Experimental Study on Bonding Performance Between Rebar and Coarse Aggregate Ultra-High Performance Concrete

-

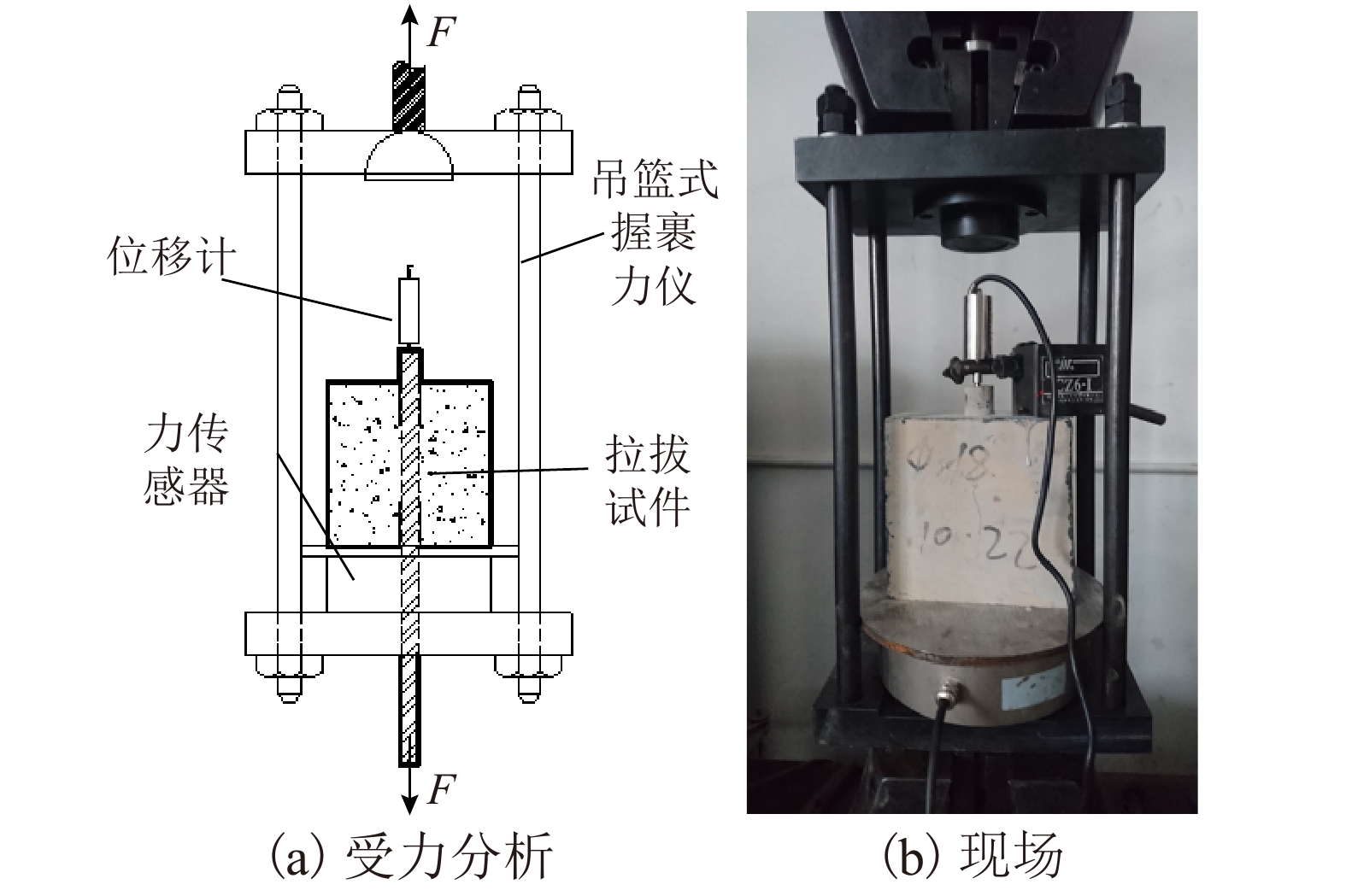

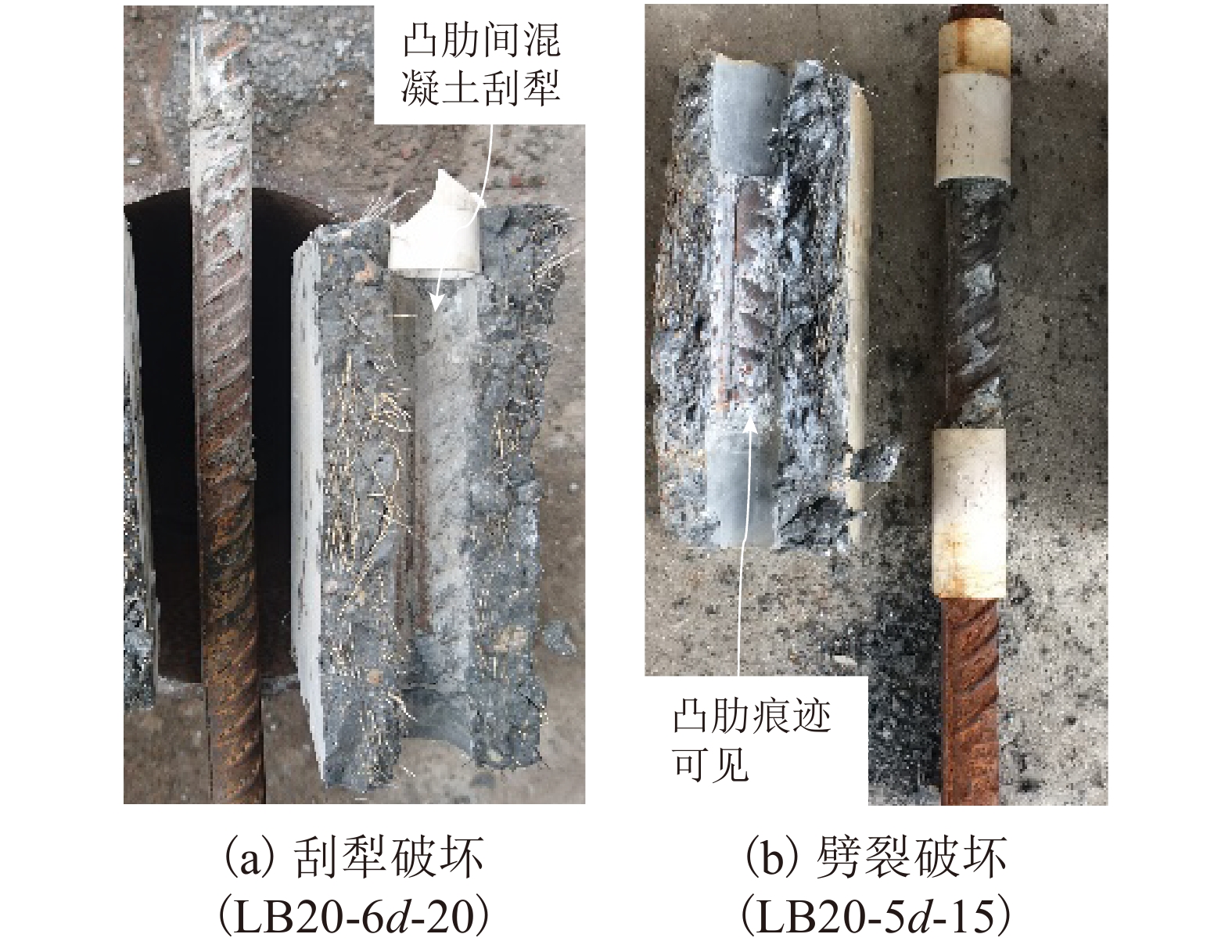

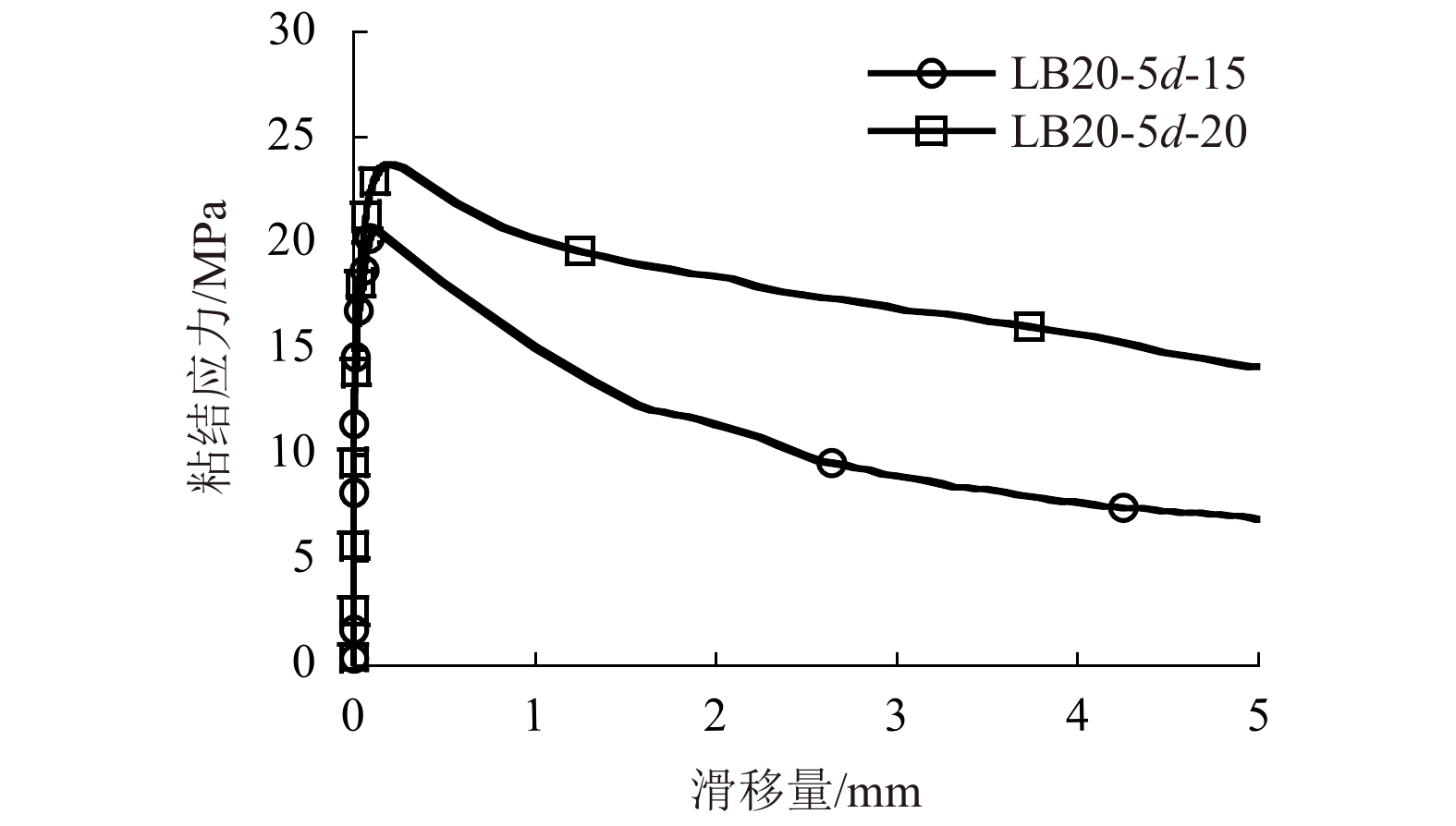

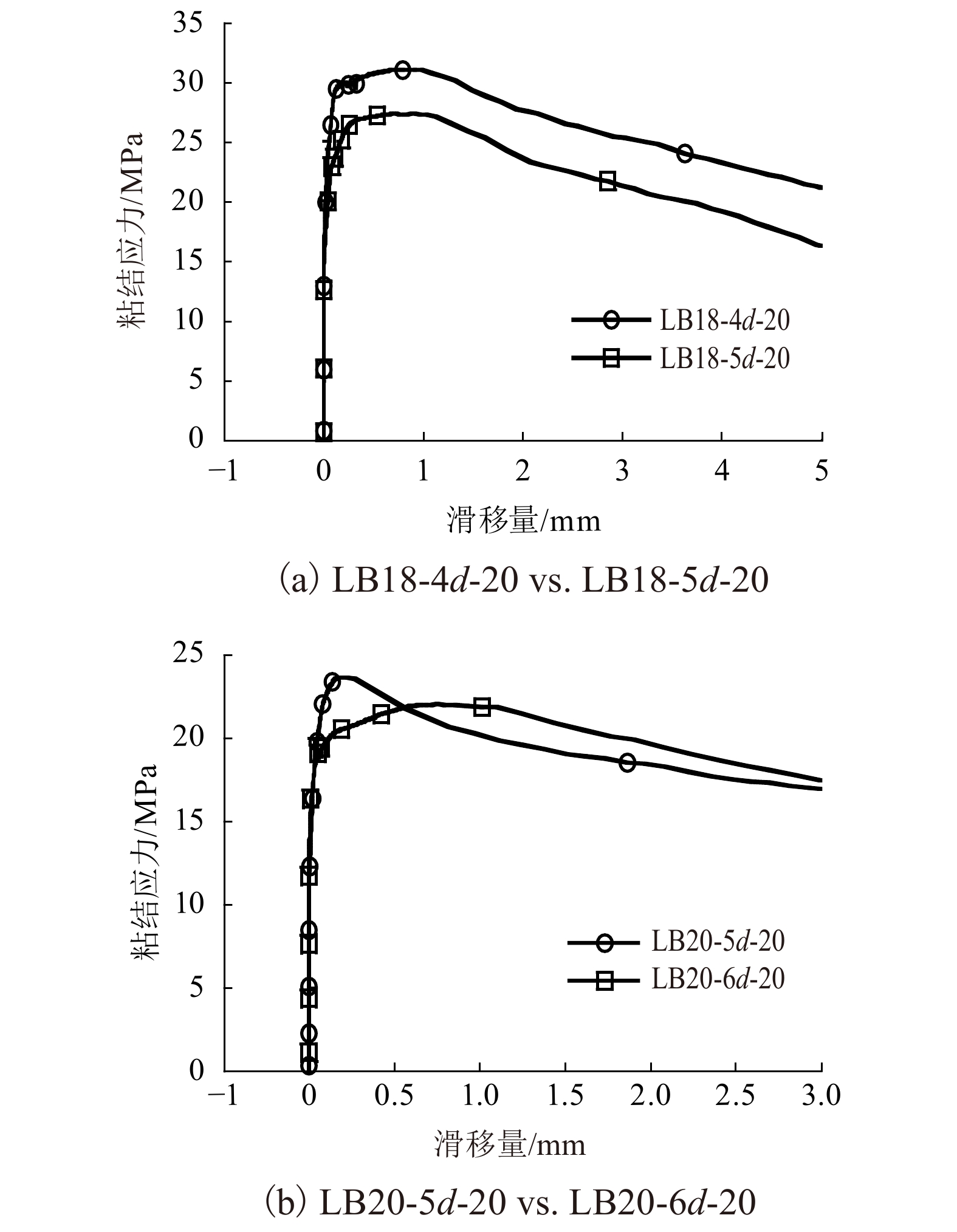

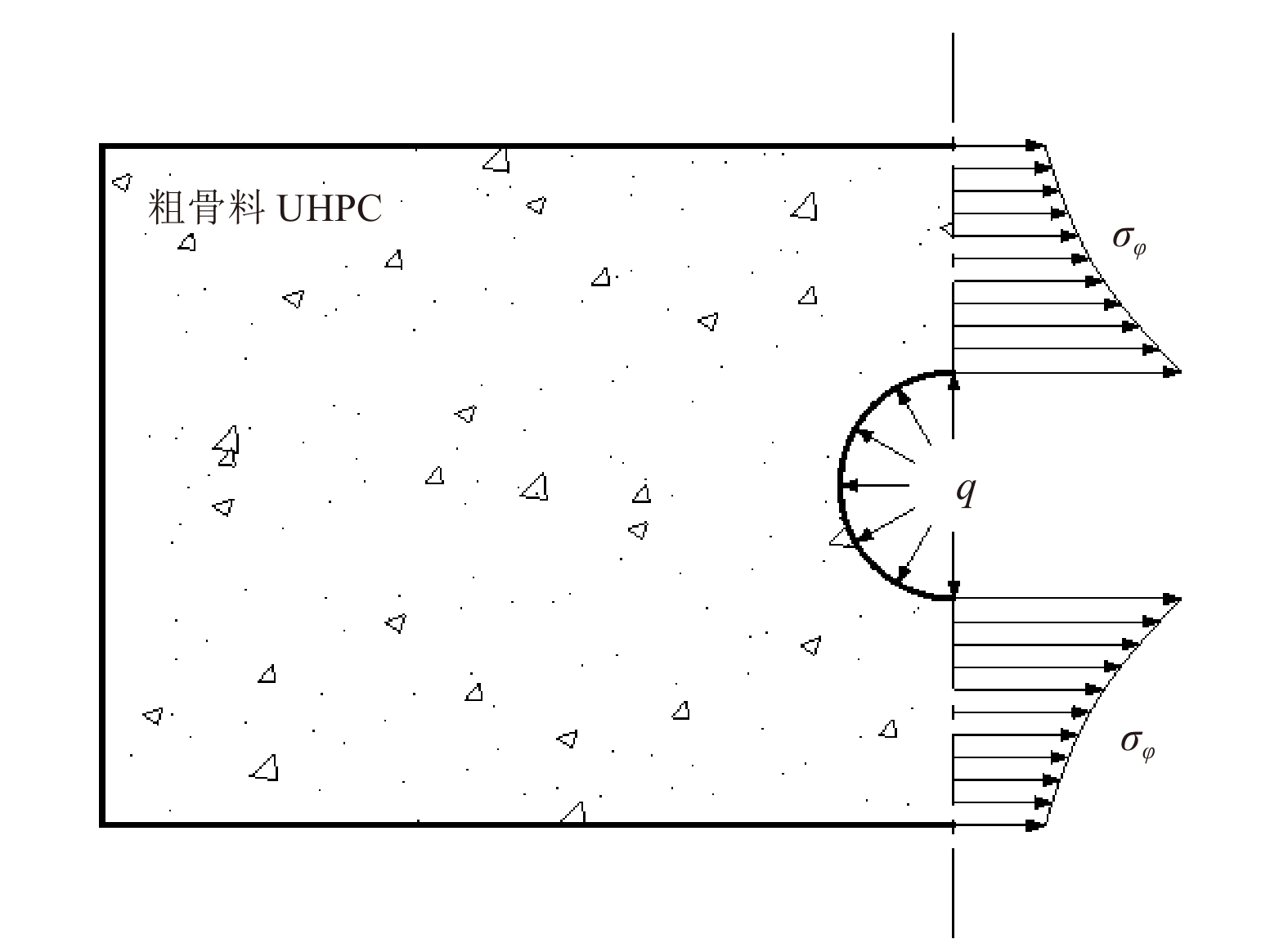

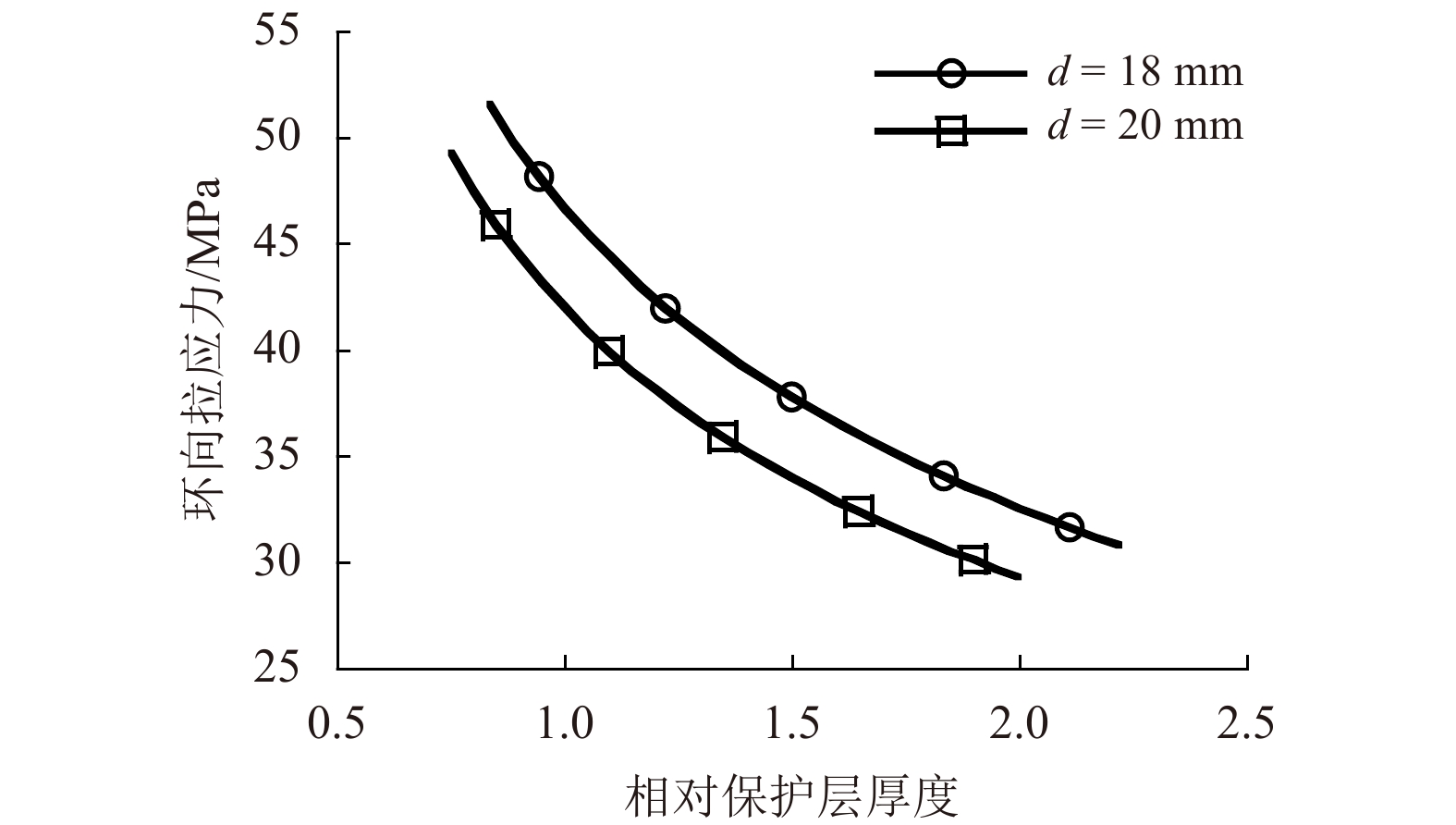

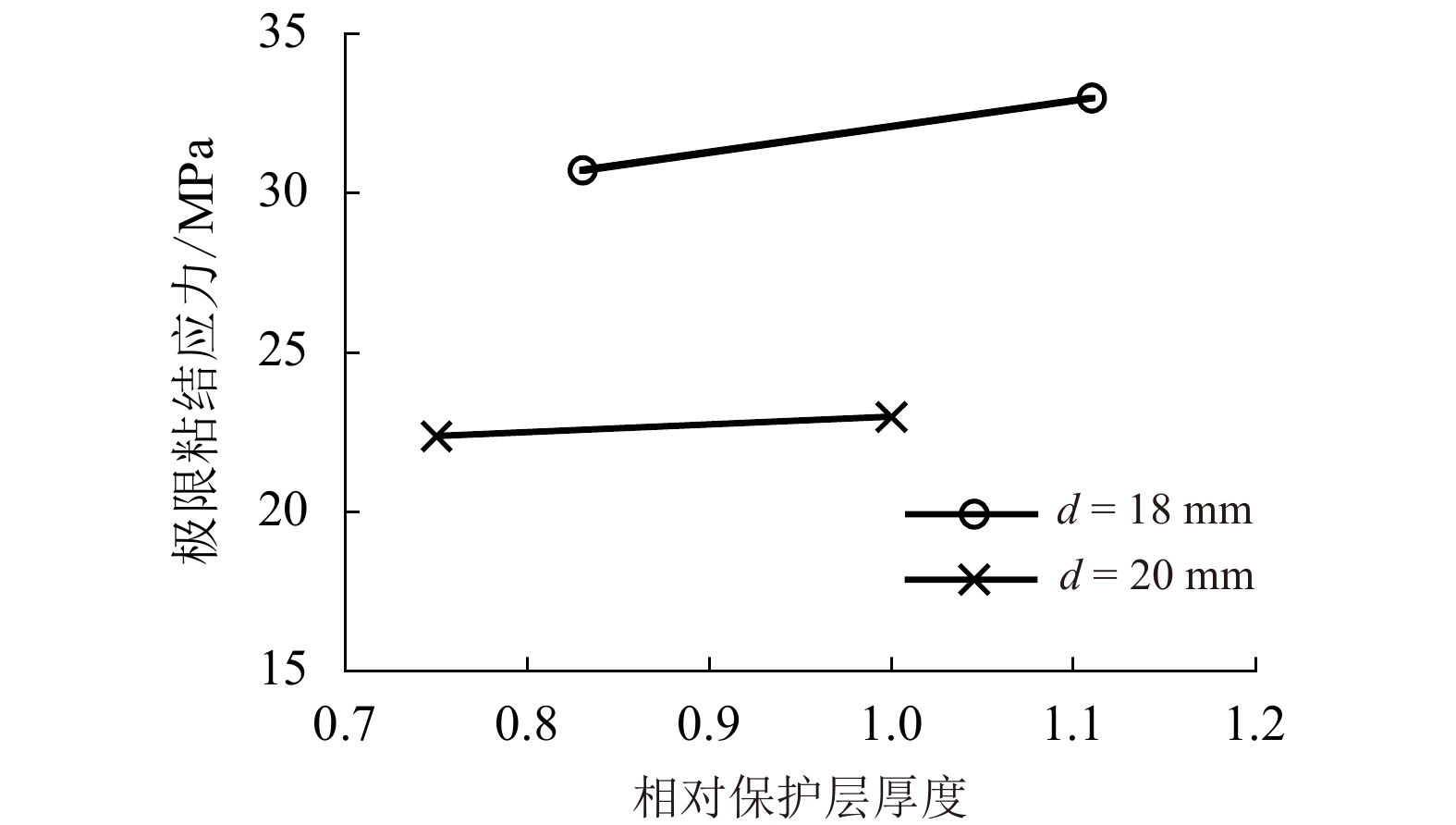

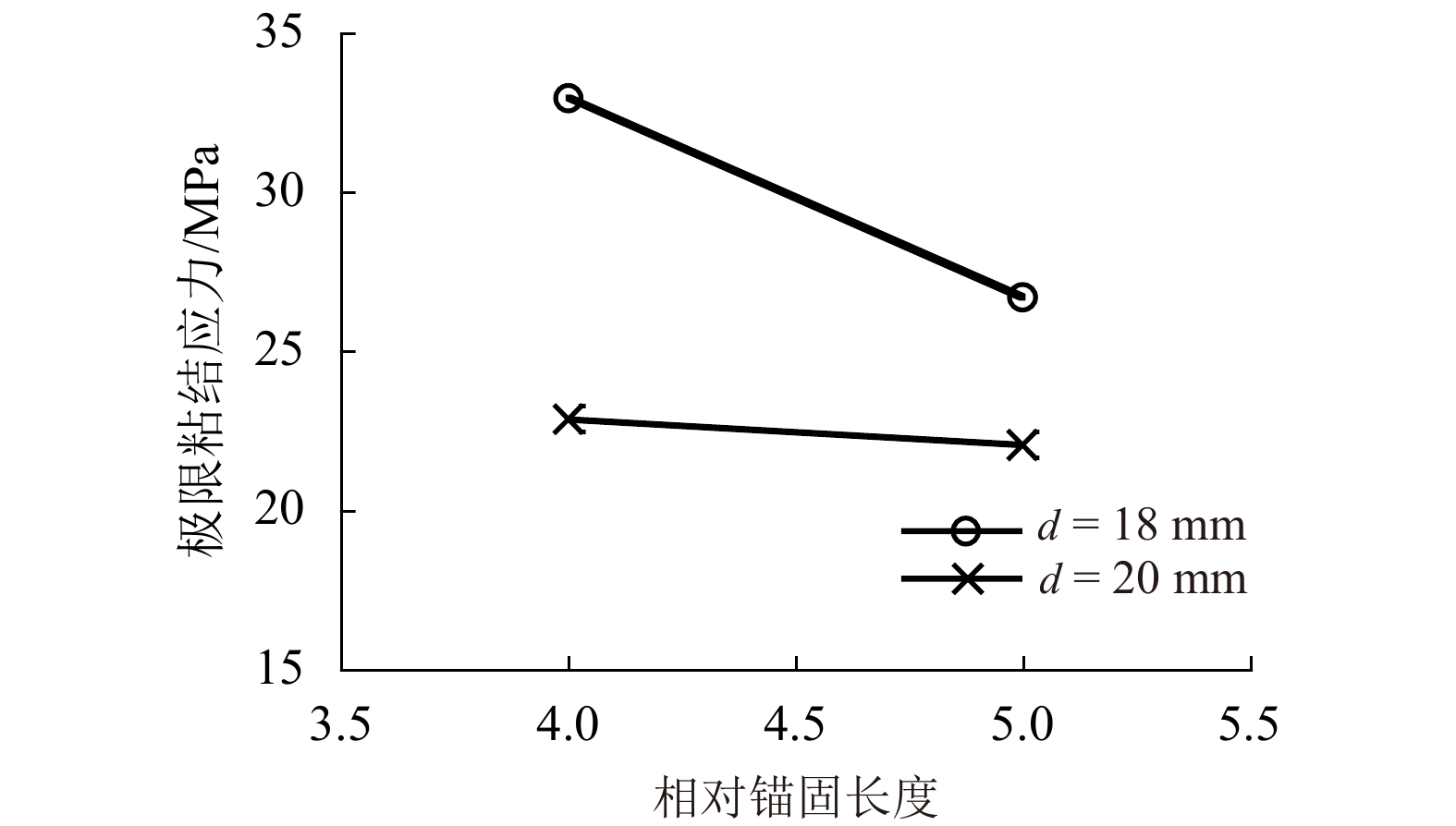

摘要: 为了研究含粗骨料超高性能混凝土(UHPC)与带肋钢筋的粘结性能,对6组钢筋-粗骨料UHPC中心拉拔试件进行了加载测试,研究了钢筋直径、保护层厚度、粘结锚固长度对粘结应力的影响,基于厚壁圆筒理论和拉梅解答分析了保护层厚度的影响. 采用回归分析的方法得到了极限粘结应力的计算公式,并采用其他文献的试验结果验证了该公式的有效性. 研究结果表明:粗骨料UHPC与钢筋的粘结锚固破坏模式与活性粉末混凝土(RPC)相似,有“刮犁破坏”和“劈裂破坏”两种模式;粗骨料UHPC所需钢筋的最小保护层厚度略大于RPC,粘结锚固长度与RPC相近;保护层厚度、粘结锚固长度存在相互影响,粘结锚固长度足够时可适当减小保护层厚度;提出了带肋钢筋在粗骨料UHPC中保护层厚度和锚固长度的建议值.

-

关键词:

- 粗骨料超高性能混凝土(UHPC) /

- 粘结性能 /

- 破坏模式 /

- 粘结长度 /

- 保护层厚度

Abstract: To investigate the bonding performance between the reinforcement and coarse aggregate UHPC(ultra-high performance concrete), six sets of pulling out specimens were tested. The effect of reinforcement diameter, cover layer thickness, and anchorage length were quantitatively studied, and further analysis based on the classic thick-cylinder theory and Lame Formula were conducted to obtain the influence of cover layer thickness. The formula for estimating the peak bonding stress was obtained through regression analysis, which was validated with the several physical tests. According to the results, the bonds between the reinforcement and coarse aggregate UHPC have similar failure modes with that of RPC(reactive powder concrete), including " wipe failure” and " split failure”. The thickness of cover layer in coarse aggregate UHPC is a little larger than that in RPC, while the demand of anchorage length is almost the same. The cover layer thickness and anchorage length have interactive effect on each other, meaning that sufficient anchorage length can reduce the requirement of cover layer thickness. Finally, the suggested anchorage length is presented. -

表 1 试验用粗骨料UHPC配合比

Table 1. Mix proportion of coarse aggressive UHPC

水泥 微硅粉 河砂 碎石 钢纤维 水 外加剂 786 136 901 410 210 159 18 表 2 粗骨料UHPC力学性能指标

Table 2. Mechanical characteristics of coarse aggressive UHPC

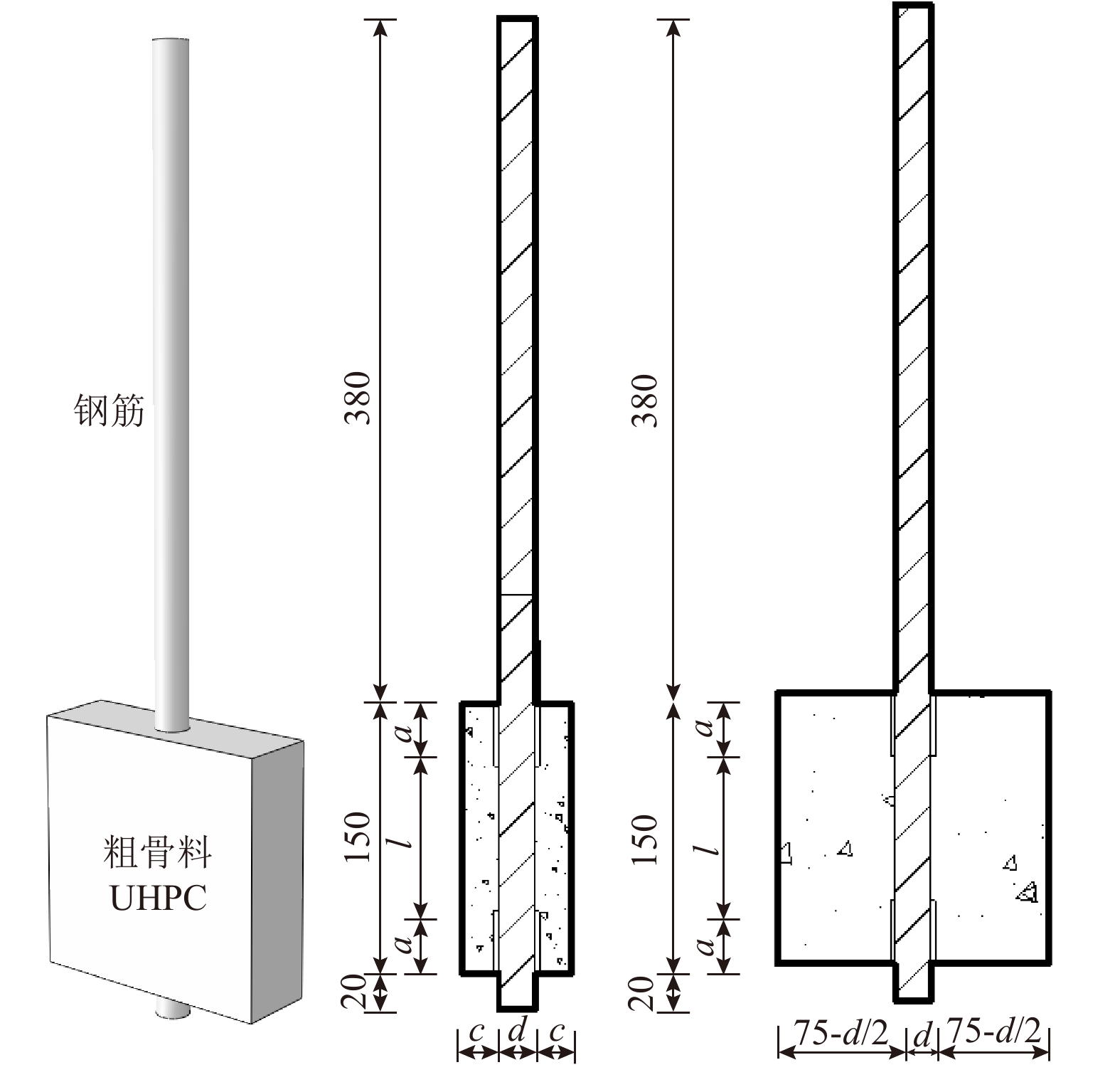

类别 fcu/MPa ft/MPa Ec/GPa 粗骨料UHPC 177.1 13.8 59.9 RPC 168.6 14.6 47.6 表 3 钢筋-UHPC中心拔出试件尺寸参数

Table 3. Parameters of specimens

试件编号 c d a l LB18-4d-15 15 18 39 72 LB18-4d-20 20 18 39 72 LB18-5d-20 20 18 30 90 LB20-5d-15 15 20 25 100 LB20-5d-20 20 20 25 100 LB20-6d-20 20 20 15 120 注:以LB18-4d-15为例说明试件编号规则,该试件标号

表示:钢筋直径为18 mm,粘结锚固长度取4倍钢筋

直径,保护层厚度为15 mm.表 4 粘结应力与钢筋应力

Table 4. Bonding stress and steel stress

试件编号 τcr τu σcr σu 破坏模式 LB18-4d-15 26.37 30.70 421.9 491.2 劈裂破坏 LB18-4d-20 24.59 33.01 393.4 528.2 刮犁破坏 LB18-5d-20 21.66 26.72 433.2 534.4 刮犁破坏 LB20-5d-15 19.87 22.40 397.4 448.0 劈裂破坏 LB20-5d-20 19.74 22.96 394.8 459.2 劈裂破坏 LB20-6d-20 20.35 22.10 488.4 530.4 刮犁破坏 注:根据材料性能试验,直径18 mm 和20 mm 的钢筋实测屈服强度分别是470 MPa和457 MPa. 表 5 粘结应力的拟合精度

Table 5. Accuracy of the regression analysis of the bonding stress

试件编号 τu,t/MPa τu,c/MPa 比值 LB18-4d-15 30.70 30.39 1.014 0 LB20-5d-15 22.40 22.31 1.004 0 LB18-4d-20 33.01 32.54 1.014 6 LB20-5d-20 22.96 25.22 0.910 2 LB18-5d-20 26.72 26.51 1.007 6 LB20-6d-20 22.10 20.92 1.056 6 表 6 式(5)精度校对

Table 6. Validation of quation(5)

试件 d/mm l/mm c/mm ${\tau _{{\rm{u,t}}}}$/

MPa${\tau _{{\rm{u,c}}}}$/

MPa比值 1 16 48 12 31.1 36.2 0.858 1 2 16 48 22 36.00 36.9 0.975 1 3 16 48 32 41.9 37.6 1.114 4 注:所选RPC试件混凝土抗压强度 fcu = 147.1 MPa,钢

纤维体积掺量Vf = 2%.表 7 最小锚固长度

Table 7. Calculation for the minimum anchorage length

试件 fy/MPa ${\tau _{\rm{u}}}$/MPa la/mm 建议锚固长度 LB18-4d-20 470 32.54 65.00 4d LB20-6d-20 457 20.92 109.22 6d -

FEHLING E, SCHMIDT M, WALRAVEN J, et al. Ultra-high performance UHPC: Fundamentals, design, examples[M]. Berlin Germany: Ernst & Sohn, 2014: 1-3 ROSSI P. Ultra-high performance fiber-reinforced concretes[J]. Concrete International, 2001, 23(12): 46-52. GRAYBEAL B. Ultra-high performance concrete [R]. [S.l.]: Federal Highway Administration, 2011 GRAYBEAL B. Material property characterization of ultra-high performance concrete[R]. [S.l.]: Federal Highway Administration, 2006 AFGC. Ultra high performance fiber-reinforced concretes interim recommendations[M]. Paris: AFGC Publication, 2002: 7-9 SCHEYDT J, HEROLD G, MUELLER H S, et al. Development and application of UHPC convenience blends[C]//Second International Symposium on Ultra High Performance Concrete. Kassel: Kassel University, 2008: 69-76 邓宗才,袁常兴. 高强钢筋与活性粉末混凝土粘结性能的试验研究[J]. 土木工程学报,2014,47(3): 69-78.DENG Zongcai, YUAN Changxing. Experimental study on bond capability between high strength rebar and reactive powder concrete[J]. China Civil Engineering Journal, 2014, 47(3): 69-78. 李鹏,郑七振,龙莉波,等. 钢筋埋长对超高性能混凝土与钢筋粘结性能的影响[J]. 建筑施工,2016,38(12): 1722-1723.LI Peng, ZHENG Qizhen, LONG Libo, et al. Impact of embedded rebar length on adhesive property between Ultra High Performance Concrete and rebar[J]. Building Construction, 2016, 38(12): 1722-1723. 安明喆,张盟. 变形钢筋与活性粉末混凝土的粘结性能试验研究[J]. 中国铁道科学,2007,28(2): 50-54. doi: 10.3321/j.issn:1001-4632.2007.02.009AN Mingzhe, ZHANG Meng. Experimental research of bond capability between deformed bars and reactive powder concrete[J]. China Railway Science, 2007, 28(2): 50-54. doi: 10.3321/j.issn:1001-4632.2007.02.009 贾方方. 钢筋与活性粉末混凝土粘结性能的试验研究[D]. 北京: 北京交通大学, 2013 程俊,刘加平,张丽辉. 含粗骨料超高性能混凝土单轴拉伸性能及机理分析[J]. 混凝土与水泥制品,2015,12: 1-5. doi: 10.3969/j.issn.1000-4637.2015.01.001CHENG Jun, LIU Jiaping, ZHANG Lihui. Properties of uniaxial tension and mechanism of strengthening and toughening of ultra-high performance concrete containing coarse aggregate[J]. China Concrete and Cement Products, 2015, 12: 1-5. doi: 10.3969/j.issn.1000-4637.2015.01.001 BOLANDER J E, CHOI S, DUDDUKURI S R. Fracture of fiber-reinforced cement composites:effects of fiber dispersion[J]. International Journal of Fracture, 2008, 154(1/2): 73-86. DEEB R, KARIHALOO B L, KULASEGARAM S. Reorientation of short steel fibres during the flow of self-compacting concrete mix and determination of the fibre orientation factor[J]. Cement and Concrete Research, 2014, 56: 112-120. doi: 10.1016/j.cemconres.2013.10.002 闫光杰,阎贵平,安明喆,等. 200 MPa级活性粉末混凝土试验研究[J]. 铁道学报,2004,26(2): 116-119. doi: 10.3321/j.issn:1001-8360.2004.02.022YAN Guangjie, YAN Guiping, AN Mingzhe, et al. Experimental study on 200 MPa reactive powder concrete[J]. Journal of The China Railway Society, 2004, 26(2): 116-119. doi: 10.3321/j.issn:1001-8360.2004.02.022 中国工程建设标准化协会标准. 钢纤维混凝土试验方法: CECS 13—2009[S]. 北京: 中国计划出版社, 2010 -

下载:

下载: