Simulation and Verification of Dynamic Response of Railway Wagon on Railway Track

-

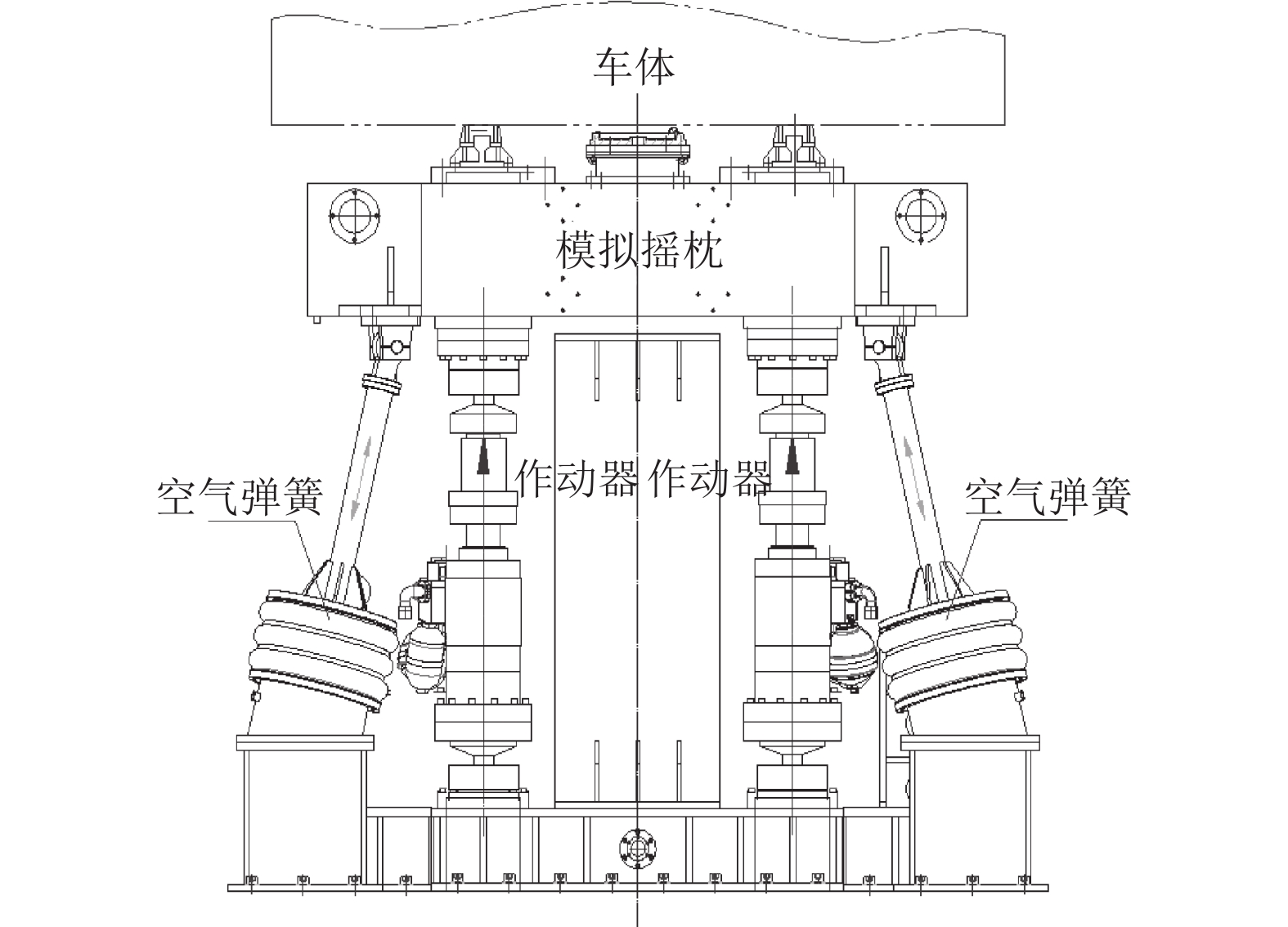

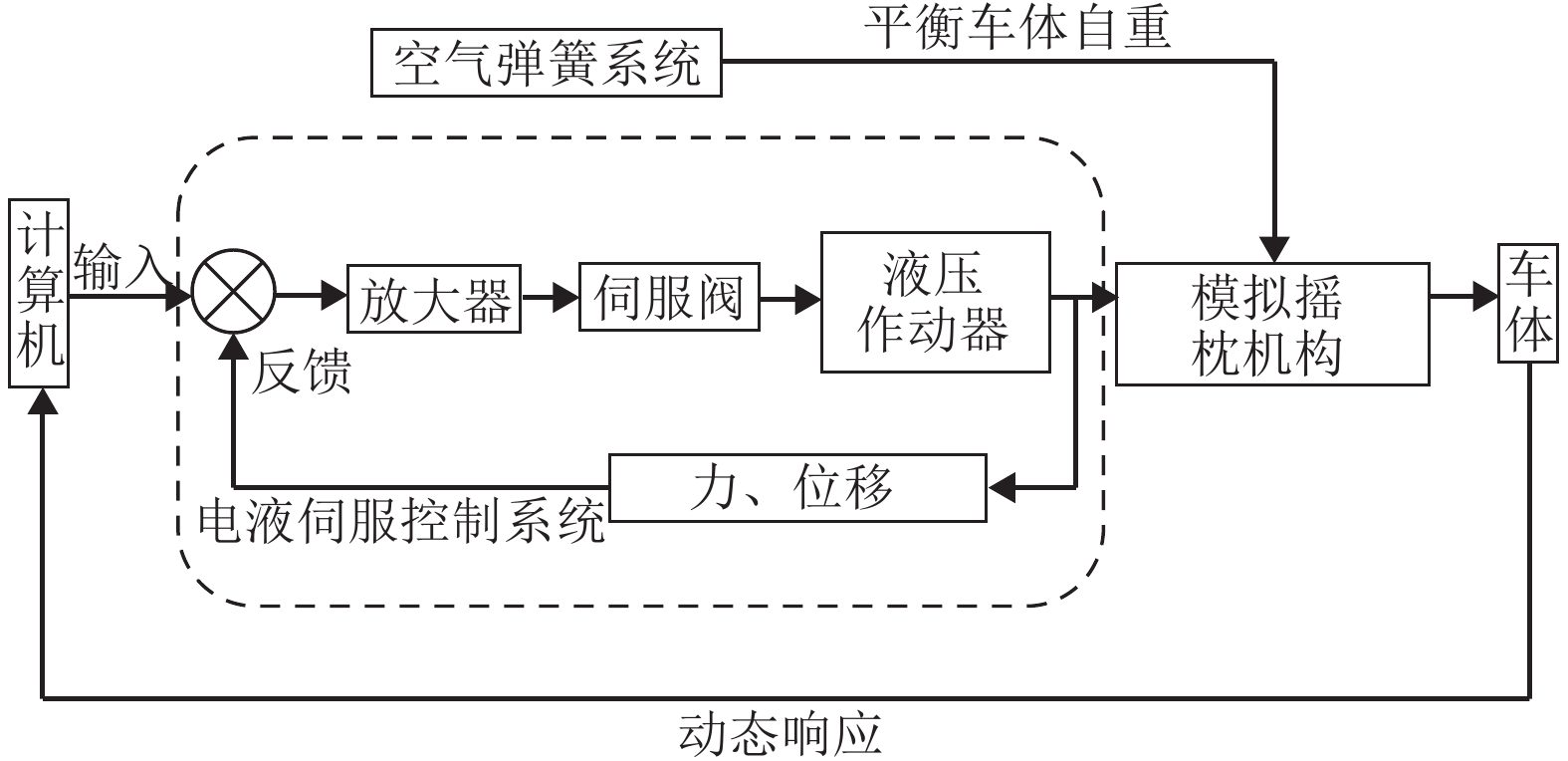

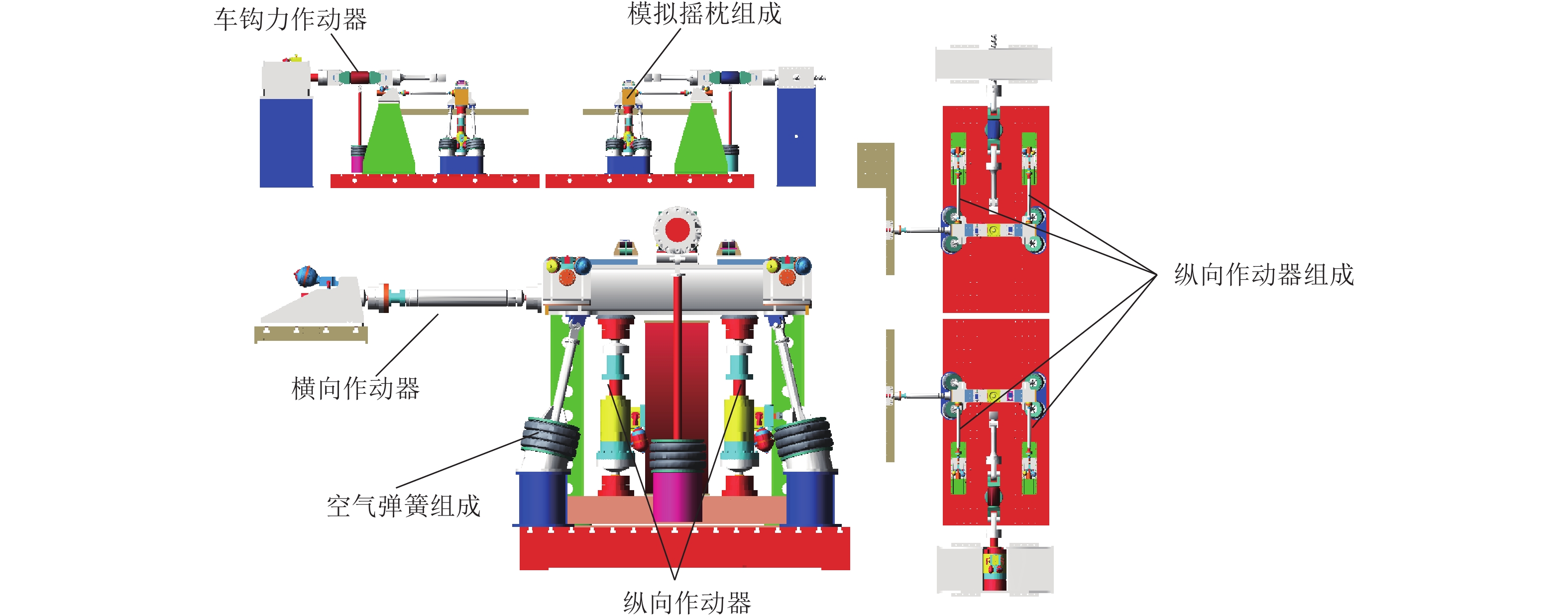

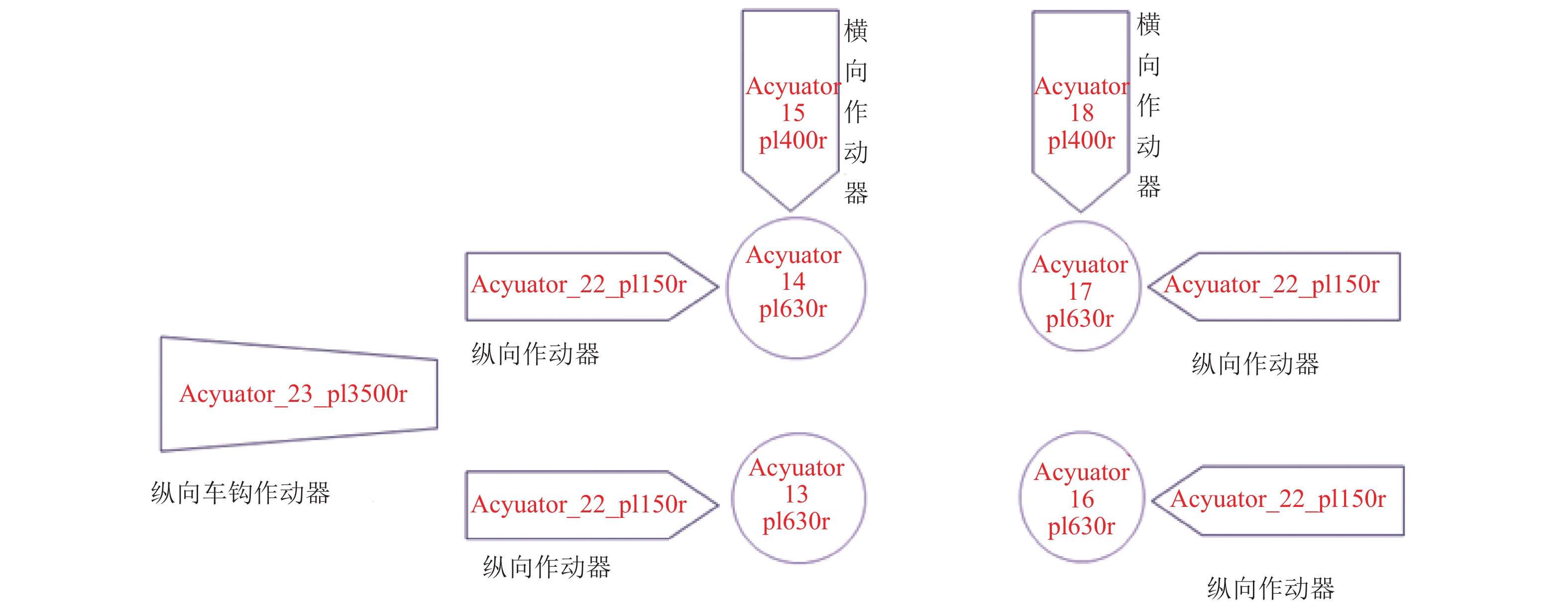

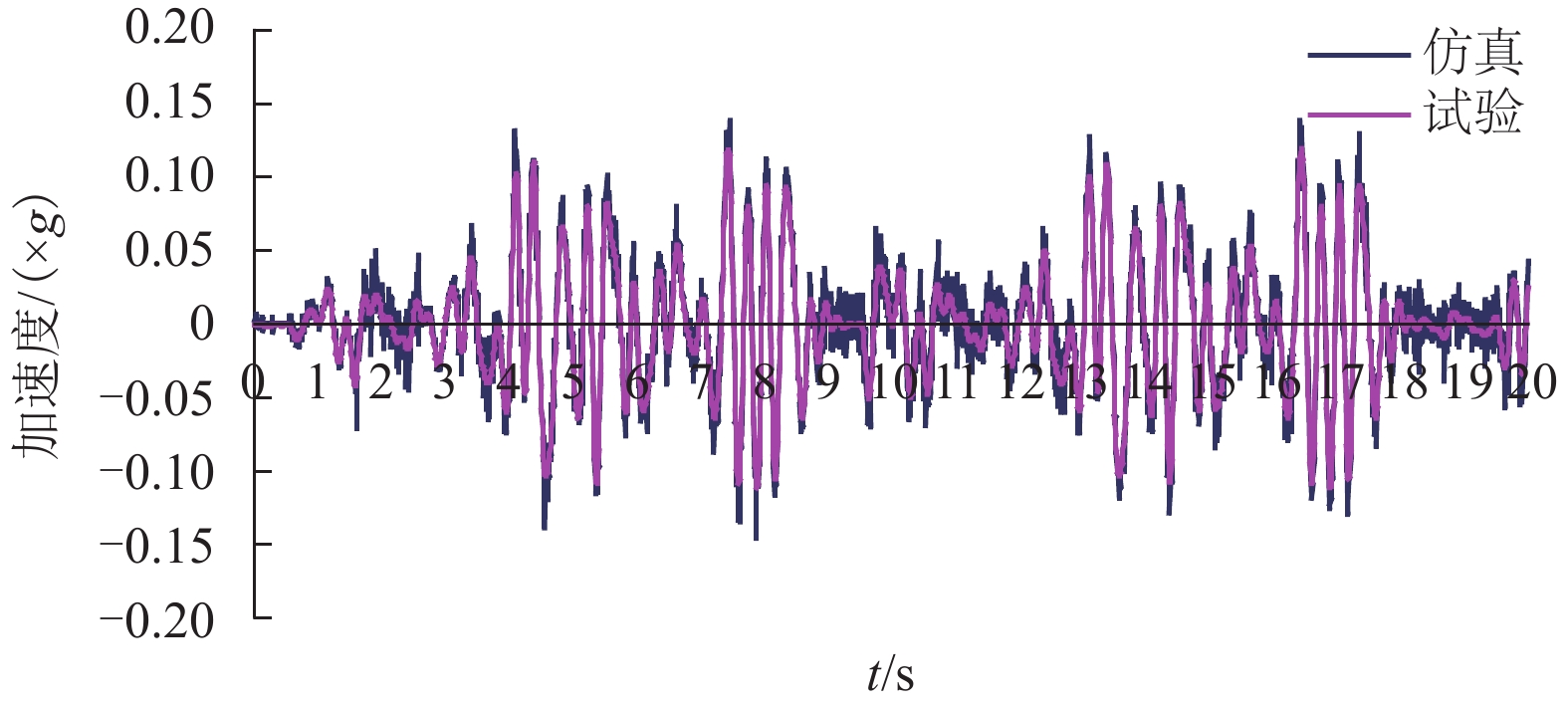

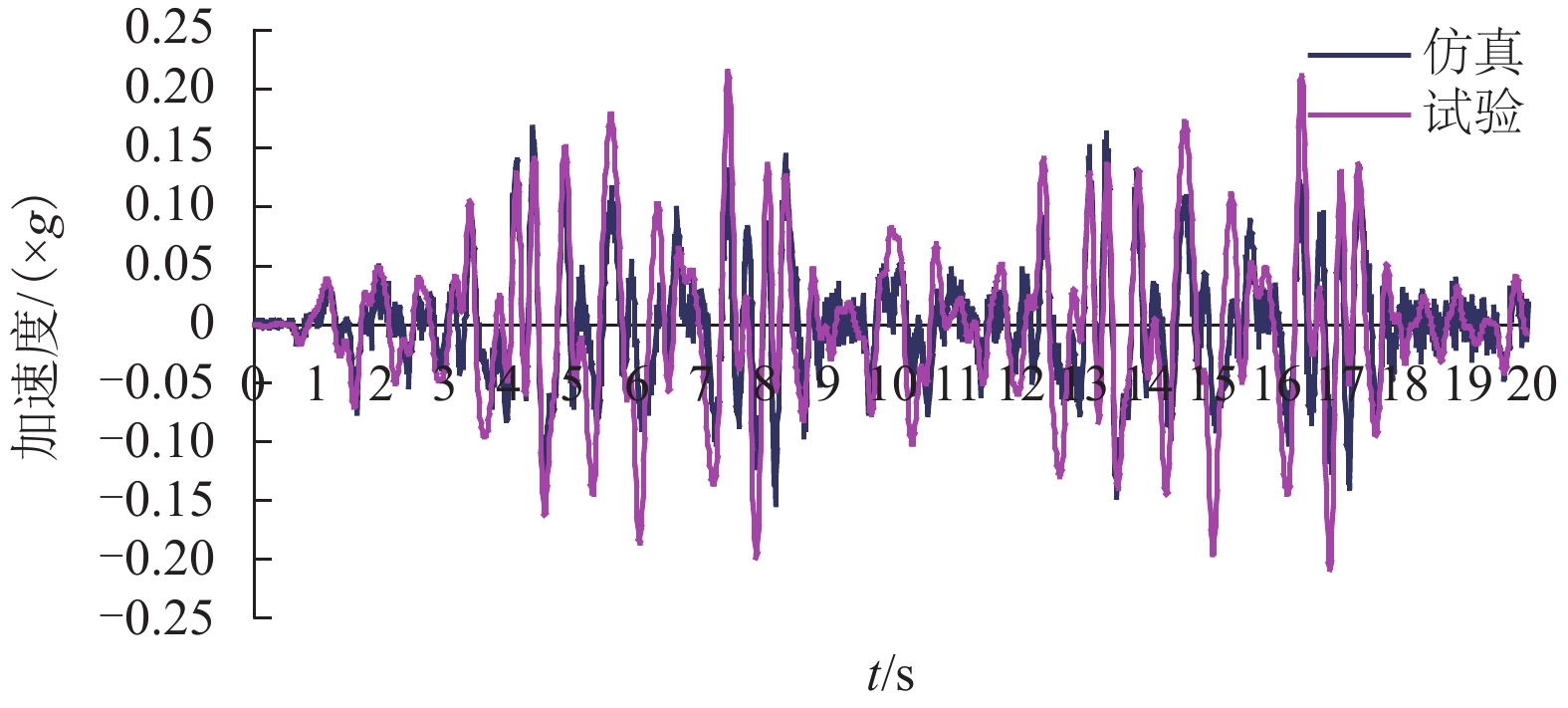

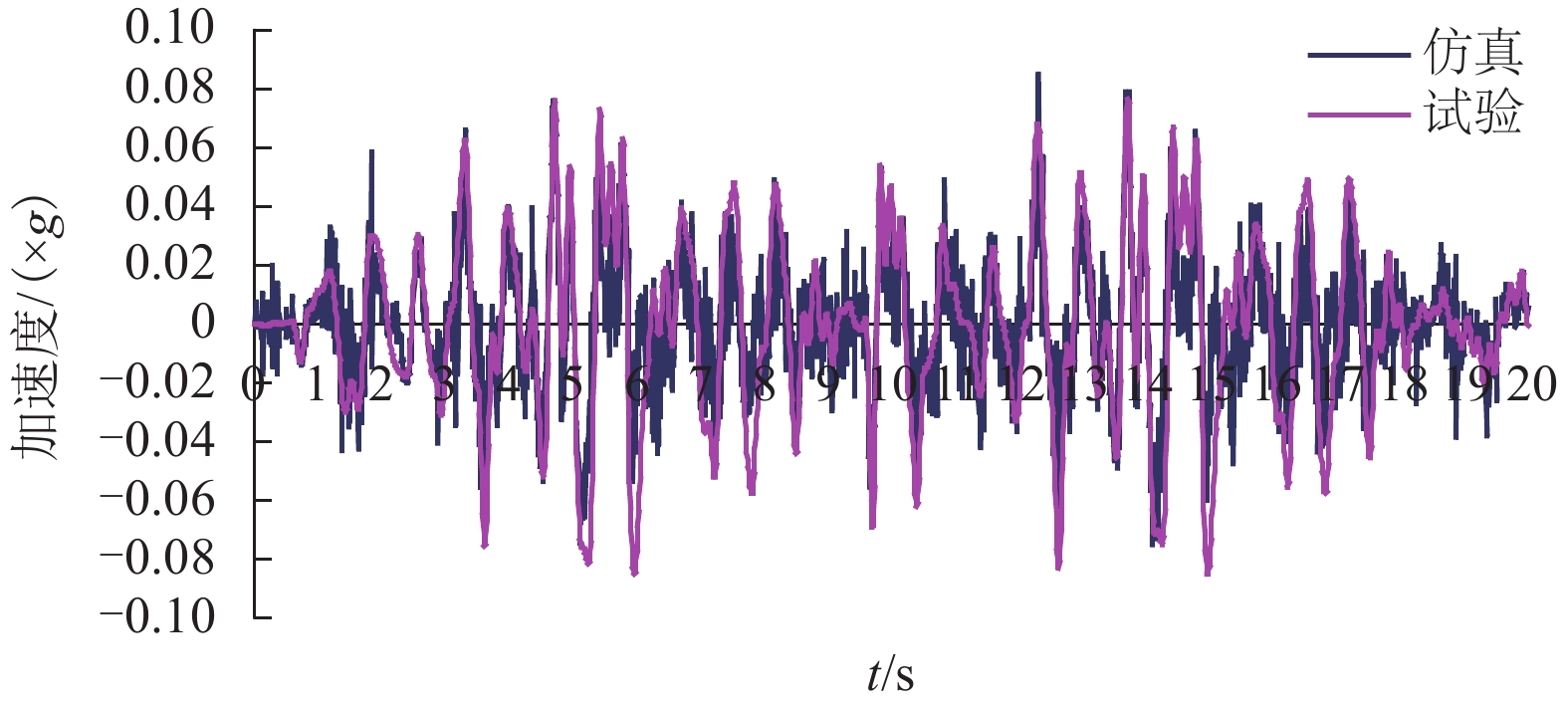

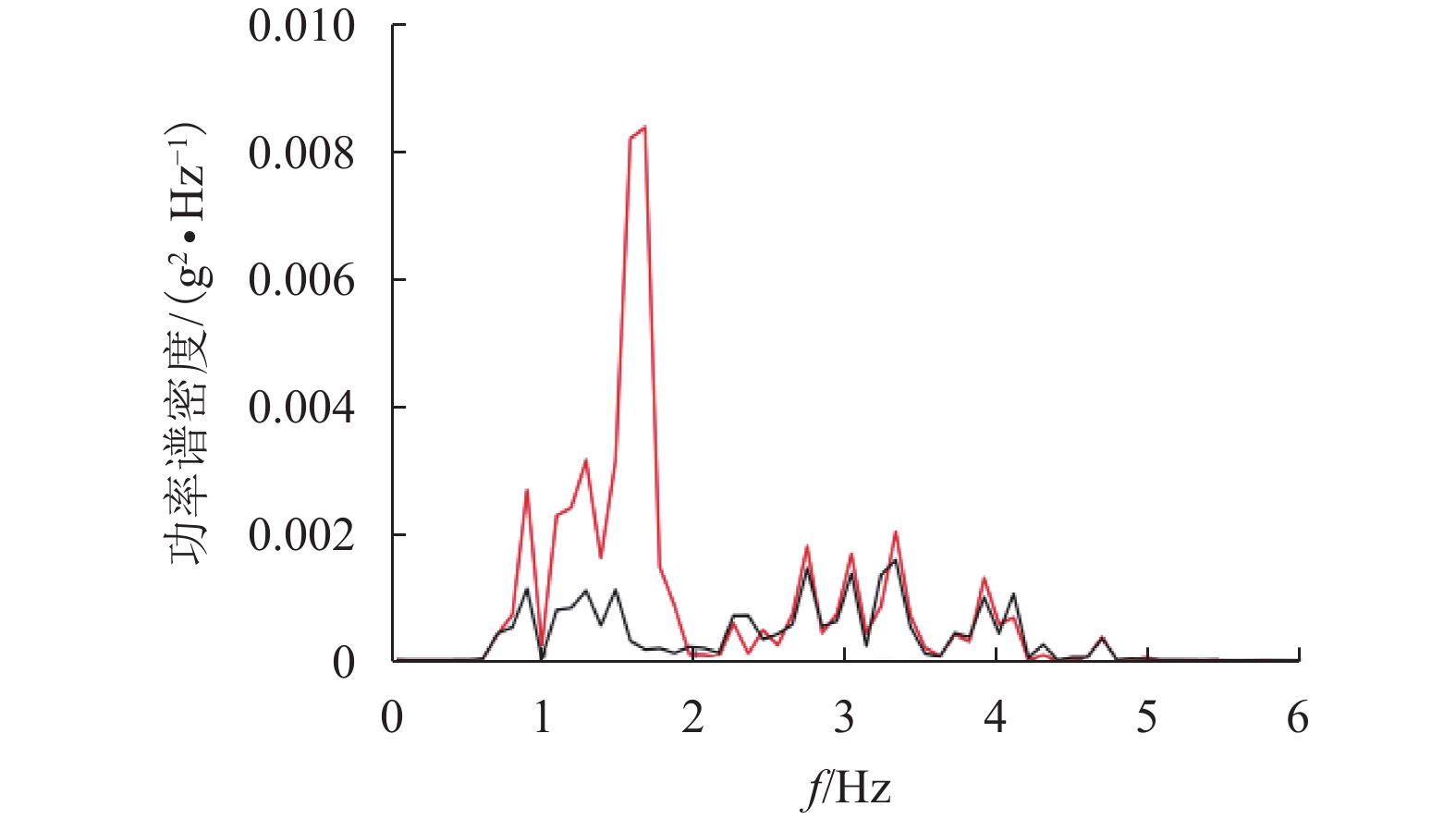

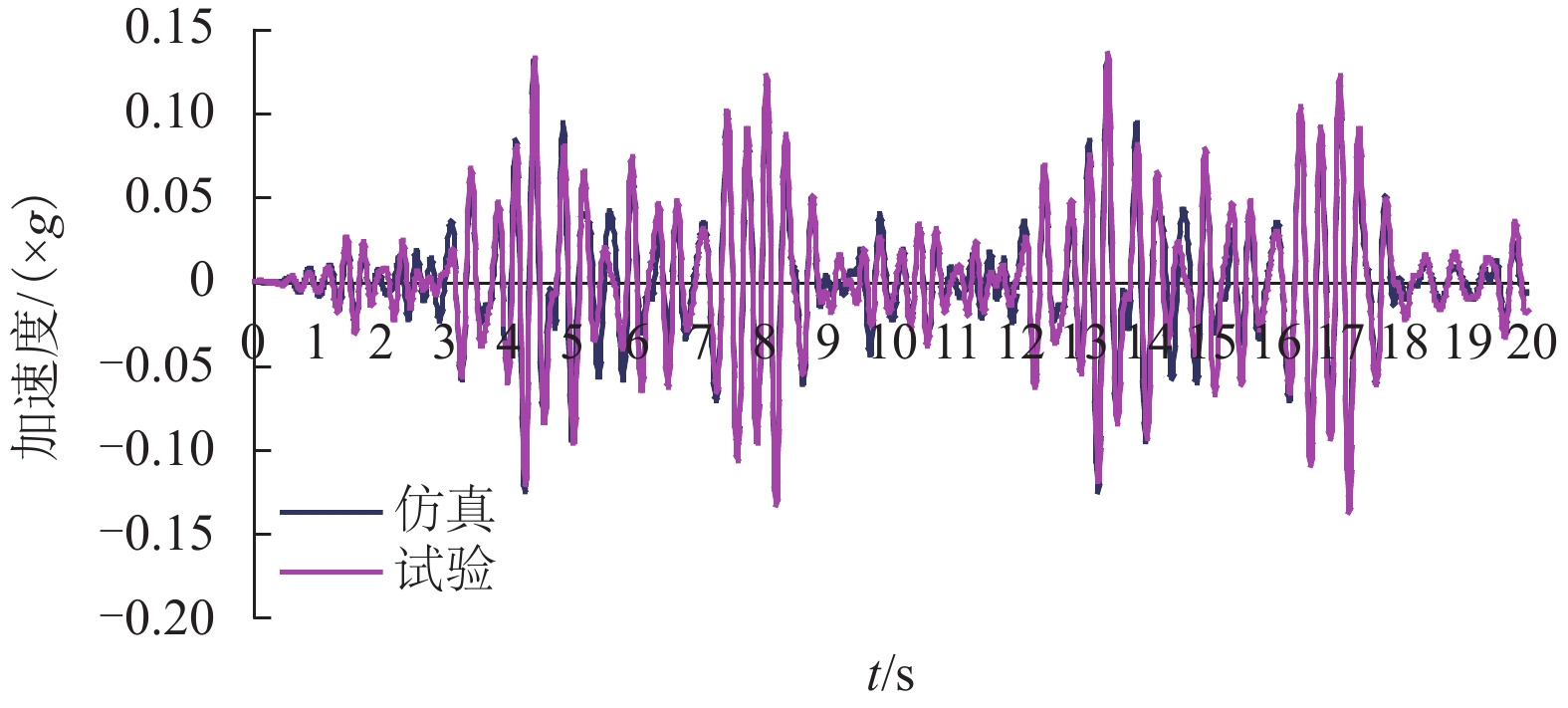

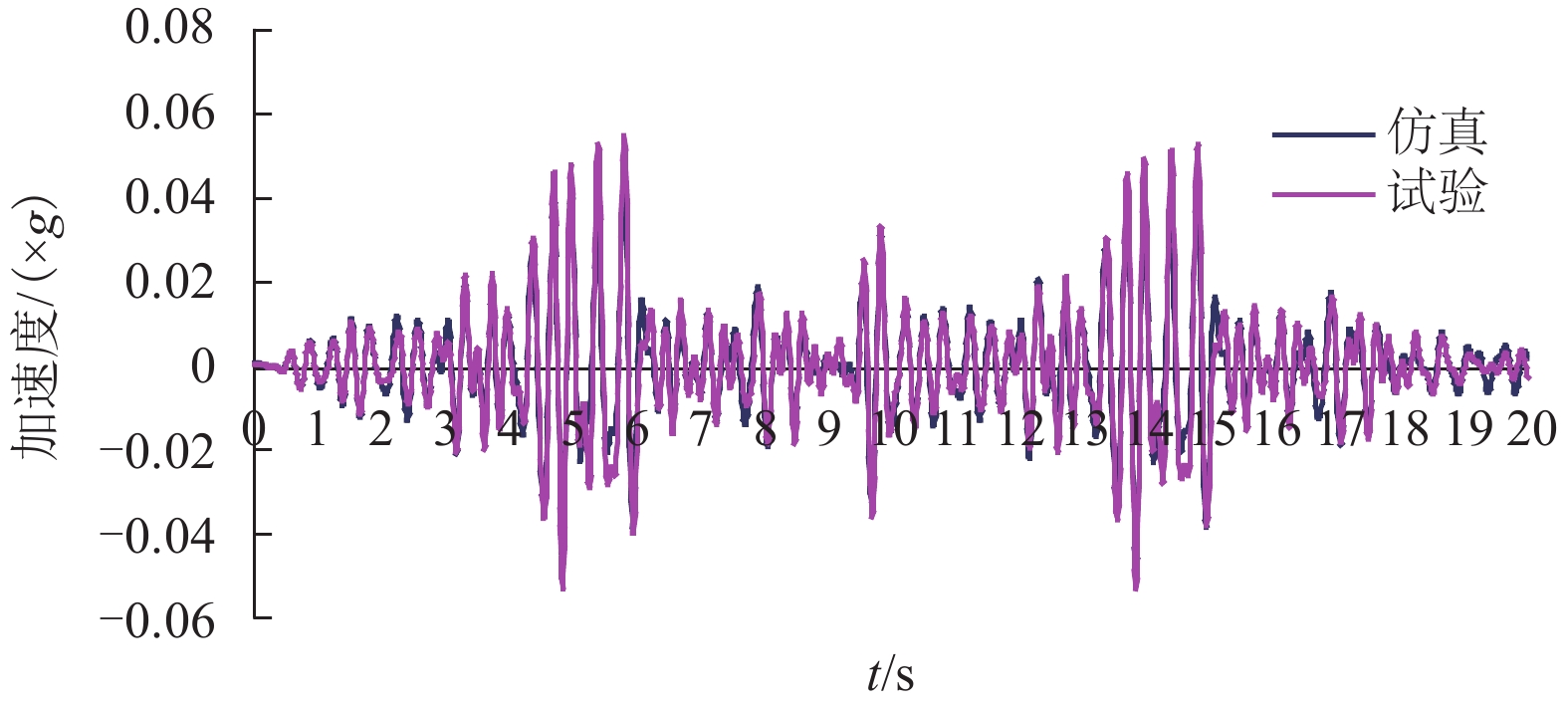

摘要: 针对大系统仿真分析方法与试验结果出现偏差问题,基于实际线路测试数据,以车体子系统为仿真对象,辅助于模拟台架的试验数据,建立了26个自由度的多体仿真模型,实现了车体线路动态响应的仿真计算. 结果表明:摇枕垂、横向加速度响应结果仿真与试验RMS (root mean square)误差最大值为9%. 在1.5~15.0 Hz主要频率段,车体枕梁垂、横向振动加速度的试验结果和仿真结果的RMS误差低于8.57%,车体关键焊缝仿真与试验的动应力响应波形基本一致. 通过与试验结果的对比验证,仿真结果基本反映了车体在实际线路运行时的动态响应情况.Abstract: For resolving errors between a simulation analysis and the test results of a large system, a multi-body simulation model of a railway wagon with 26 degrees of freedom was created using test data from a real test rig on a railway track and by incorporating the wagon body’s subsystems into the simulation object in order to realise a simulation calculation of the dynamic response of the railway wagon. The results show that the maximum RMS (root mean square) error between the simulation and the test of the wagon body bolster’s vertical and lateral vibration acceleration is 9%. Furthermore, the RMS error between the simulation and test of the wagon body bolster’s vertical and lateral vibration acceleration is less than 8.57% in the 1.5–15.0 Hz frequency range. Finally, the response signal waveforms of the dynamic stress of the simulation and that of the wagon body’s key welds are almost identical. The comparison and validation of the simulation and test results show that the simulation results substantially reproduce the dynamic response conditions of the railway wagon running along a railway track.

-

Key words:

- rails /

- dynamic simulation /

- simulation and test /

- full-scale fatigue test rig

-

表 1 模态频率结果对比

Table 1. Results comparison of modal frequency

振型 系统试验模态 系统仿真模态 侧滚 1.25 1.45 扭转 4.52 4.66 表 2 车体枕梁振动加速度的统计结果

Table 2. Statistical results of acceleration of body bolster

测点编号 RMS RMS误差/% 试验 仿真 AZN11 0.040 0.038 4.25 AYN11 0.014 0.013 8.57 -

来亚南. C_(80B)型车车体疲劳寿命分析[J]. 机械设计与制造,2015(8): 105-109. doi: 10.3969/j.issn.1001-3997.2015.08.028LAI Yanan. Fatigue analysis of C_(80B) freight train[J]. Machinery Design & Manufacture, 2015(8): 105-109. doi: 10.3969/j.issn.1001-3997.2015.08.028 徐刚,周鋐,陈栋华,等. 基于虚拟试验台的疲劳寿命预测研究[J]. 同济大学学报(自然科学版),2009,37(1): 97-100.XU Gang, ZHOU Hong, CHEN Donghua, et al. Virtual test rig based study on fatigue life prediction[J]. Journal of Tongji University (Natural Science), 2009, 37(1): 97-100. FERRY W B, FRISE P R, ANDREW G T, et al. Combining virtual simulation and physical vehicle test data to optimaze durability testing[J]. Fatigue and Fracture of Engineering Materials and Structures, 2002, 25: 1127. doi: 10.1046/j.1460-2695.2002.00605.x 陈栋华. 轿车底盘零部件耐久性虚拟试验理论与方法研究[D]. 上海: 同济大学, 2007 董明明,顾亮. 履带车辆非线性悬挂系统的ADAMS仿真[J]. 北京理工大学学报,2005,25(8): 670-673. doi: 10.3969/j.issn.1001-0645.2005.08.004DONG Mingming, GU Liang. Simulation of nonlinear tracked vehicle suspension with ADAMS[J]. Transactions of Beijing Institute of Technology, 2005, 25(8): 670-673. doi: 10.3969/j.issn.1001-0645.2005.08.004 石琴,王涛,张代胜,等. 大客车车身骨架结构动应力仿真计算[J]. 汽车工程,2011,33(5): 433-437.SHI Qin, WANG Tao, ZHANG Daisheng, et al. The simulation calculation of dynamic stress in bus body frame structure[J]. Automotive Engineering, 2011, 33(5): 433-437. 曾祥坤,田红旗. 散粒货物对铁路敞车端墙侧压力研究[J]. 铁道学报,2007,29(4): 32-37. doi: 10.3321/j.issn:1001-8360.2007.04.007ZENG Xiangkun, TIAN Hongqi. Rsearch of lateral pressure of granular cargo on end walls of open wagon[J]. Journal of the China Railway Society, 2007, 29(4): 32-37. doi: 10.3321/j.issn:1001-8360.2007.04.007 赵方伟,付秀琴,张弘,等. 散粒货物对敞车静侧压力的分布规律研究[J]. 铁道机车车辆,2016(6): 42-45,48. doi: 10.3969/j.issn.1008-7842.2016.06.11ZHAO Fangwei, FU Xiuqin, ZHANG Hong, et al. Static lateral pressure distribution study of granular cargo on gondola car[J]. Railway Locomotive & Car, 2016(6): 42-45,48. doi: 10.3969/j.issn.1008-7842.2016.06.11 刘宏友,李向伟,邓爱建等. C_(70E)型通用敞车模态试验研究[J]. 铁道车辆,2015,53(12): 32-36. doi: 10.3969/j.issn.1002-7602.2015.12.007LIU Hongyou, LI Xiangwei, DENG Aijian, et al. Research on modal test of C_(70E) general gondola car[J]. Rolling Stock, 2015, 53(12): 32-36. doi: 10.3969/j.issn.1002-7602.2015.12.007 缪炳荣. 基于多体动力学和有限元法的机车车辆结构疲劳仿真研究[D]. 成都: 西南交通大学, 2006 王勇,曾京,吕可维. 三大件转向架货车动力学建模与仿真[J]. 交通运输工程学报,2003,3(4): 30-34. doi: 10.3321/j.issn:1671-1637.2003.04.008WANG Yong, ZENG Jing, LU Kewei. Dynamic modeling and simulation of three-piece bogie freight car[J]. Journal of Traffic and Transportation Engineering, 2003, 3(4): 30-34. doi: 10.3321/j.issn:1671-1637.2003.04.008 -

下载:

下载: