Study on Design Model of Quasi-Rectangular Shield Tunnel Linings

-

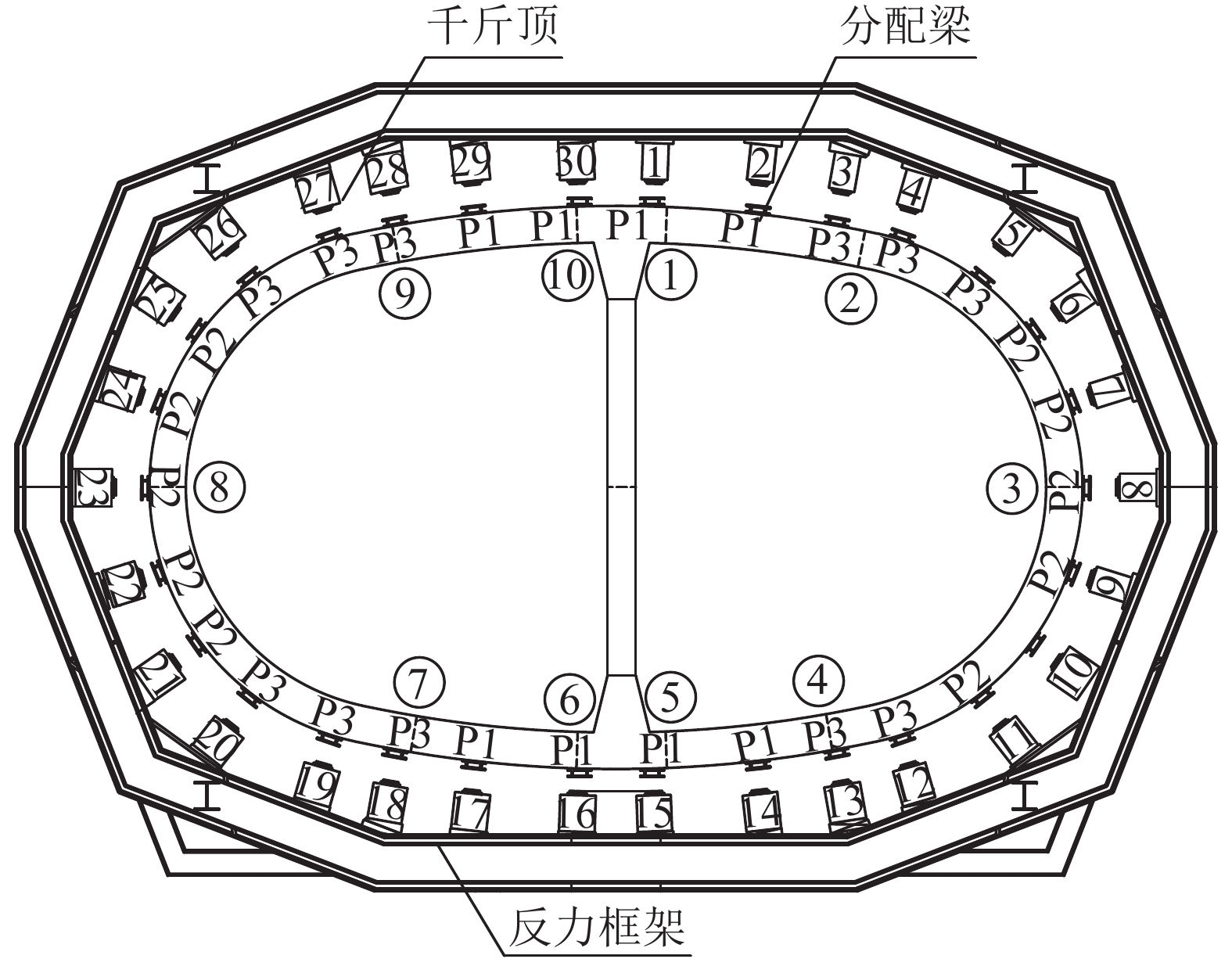

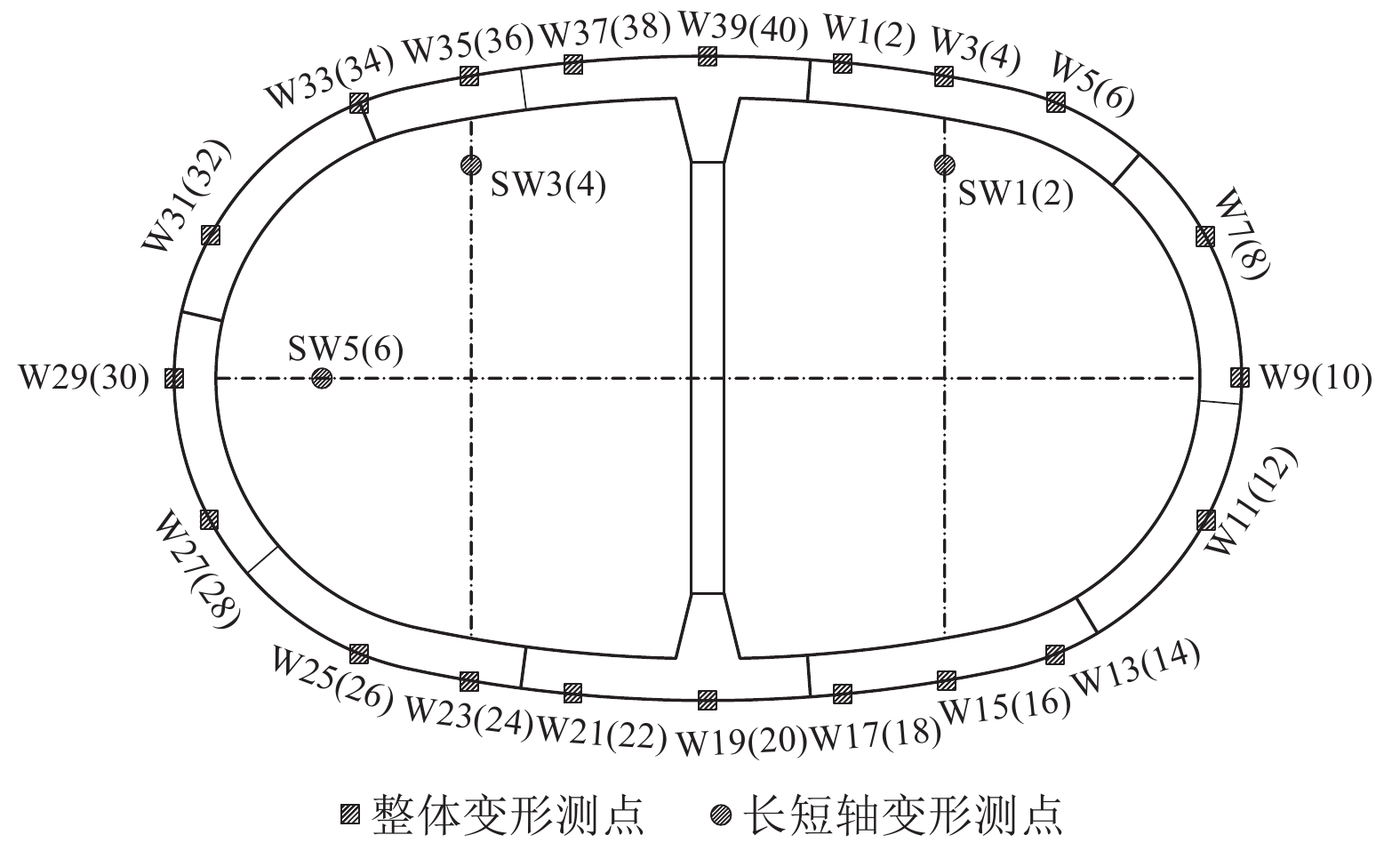

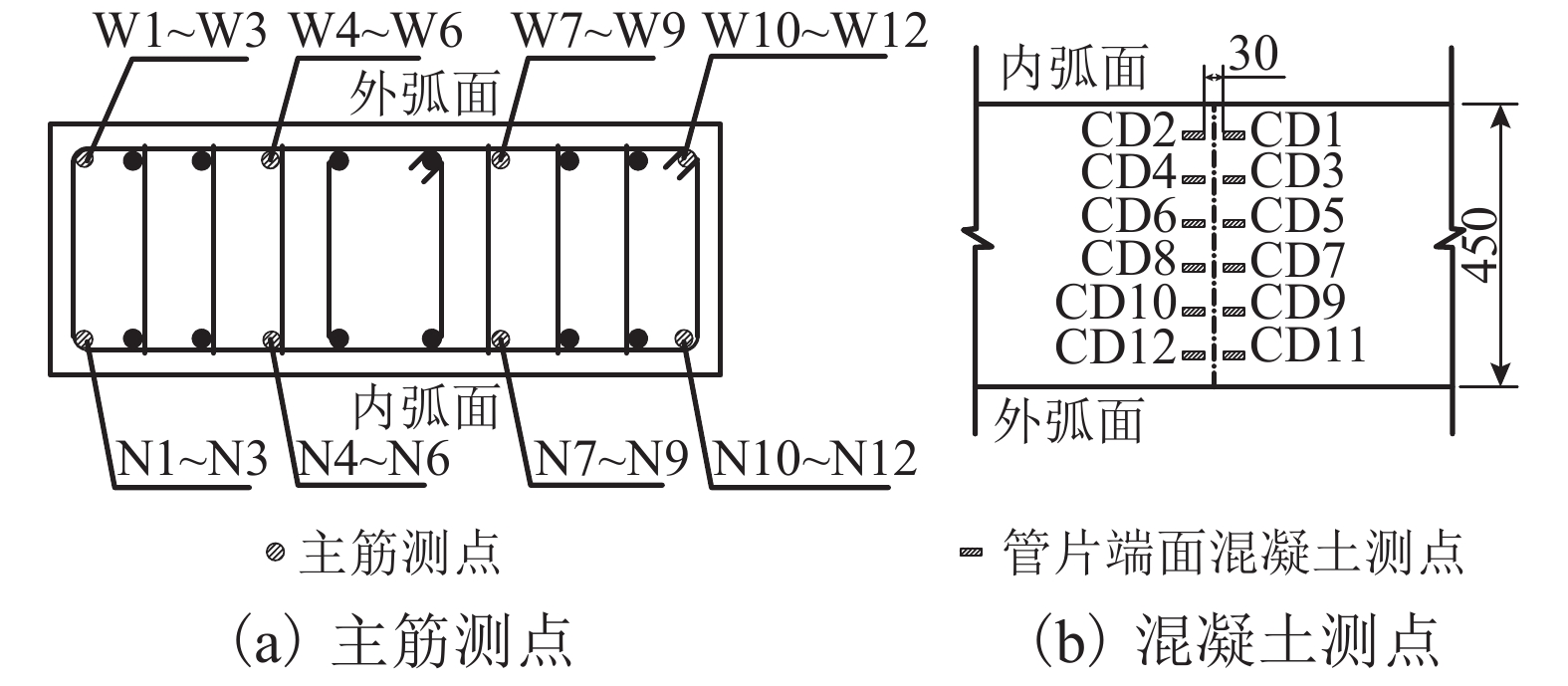

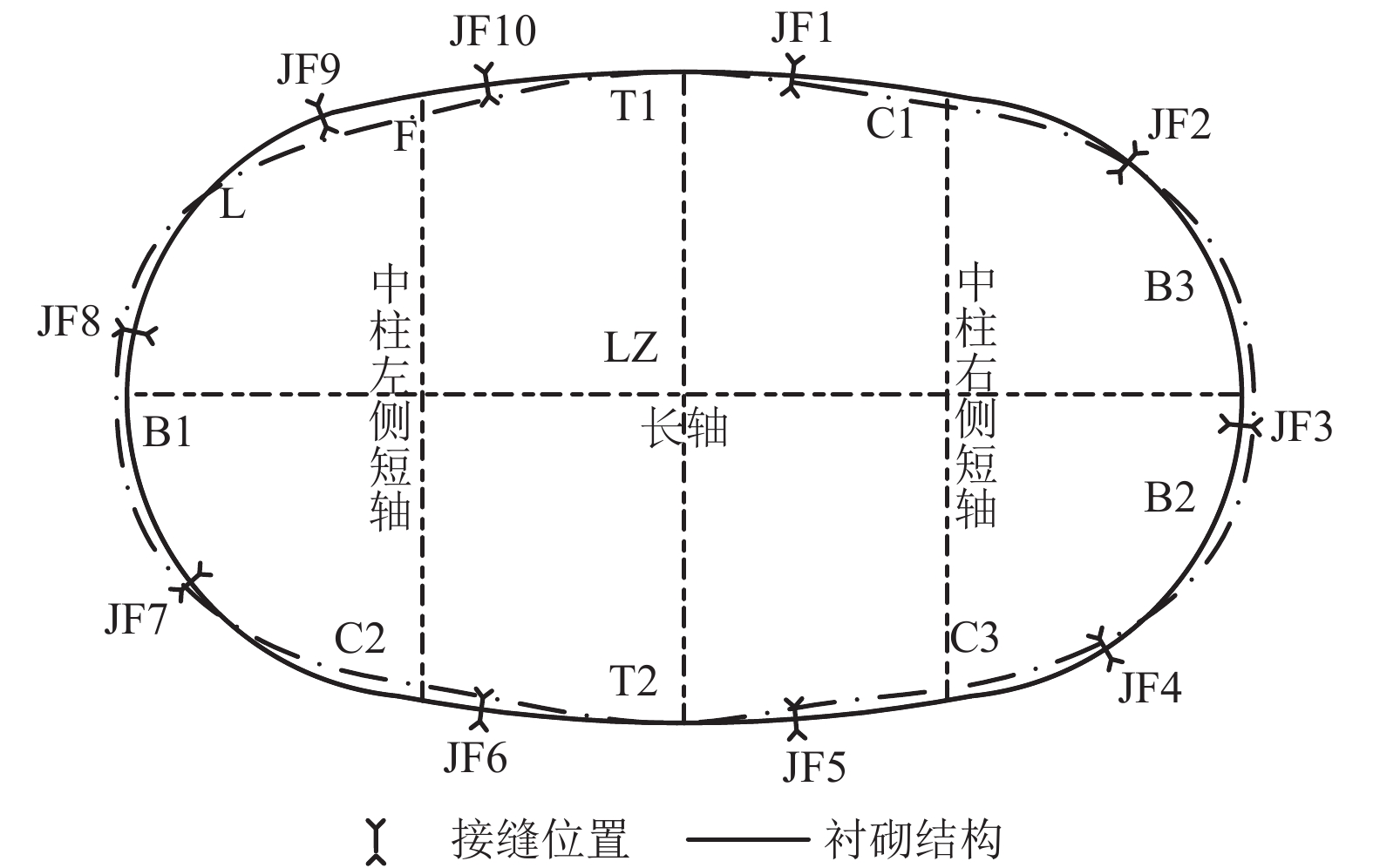

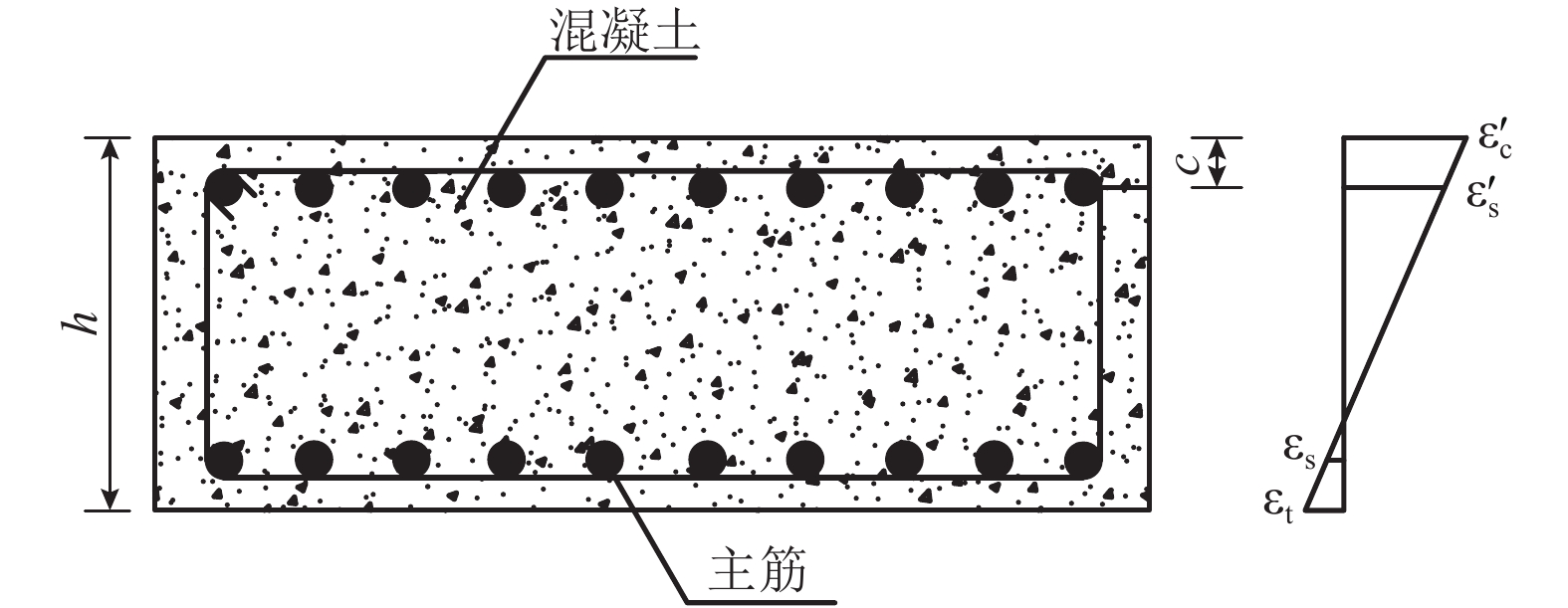

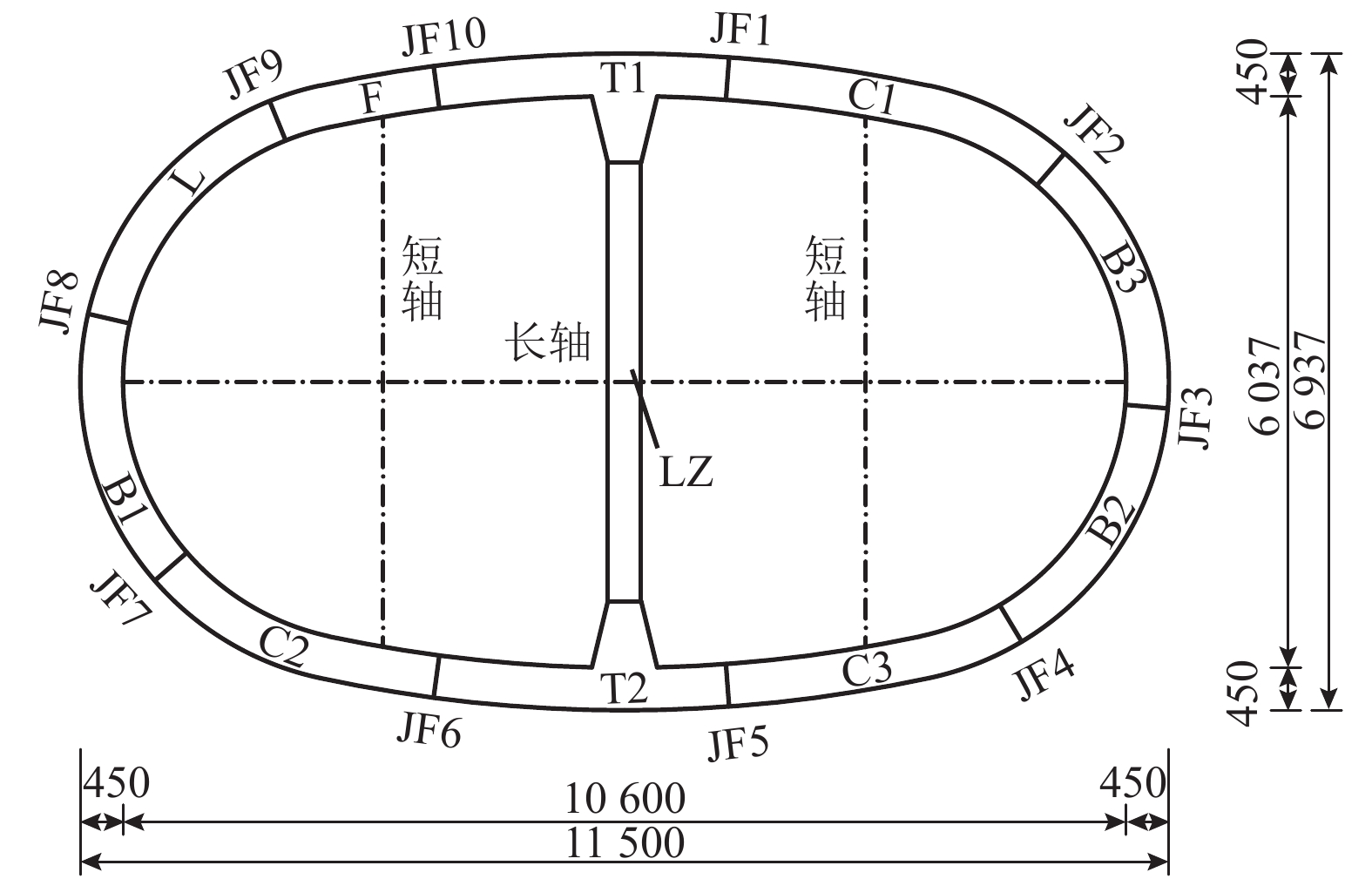

摘要: 为了得到适用于类矩形盾构隧道结构设计模型,通过整环足尺试验模拟类矩形盾构隧道在正常运营工况下的实际受力,得到试验结构的变形和内力,采用等效刚度模型和梁-弹簧模型对试验结果进行分析,得到有效的类矩形盾构隧道结构设计参数. 结果表明:采用等效刚度模型作为类矩形盾构隧道结构计算模型,难以得到同时符合结构长短轴变形的管片刚度折减系数;采用梁-弹簧模型作为类矩形盾构隧道结构计算模型,结构变形和结构内力计算结果和足尺试验结果较为匹配,能真实反应类矩形盾构隧道结构受力,选用梁-弹簧模型作为类矩形盾构隧道结构计算模型更为合理,所研究类矩形结构管片接缝的抗剪刚度建议为341 × 106~368 × 106 N/m;负弯矩接缝抗弯刚度建议为114 × 106~491 × 106 N•m/rad,正弯矩接缝抗弯刚度范围为85 × 106~177 × 106 N•m/rad.Abstract: In order to obtain a design model for quasi-rectangular shield tunnel linings, a full-scale ring test was conducted to acquire the deformation and internal forces of the linings with loads simulated according to the actual ones in normal operation conditions. The test results were then analyzed in comparison with the numerical results based on the equivalent stiffness model and the beam-spring model, to determine parameters of the design model of quasi-rectangular tunnel linings. Results show that using the equivalent stiffness model to design of the quasi-rectangular shield tunnel linings, the segment stiffness reduction factor that can account for the deformation along both the long and short axes could not be obtained. While applying the beam-spring model, the computed structural responses and the influence of longitudinal joints on moment distribution both agree well with the experimental results. Therefore, it is more reasonable to use the beam-spring model as the design model of quasi-rectangular shield tunnel linings. For the quasi-rectangular shield tunnel linings under study, input parameters for the design model, including the shearing rigidity, negative-moment bending rigidity, and positive-moment bending rigidity of segment joints, are recommended as 341 × 106 − 368 × 106 N/m, 114 × 106 − 491 × 106 N•m/rad, and 85 × 106 − 177 × 106 N•m/rad, respectively

-

表 1 试验荷载作用下衬砌结构长短轴变形

Table 1. Long and short axis deformation of ling

项目 长轴变形 中柱右侧

短轴变形中柱左侧

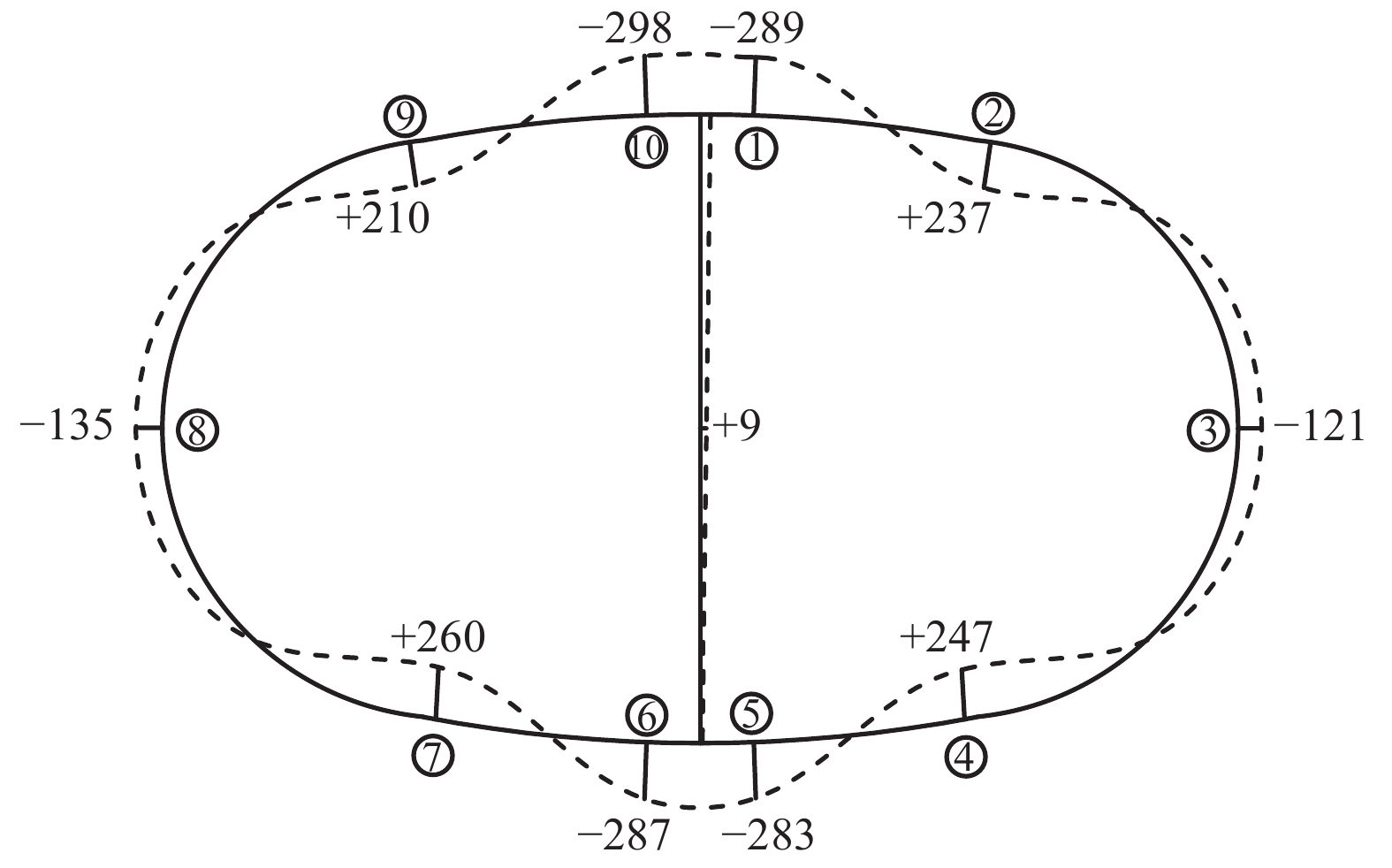

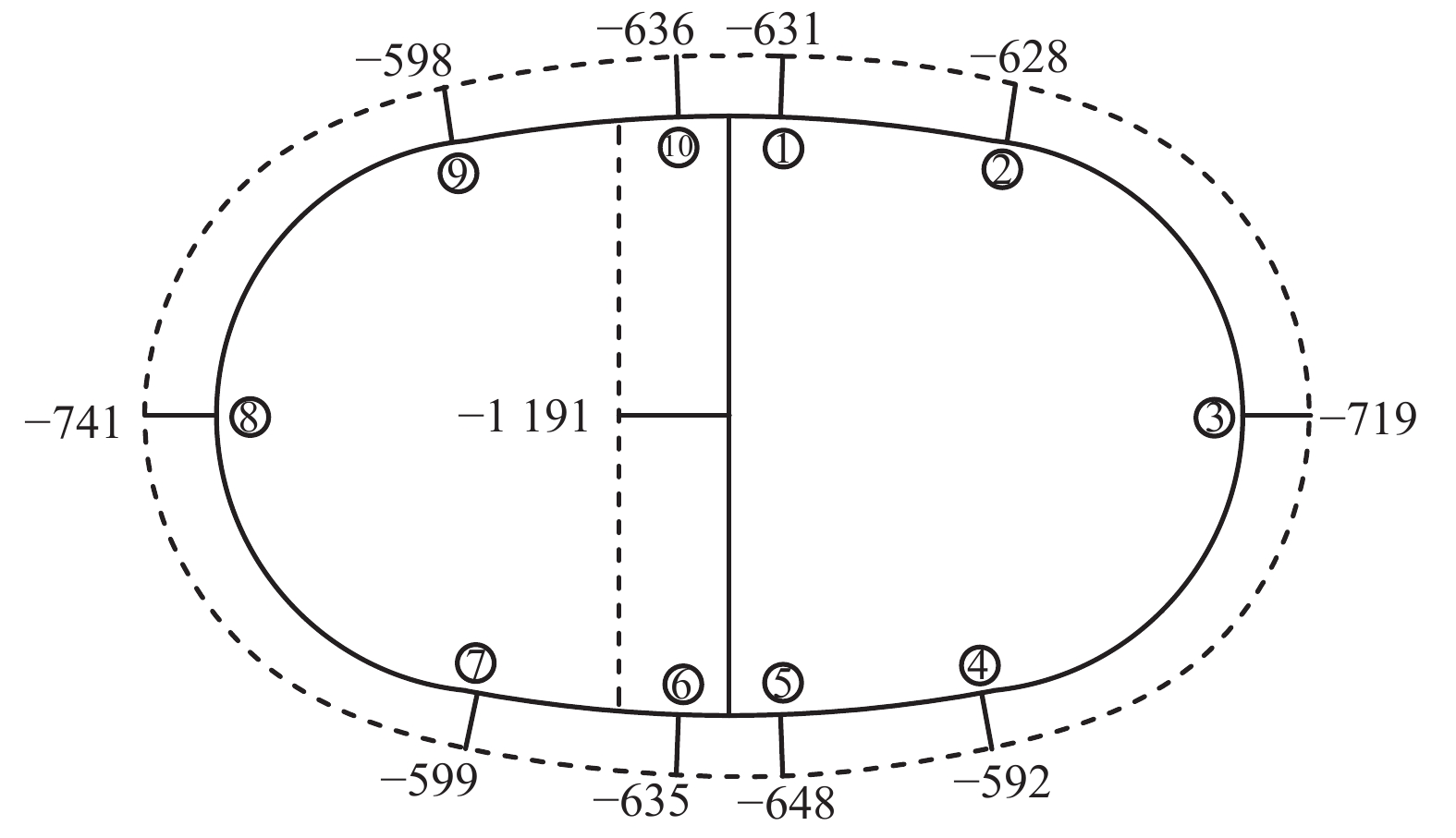

短轴变形变形值/mm 4.68 4.74 6.92 千分比/‰ 0.42 0.68 1.00 表 2 试验荷载作用下衬砌结构内力

Table 2. Internal force of ling under test load

截面编号 弯矩/(kN•m) 轴力/kN ① –289 –631 ② 237 –628 ③ –121 –719 ④ 247 –592 ⑤ –283 –648 ⑥ –287 –635 ⑦ 260 –599 ⑧ –135 –741 ⑨ 210 –598 ⑩ –298 –636 中柱 9 –1 191 表 3 试验荷载作用下结构变形数值计算结果与试验结果对比

Table 3. Comparison of numerical results of structural deformation with experimental results

mm 结构变形位置 不同管片刚度折减系数 试验结果 0.85 0.80 0.75 0.70 0.65 0.60 0.55 0.50 长轴 3.24 3.41 3.61 3.84 4.10 4.40 4.77 5.20 4.68 中柱右侧短轴 4.32 4.55 4.81 5.12 5.47 5.88 6.36 6.94 4.74 中柱左侧短轴 4.32 4.55 4.81 5.12 5.47 5.88 6.36 6.94 6.92 表 4 内力数值计算结果与试验结果对比分析

Table 4. Comparison of numerical results of internal force with experimental results

截面编号 试验结果 数值计算结果 试验/数值 弯矩/(kN•m) 轴力/kN 弯矩/(kN•m) 轴力/kN 弯矩 轴力 ① –289 –631 –277 –639 1.04 0.99 ② 237 –628 228 –607 1.04 1.03 ③ –121 –719 –153 –730 0.79 0.98 ④ 247 –592 251 –605 0.98 0.98 ⑤ –283 –648 –277 –641 1.02 1.01 ⑥ –287 –635 –277 –639 1.04 0.99 ⑦ 260 –599 251 –605 1.04 0.99 ⑧ –135 –741 –153 –730 0.88 1.02 ⑨ 210 –598 249 –605 0.88 0.99 ⑩ –298 –636 –277 –641 0.84 0.99 中柱 –9 –1 191 0 –1 191 1.00 表 5 试验荷载作用下结构变形数值计算与试验结果对比

Table 5. Comparison of numerical results of structural deformation with experimental results

结构变形位置 试验/mm 计算数值/mm 试验/数值 长轴 4.68 4.98 0.94 中柱右侧短轴 4.74 4.68 1.01 中柱左侧短轴 6.92 7.29 0.95 表 6 内力数值计算结果与试验结果对比分析

Table 6. Comparison of numerical results of internal force with experimental results

截面编号 试验结果 数值计算结果 试验/数值 弯矩/(kN•m) 轴力/kN 弯矩/(kN•m) 轴力/kN 弯矩 轴力 ① –289 –631 –278 –634 1.04 1.00 ② 237 –628 215 –603 1.10 1.04 ③ –121 –719 –117 –710 1.03 1.01 ④ 247 –592 227 –602 1.09 0.98 ⑤ –283 –648 –276 –636 1.03 1.02 ⑥ –287 –635 –289 –633 0.99 1.00 ⑦ 260 –599 211 –601 1.23 1.00 ⑧ –135 –741 –139 –711 0.97 1.04 ⑨ 210 –598 208 –603 1.01 0.99 ⑩ –298 –636 –295 –637 1.01 1.00 中柱 –9 –119 1 –14 –123 0 0.97 -

NAKAMURA H, KUBOTA T, FURUKAWA M, et al . Unified construction of running track tunnel and crossover tunnel for subway by rectangular shape double track cross-section shield machine[J]. Tunnelling and Underground Space Technology, 2003, 18(2): 253-262. 龙建兵,杨志豪,沈张勇. 类矩形盾构工法在宁波轨道交通工程中的应用探讨[J]. 地下工程与隧道,2016(3): 1-6.LONG Jianbing, YANG Zhihao, SHEN Zhangyong. Application of quasi-rectangular shield sonstruction method in Ningbo rail transit line[J]. Underground Engineering and Tunnels, 2016(3): 1-6. 前田知就,大井和憲,蛭子延彦. 地上発進. 地上到達シールドの施工[J]. 基礎工,2013,41(3): 39-45.MAEDA T, OI K, EBISU N. Ultra rapid under pass construction method[J]. The Foundation Engineering & Equipment, 2013, 41(3): 39-45. 孙巍,官林星,温竹茵. 大断面矩形盾构法隧道的受力分析与工程应用[J]. 隧道建设,2015,35(10): 1028-1033. doi: 10.3973/j.issn.1672-741X.2015.10.009SUN Wei, GUAN Linxing, WEN Zhuyin. Mechanical analysis and application of large rectangular cross section shield tunnel[J]. Tunnel Construction, 2015, 35(10): 1028-1033. doi: 10.3973/j.issn.1672-741X.2015.10.009 日本土木学会. 日本土木学会隧道标准规范(盾构篇)及解说[M]. 朱伟, 译. 北京: 中国建筑工业出版社, 2001: 1-317 KOYAMA Y, NISHIMURA T. Design of lining segment of shield tunnel using a beam-spring model[J]. Quarterly Report of RTRI (Railway Technical Research Institute), 1998, 39(1): 23-27. 卢岱岳,徐国文,王士民. 加卸载对盾构隧道材料损伤和结构特性的影响[J]. 西南交通大学学报,2017,52(6): 1104-1112.LU Daiylle, XU Guowen, WANG Shimin. Effets of material damage and structural characteristics on tunnel shield during loading and unloading[J]. Journal of Southwest Jiaotong university, 2017, 52(6): 1104-1112. 卢岱岳,何川,王士民. 千斤顶作用下带榫管片的裂纹扩展规律[J]. 西南交通大学学报,2017,52(1): 75-81.LU Daiyue, HE Chuan, WANG Shimin. Crack propagation law of segment tendon under jacking forces[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 75-81. 毕湘利,柳献,王秀志,等. 通缝拼装盾构隧道结构极限承载力的足尺试验研究[J]. 土木工程学报,2014,47(10): 17-11.BI Xiangli, LIU Xian, WANG Xiuzhi, et a1. Experimental investigation on the ultimate bearing capacity of continuous-jointed segmental tunnel linings[J]. China Civil Engineering Journal, 2014, 47(10): 17-11. 柳献, 黄晓冬. 通缝拼装盾构隧道衬砌结构抗倒塌性能的试验研究[J]. 岩石力学与工程学报, 2015, 34(增刊2): 17.LIU Xian, HUANG Xiaodong. Experimental study of collapse capacity of straight joint segmental tunnel ling[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(S2): 3703-3714. BLOM C, VANDER H, JOVANOVIC P. Three-dimensional structural analyses of the shield-drive ‘Green Heart’ tunnel of the high-speed line south[J]. Tunneling and Underground Space Technology, 1999, 14(2): 217-224. doi: 10.1016/S0886-7798(99)00035-8 SCHREYER J, WINSELMANN D. Suitability tests for the lining for the 4th Elbe Tunnel tube-results of large-scale tests[J]. Tunnel, 2000, 1: 34-44. 张厚美,吕国梁. 圆形隧道衬砌结构计算模型综述[J]. 现代隧道技术,2000(2): 1-6.ZHANG Houmei, LÜ Guoliang. Review on calculating models of lining for circular tunnel[J]. Modern Tunnelling Technology, 2000(2): 1-6. 黄正荣,朱伟,梁精华. 修正惯用法管片环弯曲刚度有效率η和弯矩提高率ξ的研究[J]. 工业建筑,2006,36(2): 45-49. doi: 10.3321/j.issn:1000-8993.2006.02.014HUANG Zhengrong, ZHU Wei, LIANG Jinghua. Study on effective bending rigidity rations and moment increasing rates in modified routine method[J]. Industrial Construction, 2006, 36(2): 45-49. doi: 10.3321/j.issn:1000-8993.2006.02.014 朱伟,胡如军,钟小春. 几种盾构隧道管片设计方法的比较[J]. 地下空间与工程学报,2003,23(4): 352-356.ZHU Wei, HU Rujun. ZHONG Xiaochun. Comparative study of several segment design methods for shield tunnels[J]. Underground Space, 2003, 23(4): 352-356. KOYAMA Y. Present status and technology of shield tunneling method in Japan[J]. Tunnelling and Underground Space Technology, 2003, 18(2): 145-159. 徐凌. 软土盾构隧道纵向沉降研究[D]. 上海: 同济大学, 2005 唐志成,何川,林刚. 地铁盾构隧道管片结构力学行为模型试验研究[J]. 岩土工程学报,2005,27(1): 85-89.TANG Zhicheng, HE Chuan, LIN Gang. Study on mechanical behavior of segment of shield tunnel of metro with model test[J]. Chinese Journal of Geotechnical Engineering, 2005, 27(1): 85-89. 彭益成,丁文其,闫治国,等. 修正惯用法中弯曲刚度有效率的影响因素分析及计算方法[J]. 岩土工程学报,2013,35(增刊1): 495-500.PENG Yicheng, DING Wenqi, YAN Zhiguo, et al. Analysis and calculation method of effective bending rigidity ratio in modified routine method[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(S1): 495-500. 林平, 张维熙, 张宸, 等. 类矩形地铁盾构隧道纵向接缝承载能力试验研究[J]. 现代隧道技术, 2016, 53(增刊1) : 98-107LIN Ping, ZHANG Weixi, ZHANG Chen, et al. Experimental study on bearing capacity of longitudinal joints in quasi-rectangular shield tunnels[J]. Modern Tunnelling Technology, 2016, 53(S1): 98-107 柳献,张维熙,王东方. 类矩形盾构隧道纵缝受剪性能试验研究[J]. 铁道科学与工程学报,2016,13(9): 1767-1775. doi: 10.3969/j.issn.1672-7029.2016.09.016LIU Xian, ZHANG Weixi, WANG Dongfang. Experimental study on shear performance of longitudinal joint in quasi-rectangular shield tunnel[J]. Journal of Railway Science and Engineering, 2016, 13(9): 1767-1775. doi: 10.3969/j.issn.1672-7029.2016.09.016 张维熙. 类矩形盾构隧道衬砌结构分析模型研究[D]. 上海: 同济大学, 2017 -

下载:

下载: