Corrosion Prediction of Coated Steel in Magnesium Cement Concrete Based on Wiener Degradation

-

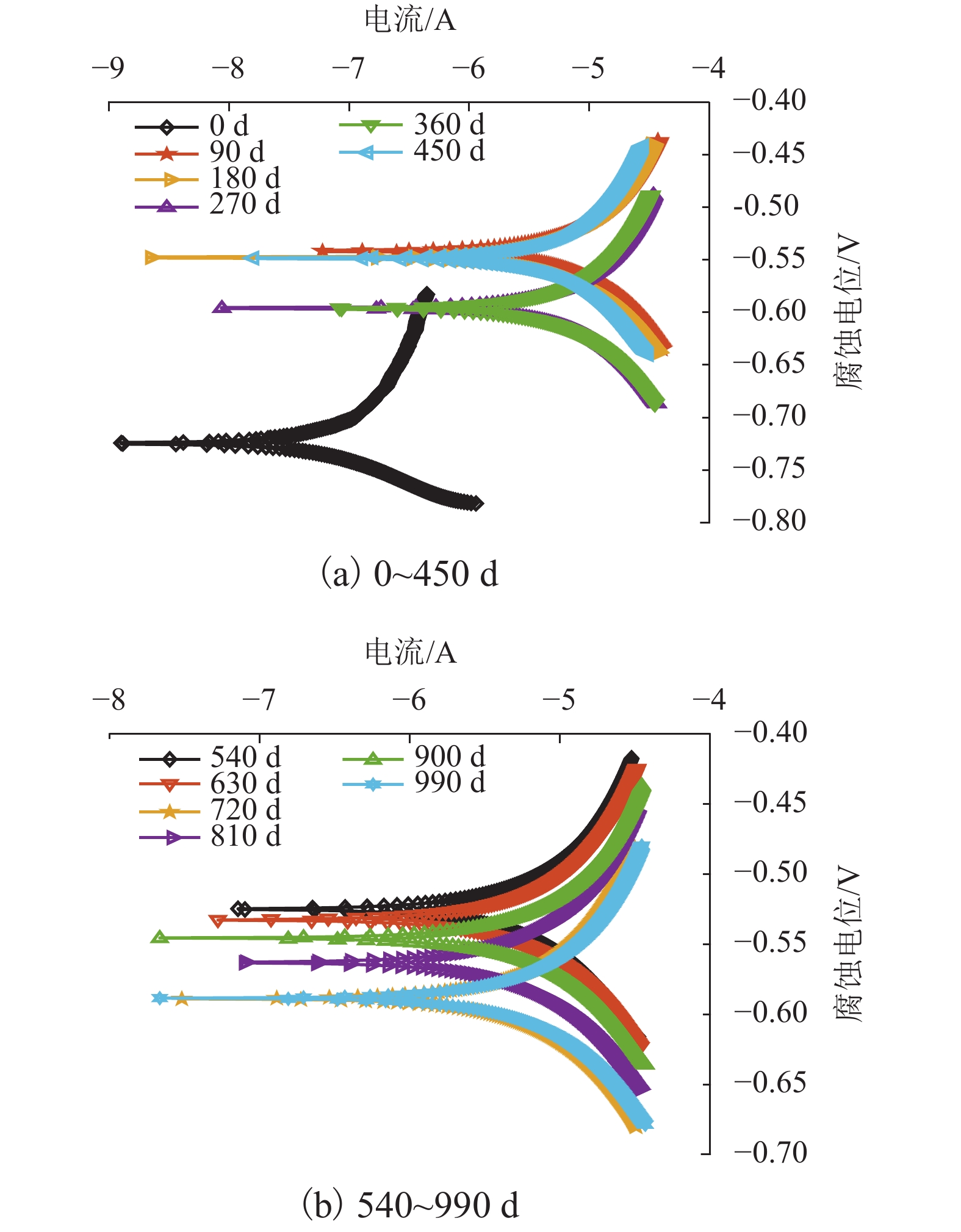

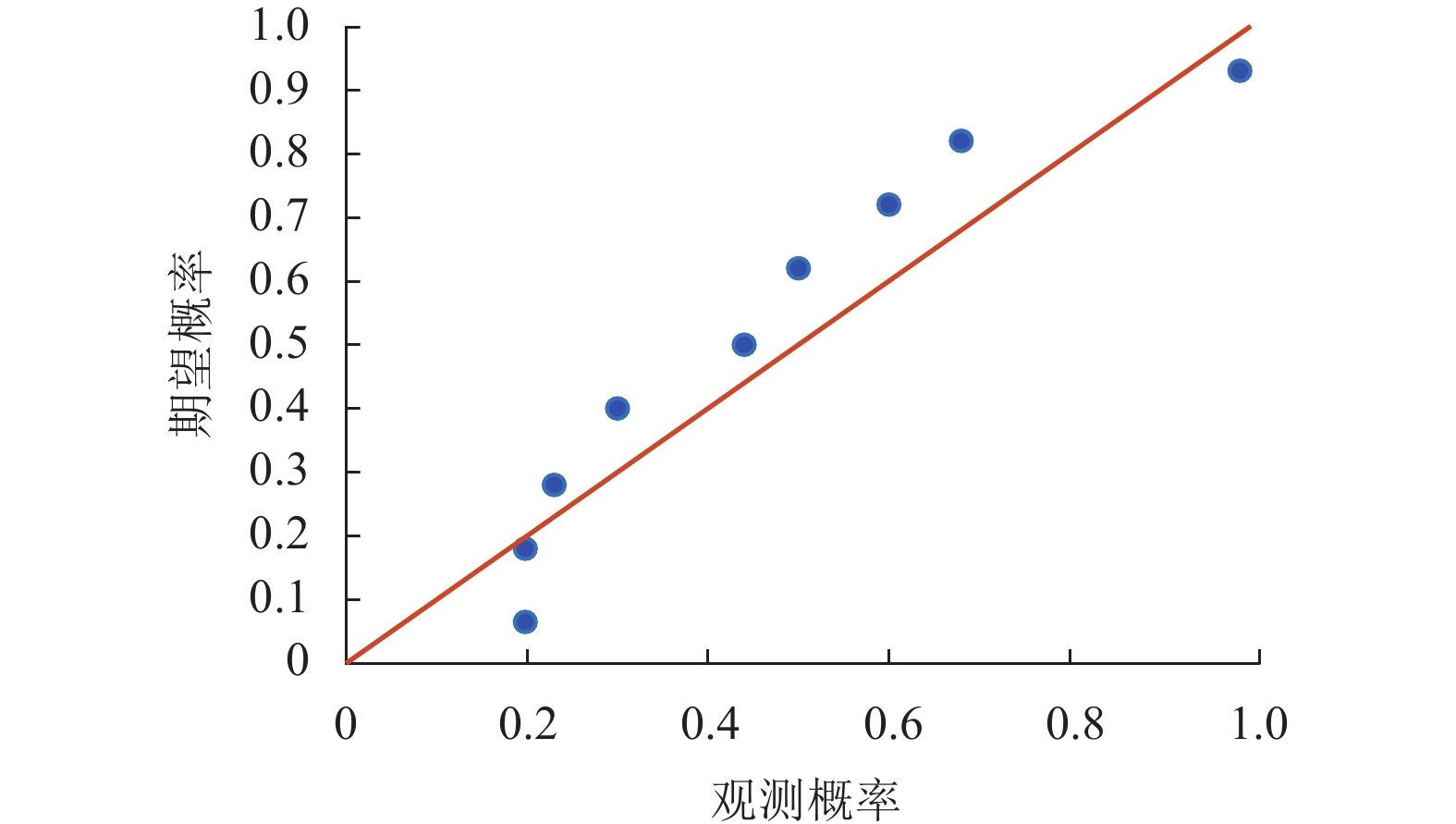

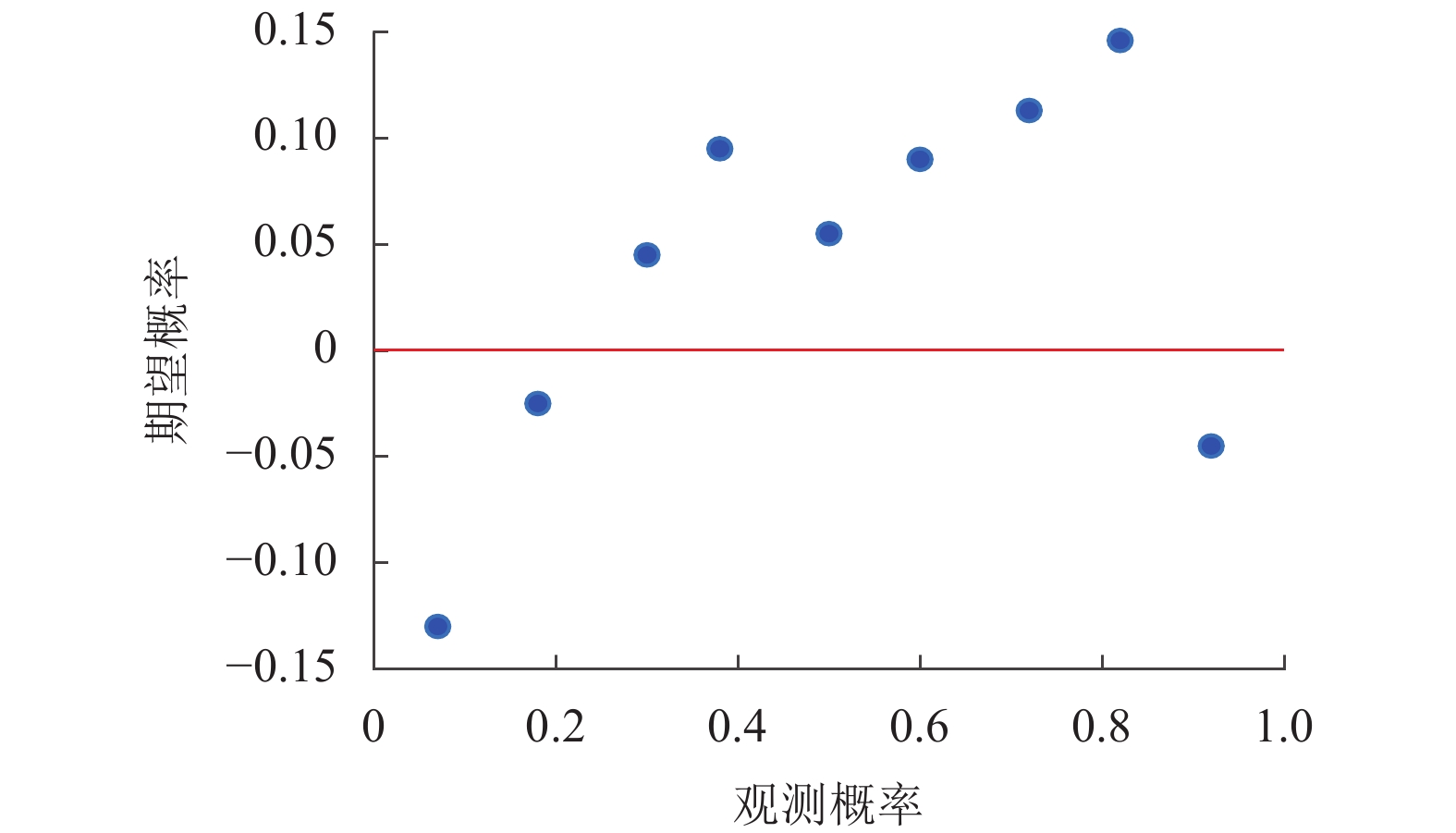

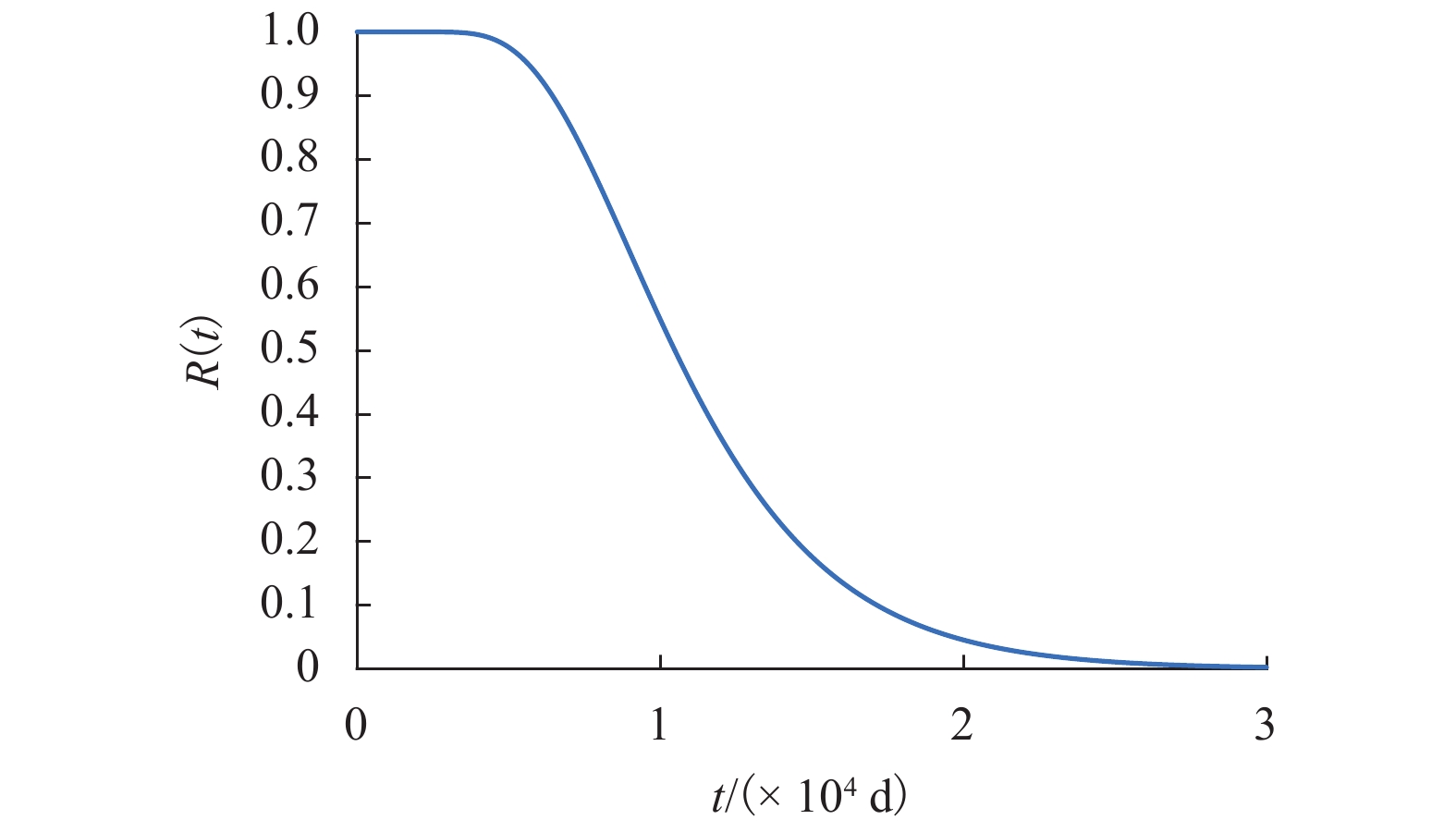

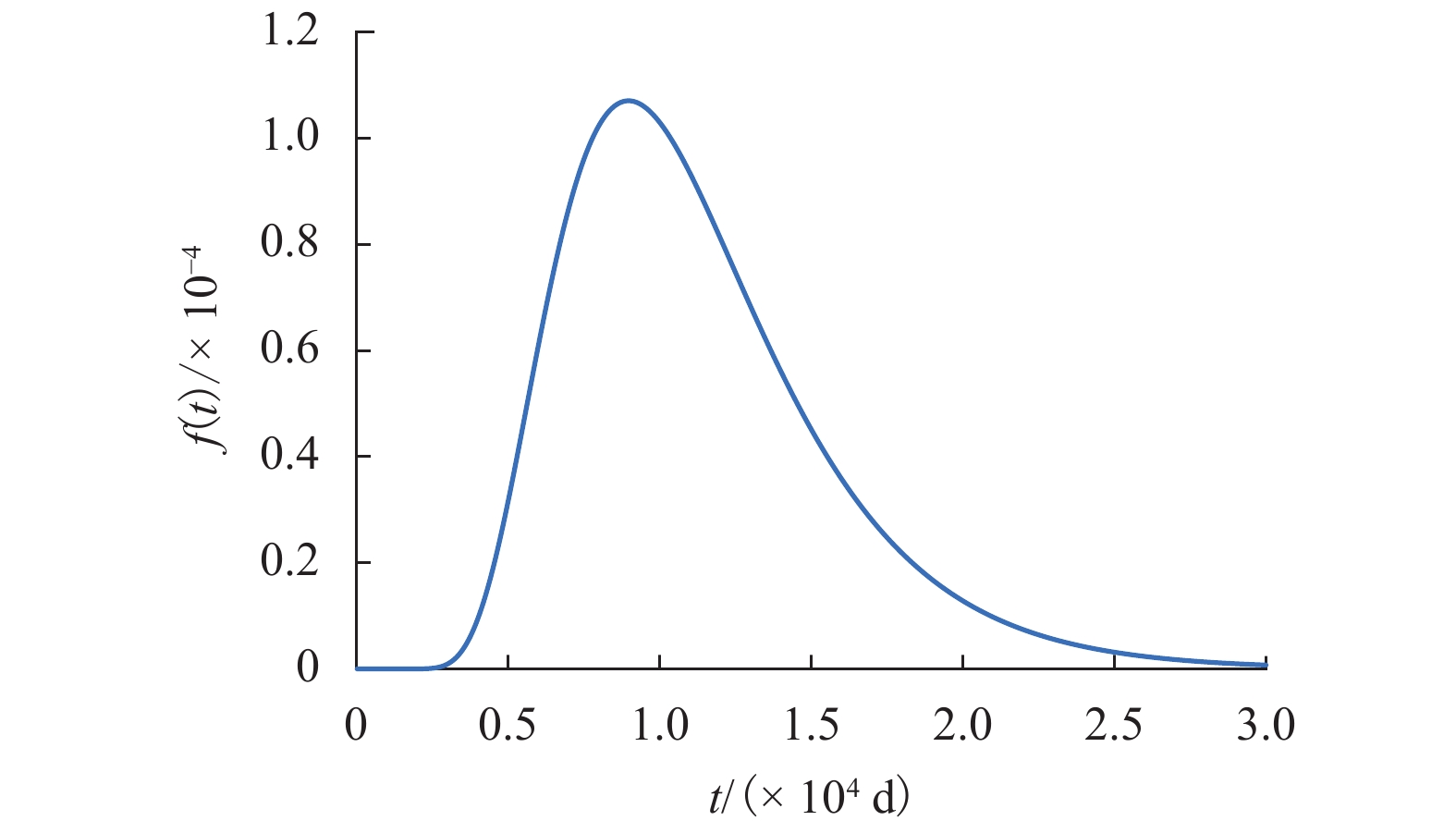

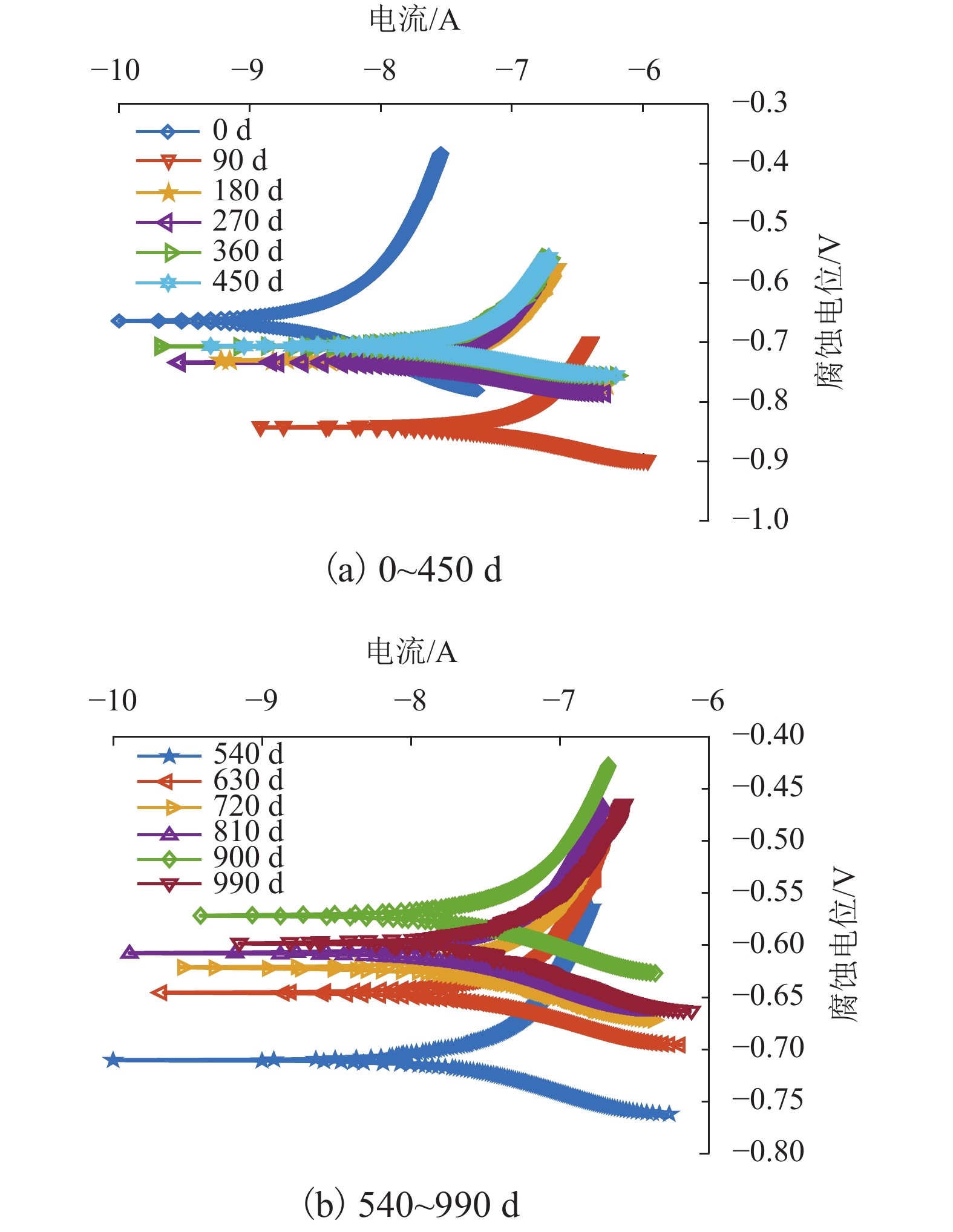

摘要: 镁水泥混凝土对钢筋的腐蚀限制了其广泛的推广应用,为解决这一难题,提出利用涂层来缓解其对钢筋的腐蚀,确保镁水泥钢筋混凝土建筑满足设计规定的使用年限要求. 根据西部盐渍土地区的自然环境,采用溶液浸泡加速锈蚀的试验方法对氯氧镁涂层钢筋混凝土进行快速腐蚀试验;运用电化学工作站周期性地对氯氧镁涂层钢筋混凝土试块进行电化学试验;以表征涂层钢筋锈蚀的电化学参数(腐蚀电流密度)作为退化指标,在Wiener退化过程的基础上进行可靠度建模并且对涂层钢筋进行锈蚀预测. 研究结果表明:利用涂层钢筋腐蚀电流密度作为耐久性退化指标可以得到镁水泥涂层钢筋混凝土中的涂层钢筋锈蚀的可靠度函数,并确定出涂层钢筋在30 000 d左右达到中等腐蚀.

-

关键词:

- 镁水泥混凝土 /

- 腐蚀电流密度 /

- Wiener退化过程 /

- 可靠度 /

- 锈蚀

Abstract: The corrosion of magnesium cement concrete on steel bars limits its widespread application. To solve this problem, coating is proposed to alleviate the corrosion of steel bars and ensure that magnesium cement-reinforced concrete buildings meet the design requirements over their service life. Based on the natural environment of the Western saline soil area, a rapid corrosion test of magnesium oxychloride-coated reinforced concrete was performed using the solution immersion accelerated corrosion test method. Electrochemical tests of magnesium oxychloride-coated reinforced concrete were periodically conducted using an electrochemical workstation. The electrochemical parameter of corrosion current density, which characterises the corrosion of a coated steel bar, was used as the degradation index; then, a reliability model was built on the basis of the Wiener degradation process, and the corrosion of a coated steel bar was predicted. The results show that the corrosion reliability function of a steel bar coated with magnesium cement-reinforced concrete can be obtained by using the corrosion current density as a durability degradation index, and the coated steel bar reaches moderate corrosion at approximately 30 000 d. -

表 1 镁水泥混凝土配合比

Table 1. Mixing proportion of magnesium oxychloride cement concrete

kg/m3 氧化镁 减水剂 抗水剂 砂 碎石 氯化镁 水 388.96 2.288 1.601 6 625 1 162 147.811 135.586 表 2 钢筋腐蚀电流密度和锈蚀程度之间的对应关系

Table 2. Relationship between corrosion current density and corrosive degree of rebars–2

μA/cm2 无锈蚀 低腐蚀 中等腐蚀 严重腐蚀 icoor < 0. 1 0. 1≤icoor < 0. 5 0. 5≤icoor < 1.0 icoor≥1.0 表 3 涂层钢筋的电化学参数

Table 3. Electrochemical parameters for a coated steel bar

×10–8A/cm2 项目 0 d 90 d 180 d 270 d 360 d 450 d 540 d 630 d 720 d 810 d 900 d 990 d 电流密度 0.112 5.660 4.420 3.780 4.060 3.590 4.430 4.850 4.050 3.520 4.100 4.500 增量 0.055 5 – 0.012 4 – 0.006 4 0.002 8 – 0.004 7 0.008 4 0.004 2 – 0.008 – 0.005 3 0.005 8 0.004 0 表 4 裸钢的电流密度

Table 4. Current density of a bare steel bar

μA/cm2 0 d 90 d 180 d 270 d 360 d 450 d 540 d 630 d 720 d 810 d 900 d 990 d 0.095 5.800 5.500 5.900 5.400 5.100 4.960 5.300 5.300 5.100 5.900 6.400 -

汪林,甘泓,于福亮,等. 西北地区盐渍土及其开发利用中存在问题的对策[J]. 水利学报,2001,46(6): 90-95. doi: 10.3321/j.issn:0559-9350.2001.06.019WANG Lin, GAN Hong, YU Fuliang, et al. Salted soil and its development in Northwest China[J]. Journal of Hydraulic Engineering, 2001, 46(6): 90-95. doi: 10.3321/j.issn:0559-9350.2001.06.019 温利强. 我国盐渍土的成因及分布特征[D]. 合肥: 合肥工业大学, 2010 薛健. " 一带一路”: 大时代大布局大战略[J]. 中国战略新兴产业, 2015(增刊1): 50-57.XUE Jian. "One Belt And One Road": great strategy, grand layout, great era[J]. China Strategic Emerging Industry, 2015(S1): 50-57. 文静,余红发,吴成友,等. 氯氧镁水泥水化历程的影响因素及水化动力学[J]. 硅酸盐学报,2013,41(5): 588-596.WEN Jing, YU Hongfa, WU Chengyou, et al. Hydration kinetic and influencing parameters in hydration process of magnesium oxychloride cement[J]. Journal of The Chinese Ceramic Society, 2013, 41(5): 588-596. MAZURANIC C, BILLINSKI H, MATKOVIC B. Reaction products in the system MgCL2-NaOH-H2O[J]. Journal of the American Ceramic Society, 1982, 65(10): 523-526. doi: 10.1111/jace.1982.65.issue-10 乔宏霞, 巩位, 程千元, 等. 盐湖地区镁水泥钢筋混凝土耐久性试验[J]. 煤炭学报, 2015, 40(增刊2): 346-352.QIAO Hongxia, GONG Wei, CHENG Qianyuan, et al. Durability of magnesium cement reinforced concrete in saline soil area[J]. Journal of China Coal Society, 2015, 40(S2): 346-352. 乔宏霞,巩位,陈广峰,等. 基于极化曲线的镁水泥混凝土中钢筋腐蚀试验[J]. 华中科技大学学报(自然科学版),2016,44(1): 6-10.QIAO Hongxia, GONG Wei, CHEN Guangfeng, et al. Experimental study on corrosion of steel bar in magnesium cement concrete based on polarization curves[J]. Journal of Huazhong University of Science and Technology (Nature Science), 2016, 44(1): 6-10. 乔宏霞,巩位,高升,等. 镁水泥混凝土中钢筋的电化学腐蚀研究[J]. 材料科学与工艺,2016,24(1): 63-69. doi: 10.11951/j.issn.1005-0299.20160110QIAO Hongxia, GONG Wei, GAO Sheng, et al. Electrochemical corrosion of steel bar in the magnesium cement concrete[J]. Materials Science and Technology, 2016, 24(1): 63-69. doi: 10.11951/j.issn.1005-0299.20160110 乔宏霞,巩位,王鹏辉,等. 硫酸盐环境氯氧镁水泥混凝土中钢筋防护试验[J]. 西南交通大学学报,2017,52(2): 247-253. doi: 10.3969/j.issn.0258-2724.2017.02.006QIAO Hongxia, GONG Wei, WANG Penghui, et al. Experimental study on steel reinforcement protection in magnesium oxychloride cement concrete under sulfate environment[J]. Journal of Southwest Jiaotong University, 2017, 52(2): 247-253. doi: 10.3969/j.issn.0258-2724.2017.02.006 朱磊,左洪福,蔡景. 基于Wiener过程的民用航空发动机性能可靠性预测[J]. 航空动力学报,2013,28(5): 1006-1012.ZHU Lei, ZUO Hongfu, CAI Jing. Performance reliability prediction for civil aviation aircraft engine based on Wiener process[J]. Journal of Aerospace Powe, 2013, 28(5): 1006-1012. 安秀杰. 非线性模拟电路Wiener核故障特征提取的优化方法研究[D]. 哈尔滨: 哈尔滨理工大学, 2014 王兵,郑秋红,郭浩. 基于Shannon-Wiener指数的中国森林物种多样性保育价值评估方法[J]. 林业科学研究,2008,21(2): 268-274. doi: 10.3321/j.issn:1001-1498.2008.02.025WANG Bing, ZHENG Qiuhong, GUO Hao. Economic value assessment of forest species diversity conservation in China based on the Shannon-Wiener index[J]. Forest Research, 2008, 21(2): 268-274. doi: 10.3321/j.issn:1001-1498.2008.02.025 罗刚,施养抗. 钢筋混凝土构件中钢筋锈蚀量的无损检测方法[J]. 福建建筑,2002,9(4): 55-57.LUO Gang, SHI Yangkang. Review of non-destructive methods in assessment corrosion in reinforced concrete member[J]. Fujian Architecture & Construction, 2002, 9(4): 55-57. 彭宝华. 基于Wiener过程的可靠性建模方法研究[D]. 长沙: 国防科学技术大学, 2010 COX D R, MILLER H D. The theory of stochastic processes[M]. London: Chapman and Hall, 1965: 5-25 杨兴民,刘保东,李娟. 基于Gaussian Copula与t-Copula的沪深股指相关性分析[J]. 山东大学学报,2007,42(12): 63-68. doi: 10.3969/j.issn.1671-9352.2007.12.014YANG Xingmin, LIU Baodong, LI Juan. Correlation analysis of the Shanghai-Shenzhen stock index based on Gaussian Copula and t-Copula[J]. Journal of Shandong University, 2007, 42(12): 63-68. doi: 10.3969/j.issn.1671-9352.2007.12.014 -

下载:

下载: