Micromechanical Analysis of Steel Fiber Corrosion in Ultra-high Performance Concrete

-

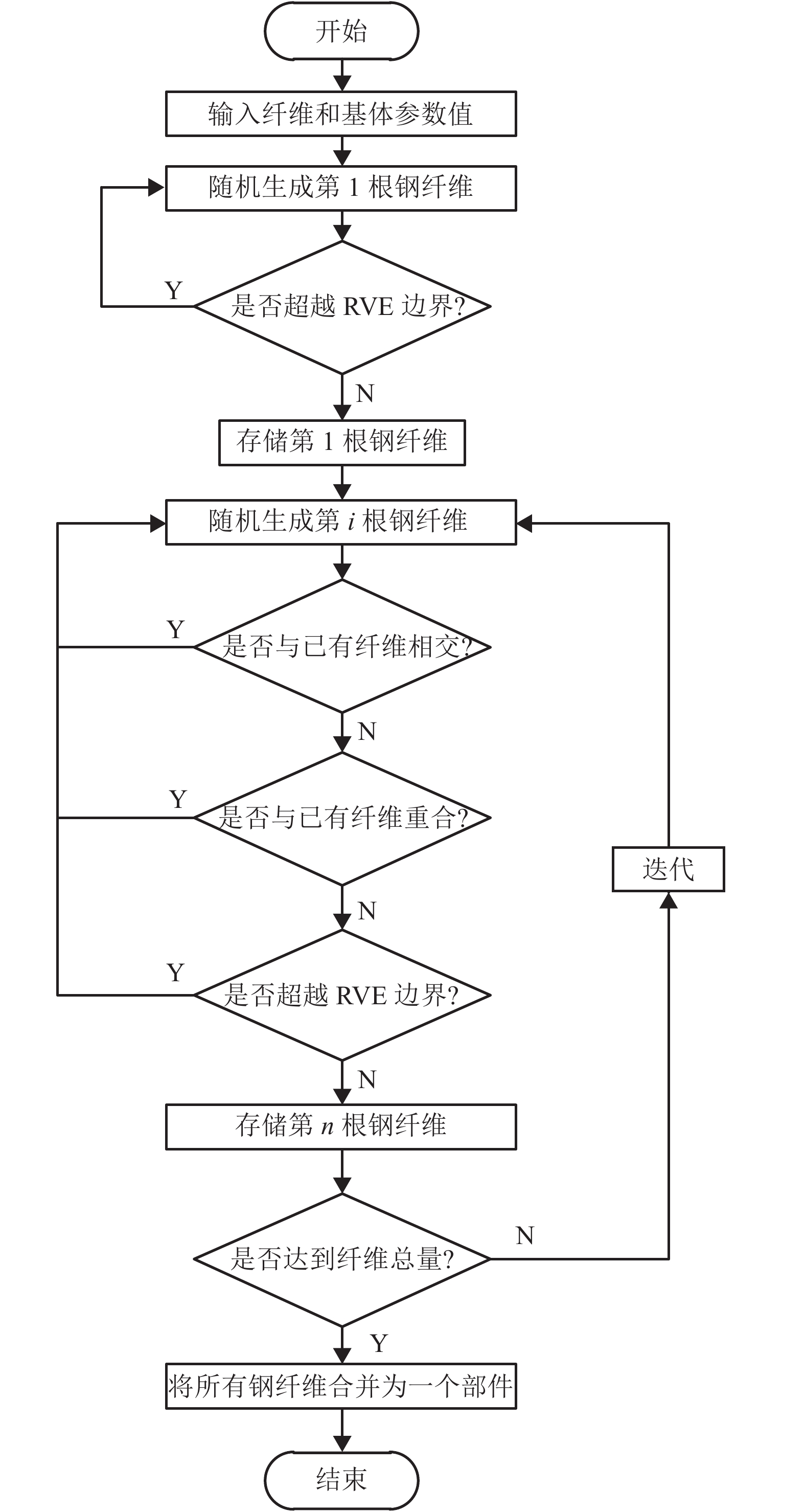

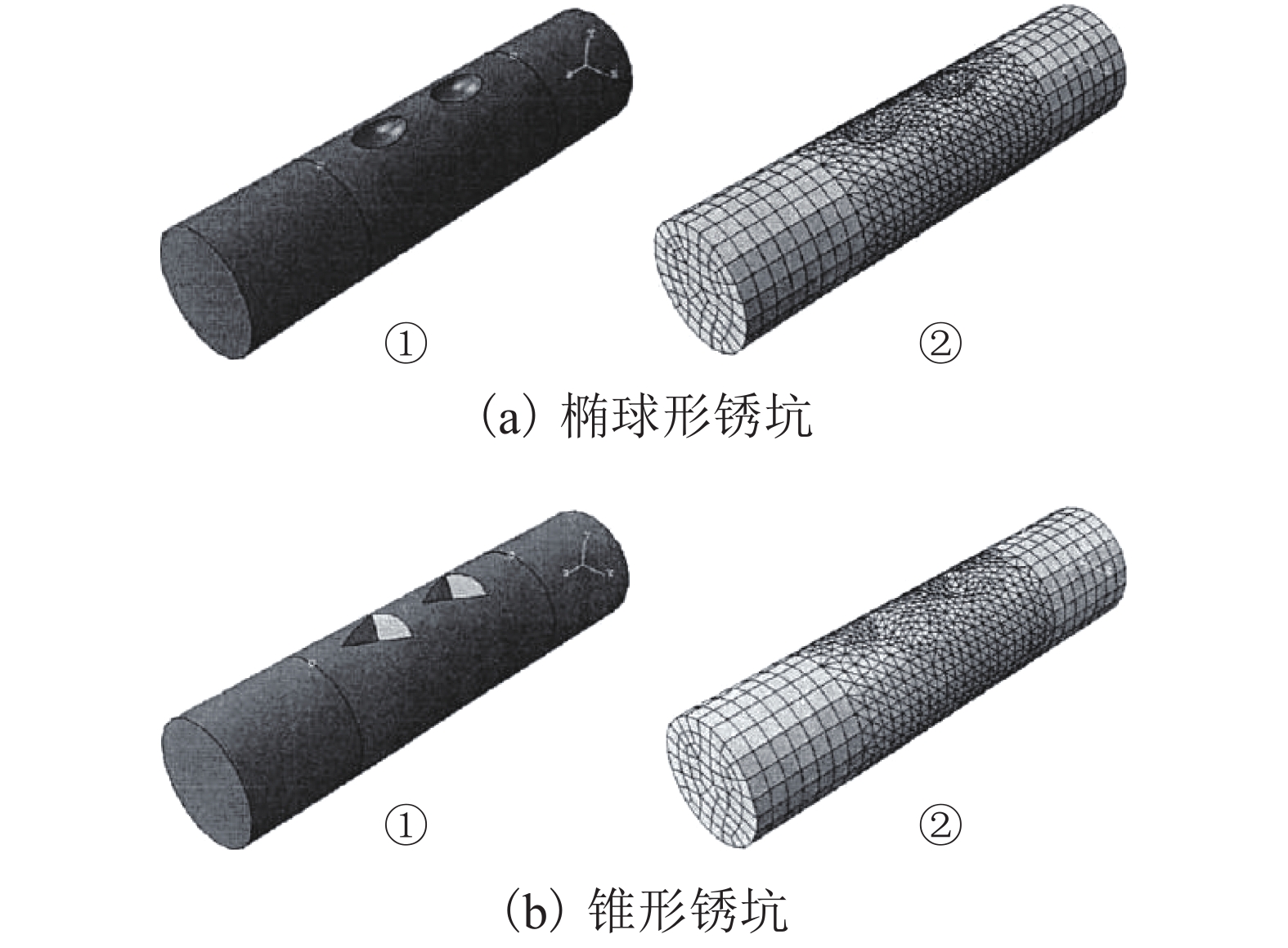

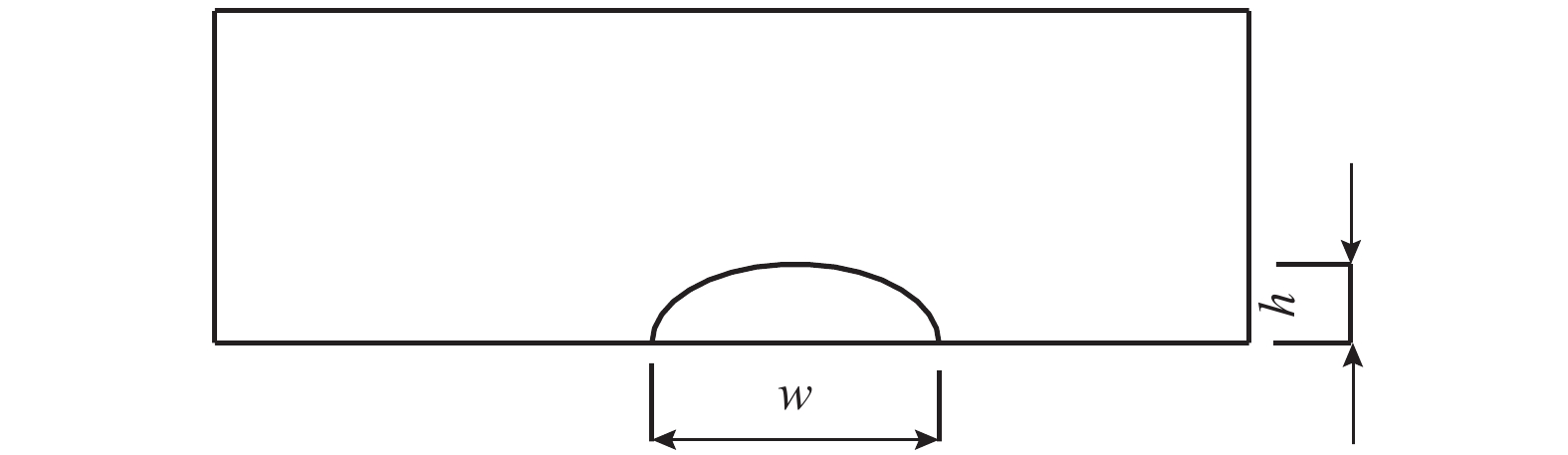

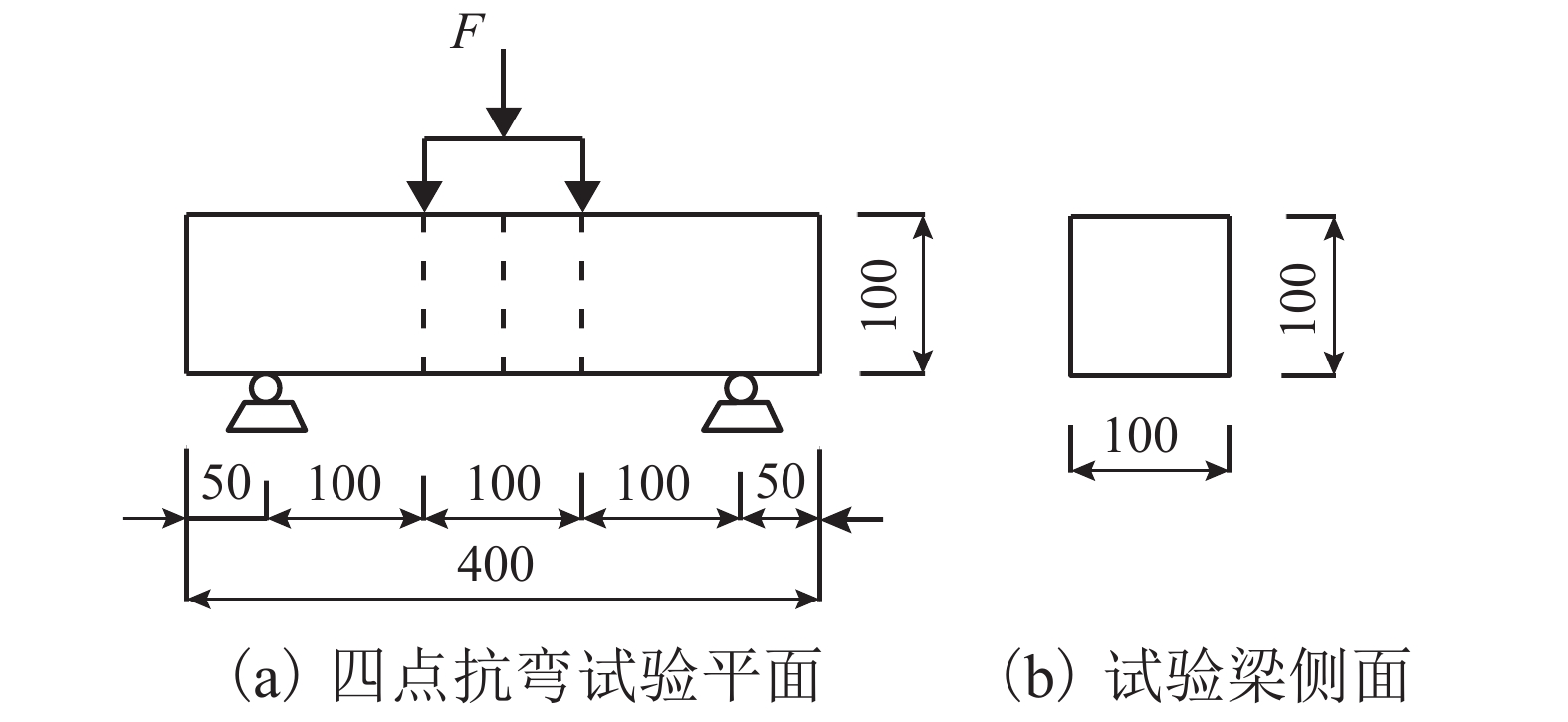

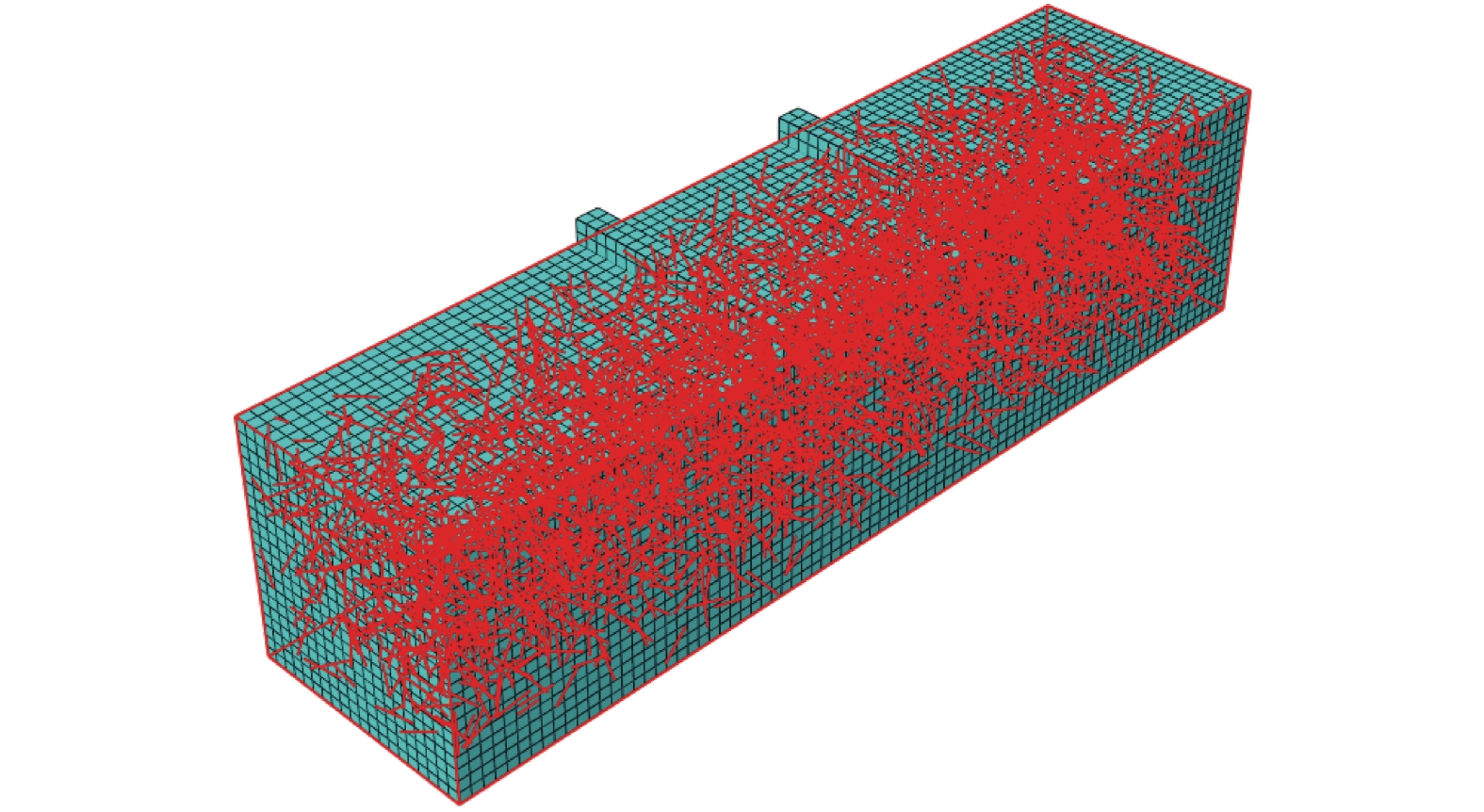

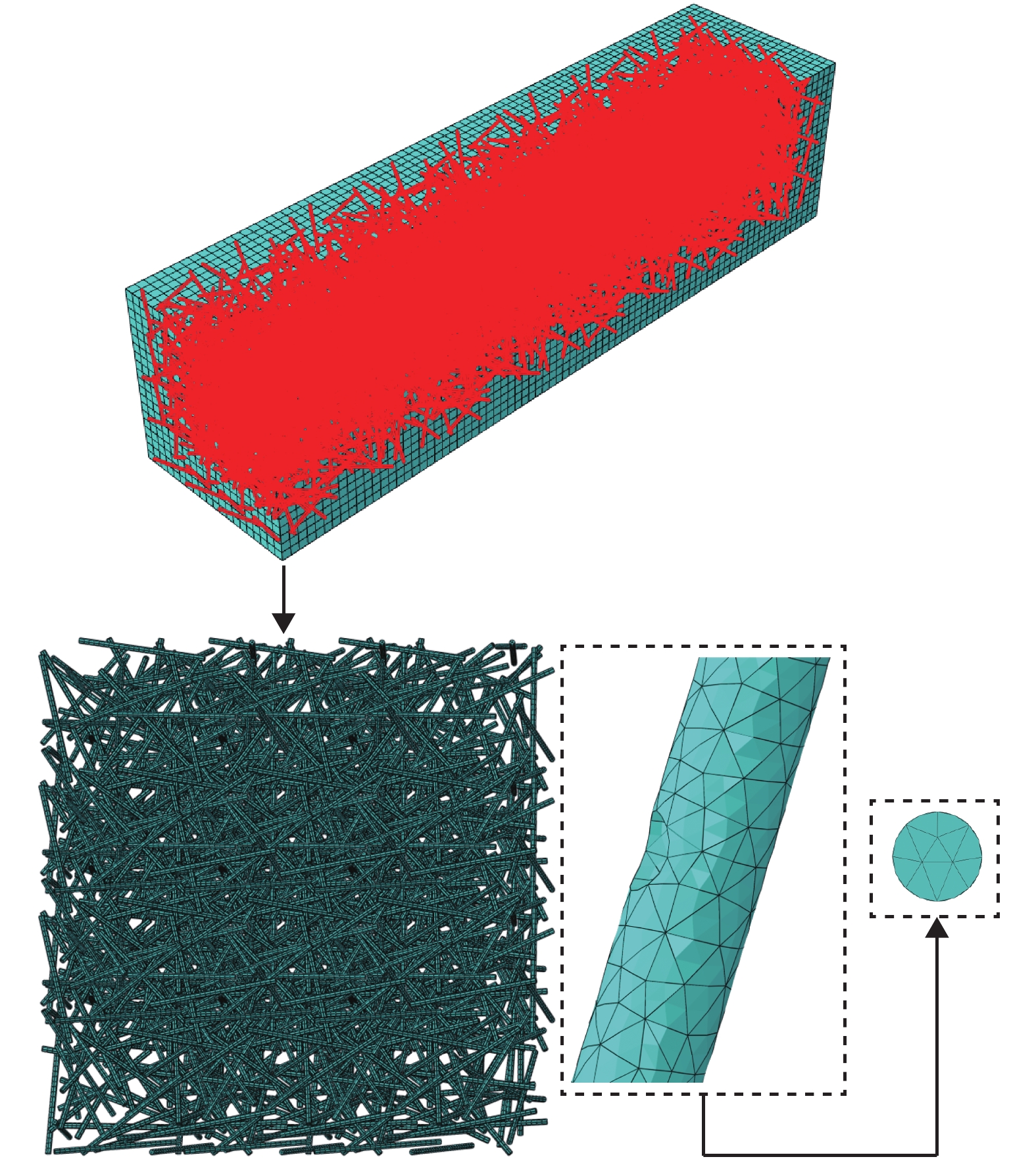

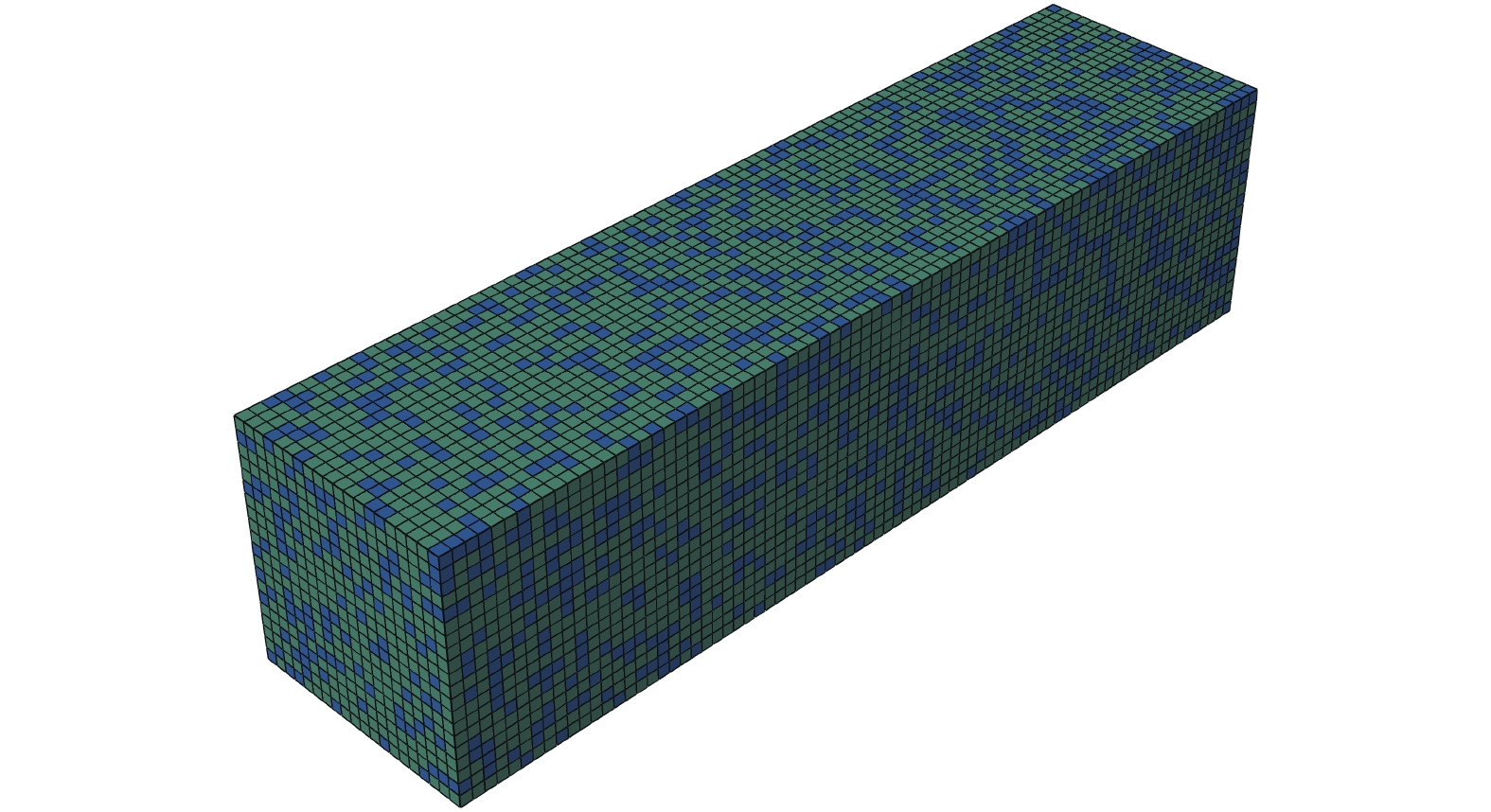

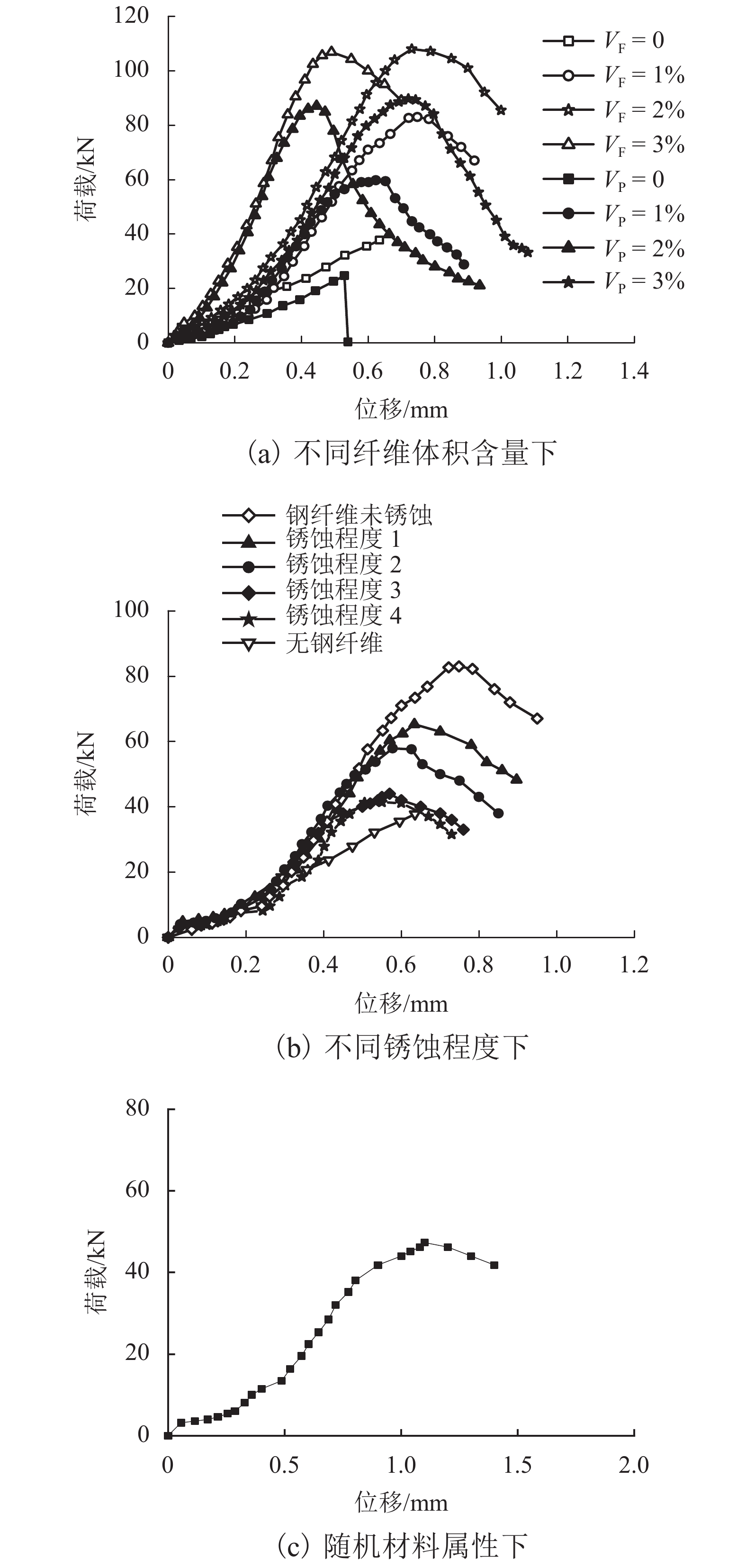

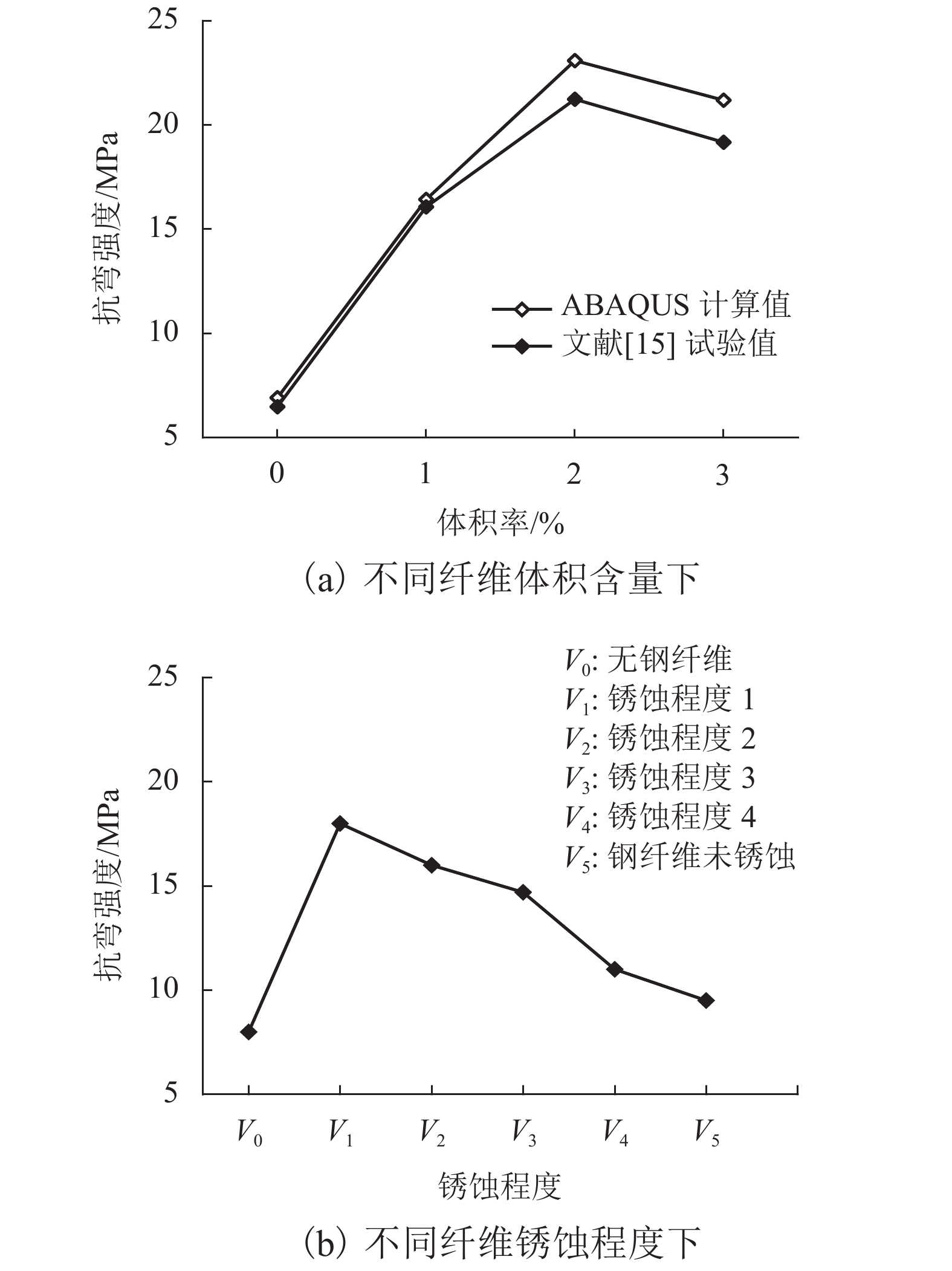

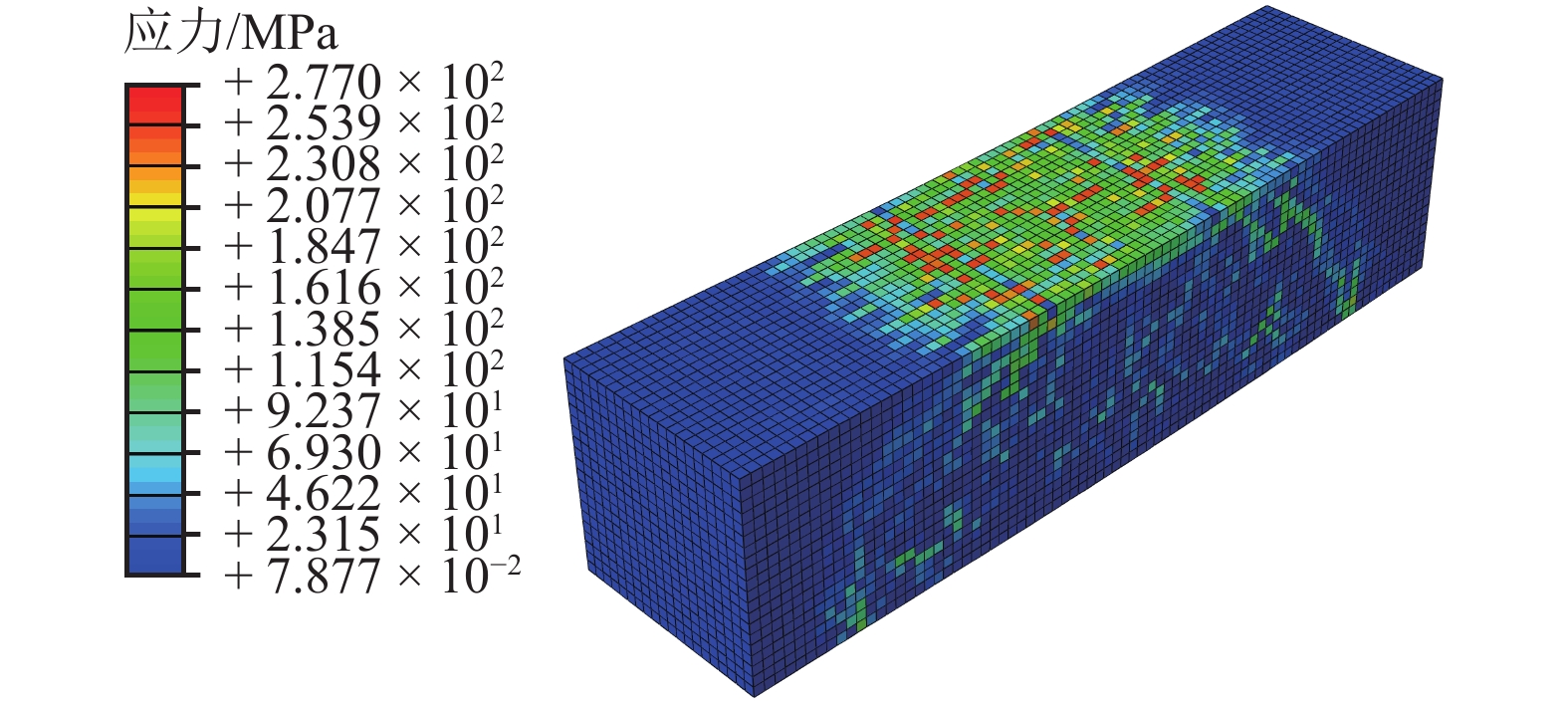

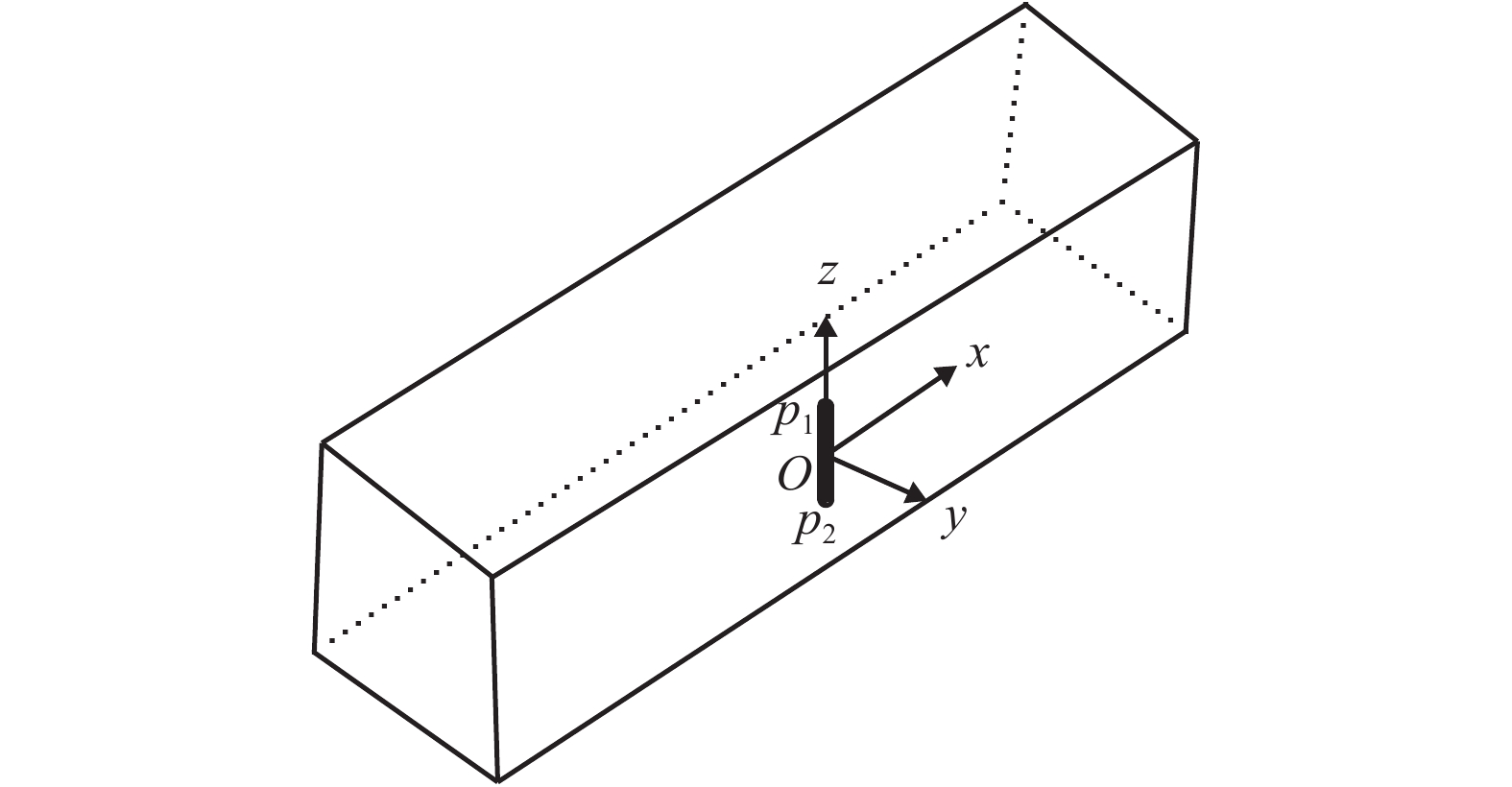

摘要: 为了研究钢纤维体积含量和锈蚀程度对结构强度和变形的影响,通过自行编写Python脚本文件,对ABAQUS软件进行二次开发,实现了钢纤维在超高性能混凝土(UHPC)基体中的大批量随机乱向均匀分布;在此基础上研究了UHPC带缺陷锈蚀模拟方法,进而探索了钢纤维锈蚀的等效方法;最后以UHPC梁四点抗弯试验为例,对UHPC细观力学分析方法、锈蚀的模拟方法和等效手段进行了验证. 研究结果表明:当纤维体积含量为2% 时,UHPC梁的抗弯曲性能最佳;影响锈蚀效应的关键因素为锈蚀造成纤维截面削弱、锈坑附近产生应力集中、界面粘结遭到破坏;采用随机材料属性分配的方式,仅局限于模拟UHPC梁的宏观变形,无法准确模拟应力场分布情况.

-

关键词:

- 超高性能混凝土(UHPC) /

- 细观力学分析 /

- 钢纤维锈蚀模拟 /

- ABAQUS二次开发 /

- PYTHON算法 /

- 模型试验

Abstract: In order to study the influence of the volume content and corrosion degree of the steel fiber on the strength and deformation of the structure, the large-volume randomization of the steel fiber in ultra-high performance concrete (UHPC) matrix was realized by the ABAQUS software redeveloped by self-compiling Python script file. Based on this, the UHPC defect corrosion simulation method was developed and the equivalent method of the steel fiber corrosion was explored. Finally, the UHPC beam four-point bending test was taked as an example to verify the UHPC micromechanics analysis method, corrosion simulation method, and equivalent means. The results show that when the fiber volume content is 2%, the UHPC beam has the best bending resistance; corrosion weakens the cross-section of fibers, stress concentration near the corrosion pits and the destroyed interfacial bonding are the key factors affecting the corrosion effect. The random material property distribution method is limited to simulate the macroscopic deformation of UHPC beams, and can’t accurately simulate the distribution of stress field. -

表 1 锈坑参数

Table 1. Pit parameters

锈蚀程度 锈坑深度/mm 锈坑宽度/mm 1 0.08 0.30 2 0.08 1.10 3 0.18 0.30 4 0.18 1.10 -

赵筠,廉慧珍,金建昌. 钢-混凝土复合的新模式——超高性能混凝土(UHPC/UHPFRC)之一:钢-混凝土复合模式的现状、问题及对策与UHPC发展历程[J]. 混凝土世界,2013,52: 56-69. doi: 10.3969/j.issn.1674-7011.2013.05.013ZHAO Jun, LIAN Huizhen, JIN Jianchang. A new model of steel concrete composite— ultra-high performance concrete (UHPC/UHPFRC):the current situation,problems and countermeasures of steel concrete composite model and the development of UHPC[J]. China Concrete, 2013, 52: 56-69. doi: 10.3969/j.issn.1674-7011.2013.05.013 AITCIN P C. High-performance concrete[M]. London: E & FN Spon, 2004: 22-30. WILLE K, NAAMAN A E, EL-TAWIL S, et al. Ultra-high performance concrete and fiber reinforced concrete:achieving strength and ductility without heat curing[J]. Materials & Structures, 2012, 45(3): 309-324. 阎培渝. 超高性能混凝土(UHPC)的发展与现状[J]. 混凝土世界,2010,15: 36-41. doi: 10.3969/j.issn.1674-7011.2010.02.010YAN Peiyu. Development and present situation of ultra-high performance concrete (UHPC)[J]. China Concrete, 2010, 15: 36-41. doi: 10.3969/j.issn.1674-7011.2010.02.010 PIMIENTA P, CHANVILLARD G. Durability of UHPFRC specimens kept in various aggressive environments[C]//10DBMC International Conference on Durability of Building Materials and Components. Paris: [s.n.], 2005: 17-20. TOUTLEMONDE F, BOUTEILLER V, PLATRET G, et al. Field demonstration of UHPFRC durability[J]. Concrete International, 2010, 10: 39-45. 赵军,李洪杰,高丹盈. 锈蚀后钢纤维和钢纤维混凝土的力学性能[J]. 建筑材料学报,2015,18(3): 409-414. doi: 10.3969/j.issn.1007-9629.2015.03.009ZHAO Jun, LI Hongjie, GAO Danying. Mechanical properties of steel fiber and steel fiber reinforced concrete after corrosion[J]. Journal of Building Materials, 2015, 18(3): 409-414. doi: 10.3969/j.issn.1007-9629.2015.03.009 高丹盈,陈刚,HADI M N S,et al. 锈蚀钢纤维力学性能及极限拉伸荷载计算方法[J]. 建筑材料学报,2016,19(3): 436-441. doi: 10.3969/j.issn.1007-9629.2016.03.004GAO Danying, CHEN Gang, HADI M N S, et al. Mechanical properties and calculation method for ultimate tensile load of corroded steel fibers[J]. Journal of Building Materials, 2016, 19(3): 436-441. doi: 10.3969/j.issn.1007-9629.2016.03.004 张研, 张子明. 材料细观力学[M]. 北京: 科学出版社, 2008: 10-15. 王娟,李庆斌,卿龙邦,等. 基于细观结构统计特征的混凝土几何代表体尺寸研究[J]. 工程力学,2012,29(12): 1-6. doi: 10.6052/j.issn.1000-4750.2011.05.0278WANG Juan, LI Qingbin, QING Longbang, et al. Studies on representative volume element size of concrete based on meso-structure statistics[J]. Engineering Mechanics, 2012, 29(12): 1-6. doi: 10.6052/j.issn.1000-4750.2011.05.0278 王文谈. 超高性能纤维增强混凝土(UHPFRC)的实验研究及低速冲击有限元模拟[D]. 成都: 西南交通大学, 2015. 徐亦冬. 混凝土中钢筋的不均匀锈蚀特征与本构关系[D]. 南京: 东南大学, 2013. 中国工程建设标准化协会标准. 纤维混凝土试验方法标准: CECS 13—2009[S]. 北京: 中国计划出版社, 2010. 杨克家, 李桅, 陈联盟. RPC损伤塑性本构模型建构及应用[C]// 第23届全国结构工程学术会议论文集(第Ⅱ册). 北京: [出版者不详], 2014: 161-167. 王文谈, 魏耀富, 蒋晗, 等.超高性能钢纤维增强混凝土力学性能的实验研究[J].应用数学和力学, 2014, 35(增刊1):295-298.WANG Wentan, WEI Yaofu, JIANG Han, et al. Mechanical properties of ultrahigh performance steel fiber reinforced concrete[J]. Experimental Study, 2014, 35 (S1): 295-298 ROSSI P. Development of new cement composite materials for construction[J]. Proceedings of the Institution of Mechanical Engineers,Part L:Journal of Materials:Design and Applications, 2005, 219(1): 67-74. doi: 10.1243/146442005X10193 王发洲,胡曙光,丁庆军,等. 高性能复合道路水泥混凝土的研究[J]. 中国公路学报,2000,13(3): 12-14. doi: 10.3321/j.issn:1001-7372.2000.03.004WANG Fazhou, HU Shuguang, DING Qingjun, et al. Research on the high performance composite road concrete[J]. China Journal of Highway and Transport, 2000, 13(3): 12-14. doi: 10.3321/j.issn:1001-7372.2000.03.004 -

下载:

下载: