Wear Predication of Tunnel Boring Machine Cutters Based on In-situ Measured Data

-

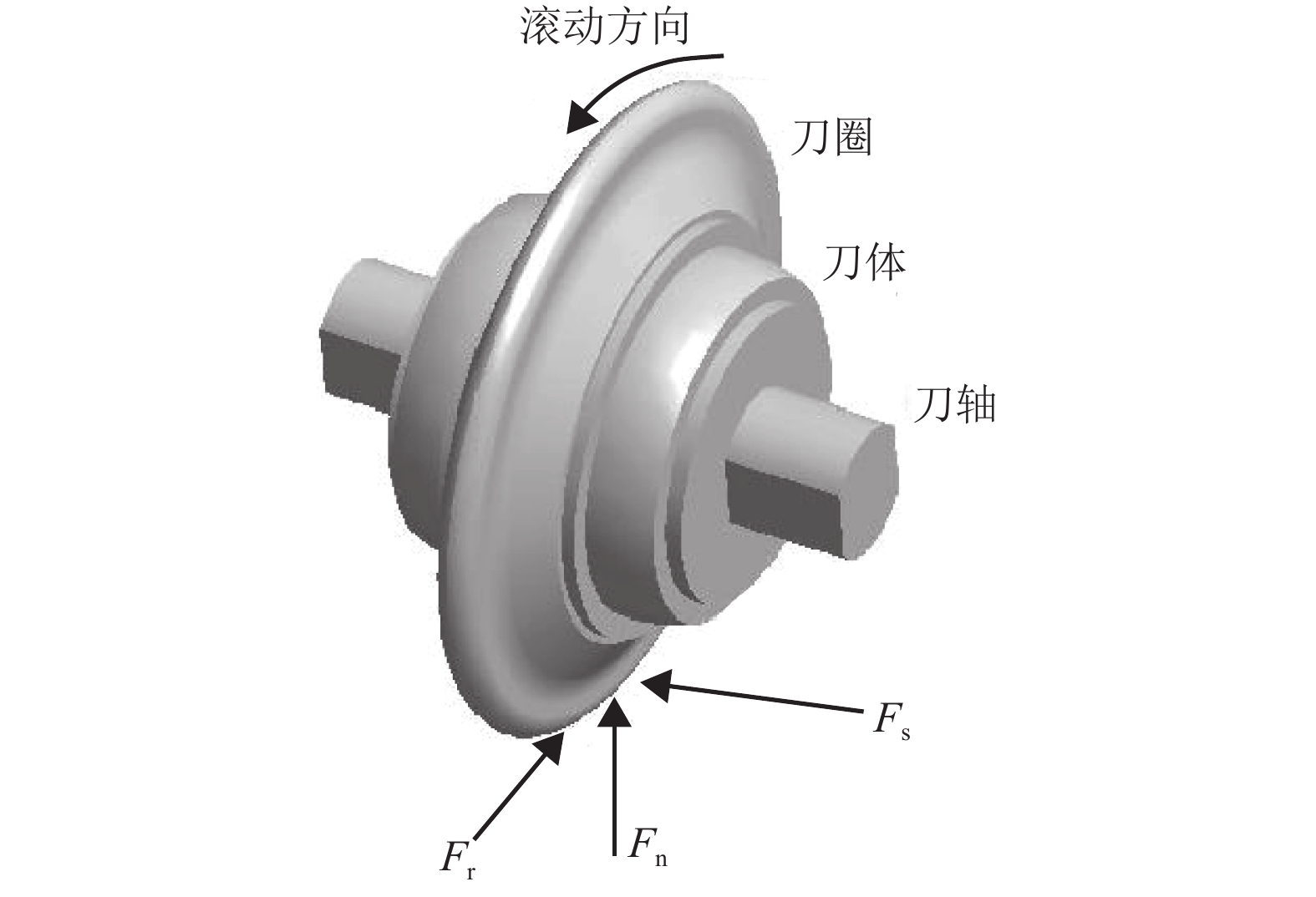

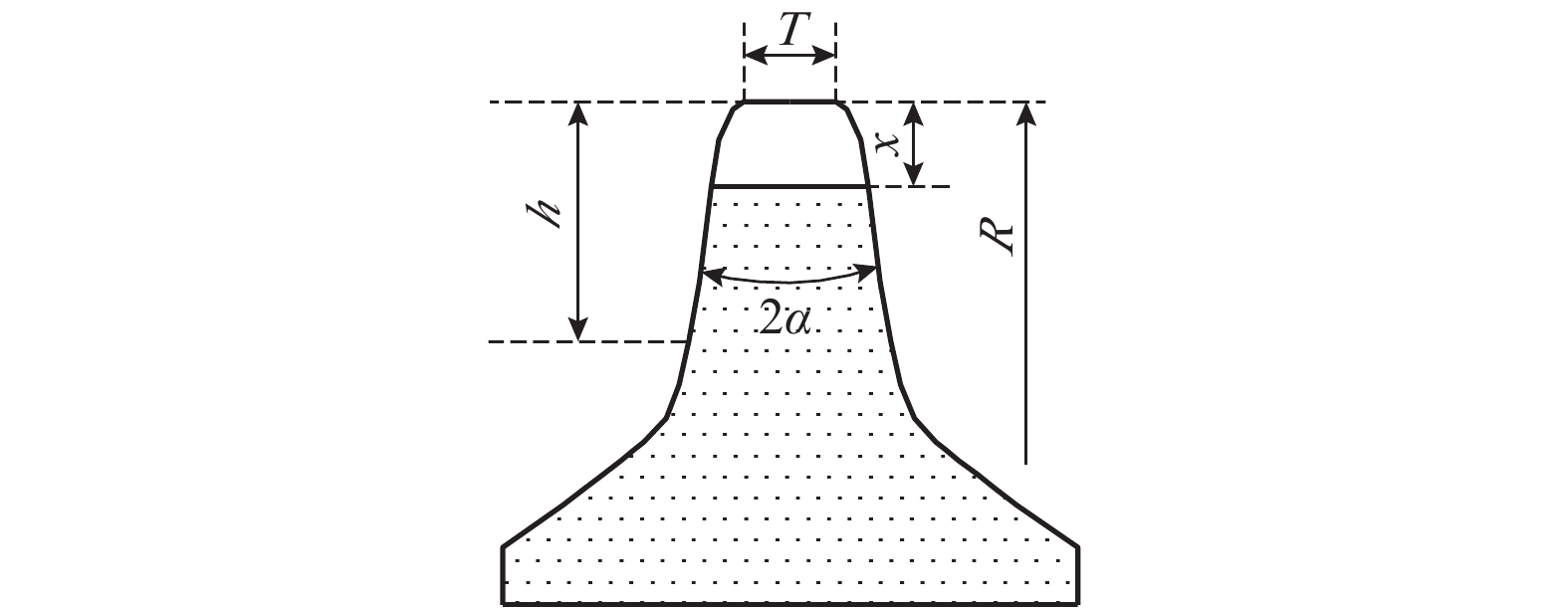

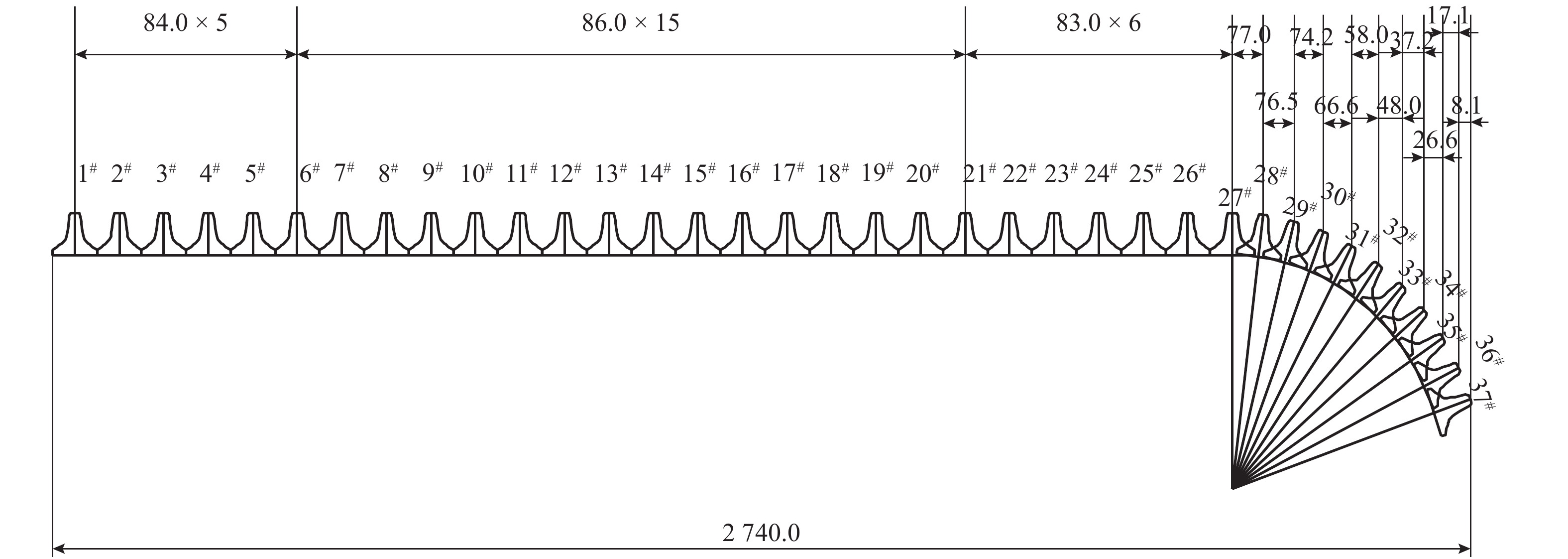

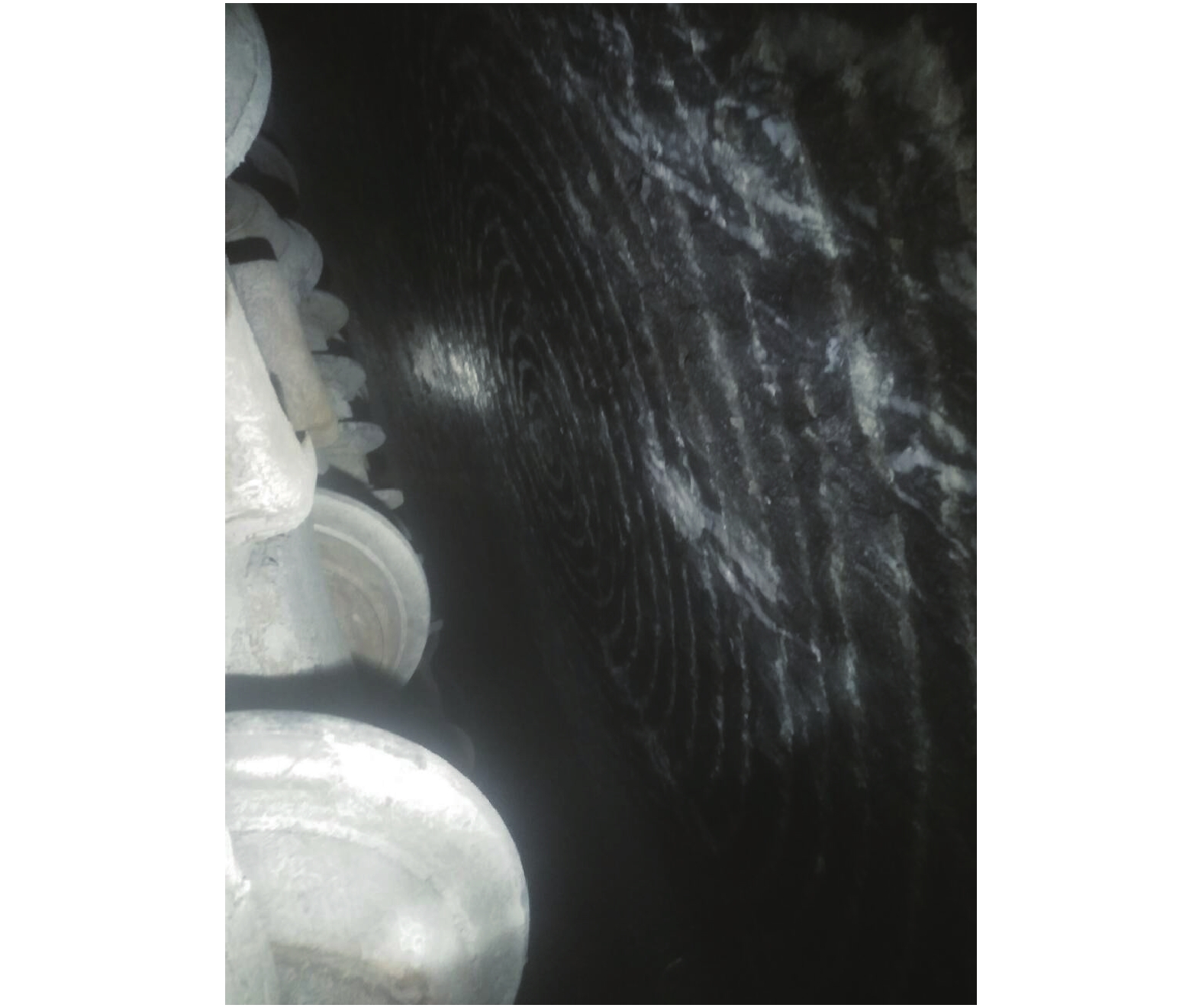

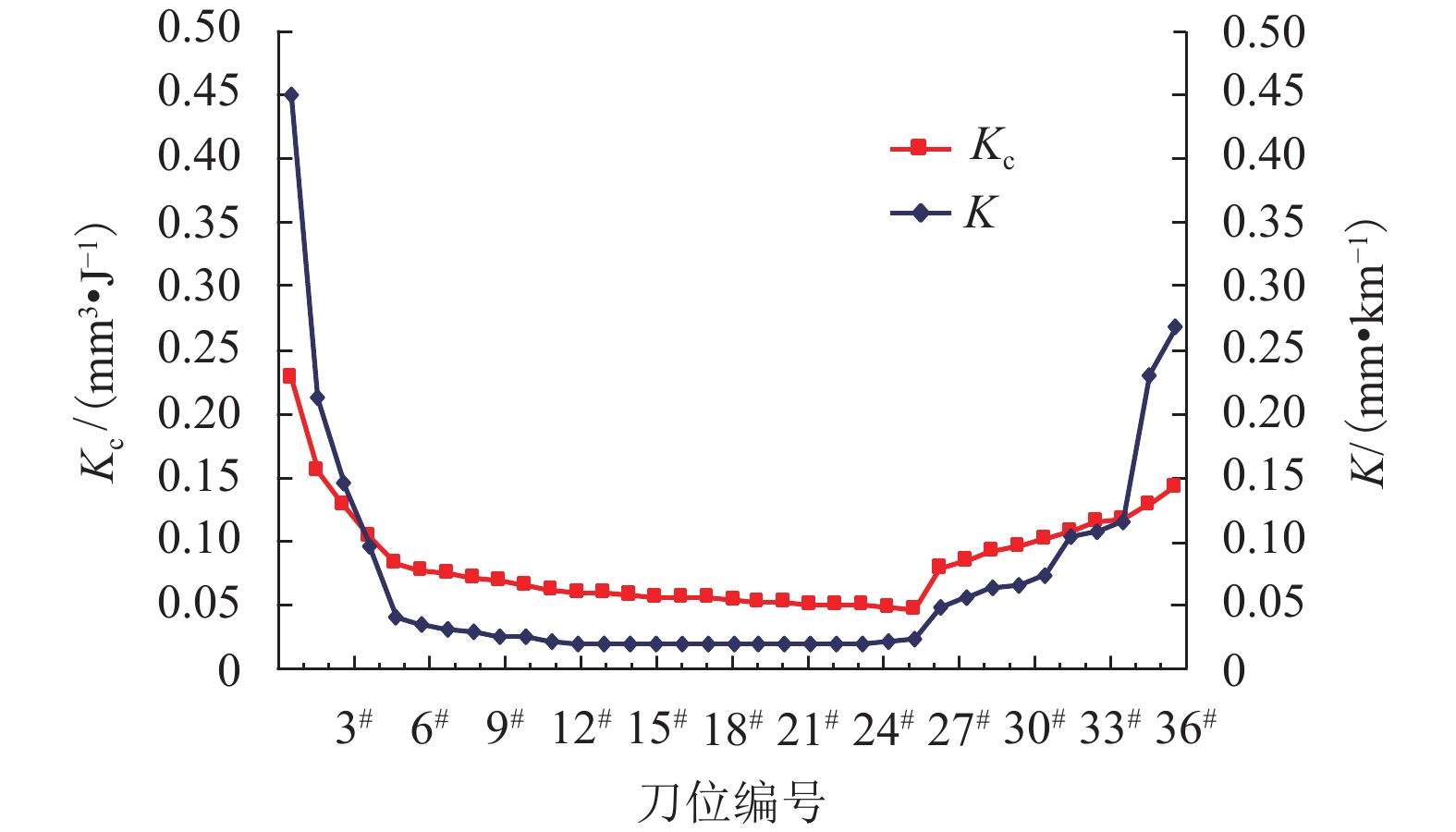

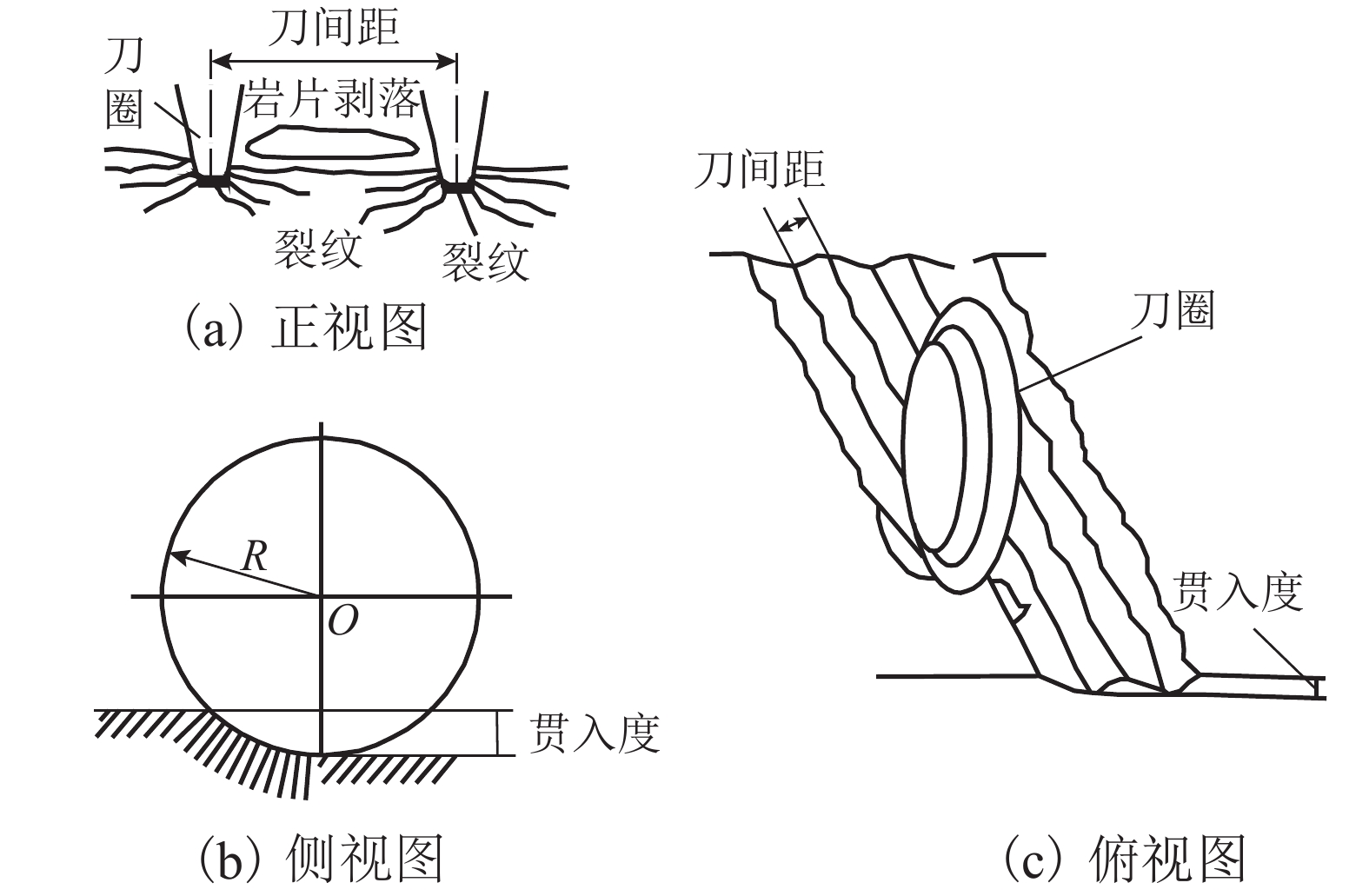

摘要: 为了合理预测隧道掘进机(TBM)施工过程中地质条件、掘进参数及刀圈特性等多种因素对盘形滚刀刀圈磨损的影响,对TBM滚刀破岩机理和刀圈磨损机理进行了研究. 基于现场实测数据,如掘进推力、贯入度、磨损量、滚刀半径、滚刀安装半径、刀圈几何尺寸等,根据摩擦学理论,综合考虑各影响因素的相互作用,提出了刀圈综合磨损系数的概念,并建立了滚刀磨损预测模型,同时可对刀盘上各滚刀的有效掘进距离进行预测;将预测模型应用到兰州市水源地建设工程输水隧洞双护盾TBM施工中,同时与其他预测模型对比,验证了综合磨损系数预测模型的有效性. 研究结果表明:刀圈综合磨损系数随滚刀安装半径的增大而减小,随滚刀安装角度的增大而增大;综合磨损系数与其他模型磨损系数变化规律基本一致;基于综合磨损系数预测得到的有效掘进距离与实际掘进距离基本吻合,误差在10%以内,说明基于综合磨损系数建立的TBM滚刀预测模型是可靠的.Abstract: To reasonably predict the influence of geological conditions, tunneling parameters, and cutter ring characteristics on the wear of disc cutter rings during tunnel boring machine (TBM) construction, the rock breaking mechanism and cutter ring wear mechanism were studied. The concept of comprehensive wear coefficient was put forward according to tribology theory by considering the in-situ measured data such as tunneling thrust, penetration, wear rate, disc cutter radius, disc cutter installation radius, and disc cutter ring sizes. The wear prediction model of disc cutter ring was finally established with consideration of the interaction of various factors, such wear prediction model of disc cutter ring can predict the effective tunneling length of every disc cutters. The wear prediction model was applied in the hard rock tunneling of water conveyance tunnel by double shield TBM in Lanzhou water source construction project, and its validity was also verified by comparing with other prediction models. The results show that the comprehensive wear coefficient decrease with the installation radius of disc cutters increasing and increases with the disc cutter installation angle increasing. The comprehensive wear coefficient has the similar rule as that of other comparing models. The predicted effective tunneling length is consistent with the actual tunneling length with error of less than 10%, which illustrates that the disc cutter wear prediction model based on comprehensive wear coefficient is reliable.

-

Key words:

- tunnel boring machine (TBM) /

- measured data /

- cutter /

- wear /

- prediction /

- comprehensive wear coefficient

-

表 1 TBM1施工段各刀位实测参数

Table 1. Parameters and comprehensive wear coefficients of various disc cutters in TBM1 section

滚刀号 R1/mm Fn/kN P/mm L1/m L/m R/mm T/mm α/(°) x/mm Kc/(mm3•J−1) 1# 42.7 22.0 4.7 744.0 42 448.5 216.0 19.0 10 12.0 0.368 0 2# 126.7 21.4 6.2 744.0 95 481.1 216.0 19.0 10 20.0 0.299 1 3# 210.7 21.2 6.0 744.0 164 076.3 216.0 19.0 10 25.0 0.228 2 4# 294.7 21.5 5.8 744.0 237 402.2 216.0 19.0 10 25.0 0.155 5 5# 378.7 21.6 6.2 744.0 285 388.3 216.0 19.0 10 25.0 0.128 8 6# 462.7 21.5 6.1 744.0 354 407.0 216.0 19.0 10 25.0 0.104 2 7# 548.7 21.5 6.2 1 119.0 621 917.8 241.5 19.0 10 30 0.082 6 8# 634.7 21.3 6.1 1 035.0 676 298.9 241.5 19.0 10 30 0.076 7 9# 720.7 21.5 6.3 966.0 693 986.1 241.5 19.0 10 30 0.074 1 10# 806.7 21.5 6.4 910.0 720 332.7 241.5 19.0 10 30 0.071 4 11# 892.7 21.0 6.4 872.0 763 838.8 241.5 19.0 10 30 0.068 9 12# 978.7 21.5 6.6 837.0 779 454.5 241.5 19.0 10 30 0.065 9 13# 1 064.7 20.8 6.2 798.0 860 593.6 241.5 19.0 10 30 0.061 7 14# 1 150.7 21.5 6.3 755.0 866 020.5 241.5 19.0 10 30 0.059 3 15# 1 236.7 21.0 6.2 704.0 881 870.8 241.5 19.0 10 30 0.059 7 16# 1 322.7 21.5 6.1 663.0 902 827.3 241.5 19.0 10 30 0.056 9 17# 1 408.7 21.2 6.2 599.0 854 699.2 241.5 19.0 10 28 0.056 1 18# 1 494.7 21.5 6.4 553.0 811 070.9 241.5 19.0 10 27 0.055 8 19# 1 580.7 22.3 5.6 469.0 831 369.2 241.5 19.0 10 28 0.054 8 20# 1 666.7 22.5 5.8 455.0 821 108.4 241.5 19.0 10 27 0.052 7 21# 1 752.7 21.5 6.0 430.0 788 831.8 241.5 19.0 10 25 0.052 3 22# 1 845.7 21.5 6.2 412.0 770 240.4 241.5 19.0 10 24 0.051 1 23# 1 972.7 21.5 6.0 399.0 823 839.0 241.5 19.0 10 25 0.050 1 24# 2 001.7 21.5 6.2 373.0 756 268.1 241.5 19.0 10 23 0.049 5 25# 2 084.7 22.3 5.9 346.0 767 763.2 241.5 19.0 10 24 0.049 4 26# 2 167.7 21.5 6.2 304.0 667 483.8 241.5 19.0 10 20 0.047 6 27# 2 250.7 22.0 6.2 259.0 590 453.0 241.5 19.0 10 18 0.046 6 28# 2 327.7 21.5 6.3 195.0 452 460.5 241.5 19.0 10 22 0.078 5 29# 2 404.2 21.7 6.4 178.0 419 923.6 241.5 19.0 10 22 0.083 8 30# 2 478.4 21.9 6.5 168.0 402 278.6 241.5 19.0 10 23 0.091 3 31# 2 545.0 21.5 6.2 166.0 427 921.2 241.5 19.0 10 25 0.096 5 32# 2 603.0 21.5 6.2 155.0 408 671.0 241.5 19.0 10 25 0.101 0 33# 2 651.0 20.4 6.6 123.0 310 263.4 241.5 19.0 10 20 0.107 9 34# 2 688.2 20.1 6.5 121.0 314 263.0 241.5 19.0 10 21 0.114 5 35# 2 714.8 19.9 6.7 116.0 295 175.7 241.5 19.0 10 20 0.116 3 36# 2 731.9 19.6 6.8 66.0 166 517.3 241.5 19.0 10 13 0.128 6 37# 2 740.0 19.5 6.8 65.0 164 480.6 241.5 19.0 10 14 0.142 1 表 2 预测掘进距离与实际掘进距离对比

Table 2. Comparison between predicated tunneling lengths and actual tunneling lengths

滚刀号 综合磨损系数 刀圈磨损量/mm 预测有效掘进距离/m 实际掘进距离/m 误差/% 4# 0.155 5 24.0 730.6 701.3 4.2 8# 0.076 7 28.0 901.2 984.4 8.5 13# 0.061 7 29.0 711.6 650.4 9.4 19# 0.054 8 29.0 596.7 624.2 4.4 23# 0.050 1 25.0 397.9 411.4 3.3 28# 0.078 5 23.0 195.8 185.3 5.7 32# 0.101 0 25.0 145.5 140.4 3.6 -

张镜剑,傅冰骏. 隧道掘进机在我国应用的进展[J]. 岩石力学与工程学报,2007,26(2): 226-238. doi: 10.3321/j.issn:1000-6915.2007.02.002ZHANG Jingjian, FU Bingjun. Advances in tunnel boring machine application in China[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(2): 226-238. doi: 10.3321/j.issn:1000-6915.2007.02.002 张镜剑. TBM的应用及其有关问题和展望[J]. 岩石力学与工程学报,1999,18(3): 363-367. doi: 10.3321/j.issn:1000-6915.1999.03.029ZHANG Jingjian. The application and some problems of TBM and its prospects[J]. Chinese Journal of Rock Mechanics and Engineering, 1999, 18(3): 363-367. doi: 10.3321/j.issn:1000-6915.1999.03.029 尹俊涛,尚彦军,傅冰骏,等. TBM掘进技术发展及有关工程地质问题分析和对策[J]. 工程地质学报,2005,13(3): 389-397. doi: 10.3969/j.issn.1004-9665.2005.03.019YIN Juntao, SHANG Yanjun, FU Bingjun, et al. Development of TBM-excavation technology and analyses & countermeasures of related engineering geological problems[J]. Journal of Engineering Geology, 2005, 13(3): 389-397. doi: 10.3969/j.issn.1004-9665.2005.03.019 茅承觉. 我国全断面岩石掘进机(TBM)发展的回顾与思考[J]. 建设机械技术与管理,2008,21(5): 81-84. doi: 10.3969/j.issn.1004-0005.2008.05.022MAO Chengjue. Review and thoughts of developmental full face rock tunnel boring machine (TBM) in China[J]. Construction Machinery Technology & Management, 2008, 21(5): 81-84. doi: 10.3969/j.issn.1004-0005.2008.05.022 万治昌,沙明元,周雁领. 盘形滚刀的使用与研究(1)——TB880E型掘进机在秦岭隧道施工中的应用[J]. 现代隧道技术,2002,39(5): 1-11. doi: 10.3969/j.issn.1009-6582.2002.05.001WAN Zhichang, SHA Mingyuan, ZHOU Yanling. Study on disk cutters for hard rock —application of TB880E TBM in Qinling Tunnel[J]. Modern Tunnelling Technology, 2002, 39(5): 1-11. doi: 10.3969/j.issn.1009-6582.2002.05.001 万治昌,沙明元,周雁领. 盘形滚刀的使用与研究(2)——TB880E型掘进机在秦岭隧道施工中的应用[J]. 现代隧道技术,2002,39(6): 1-12. doi: 10.3969/j.issn.1009-6582.2002.06.001WAN Zhichang, SHA Mingyuan, ZHOU Yanling. Study on disk cutters for hard rock —application of TB880E TBM in Qinling Tunnel[J]. Modern Tunnelling Technology, 2002, 39(6): 1-12. doi: 10.3969/j.issn.1009-6582.2002.06.001 万治昌,沙明元,周雁领. 盘形滚刀的使用与研究(3)——TB880E型掘进机在秦岭隧道施工中的应用[J]. 现代隧道技术,2003,40(1): 1-6. doi: 10.3969/j.issn.1009-6582.2003.01.001WAN Zhichang, SHA Mingyuan, ZHOU Yanling. Study on disk cutters for hard rock —application of TB880E TBM in Qinling Tunnel[J]. Modern Tunnelling Technology, 2003, 40(1): 1-6. doi: 10.3969/j.issn.1009-6582.2003.01.001 JAMAL R. Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure[D]. Colorado: Colorado School of Mines, 1997. ZARE S, BRULAND A. Applications of NTNU/SINTEF drill ability indices in hard rock tunneling[J]. Rock Mechanics and Rock Engineering, 2013, 46(1): 179-187. doi: 10.1007/s00603-012-0253-y ATTANASIO A, CERETTI E, RIZZUTI S, et al. 3D finite element analysis of tool wear in machining[J]. Manufacturing Technology, 2008, 57(1): 61-64. FRENZEL C K A, SLING H, THURO K. Factors influencing disc cutter wear[J]. Geomechanics and Tunneling, 2008, 1(1): 55-60. doi: 10.1002/geot.200800006 MICHAEL A. Stress dependency of the cerchar abrasivity index (CAI) and its effects on wear of selected rock cutting tools[J]. Tunnelling and Underground Space Technology, 2008, 23(4): 351-359. doi: 10.1016/j.tust.2007.05.008 TANIMOTO C, YAMANAKA S, TSUSAKA K, et al. A study on cutter wear and mechanical properties of rocks in tunneling with a TBM[J]. Journal of the Society of Materials Science, 2006, 55(1): 29-36. doi: 10.2472/jsms.55.29 WANG Lihui, KANG Yilan. The energy method to predict disc cutter wear extent for hard rock TBMs[J]. Tunneling and Underground Space Technology, 2012, 28(3): 183-191. 王旭,赵羽,张宝刚,等. TBM滚刀刀圈磨损机理研究[J]. 现代隧道技术,2010,47(5): 15-19. doi: 10.3969/j.issn.1009-6582.2010.05.003WANG Xu, ZHAO Yu, ZHANG Baogang, et al. Research on the ring wear mechanism of TBM disc cutter[J]. Modern Tunnel Technology, 2010, 47(5): 15-19. doi: 10.3969/j.issn.1009-6582.2010.05.003 杨媛媛,黄宏伟. 围岩分类TBM滚刀寿命预测中的应用[J]. 地下空间与工程学报,2005,1(5): 721-724.YANG Yuanyuan, HUANG Hongwei. Application of rock mass classification in cutter life prediction of TBM[J]. Chinese Journal of Underground Space and Engineering, 2005, 1(5): 721-724. 张照煌. 全断面岩石掘进机平面刀盘上盘形滚刀磨损研究[J]. 现代隧道技术,2007,44(6): 32-36. doi: 10.3969/j.issn.1009-6582.2007.06.007ZHANG Zhaohuang. Study on the abrasion of disc cutters on full face rock tunnel boring machine[J]. Modern tunnelling Technology, 2007, 44(6): 32-36. doi: 10.3969/j.issn.1009-6582.2007.06.007 张照煌,孙显星,孙飞. 全断面岩石掘进机刀盘上盘形滚刀等寿命布置理论[J]. 矿山机械,2015,43(3): 15-18.ZHANG Zhaohuang, SUN Xianxing, SUN Fei. Same-lifespan layout theory of disc cutters on cutter head of TBM[J]. Construction Machinery Technology & Management, 2015, 43(3): 15-18. 张照煌,纪昌明. 全断面岩石掘进机盘形滚刃破岩点弧长的解析解及应用研究[J]. 应用基础与工程科学学报,2009,17(2): 265-273. doi: 10.3969/j.issn.1005-0930.2009.02.012ZHANG Zhaohuang, JI Changming. Analytic solution and its usage of arc length of rock breakage point of disc edge on full face rock tunnel boring machine[J]. Journal of Basic Science and Engineering, 2009, 17(2): 265-273. doi: 10.3969/j.issn.1005-0930.2009.02.012 赵海鸣,舒标,夏毅敏,等. 基于磨料磨损的TBM滚刀磨损预测研究[J]. 铁道科学与工程学报,2014,11(4): 152-158. doi: 10.3969/j.issn.1672-7029.2014.04.026ZHAO Haiming, SHU Biao, XIA Yimin, et al. Study of wear prediction for TBM cutter based on abrasive wear model[J]. Journal of Railway Science and Engineering, 2014, 11(4): 152-158. doi: 10.3969/j.issn.1672-7029.2014.04.026 谭青,孙鑫健,夏毅敏,等. TBM盘形滚刀磨损预测模型TBM盘形滚刀磨损速率研究[J]. 中南大学学报(自然科学版),2017,48(1): 54-60. doi: 10.11817/j.issn.1672-7207.2017.01.008TAN Qing, SUN Xinjian, XIA Yimin, et al. A wear prediction model of disc cutter for TBM[J]. Journal of Central South University (Science and Technology), 2017, 48(1): 54-60. doi: 10.11817/j.issn.1672-7207.2017.01.008 谭青,谢吕坚,夏毅敏,等. TBM盘形滚刀磨损速率研究[J]. 中南大学学报(自然科学版),2015,46(3): 843-848. doi: 10.11817/j.issn.1672-7207.2015.03.011TAN Qing, XIE Lüjian, XIA Yimin, et al. Analysis of wear rate of TBM disc cutter[J]. Journal of Central South University (Science and Technology), 2015, 46(3): 843-848. doi: 10.11817/j.issn.1672-7207.2015.03.011 杨延栋,陈馈,李凤远,等. 盘形滚刀磨损预测模型[J]. 煤炭学报,2015,40(6): 1290-1296.YANG Yandong, CHEN Kui, LI Fengyuan, et al. Wear prediction model of disc cutter[J]. Journal of China Coal Society, 2015, 40(6): 1290-1296. 杜立杰,纪珊珊,左立富,等. 巨斑状花岗岩条件下TBM大直径盘形滚刀磨耗规律[J]. 煤炭学报,2015,40(12): 2974-2978.DU Lijie, JI Shanshan, ZUO Lifu, et al. Wear and consumption of large diameter disc cutters for hard rock TBM under giant porphyritic granite[J]. Journal of China Coal Society, 2015, 40(12): 2974-2978. 聂灿. H13钢滚刀刀圈磨损行为及磨损量预测方法研究[D]. 长沙: 中南大学, 2013. 张凤祥, 朱合华, 傅德明. 盾构隧道[M]. 北京: 人民交通出版社, 2004: 102-113. 龚秋明,佘祺锐,丁宇. 大理岩磨擦试验及隧道掘进机刀具磨损分析——锦屏二级水电站引水隧洞工程[J]. 北京工业大学学报,2012,38(8): 1196-1203. doi: 10.11936/bjutxb2012081196GONG Qiuming, SHE Qirui, DING Yu. Abrasivity tests of marbles and cutter wear analysis of TBM:headrace tunnels of jinping Ⅱ hydropower station[J]. Journal of Beijing University of Technology, 2012, 38(8): 1196-1203. doi: 10.11936/bjutxb2012081196 ZHAO J, GONG Q M, EISENSTEN Z. Tunnelling through a frequently changing and mixed ground:A case history in Singapore[J]. Tunnelling and Underground Space Technology, 2007, 22(4): 388-400. doi: 10.1016/j.tust.2006.10.002 CHANG S H, CHOI S W, BAE G J, et al. Performance prediction of TBM disccutting on granitic rock by the linear cutting test[J]. Tunnelling and Underground Space Technology, 2006, 21(3): 237-248. 赵金华,费学婷,袁国,等. 国产与进口TBM滚刀刀圈显微组织与磨损机理的对比分析[J]. 矿山机械,2012,40(8): 120-124.ZHAO Jinhua, FEI Xueting, YUAN Guo, et al. Comparison and analysis of domestic and imported TBM cutter ring in microstructure and wear mechanism[J]. Mining & Processing Equipment,Construction Machinery Technology & Management, 2012, 40(8): 120-124. 蔡送宝. 基于摩擦学的TBM盘形滚刀刀圈磨料磨损的数值研究[D]. 天津: 天津大学, 2013. 陈洁,熊翔,姚萍屏,等. 摩擦面温度对铁基摩擦材料摩擦磨损性能影响机理的研究[J]. 粉末治金技术,2004,22(4): 223-227.CHEN Jie, XIONG Xiang, YAO Pingping, et al. Effect of rubbed surface temperature on frictional behavior of iron based P/M friction materials[J]. Powder Metallurgy Technology, 2004, 22(4): 223-227. 詹武, 闫爱淑, 丁晨旭, 等. 金属摩擦磨损机理剖析[J]. 天津理工学院学报, 2001, 17(增刊): 19-22.ZHAN Wu, YAN Aishu, DING Chenxu, et al. Analysis on the principle of metal friction and abrade wear[J]. Journal of Tianjin Institute of Technology, 2001, 17(S): 19-22. 谢友柏. 摩擦学的三个公理[J]. 摩擦学学报,2001,21(3): 161-166. doi: 10.3321/j.issn:1004-0595.2001.03.001XIE Youbai. Three axioms in tribology[J]. Tribology, 2001, 21(3): 161-166. doi: 10.3321/j.issn:1004-0595.2001.03.001 中华人民共和国国家标准编写组. 水利水电工程地质勘察规范: GB50487—2008[S]. 北京: 中国计划出版社, 2009. -

下载:

下载: