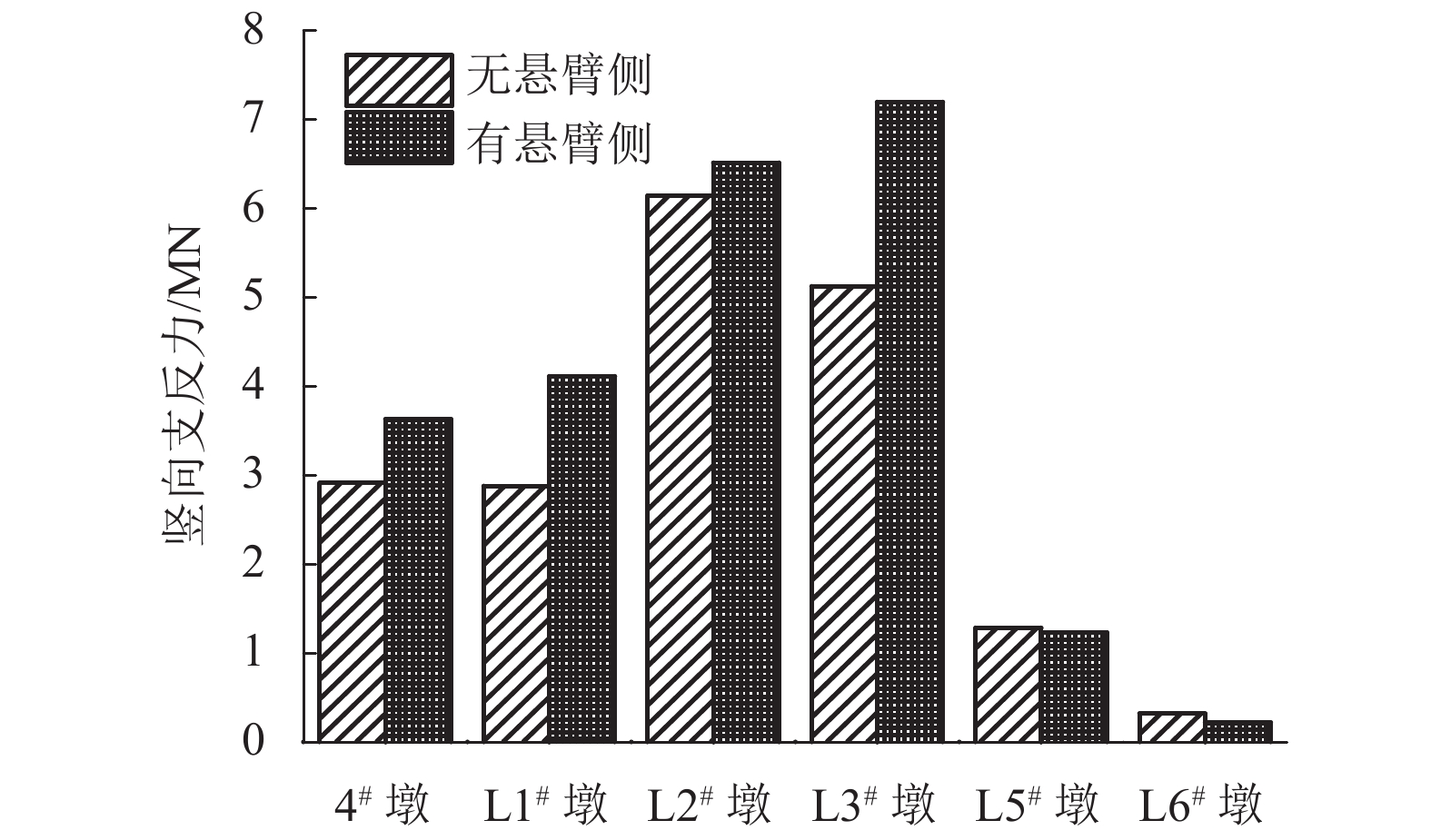

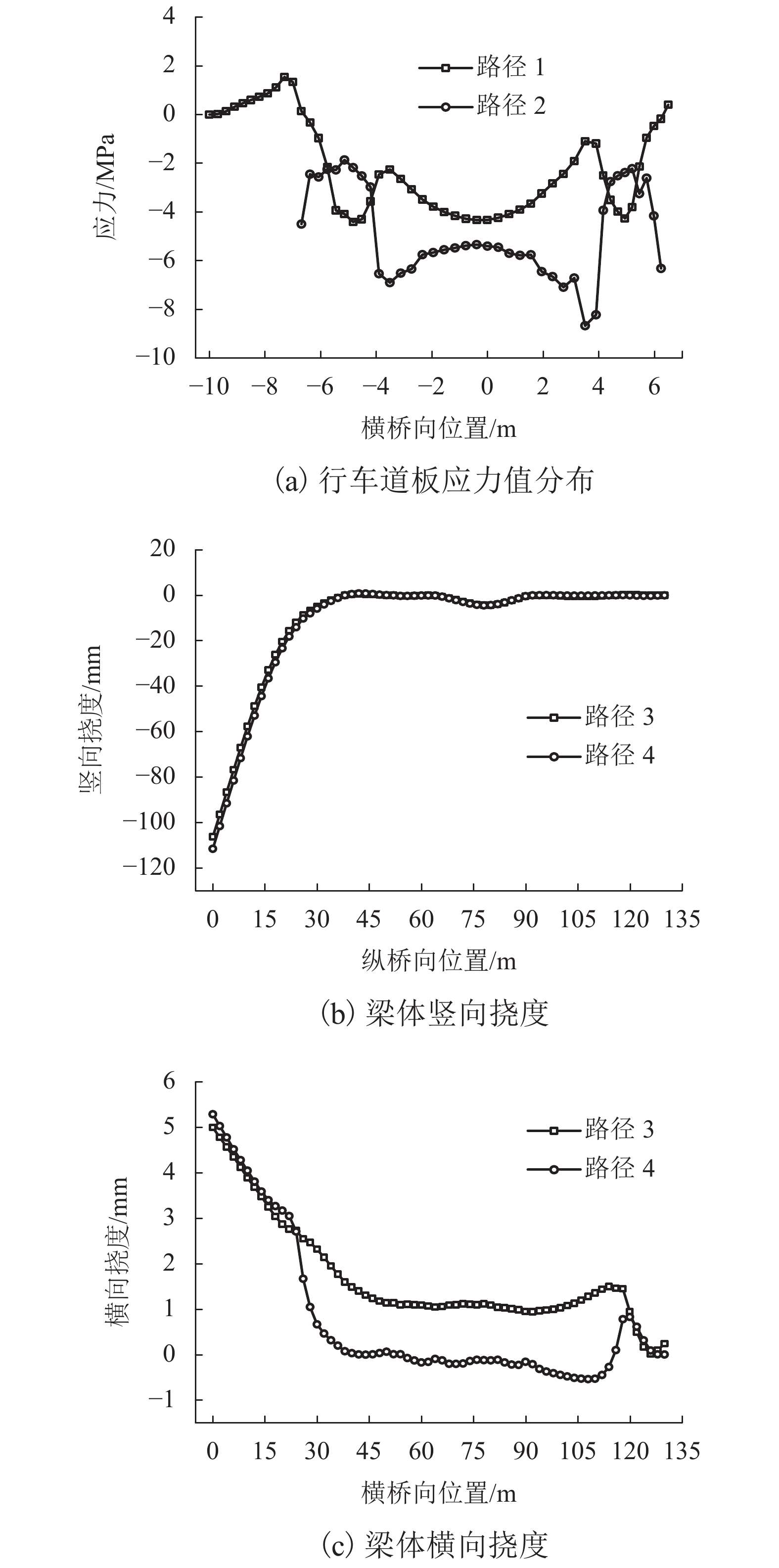

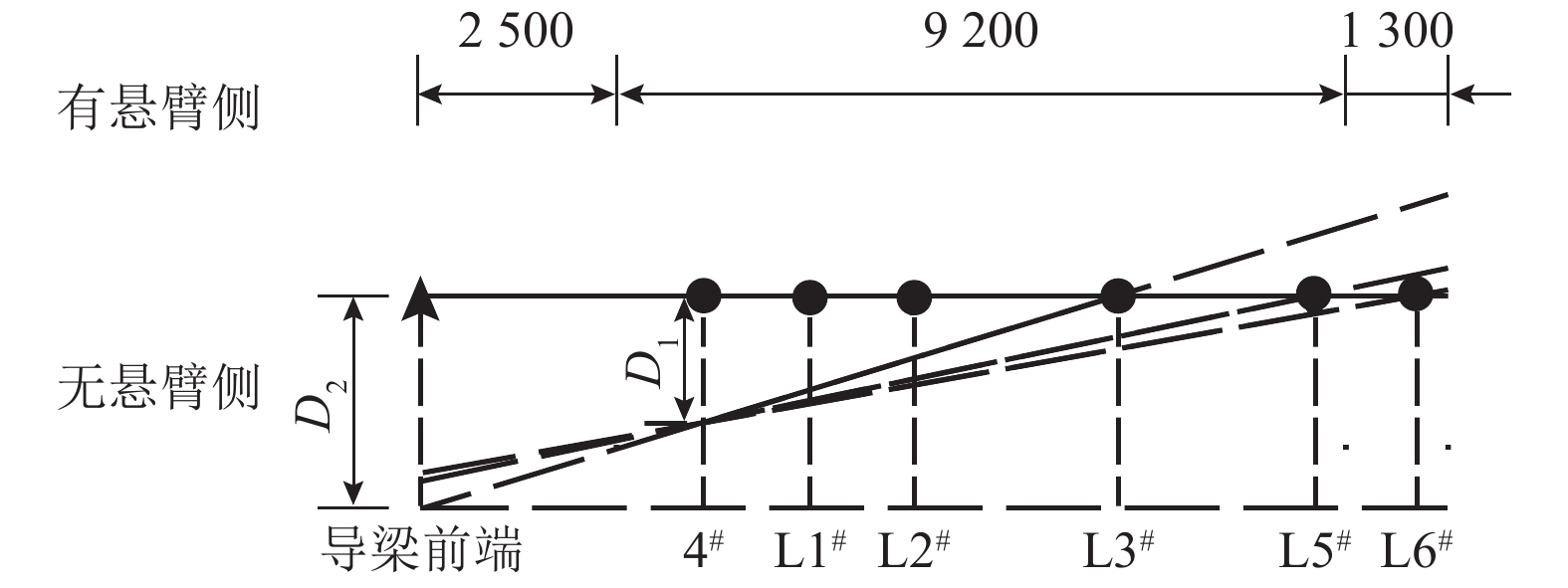

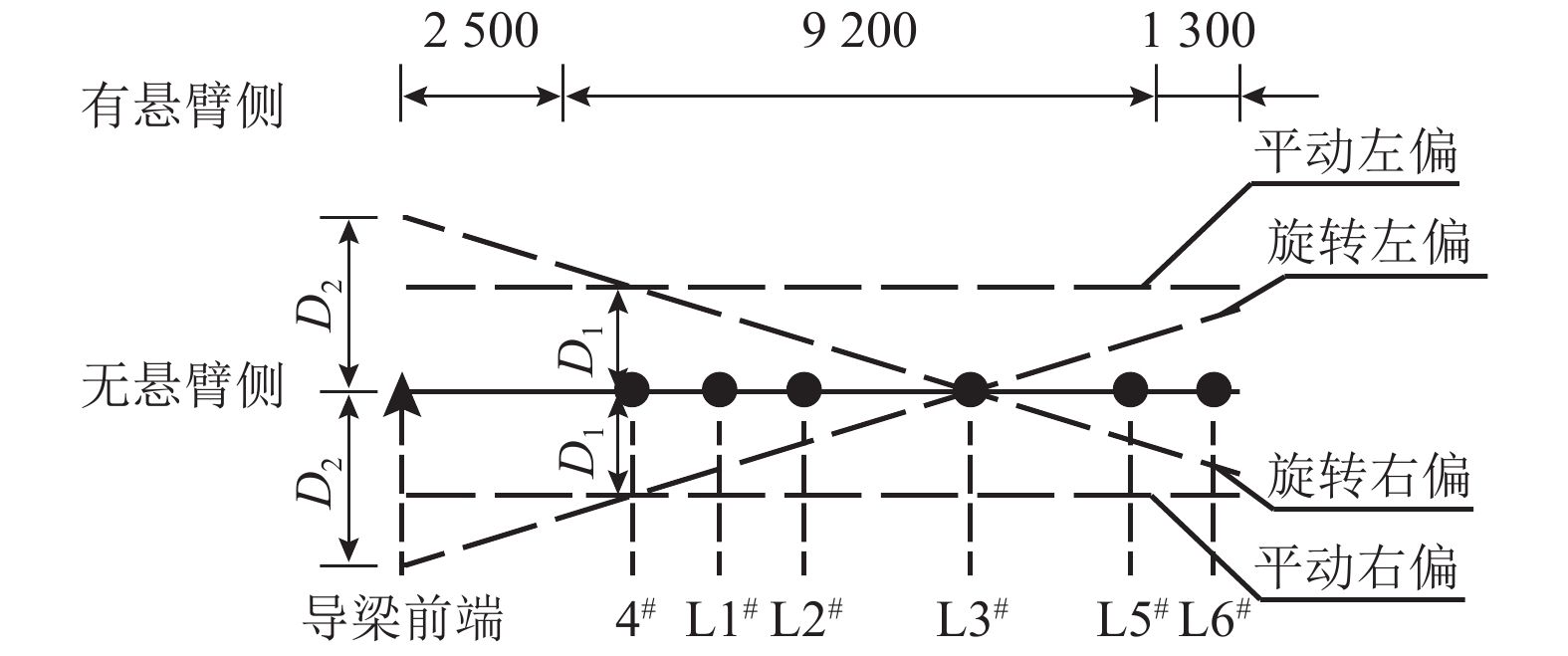

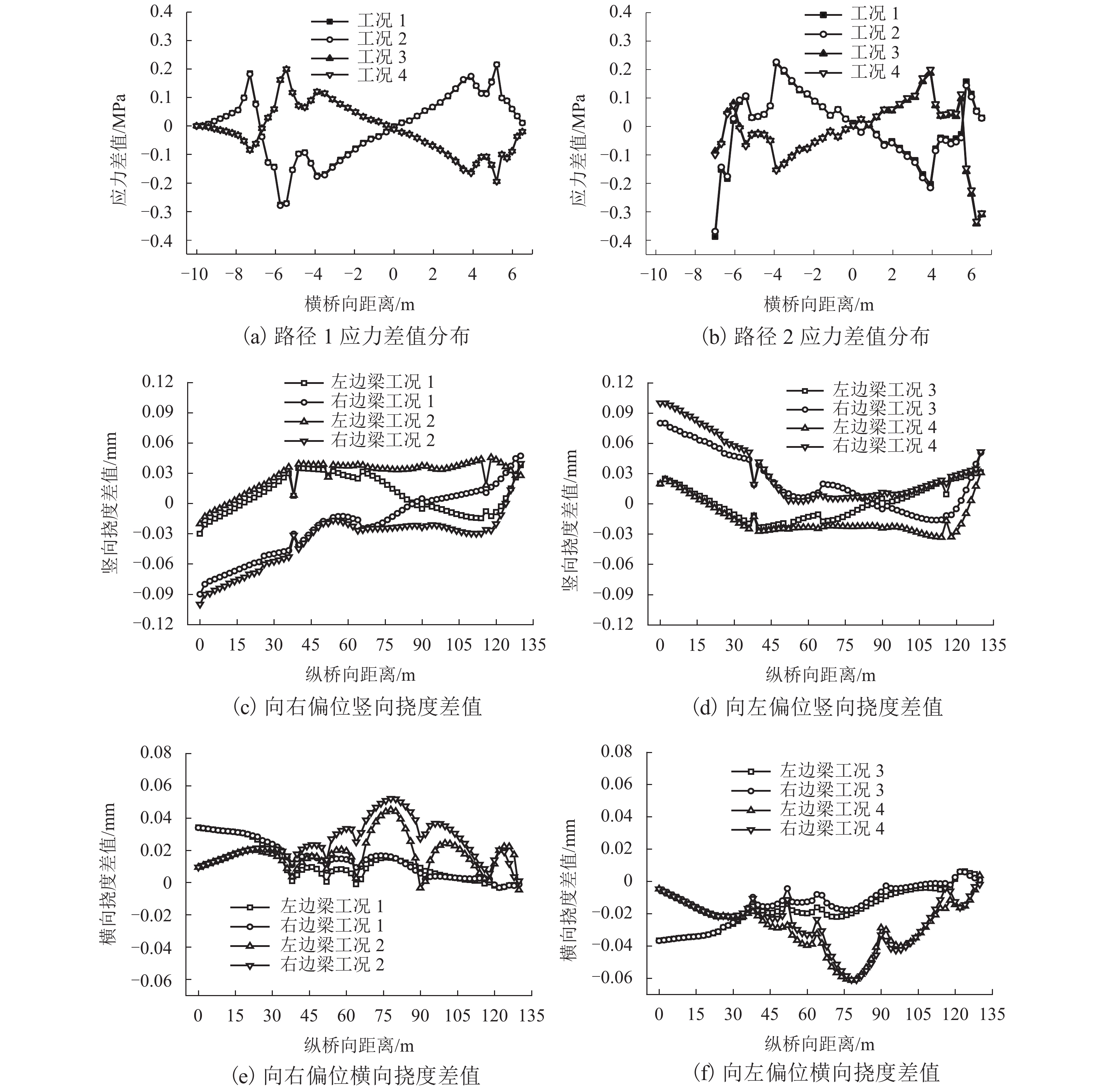

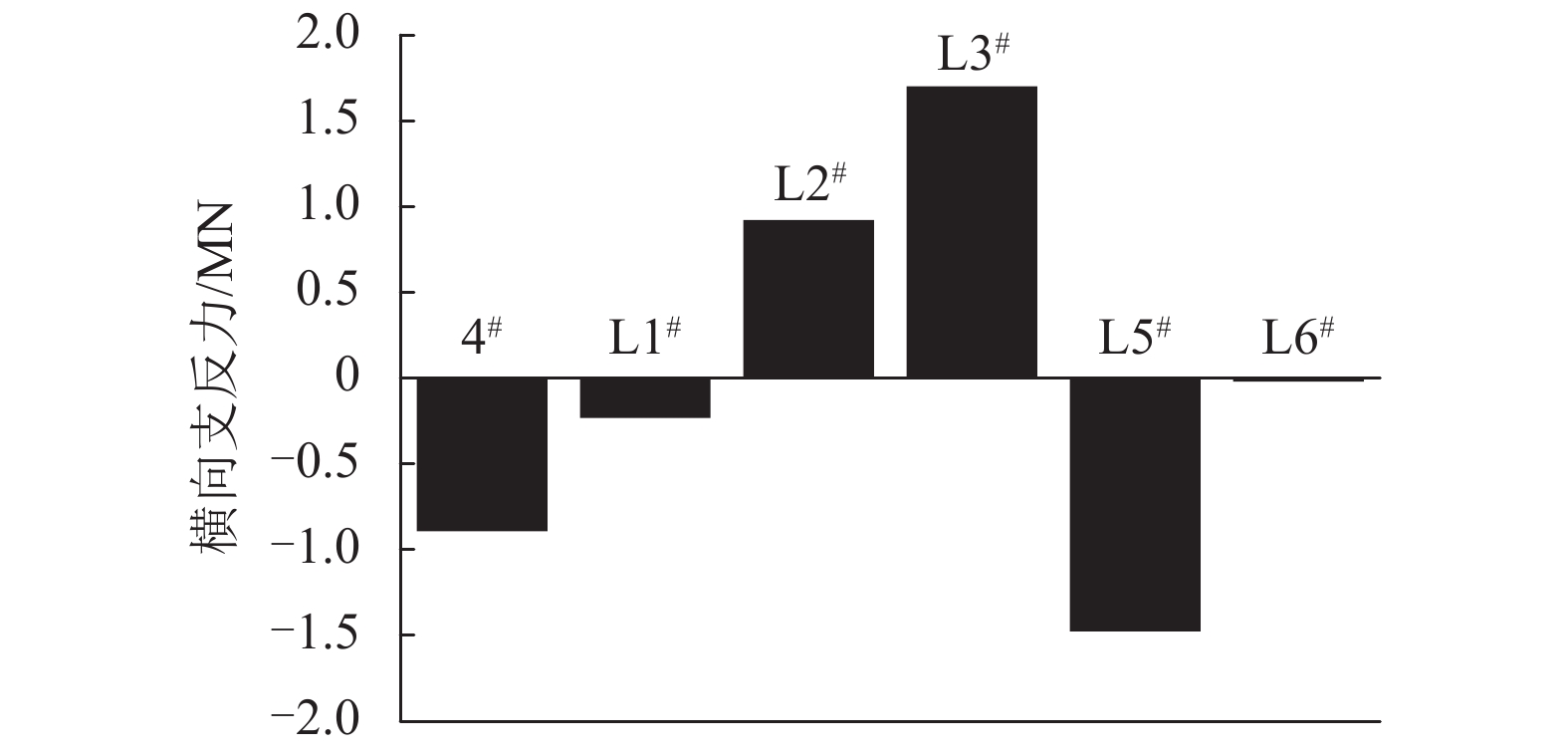

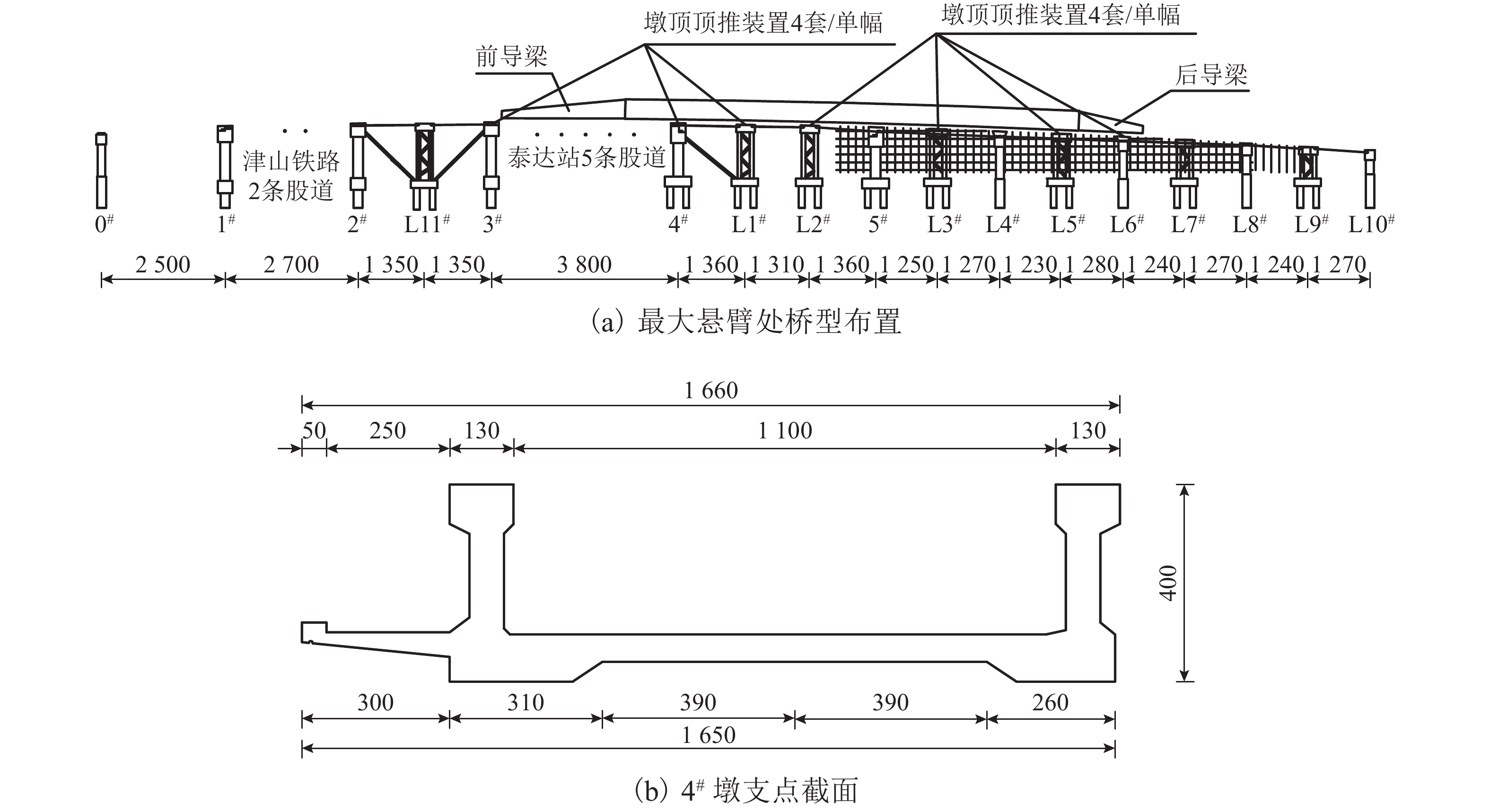

摘要: 为了研究梁体横向偏位对截面不对称PC (prestressed concrete)开口薄壁梁顶推施工的影响,并提出合理纠偏阈值,以世界首例顶推施工的不对称截面槽形梁——天津第二大街跨津山铁路立交工程为背景,利用有限元软件ANSYS建立实桥模型,研究槽形梁在最不利状态下未发生横向偏位时受力状态,在此基础上以满足安全落梁的横向偏位距离为最大偏位距离,分析不同横向偏位方式对梁体受力的影响. 研究结果表明:槽形梁在未发生偏位时横截面受力不均衡,而平动向右偏位方式加剧受力的不均衡;梁体以最不利偏位方式偏移96 mm后,槽型梁整体内力变化值较小,且下一步顶推后可以安全落梁. 因此,认为顶推施工中,横向偏位纠偏阈值可适当放宽至96 mm.Abstract: This work aims to study the influence of transverse deflection of a beam body on pushing construction of an prestressed concrete (PC) open thin-walled beam with asymmetric cross-section and provide a reasonable deviation correction threshold for the incremental launching technique. Taking as a prototype the world’s first case of an asymmetrical cross-section trough girder—Tianjin Second Avenue Cross-Jinshan Railway Interchange Project, an actual bridge model was built using the finite element software ANSYS to study the stress state of the trough girder under the most unfavourable conditions. On this basis, using the maximum deviation distance that meets safety requirements for girder placement as the deviation limit, the influence of different transverse deflection modes on the force of the beam body was analysed. Results show that the cross-section force of the trough girder is not balanced when the deflection does not occur; however, the force imbalance is aggravated by translation to the right. When the most unfavourable transverse deflection occurs in the beam with a displacement of 96 mm, the internal force change of the trough girder is small. Therefore, it is suggested that the transverse deviation correction threshold could be relaxed to 96 mm in jacking construction.

-

表 1 结构材料参数

Table 1. Parameters of structural materials

结构 单元类型 材料 弹性模量/Pa 泊松比 密度/(kg•m–3) 导梁 SHELL63 Q345 2.06 × 1011 0.3 7 850 横联 BEAM189 Q235 2.06 × 1011 0.3 7 850 主体 SOLID65 C50 3.25 × 1010 0.2 2 500 钢束 LINK8 1860钢绞线 1.95 × 1010 0.3 7 850 表 2 横向偏位工况

Table 2. Transverse deflection conditions

工况 工况描述 1 以L3# 墩中心为支点旋转右偏 2 平动向右偏位 3 以L3# 墩中心为支点旋转左偏 4 平动向左偏位 表 3 行车道板左右侧应力对比

Table 3. Stress comparison between two sides of carriageway slab

工况 路径 1 路径 2 左侧应力/MPa 右侧应力/MPa 差值百分比/% 左侧应力/MPa 右侧应力/MPa 差值百分比/% 1 –2.64 –1.79 32.4 –6.71 –8.84 31.7 2 –2.64 –1.78 32.5 –6.71 –8.86 32.0 3 –2.35 –2.04 13.2 –7.04 –8.52 21.1 4 –2.34 –2.04 13.0 –7.04 –8.51 20.9 表 4 导梁前端挠度值对比

Table 4. Comparison of vertical deflection values in front of guide beams

mm 工况 竖向挠度 横向挠度 累计横向偏位距离 左边梁 右边梁 差值 左边梁 右边梁 差值 1 –106.35 –111.67 –5.32 5.04 5.32 0.29 170.32 2 –106.34 –111.68 –5.34 5.01 5.30 0.29 101.30 3 –106.30 –111.50 –5.20 4.96 5.25 0.29 170.25 4 –106.30 –111.48 –5.18 5.00 5.28 0.29 101.28 -

顾乾岗. 兰州深安黄河大桥钢拱梁步履式顶推施工技术[J]. 世界桥梁,2014,42(5): 22-26.GU Qiangang. Application of hydraulic-walking increamental launching to steel archgirer construction of Shen ’an huanghe river in Lanzhou[J]. World Bridges, 2014, 42(5): 22-26. 李向红,赵人达,徐腾飞. 箱梁步履式顶推横向偏位测 试与统计分析[J]. 地下工程与隧道,2015(2): 33-35 .LI Xianghong, ZHAO Renda, XU Tengfei. Test and statistical analysis of transverse deflection of walking-type incremental launching for box girder[J]. Underground Engineering and Tunnels, 2015(2): 33-35 . 张华平. 混凝土斜连续梁桥顶推施工控制技术研究[D]. 长沙: 长沙理工大学, 2005 徐化轩. 顶推梁桥施工中可能出现的技术问题及对策[J]. 铁道工程学报,2002,19(2): 30-33. doi: 10.3969/j.issn.1006-2106.2002.02.007XU Huaxuan. The possible technical problems and countermeasures during construction of launched bridges[J]. Journal of Railway Engineering Society, 2002, 19(2): 30-33. doi: 10.3969/j.issn.1006-2106.2002.02.007 交通部第一公路工程局. 公路桥涵施工技术规范[M]. 北京: 人民交通出版社, 1980: 408 张培炎. 桥梁顶推施工过程受力分析及关键问题研究[D]. 成都: 西南交通大学, 2014 安亚平. 跨铁路线预应力混凝土连续箱梁桥顶推施工关键问题分析[D]. 长沙: 长沙理工大学, 2014 王彪. 钢混组合梁步履式顶推横向偏位产生原因及纠偏对策研究[D]. 成都: 西南交通大学, 2015 曾国梁,冯威,李琦. 多孔连续曲线梁桥偏位成因分析及同步纠偏技术[J]. 公路交通科技(应用技术版),2015(3): 173-176. 彭雁兵. 桥梁顶推施工横向导向纠偏装置研究[J]. 建筑技术,2012,43(9): 803-805. doi: 10.3969/j.issn.1000-4726.2012.09.011PENG Yanbing. Research on transverse guiding deviation corrosion device in construction of bridge jacking and pushing construction[J]. Architecture Technology, 2012, 43(9): 803-805. doi: 10.3969/j.issn.1000-4726.2012.09.011 伍彦斌,黄方林. 空间预应力钢束精细化有限元建模方法[J]. 西南交通大学学报,2017,52(6): 1082-1087.WU Yanbin, HUANG Fanglin. Refined finite element modeling method of spatial prestressed steel beam[J]. Journal of Southwest Jiaotong University, 2017, 52(6): 1082-1087. 董长军,刘世忠,李爱军. 变曲率曲线梁的单元刚度矩阵分析[J]. 西南交通大学学报,2017,52(3): 474-481.DONG Changjun, LIU Shizhong, LI Aijun. Element stiffness matrix analysis for variable curvature curved beam[J]. Journal of Southwest Jiaotong University, 2017, 52(3): 474-481. 杨昌付,宋新刚. 预应力混凝土连续梁横向顶推过程仿真分析[J]. 公路,2013,58(8): 135-137. doi: 10.3969/j.issn.0451-0712.2013.08.033YANG Changfu, SONG Xingang. Simulation analysis of lateral pushing process of prestressed concrete continuous beam[J]. Highway, 2013, 58(8): 135-137. doi: 10.3969/j.issn.0451-0712.2013.08.033 赖亚平,王科,李锦. 泸州沱江四桥主桥扭转、剪力滞效 应及关键构造研究[J]. 桥梁建设,2016,46(4): 17-22 .LAI Yaping, WANG Ke, LI Jin. Research of torsion,shear lag effect and critical structures of main bridhe of fourth luzhou tuojiang river bridge[J]. Bridge Construction, 2016, 46(4): 17-22 . -

下载:

下载: