Fatigue Performance of Orthotropic Steel Decks with Thickened Edge U-Ribs

-

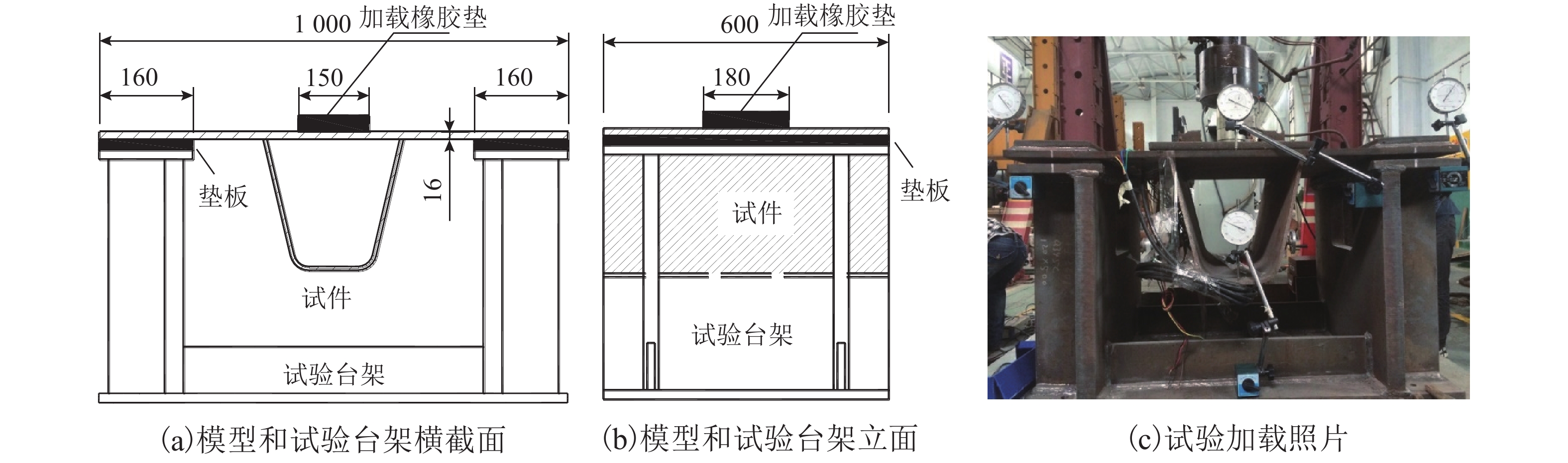

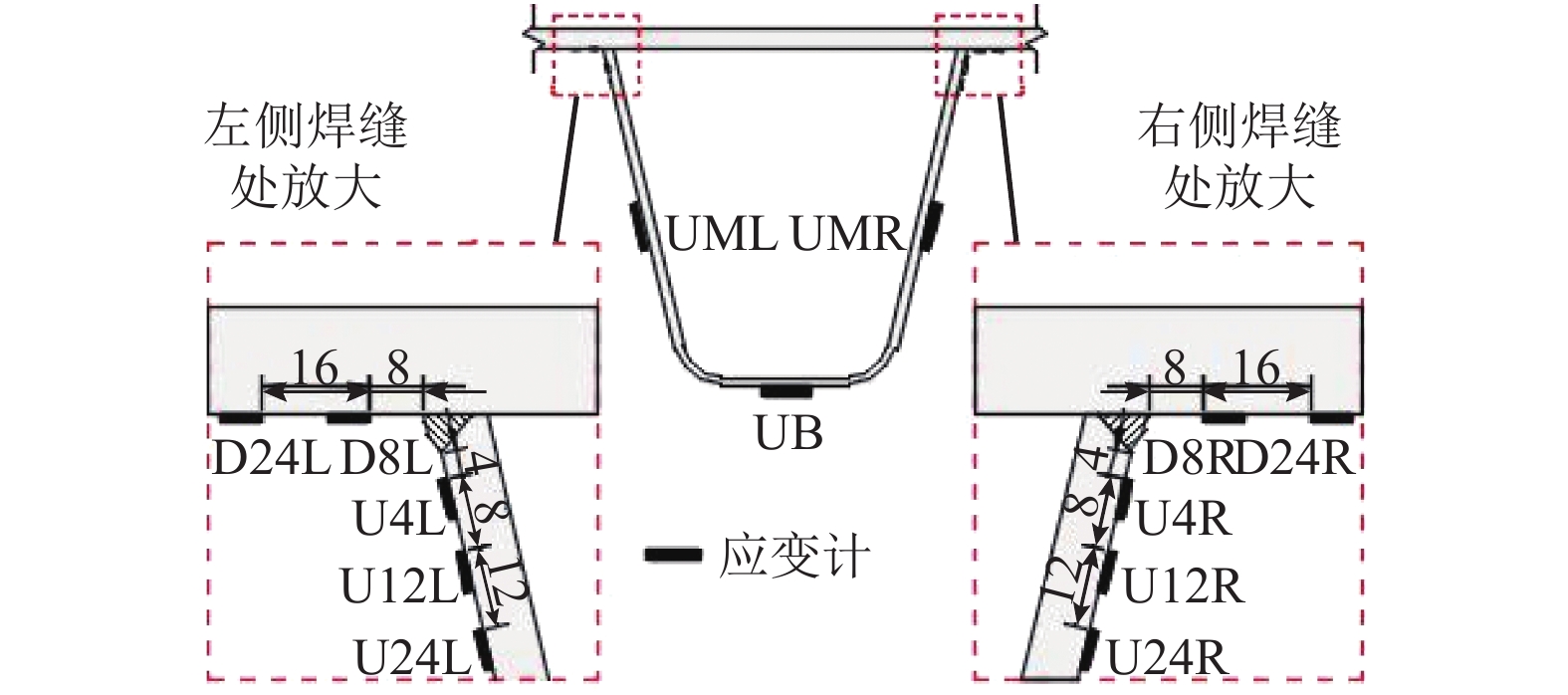

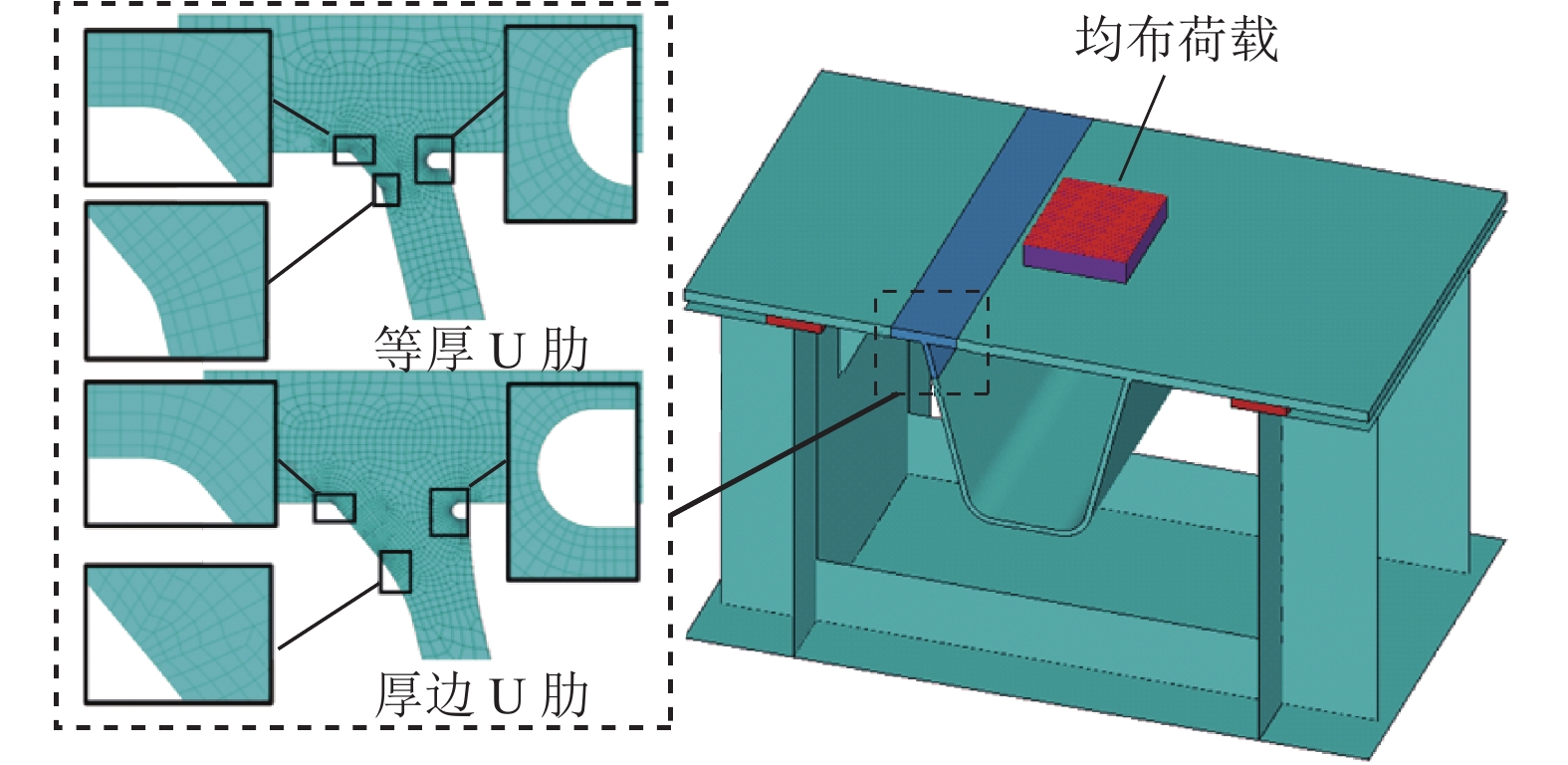

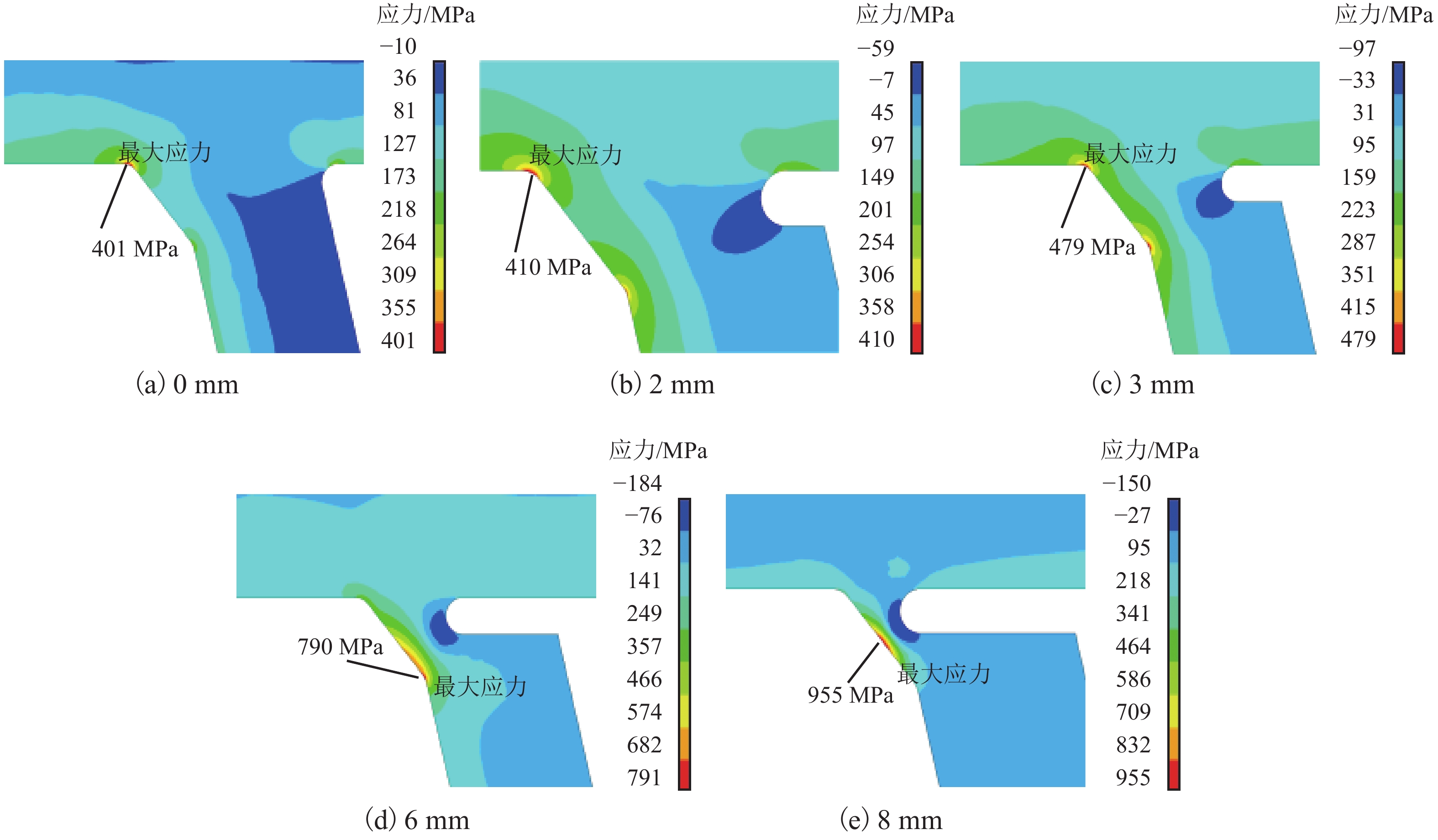

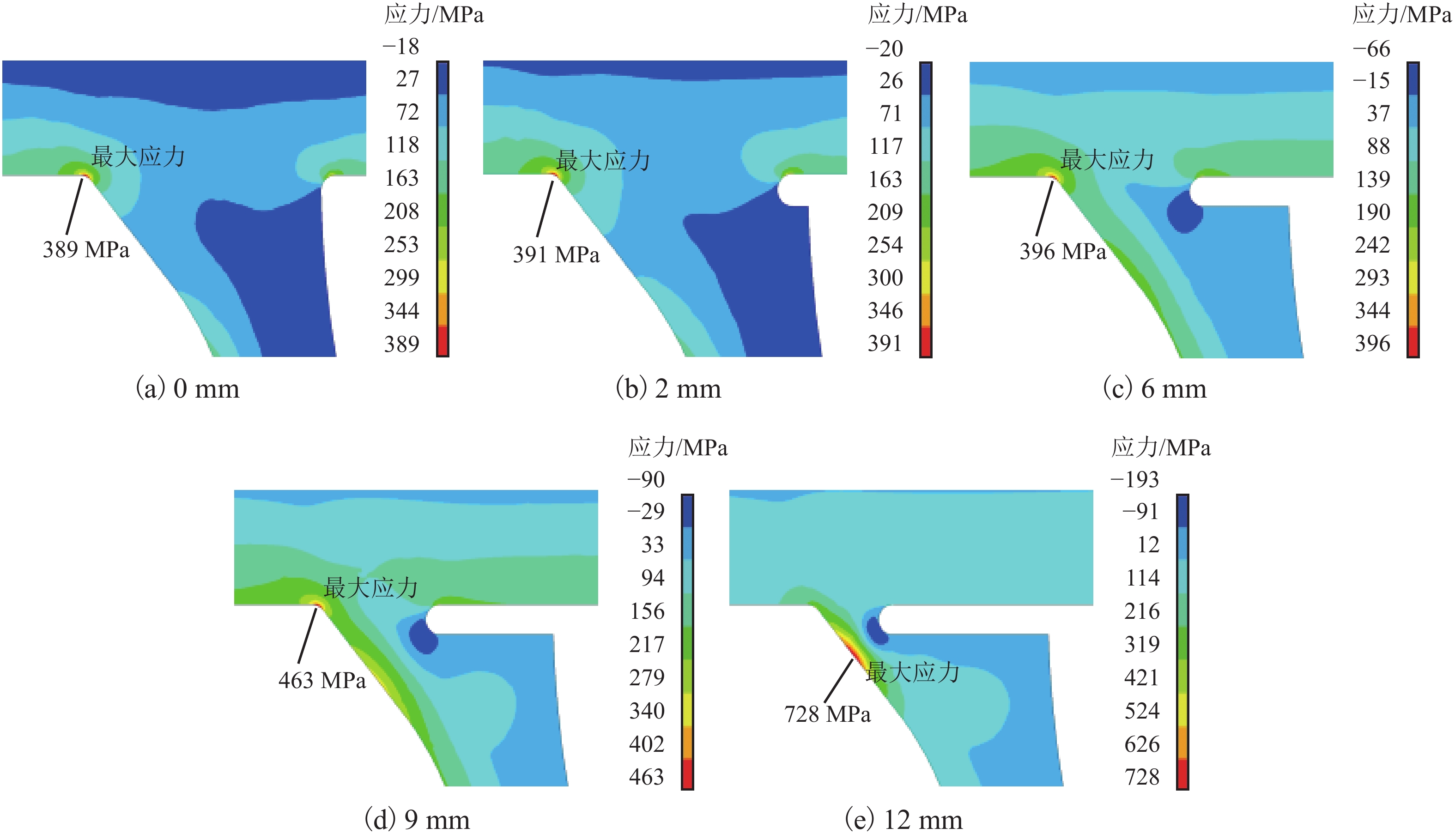

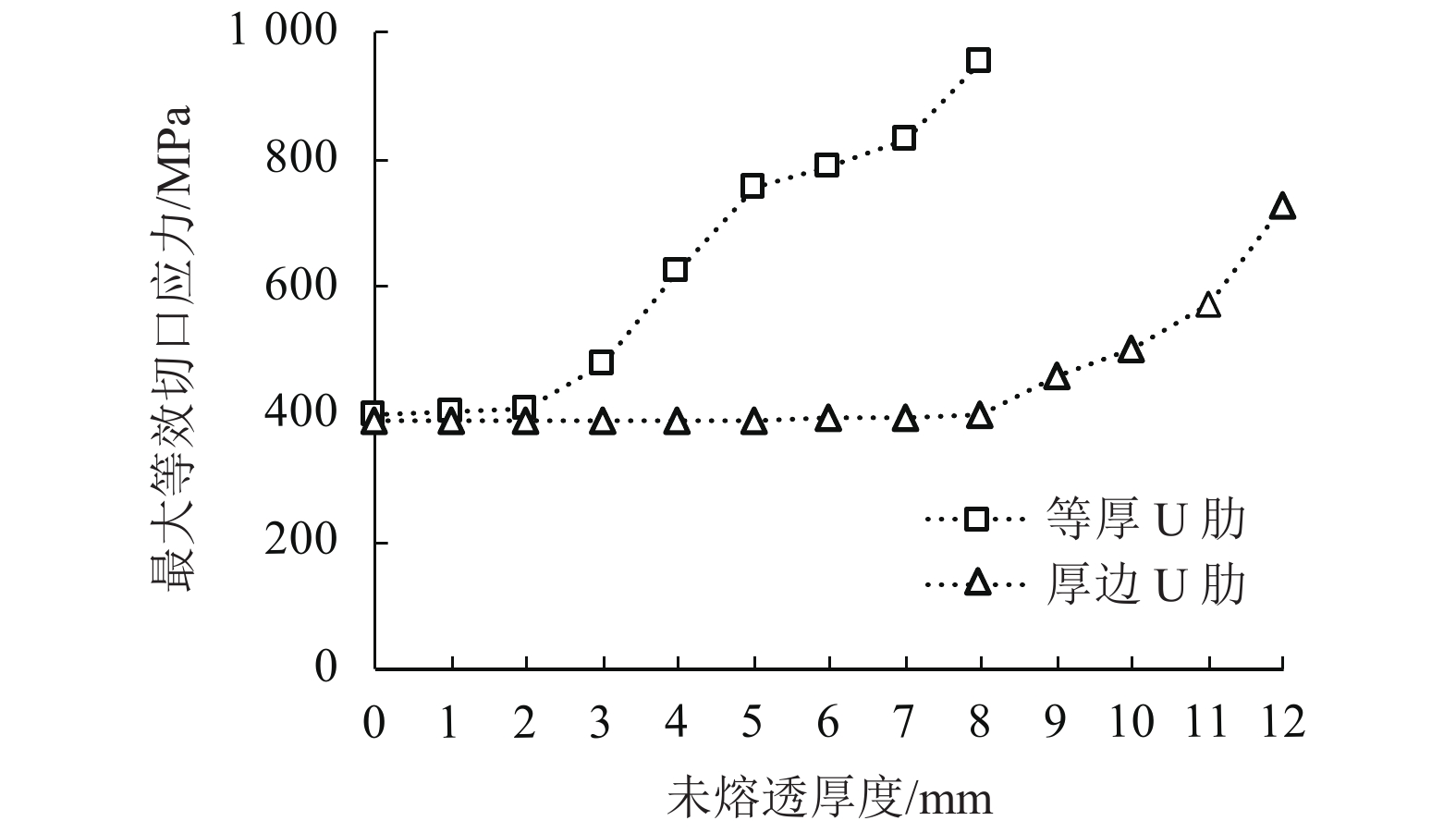

摘要: 新型厚边U肋正交异性钢桥面的应用有望提高顶板与U肋连接焊缝的抗疲劳寿命. 为研究其实际疲劳性能和具体提升机理,对该类钢桥面中顶板与U肋连接焊缝开展了疲劳试验和数值分析. 通过足尺模型疲劳试验,采用名义应力法和热点应力法对常规等厚U肋钢桥面和新型厚边U肋钢桥面进行了对比;在疲劳试验的基础上,建立了精细化有限元模型并通过试验数据验证了其有效性;通过该模型对厚边U肋钢桥面顶板与U肋焊缝的疲劳性能提升机理进行了分析. 结果表明:厚边U肋的使用有效地提高了顶板与U肋连接焊缝的疲劳强度;在焊接负公差存在的情况下,厚边U肋试件对未熔透厚度的变化相对不敏感,从而保障了顶板与U肋连接焊缝疲劳性能的稳定性. 厚边U肋正交异性钢桥面在北京三元桥新桥和成都凤凰山高架桥等工程项目中的应用验证了其抗疲劳的有效性.Abstract: The fatigue performance of rib-to-deck (RD) joints is expected to be enhanced by the application of the orthotropic steel deck (OSD) with thickened edge U-ribs (TEUs). To investigate its actual fatigue performance and the mechanism of enhancement, the RD joints in the OSD with TEUs using the fatigue test and numerical analysis was evaluated.Through the fatigue model test of full-scale specimens, comparative analysis was performed on the OSD with conventional U-ribs (CUs) and the OSD with TEUs,in the test, both the nominal stress and hot spot stress approaches were incorporated. A refined finite element (FE) model was established based on the test, and validated by the test data. Using the model, numerical analysis was carried out to study the mechanism of the enhancement in RD joints by the application of TEUs.The results show that: the use of TEUs improve the fatigue strength of rib-to-deck joints effectively; in the presence of negative welding errors, the specimens with TEUs are relatively insensitive to the variations in unpenetrated thicknessthat leading to the robustness of the fatigue strength of rib-to-deck joints. The fatigue performance of the OSD with TEUs has been further validated through its application in several engineering projects such as New Sanyuan bridge in Beijing and Fenghuangshan Viaduct in Chengdu.

-

Key words:

- bridge engineering /

- orthotropic steel deck /

- fatigue test /

- thickened edge U-rib /

- U-rib-to-deck joint

-

表 1 实际施加荷载

Table 1. Applied loads on the specimens

试件

编号施加 最小 (Fmin) 最大 (Fmax) 荷载幅 (Fmax – Fmin) CU-1 13.0 39.0 26.0 CU-2 16.5 49.5 33.0 CU-3 20.0 60.0 40.0 TEU-1 18.0 54.5 36.5 TEU-2 19.0 57.0 38.0 TEU-3 20.0 60.0 40.0 TEU-4 20.5 62.0 41.5 表 2 试验结果汇总

Table 2. Summary of the testing results

试件

编号顶板测点

应力/MPaU肋测点

应力/MPa裂纹贯穿次数

Ntest/ (× 104次)等效疲劳

强度/MPa名义 热点 名义 热点 名义 热点 CU-1 81 98 99 101 269 89 108 CU-2 103 121 109 117 255 112 131 CU-3 123 149 130 145 91 95 115 TEU-1 114 144 150 126 147 103 130 TEU-2 119 146 145 123 162 111 136 TEU-3 125 154 140 115 234 132 162 TEU-4 129 153 138 122 193 127 157 表 3 静载作用下试件部分测点静载应力实测值与计算值对比

Table 3. Comparison between measured and computed stress under static load

截面

位置测点

编号CU-3 TEU-3 计算值 实测值 偏差

/%计算值 实测值 偏差

/%前端 D24L 125 123 2 124 125 –1 U12L 141 130 8 148 140 6 UB –43 –45 –4 –45 –47 –4 中部 D24L 100 105 –5 100 105 –5 U12L 145 153 –5 155 149 4 UB –45 –47 –4 –47 –48 –2 -

CONNOR R, FISHER J, GATTI W, et al. Manual for design, construction, and maintenance of orthotropic steel deck bridges FHWA Report No. FHWA-IF-12-027[R]. New Jersey: Federal Highway Administration, 2012 FISHER J W, ROY S. Fatigue of steel bridge infrastructure[J]. Structure and Infrastructure Engineering:Maintenance,Management,Life-Cycle Design and Performance, 2011, 7(7): 457-475. 曾志斌. 正交异性钢桥面板典型疲劳裂纹分类及其原因分析[J]. 钢结构,2011(2): 9-15. doi: 10.3969/j.issn.1007-9963.2011.02.003ZENG Zhibin. Classification and reasons of typical fatigue cracks in orthotropic steel deck[J]. Steel Construction, 2011(2): 9-15. doi: 10.3969/j.issn.1007-9963.2011.02.003 XIAO Z G, YAMADA K, YA S, et al. Stress analyses and fatigue evaluation of rib-to-deck joints in steel orthotropic decks[J]. International Journal of Fatigue, 2008, 30(8): 1387-1397. doi: 10.1016/j.ijfatigue.2007.10.008 SAMOL Y, YAMADA K, ISHIKAWA T. Fatigue durability of trough rib to deck plate welded detail of some orthotropic steel decks[J]. Kozo Kogaku Ronbunshu A, 2010, 56: 77-90. SIM H B, UANG C M, SIKORSKY C. Effects of fabrication procedures on fatigue resistance of welded joints in steel orthotropic decks[J]. Journal of Bridge Engineering, 2009, 14(5): 366-373. doi: 10.1061/(ASCE)1084-0702(2009)14:5(366) YA S, YAMADA K, SHIKAWA T. Fatigue evaluation of rib-to-deck welded joints of orthotropic steel bridge deck[J]. Journal of Bridge Engineering, 2013, 18(5): 492-499. 丁楠,邵旭东. 轻型组合桥面板的疲劳性能研究[J]. 土木工程学报,2015,48(1): 74-81.DING Nan, SHAO Xudong. Study on fatigue performance of light-weighted composite bridge deck[J]. China Civil Engineering Journal, 2015, 48(1): 74-81. 郭萍萍, 黄峰. 沌口长江公路大桥主桥顶板U肋内焊工艺及验收规则[R]. 武汉: 武船重工工程股份有限公司, 2016 郑凯锋, 范文理, 苟超, 等. 700 m跨度钢箱梁厚边U肋正交异性钢桥面足尺模型疲劳试验研究报告[R]. 成都: 西南交通大学, 2013 全国钢标准化技术委员会. 桥梁结构用钢: GB/T 714—2015[S]. 北京: 中国标准出版社, 2015 中华人民共和国工业和信息化部. 桥梁钢结构用U形肋冷弯型钢: YB/T 4624—2017 [S]. 北京: 中国标准出版社, 2017 HOBBACHER A. Recommendations for fatigue design of welded joints and components[M]. [S.l.]: Springer International Publishing, 2016: 24-30 蒲黔辉,高立强,刘振标,等. 基于热点应力法的正交异性钢桥面板疲劳验算[J]. 西南交通大学学报,2013,48(3): 395-401. doi: 10.3969/j.issn.0258-2724.2013.03.001PU Qianhui, GAO Liqiang, LIU Zhengbiao, et al. Fatigue assessment of orthotropic steel bridge deck based on hot spot stress method[J]. Journal of Southwest Jiaotong University, 2013, 48(3): 395-401. doi: 10.3969/j.issn.0258-2724.2013.03.001 卫星,姜苏. 基于断裂力学的钢桥面肋-板接头疲劳寿命预测[J]. 西南交通大学学报,2017,52(1): 16-22. doi: 10.3969/j.issn.0258-2724.2016.04.006WEI Xing, JIANG Su. Fatigue life prediction on rib-to-deck welded joints of steel bridge deck based on LEFM[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 16-22. doi: 10.3969/j.issn.0258-2724.2016.04.006 中华人民共和国交通运输部. 公路钢结构桥梁设计规范: JTG D64—2015[S]. 北京: 人民交通出版社, 2015 CEN. Eurocode 3—design of steel structures—part 2: steel bridges EN 1993-2[S]. Brussels: [s.n.], 2006 ANSYS Inc. ANSYS mechanical APDL finite element system [CP/OL]. (2015-04-08)[2017-05-01]. http://www.ansys.com RADAJ D, SONSINO C M, FRICKE W. Fatigue assessment of welded joints by local approaches[M].2nd edition. Cambridge: Woodhead Publishing Ltd., 2006: 579-634 FRICKE W. IIW recommendations for the fatigue assessment of welded structures by notch stress analysis[M]. Cambridge: Woodhead Publishing Ltd., 2012: 2-41 崔闯,刘益铭,廖贵星,等. 正交异性钢桥面板焊接接头疲劳评估方法[J]. 西南交通大学学报,2015,50(6): 1011-1017. doi: 10.3969/j.issn.0258-2724.2015.06.006CUI Chuang, LIU Yiming, LIAO Guixing, et al. Fatigue evaluation approaches of welded joint on orthotropic steel bridge deck[J]. Journal of Southwest Jiaotong University, 2015, 50(6): 1011-1017. doi: 10.3969/j.issn.0258-2724.2015.06.006 FISHER J W, BARSOM J M. Evaluation of cracking in the rib-to-deck welds of the Bronx-Whitestone bridge[J]. Journal of Bridge Engineering, 2015, 21(3): 04015065-1-04015065-10. -

下载:

下载: