Mechanical Behavior and Structural Optimization of Steel-Concrete Composite Cable-Pylon Anchor

-

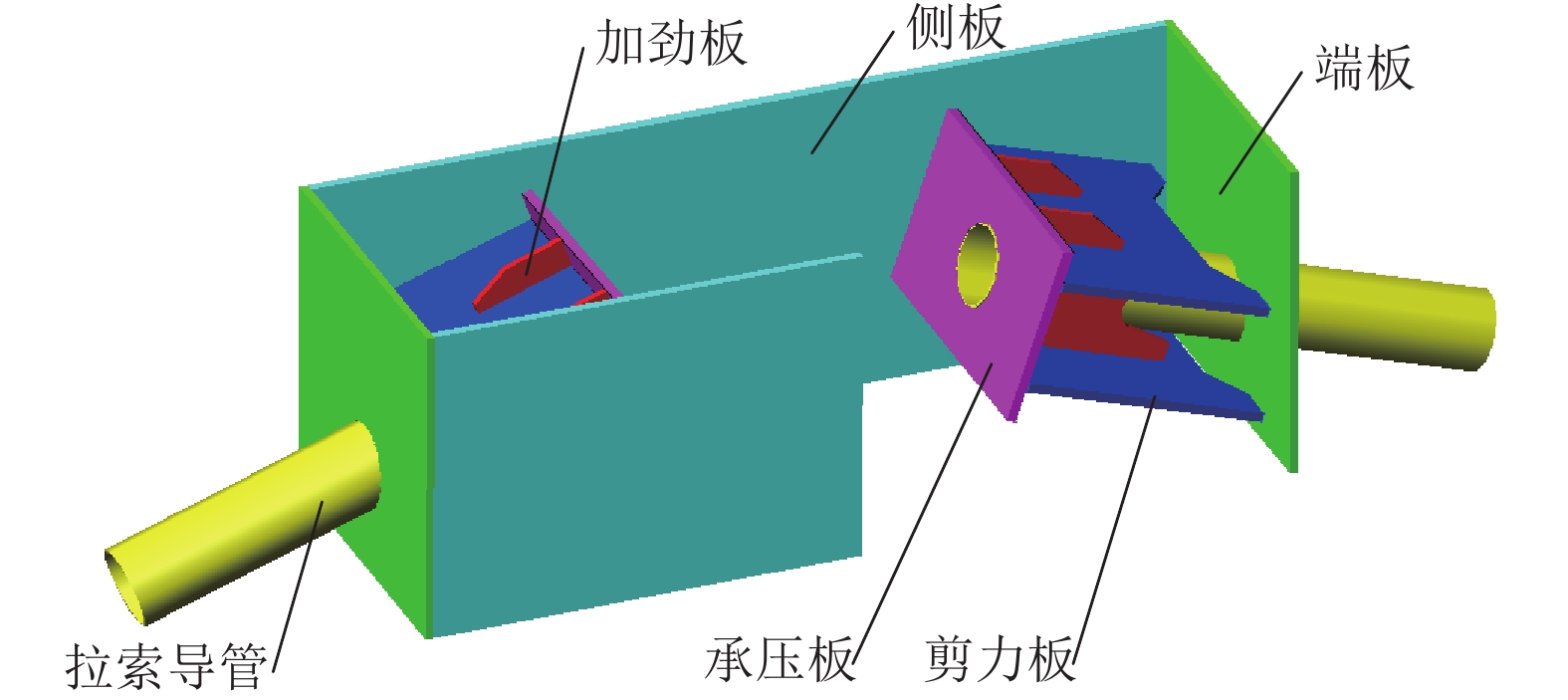

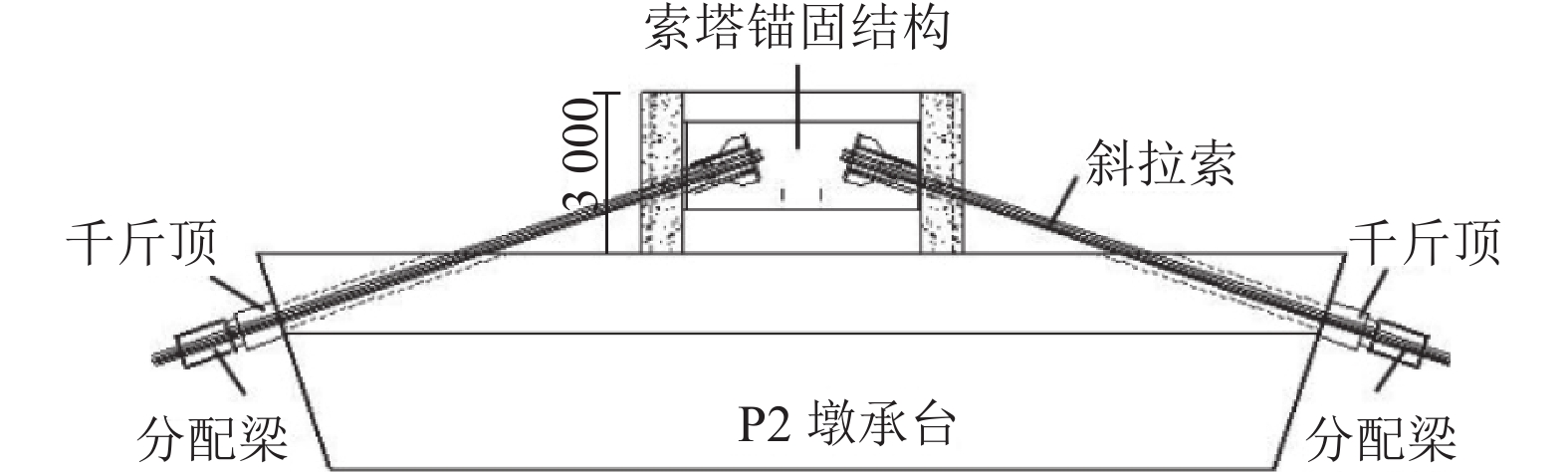

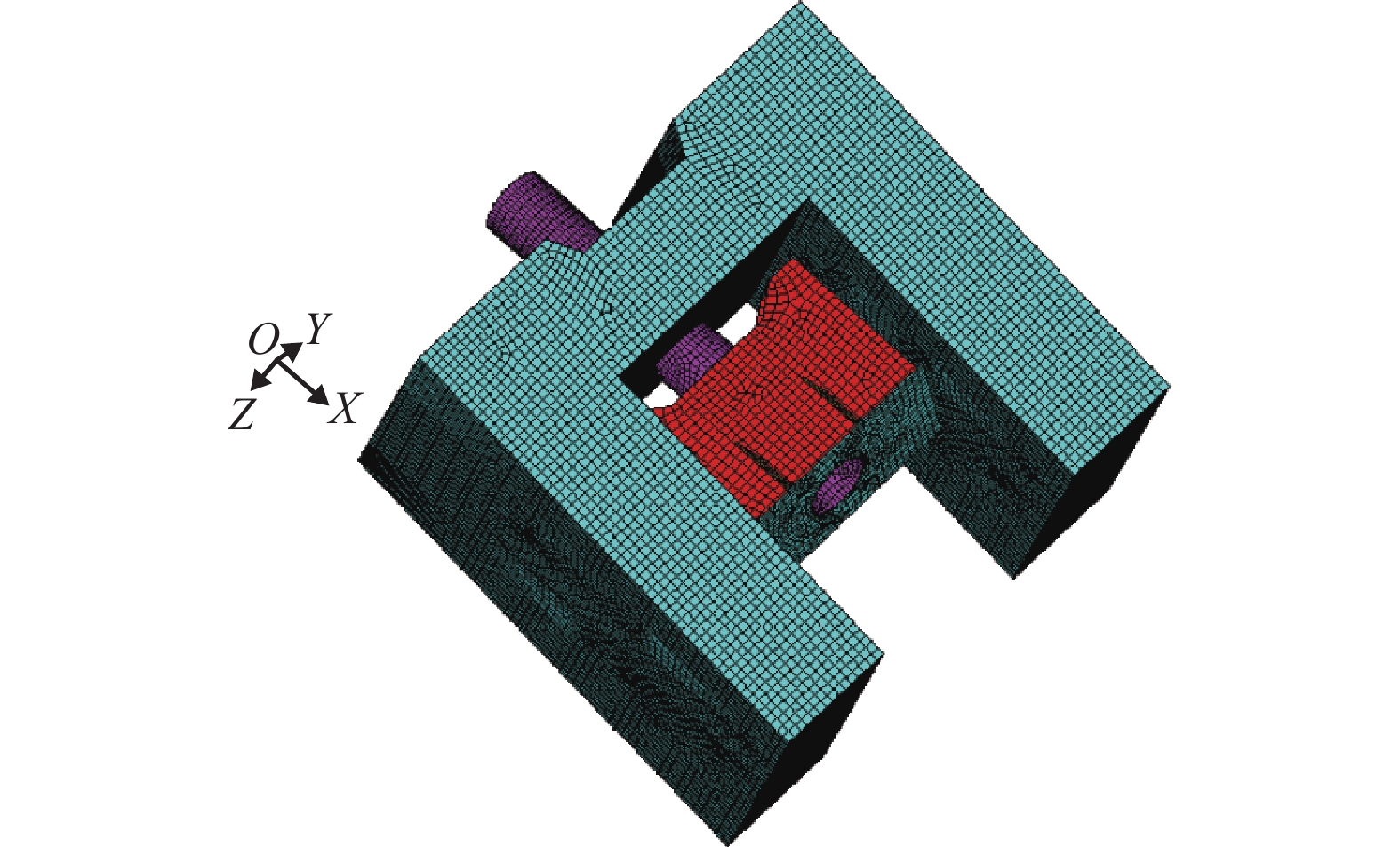

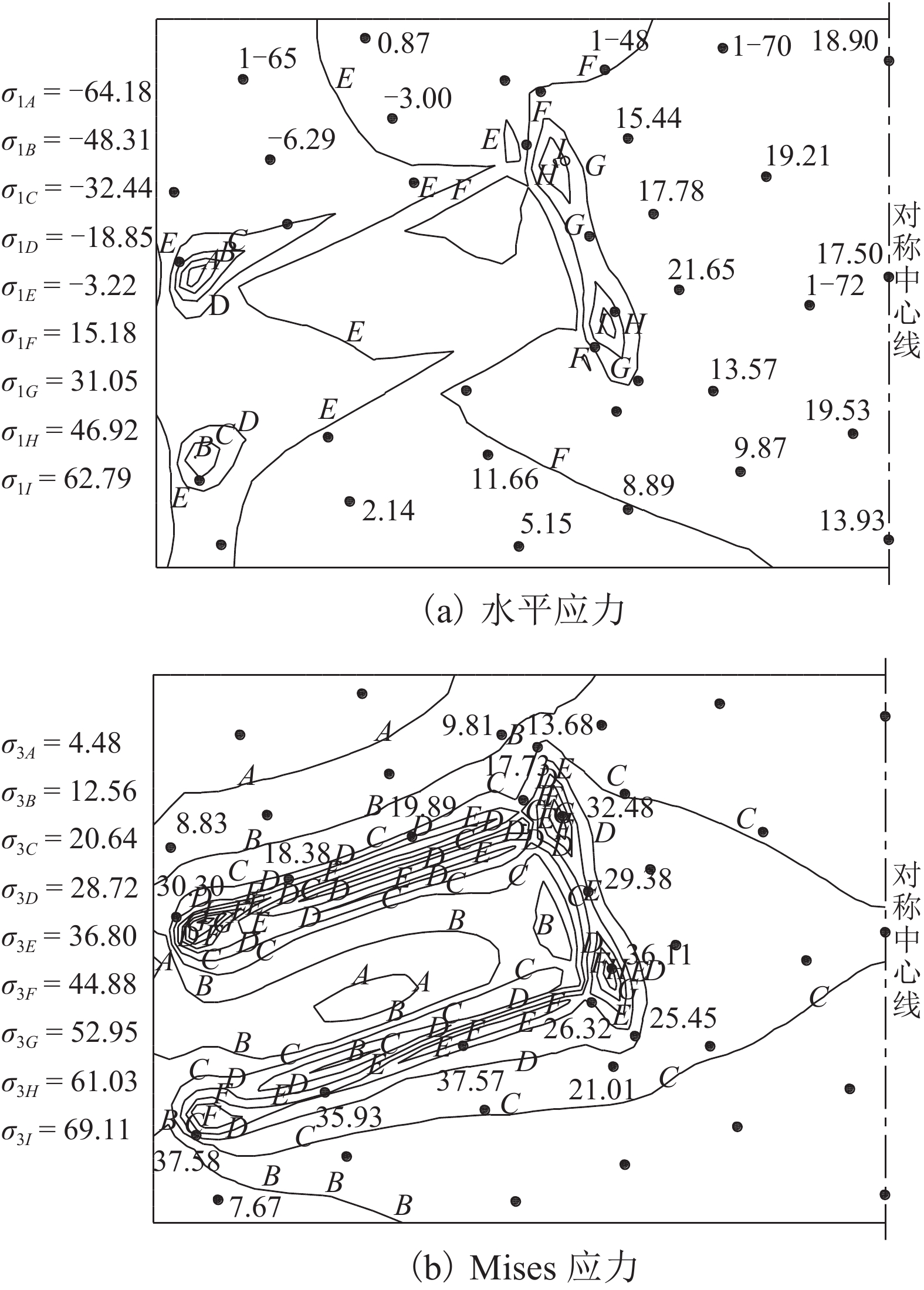

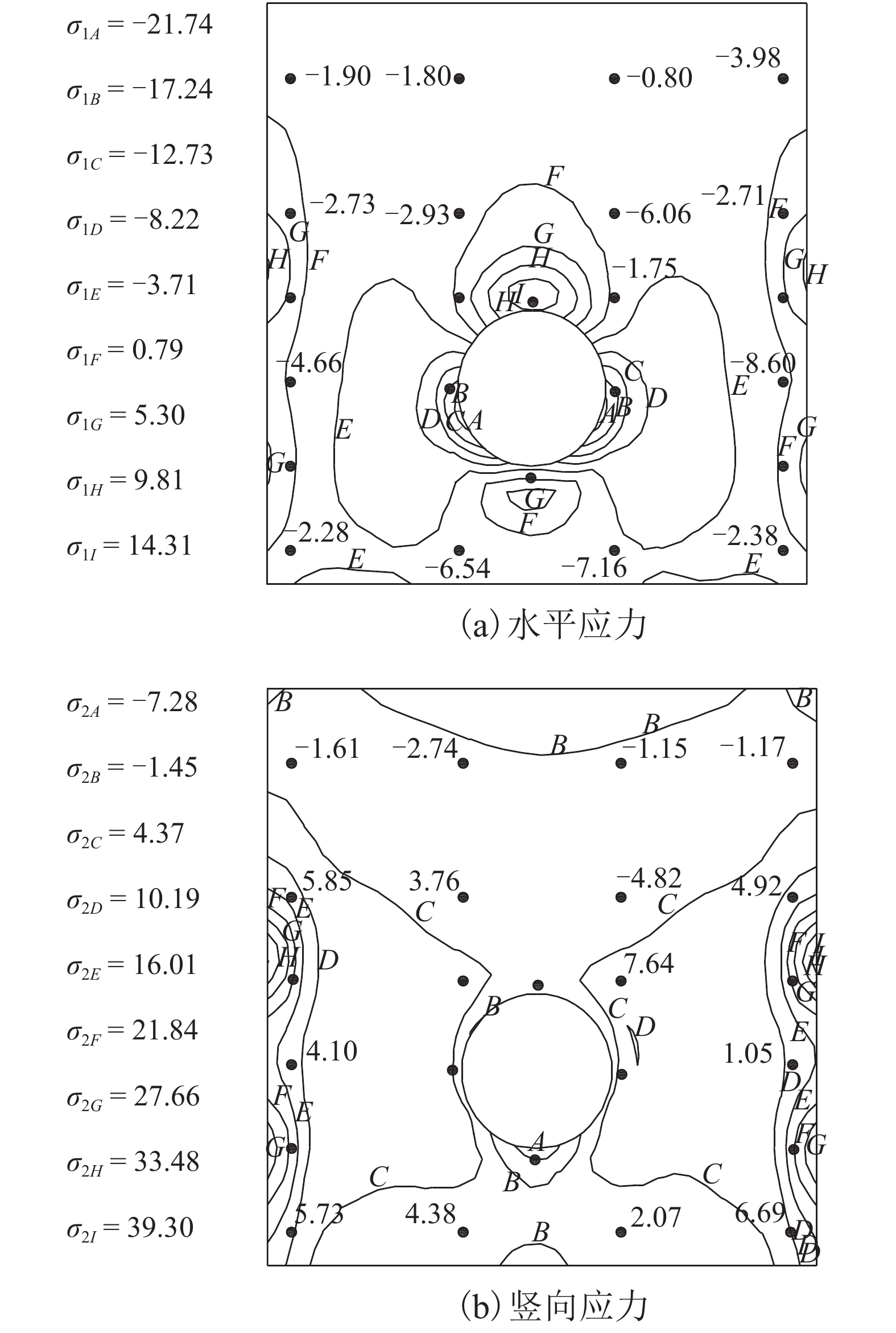

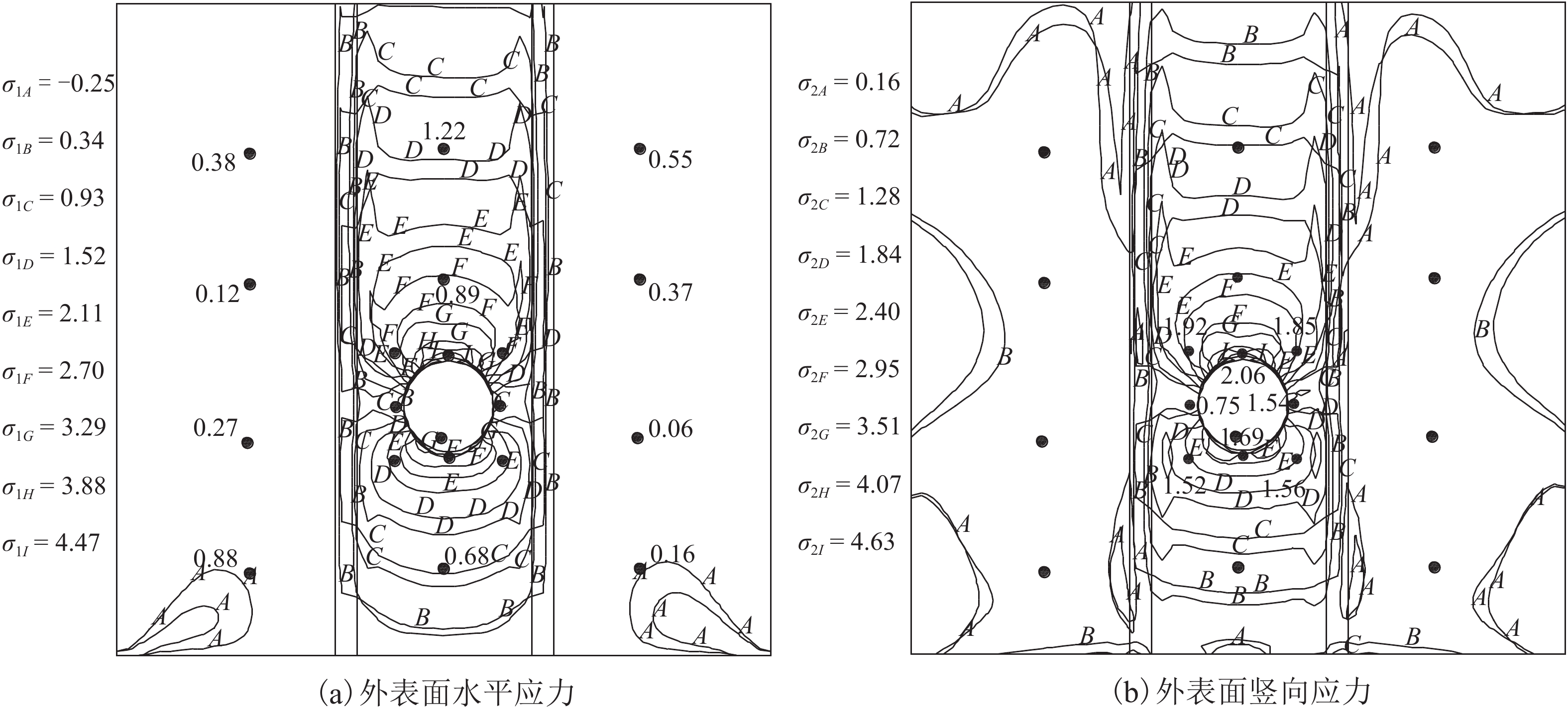

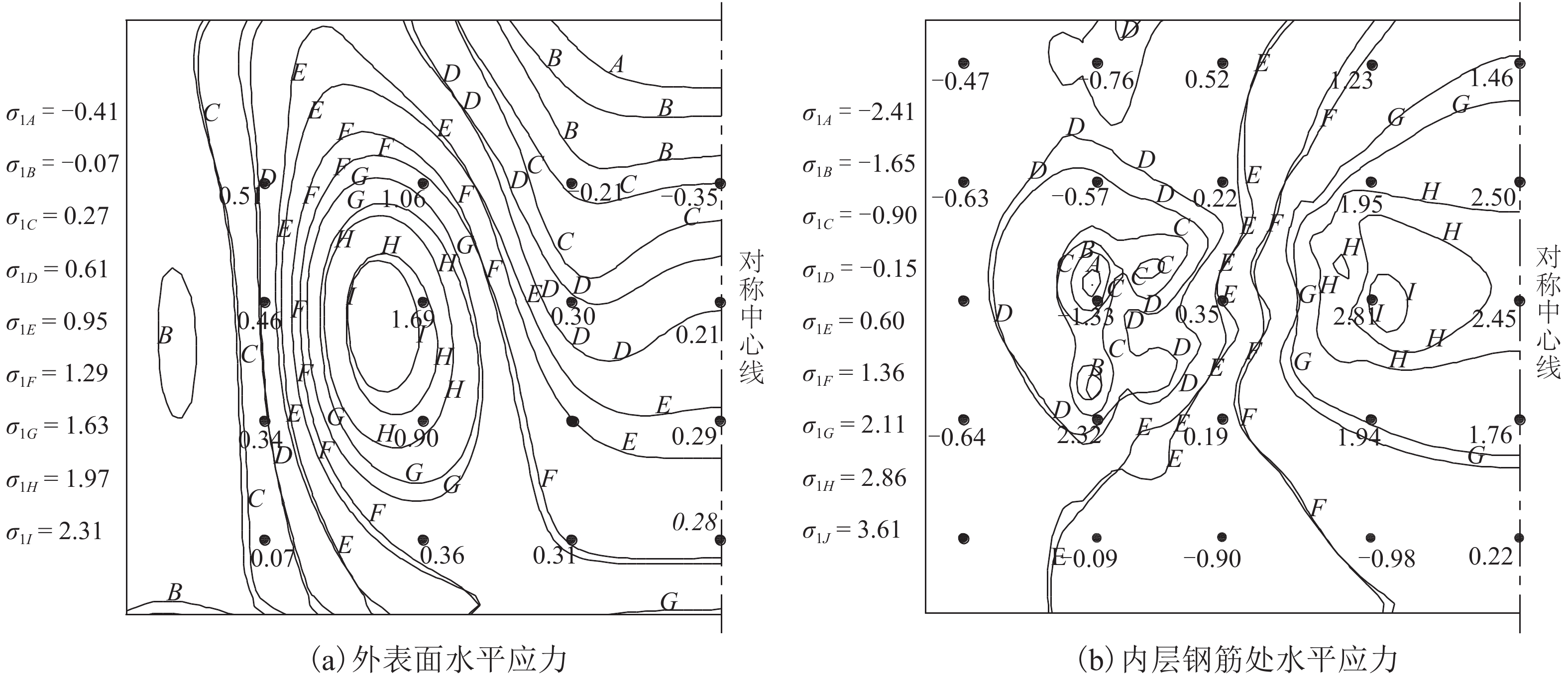

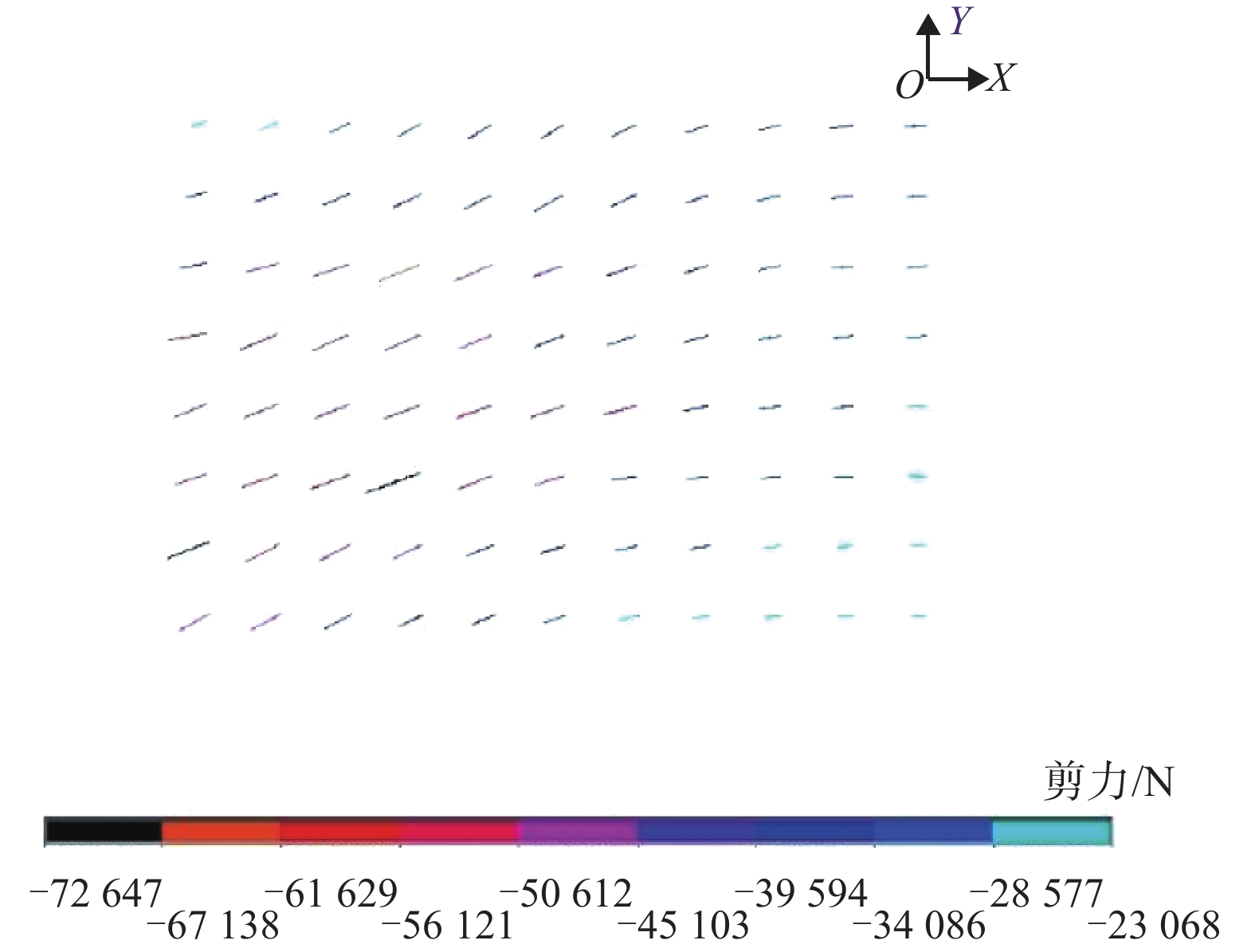

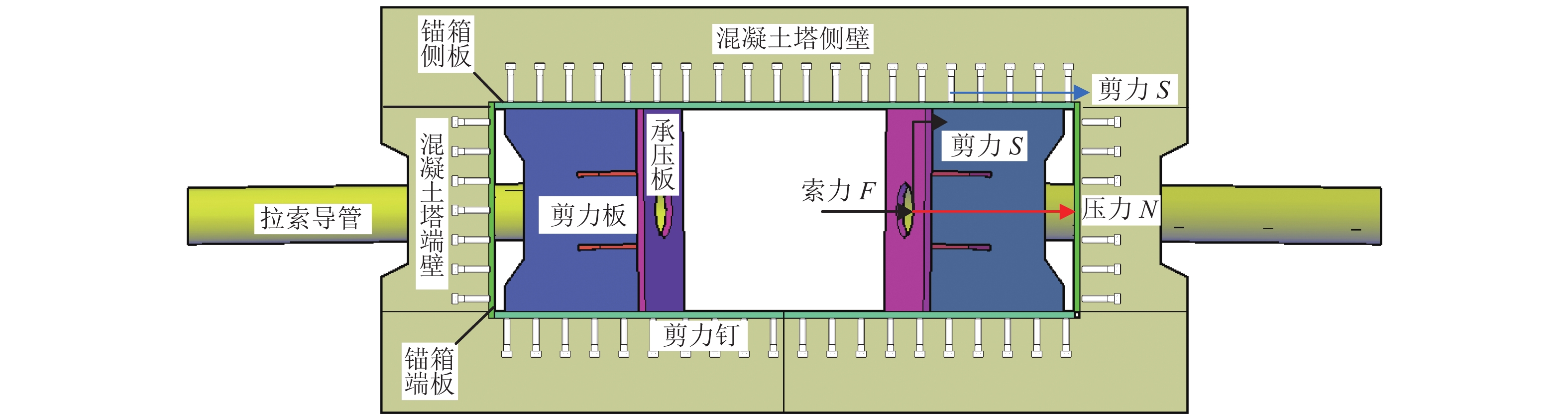

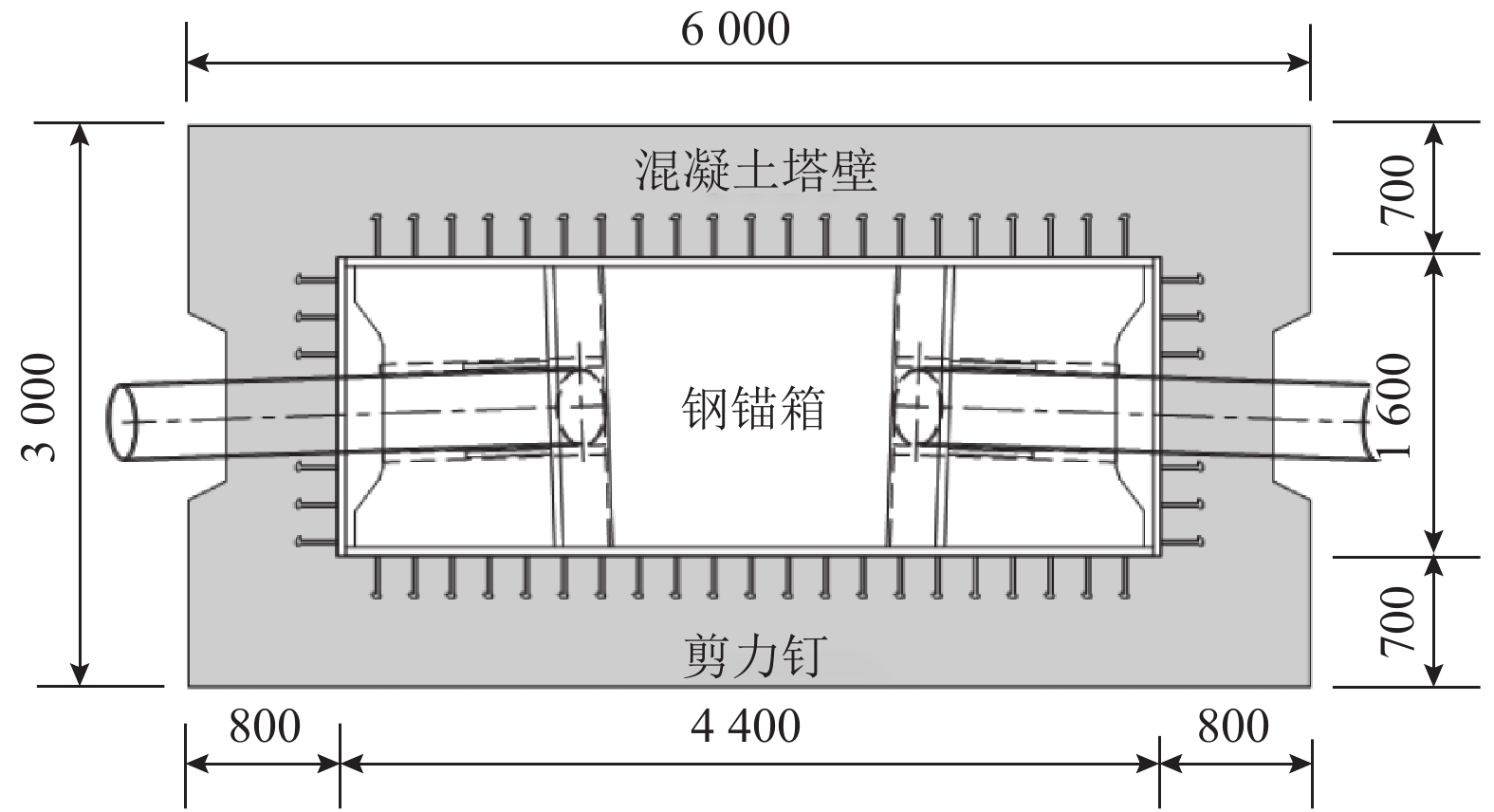

摘要: 为了解斜拉桥钢-混组合索塔锚固结构的力学行为并对结构设计进行优化,以重庆嘉悦大桥为依托,通过足尺模型试验及非线性有限元分析的对比分析,对钢-混凝土组合索塔锚固结构的力学性能、荷载传递机理进行了研究;采用正交试验方法对索塔锚固区混凝土主拉应力进行参数敏感性分析,进而提出了结构优化设计参数. 研究结果表明:钢锚箱与混凝土塔壁的应力水平较低,应力分布均匀流畅;钢锚箱与混凝土塔壁的相对滑移值均很小,最大值仅0.029 mm;剪力键的抗剪刚度对混凝土端塔壁的主拉应力水平有较为显著的影响,当刚度增加5倍,混凝土端塔壁主拉应力减少了17.3%;该桥所采用的组合索塔锚固区结构参数是安全、经济的.Abstract: Full-size model test and nonlinear finite element analysis (FEA) are carried out to investigate the mechanical behavior and optimize the structure design of the steel-concrete composite cable-pylon anchor of Jiayue Bridge, Chongqing. The mechanical performance and load transfer mechanism of the steel-concrete composite cable-pylon anchor are studied first by the model test comparing with the nonlinear FEA. Then, the optimized structural parameters of the composite cable-pylon anchor are analyzed by FEA. Results show that the stresses of components of cable-pylon anchor are on a low level and distribute evenly. The relative slippage between anchor box and concrete pylon is small, and the maximum value is only 0.029 mm. The stiffness of shear connectors has a great impact on the principle stress of concrete pylon. When the stiffness is increased by 5 times, the principle stress of concrete pylon is reduced by 17.3%. The cable-pylon anchor’s structural design of Jiayue Bridge meet the requirement of safety and economics.

-

表 1 因素水平表

Table 1. Levels of impact factors

因素 水平 1 2 3 4 5 剪力键抗剪刚度/(kN•mm–1) 100 200 300 400 500 侧板厚度/mm 20 30 40 50 60 剪力板厚度/mm 20 30 40 50 60 表 2 试验方案及混凝土塔壁主拉应力计算结果

Table 2. Experimental scheme and calculated principal tensile stresses of concrete walls

试验号 试验值 混凝土塔壁主拉应力/MPa a/(kN•mm–1) b/mm c/mm 侧塔壁 端塔壁 1 100 20 20 11.134 6.100 2 100 30 30 11.045 5.530 3 100 40 40 10.937 5.231 4 100 50 50 10.818 5.042 5 100 60 60 10.701 4.903 6 200 20 30 10.862 5.485 7 200 30 40 10.793 4.909 8 200 40 50 10.723 4.595 9 200 50 60 10.642 4.399 10 200 60 20 10.64 4.871 11 300 20 40 10.704 5.13 12 300 30 50 10.656 4.583 13 300 40 60 10.612 4.279 14 300 50 20 10.621 4.749 15 300 60 30 10.606 4.426 16 400 20 50 10.608 4.886 17 400 30 60 10.575 4.369 18 400 40 20 10.560 4 4.772 19 400 50 30 10.599 4.382 20 400 60 40 10.574 4.137 21 500 20 60 10.548 4.706 22 500 30 20 10.447 4.944 23 500 40 30 10.548 4.437 24 500 50 40 10.57 4.135 25 500 60 50 10.558 3.929 表 3 极差分析结果表

Table 3. Results of range analysis

指标平均值 混凝土侧塔壁最大主拉应力/MPa 混凝土端塔壁最大主拉应力/MPa a b c a b c k1 10.927 10.771 10.681 5.361 5.261 5.087 k2 10.732 10.703 10.732 4.852 4.867 4.852 k3 10.640 10.676 10.716 4.633 4.663 4.708 k4 10.583 10.650 10.673 4.509 4.541 4.607 k5 10.534 10.616 10.616 4.430 4.453 4.531 R 0.393 0.155 0.116 0.931 0.808 0.556 表 4 混凝土端塔壁主拉应力方差分析结果表

Table 4. Results of variance analysis of principal tensile stress on the surface of concrete end walls

变异来源 变动平方和 自由度 均方根 F F0.05 F0.01 显著性 因素a 2.788 4 0.697 256.372 6.39 15.98 显著 因素b 2.071 4 0.518 190.452 显著 因素c 0.97 4 0.242 89.165 显著 误差 0.022 4 0.003 总和 5.851 -

崔冰,孟凡超,冯良平,等. 南京长江第三大桥钢塔柱设计与加工[J]. 中国铁道科学,2005,26(3): 42-47. doi: 10.3321/j.issn:1001-4632.2005.03.009CUI Bing, MENG Fanchao, FENG Liangping, et al. Design and fabrication of the tower column of Nanjing No. 3 Yangtze river bridge[J]. China Railway Science, 2005, 26(3): 42-47. doi: 10.3321/j.issn:1001-4632.2005.03.009 周岺, 许春荣. 斜拉桥索-塔锚固结构形式的比较研究[C]//2004年全国桥梁学术会议. 昆明: 中国公路学会, 2004: 273-279 范立础. 世界最大跨径的斜拉桥-法国诺曼底(Normandy)大桥的设计及施工[J]. 重庆交通学院学报,1995,14(3): 1-8.Fan Lichu. The design and construction of the world longest span cable stayed bridge Normandy bridge in France[J]. Journal of Chongqing Jiaotong Institute, 1995, 14(3): 1-8. 杨允表,吕忠达. 大跨度斜拉桥索塔锚固区钢-混凝土结构竖向受力机理的有限元法[J]. 工程力学,2008,25(12): 153-161.YANG Yunbiao, LÜ Zhongda. A finite element method for vertical mechanics analysis of steel-concrete composite structure in pylon cable anchor zone of long span cable-stayed bridge[J]. Engineering Mechanics, 2008, 25(12): 153-161. 苏庆田,曾明根,吴冲. 上海长江大桥索塔钢锚箱模型试验研究[J]. 工程力学,2008,25(10): 126-132.SU Qingtian, ZENG Minggen, WU Chong. Experiment study on steel-anchor-box of cable-pylon in Shanghai Yangtze river bridge[J]. Engineering Mechanics, 2008, 25(10): 126-132. 苏庆田,翟慧娜,吴冲. 济南黄河三桥索塔锚固区水平受力性能模型试验研究[J]. 桥梁建设,2008(3): 12-14.SU Qingtian, ZHAI Huina, WU Chong. Model test study of horizontal load-bearing behavior of anchorage zone in cable pylon of the 3rd Jinan Huanghe river bridge[J]. Bridge Construction, 2008(3): 12-14. 肖林,叶华文,卫星,等. 斜拉桥桥塔钢-混结合段的力学行为和传力机理研究[J]. 土木工程学报,2014,47(3): 88-96.XIAO Lin, YE Huawen, WEI Xing, et al. Study on mechanical behavior and load transfer mechanism of steel-concrete composite joint of cable-stayed bridge pylon[J]. China Civil Engineering Journal, 2014, 47(3): 88-96. 陈开利. 钢锚箱索塔锚固区受力机理[J]. 中国铁道科学,2008,29(4): 58-64.CHEN Kaili. Mechanical mechanism of the steel anchor housing in the anchorage zones of the cable pylons[J]. China Railway Science, 2008, 29(4): 58-64. 汪昕,吕志涛. 斜向索荷载传递与分配关系分析力下钢混凝土组合索塔锚固区[J]. 东南大学学报,2006,36(4): 587-589.WANG Xin, LÜ Zhitao. Analysis of load transferring and distribution in anchorage zone of steel-concrete composite pylon under inclined cable forces[J]. Journal of Southeast University, 2006, 36(4): 587-589. 刘钊,孟少平,吕志涛. 两座大型斜拉桥索塔锚固区模型试验及对比研究[J]. 中国工程科学,2003,5(12): 48-53. doi: 10.3969/j.issn.1009-1742.2003.12.008LIU Zhao, MENG Shaoping, LÜ Zhita. Model test and comparative study of the pylon’s anchorage zone of two long-span cable-stayed bridges[J]. Engineering Science, 2003, 5(12): 48-53. doi: 10.3969/j.issn.1009-1742.2003.12.008 白光亮,蒲黔辉,袁万城,等. 栓钉在斜拉桥索塔锚固区中的试验研究与非线性分析[J]. 铁道学报,2009,31(3): 75-81. doi: 10.3969/j.issn.1001-8360.2009.03.014BAI Guangliang, PU Qianhui, YUAN Wancheng, et al. Experimental research and FEM analysis of stud connectors in anchorage zone of pylon of cable-stayed bridge[J]. Journal of the China Railway Society, 2009, 31(3): 75-81. doi: 10.3969/j.issn.1001-8360.2009.03.014 OLLGAARD J G, SLUTTER R G, FISHER J W. Shear strength of stud connectors in lightweight and normal weight concrete[J]. AISC Enginneering Journal, 1971: 55-64. LIN Xiao, LI Xiaozhen, MA Z J. Behavior of perforated shear connectors in steel-concrete composite joints of hybrid bridges[J]. Journal of Bridge Engineering. 2017, 22(4): 04016135 肖林,卫星,强士中. 两类PBL剪力键推出试验的对比研究[J]. 土木工程学报,2013,46(11): 70-81.XIAO Lin, WEI Xing, QIANG Shizhong. Comparative study on two kinds of push-out tests of PBL shear connector[J]. China Civil Engineering Journal, 2013, 46(11): 70-81. ZHANG Qinghua, PEI Shiling, CHENG Zhenyu, et al. Theoretical and experimental studies of the internal force transfer mechanism of perfobond rib shear connector group[J]. Journal of Bridge Engineering. 2017, 22(4): 0000997 宋随弟,黄博,祝兵,等. 预应力PBL剪力键的承载能力试验研究[J]. 西南交通大学学报,2017,52(4): 647-654.SONG Suidi, HAUNG Bo, ZHU Bing, et al. Analysis of the bearing capacity of PBL shear connector[J]. Journal of Southwest Jiaotong Uiversity, 2017, 52(4): 647-654. -

下载:

下载: