Temperature Field of in-Wheel Motor Using Coupled Multi-physics Domain Solution

-

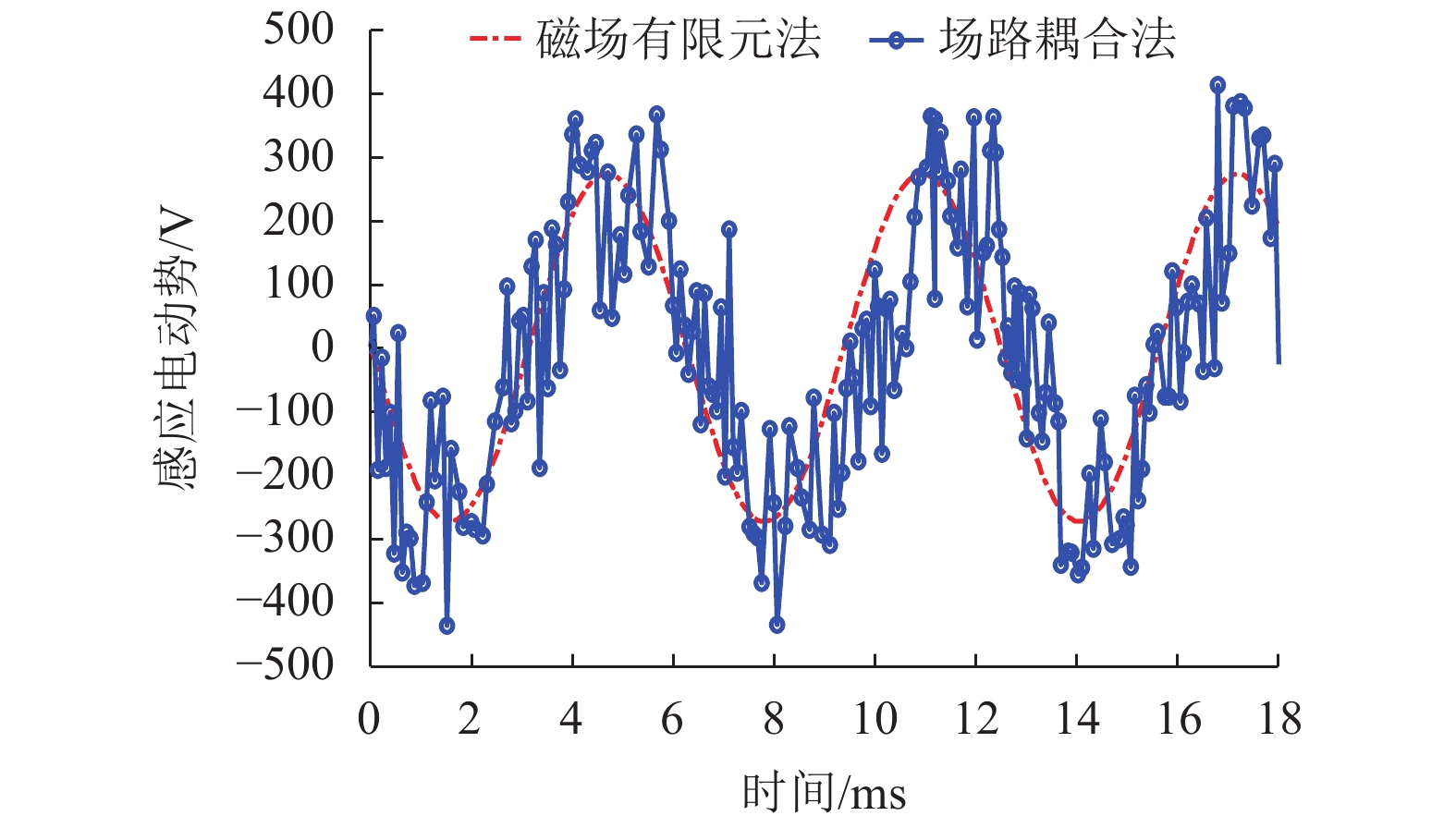

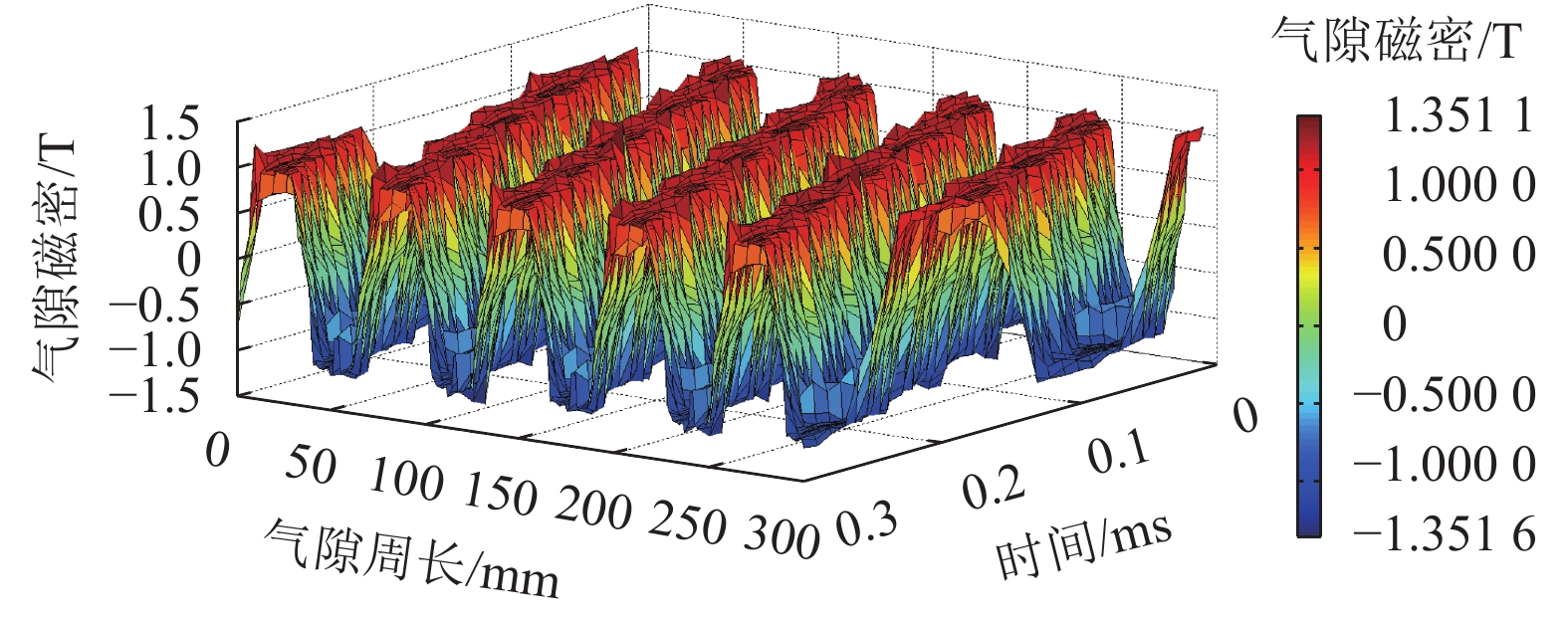

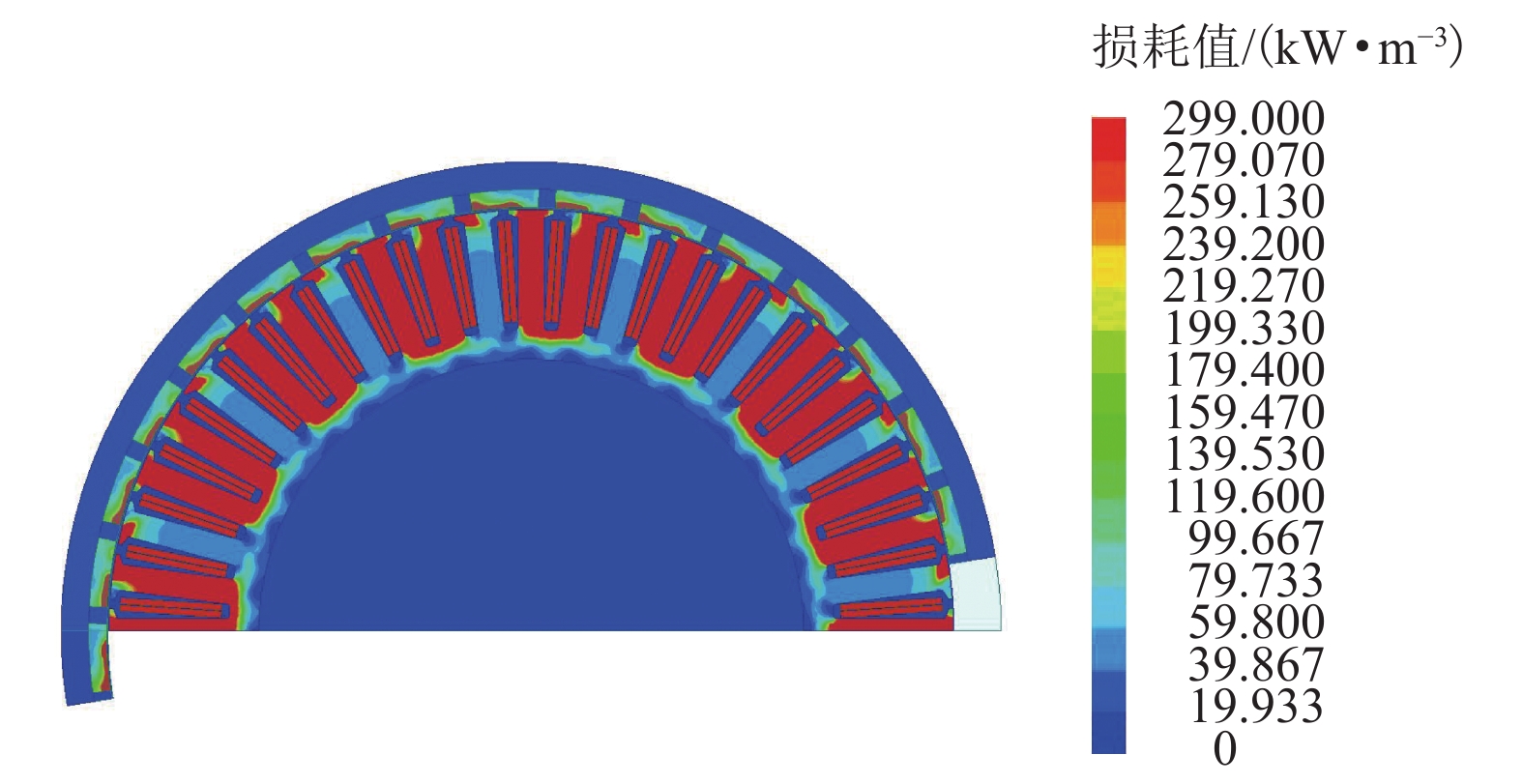

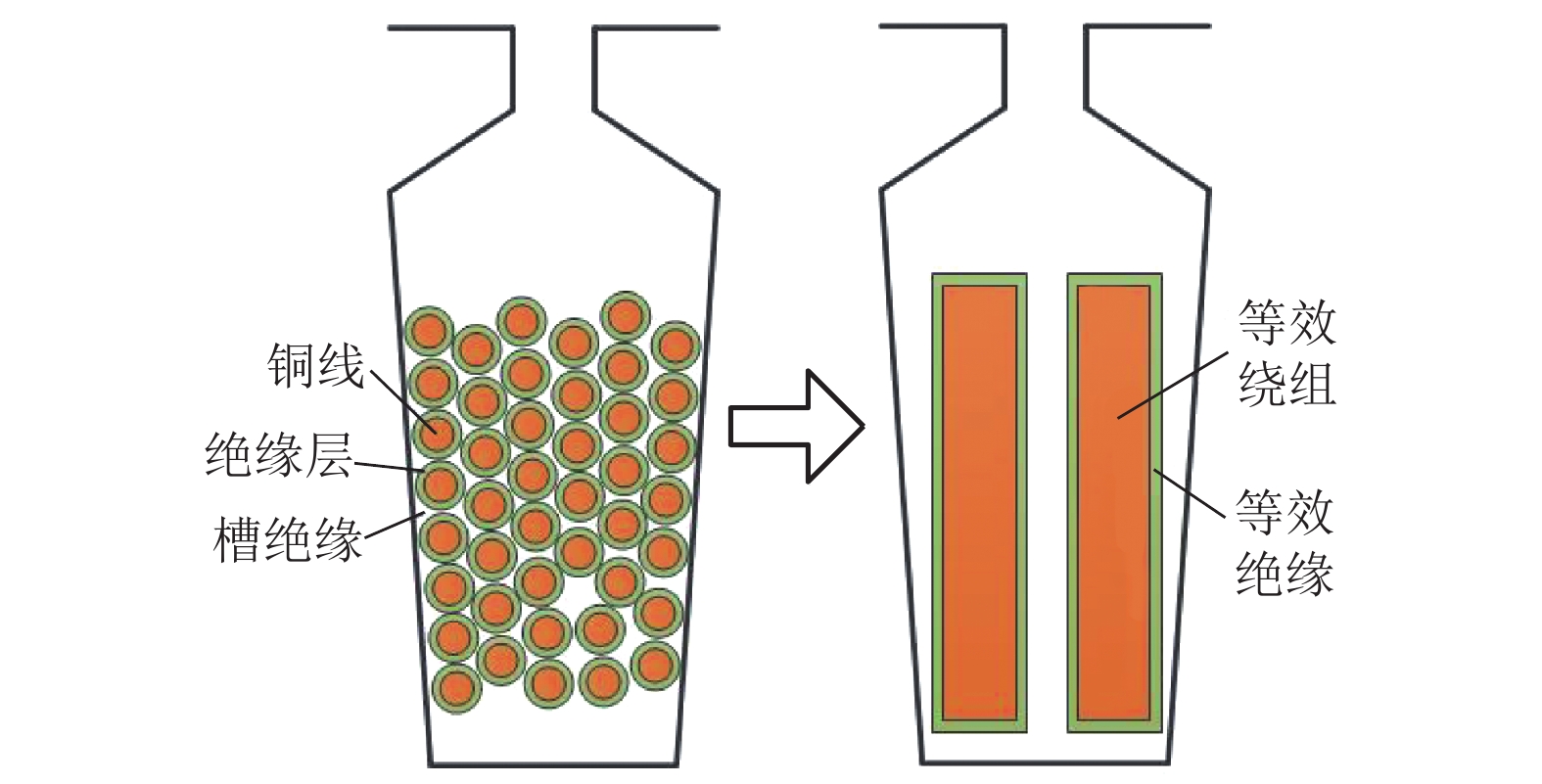

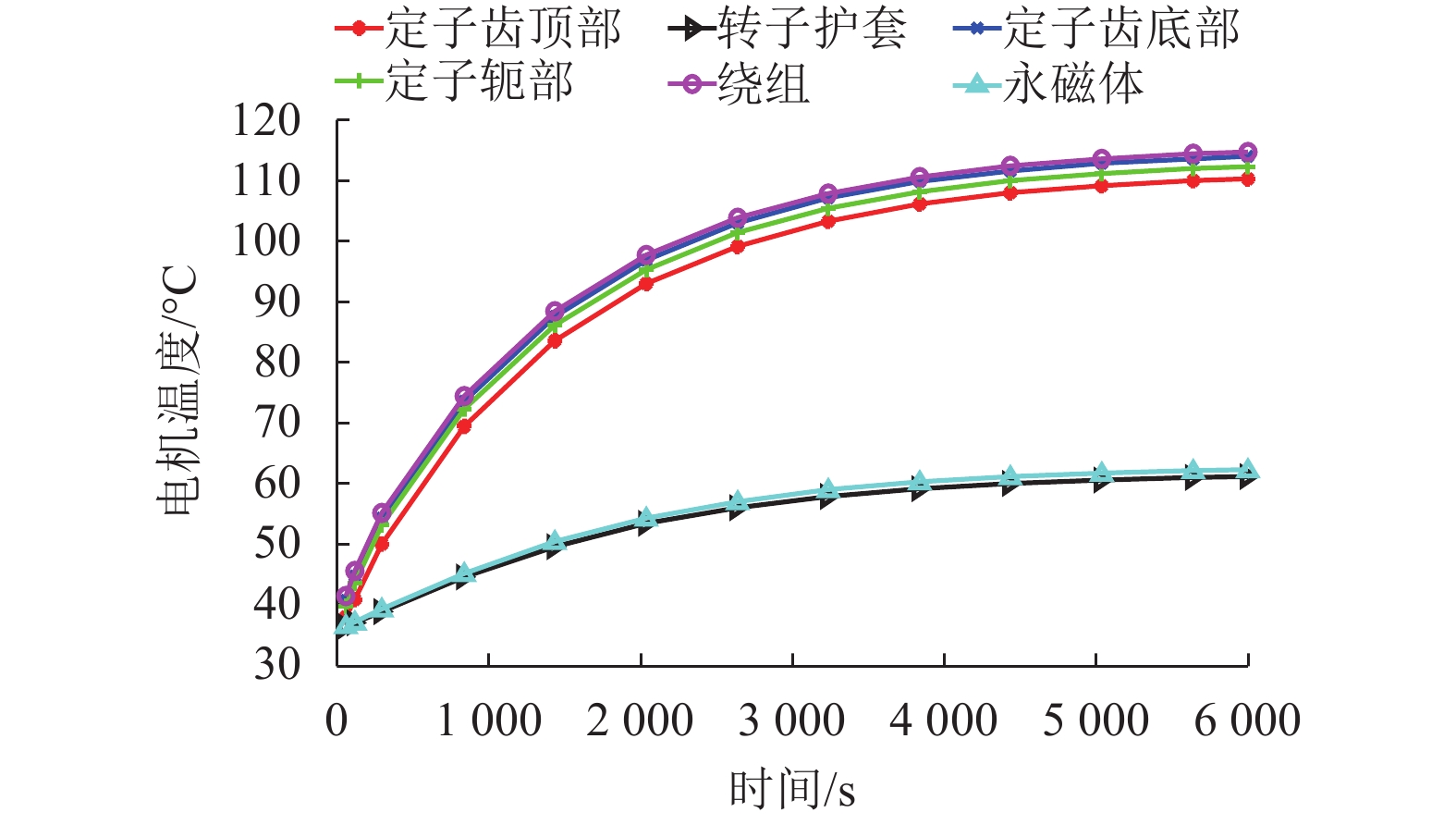

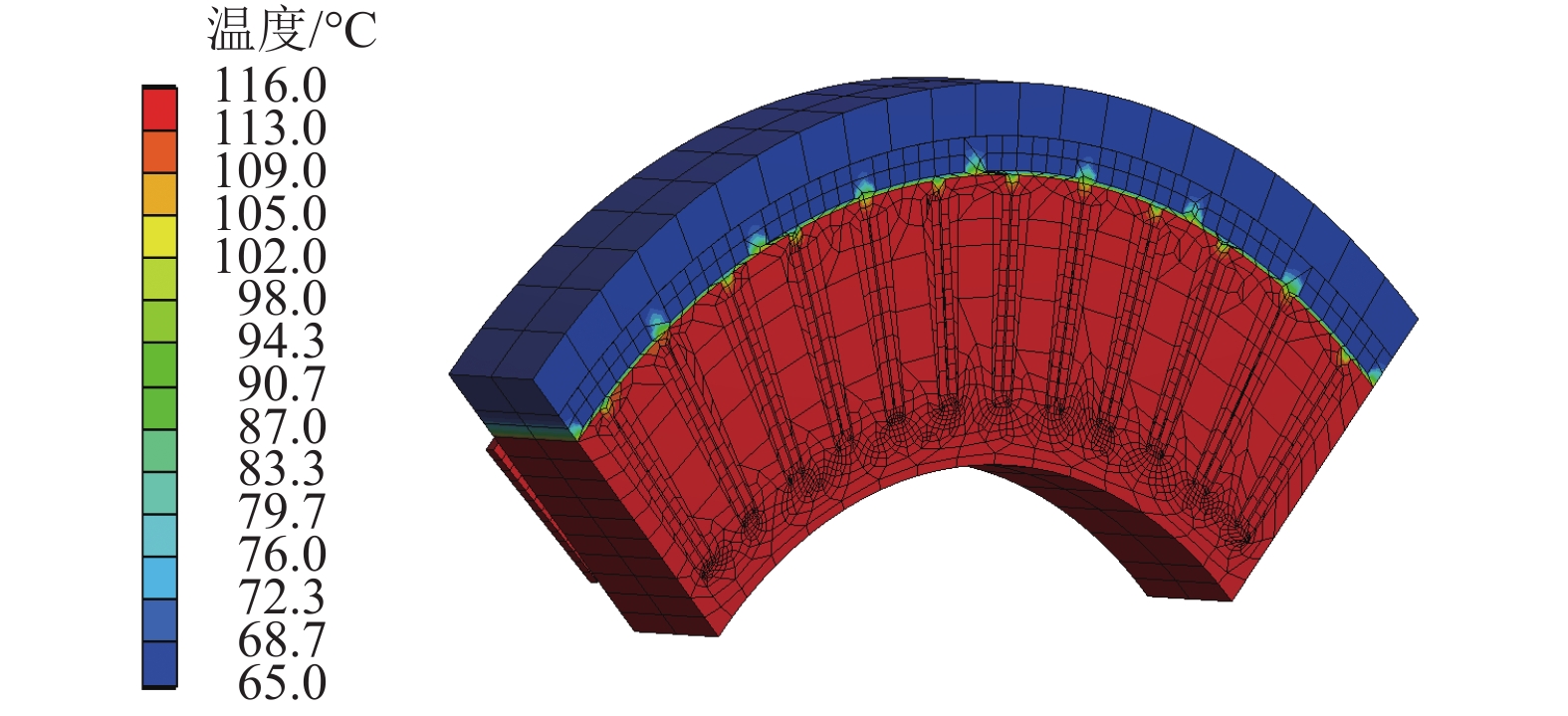

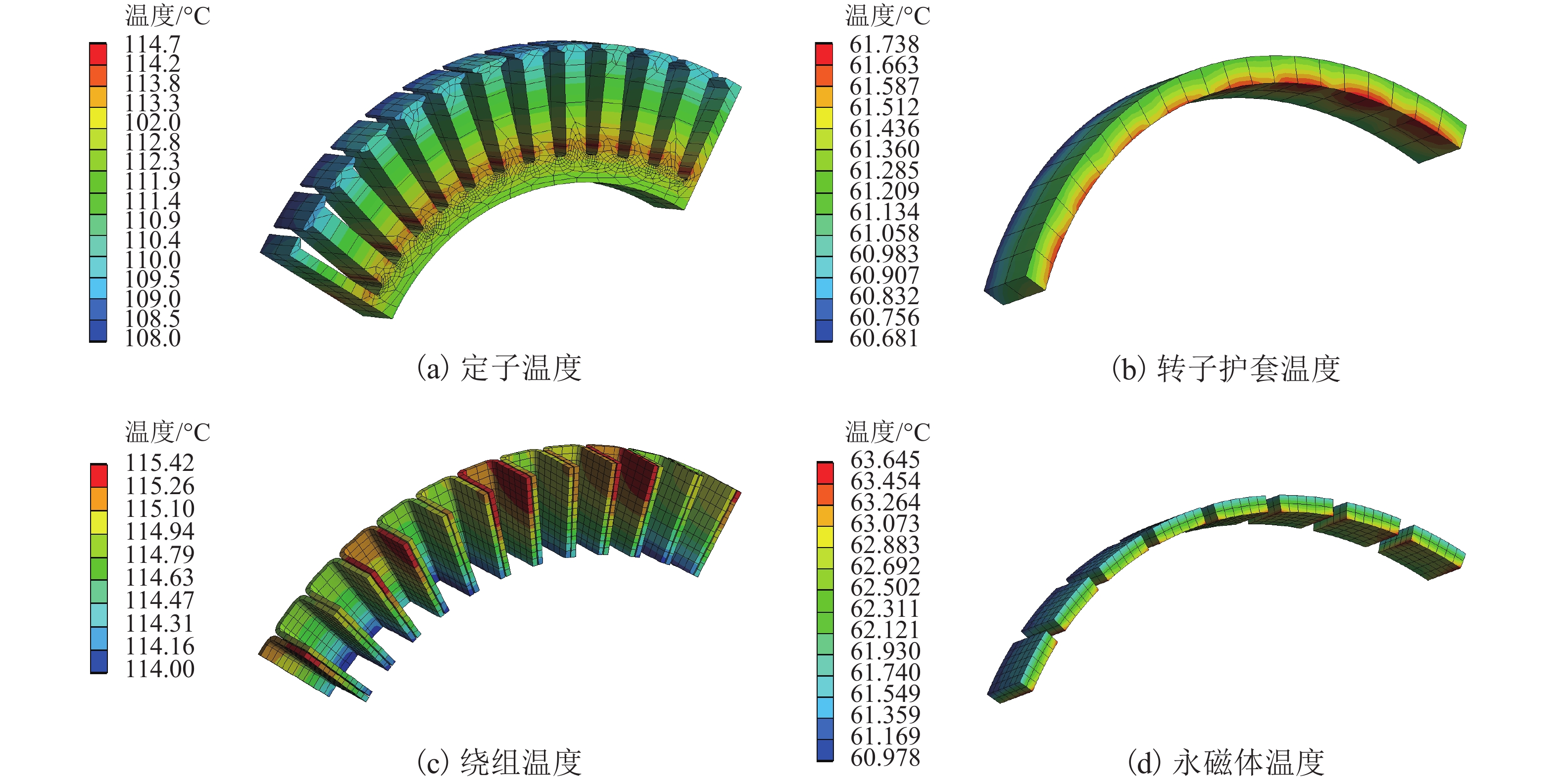

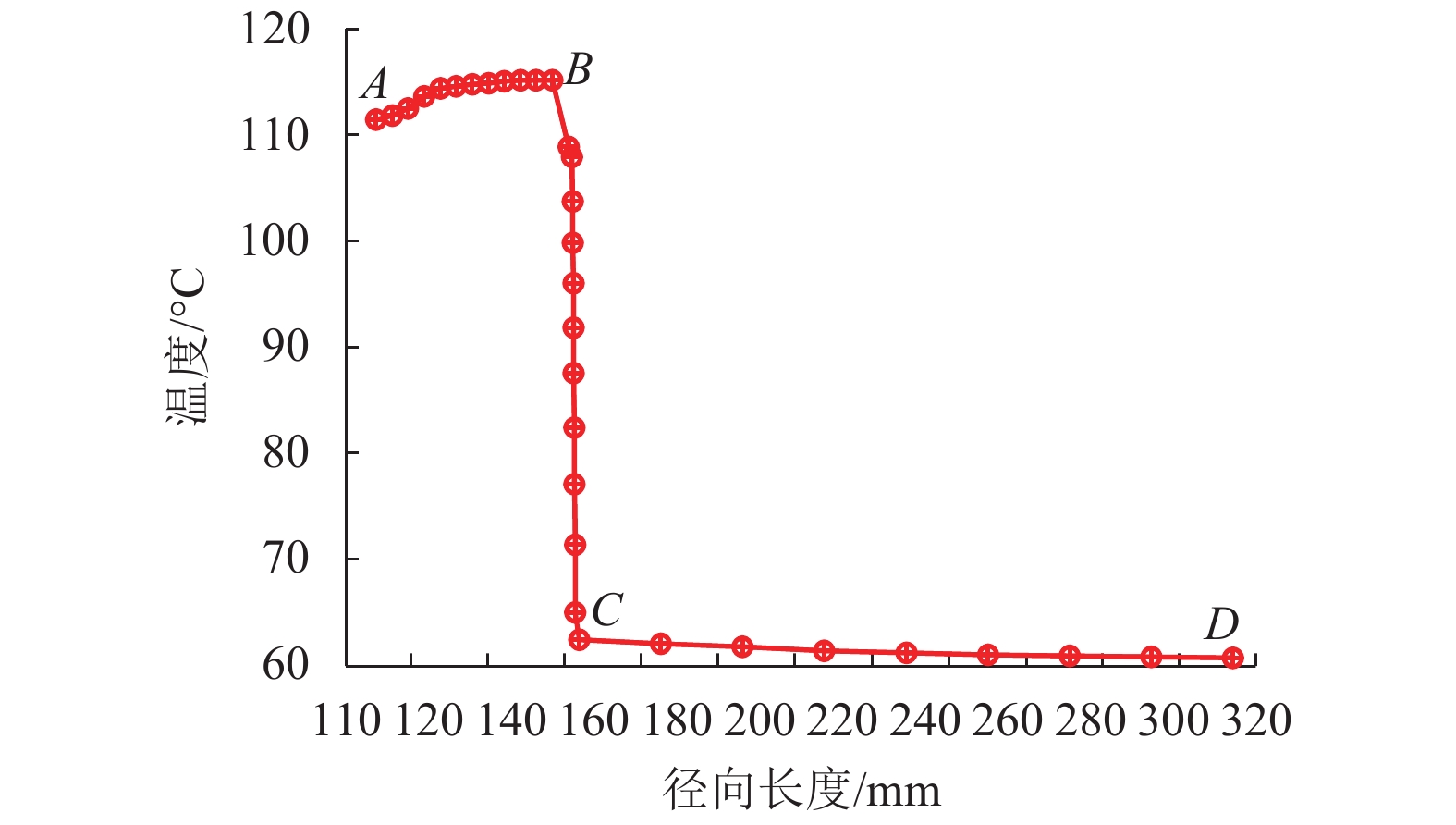

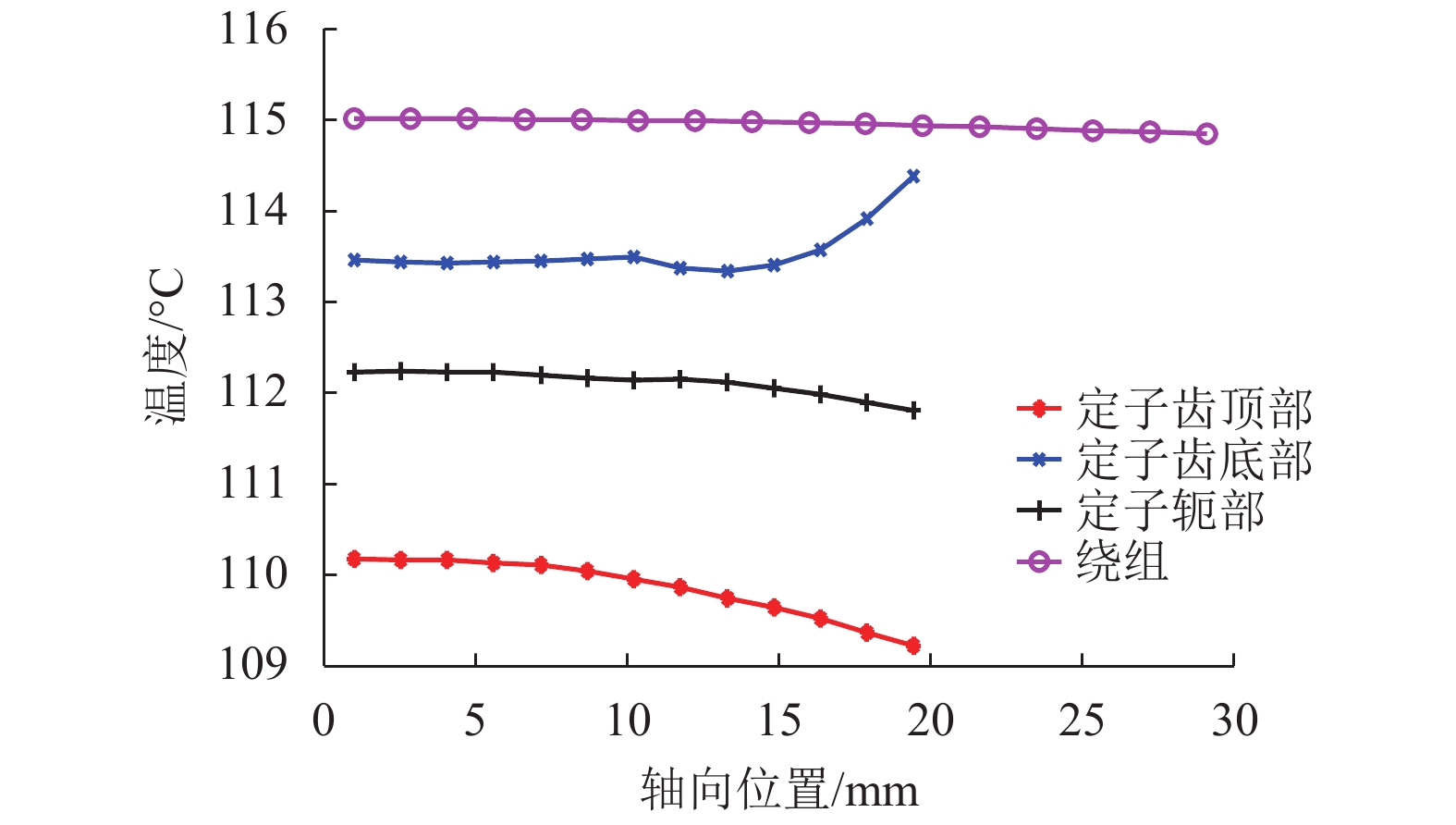

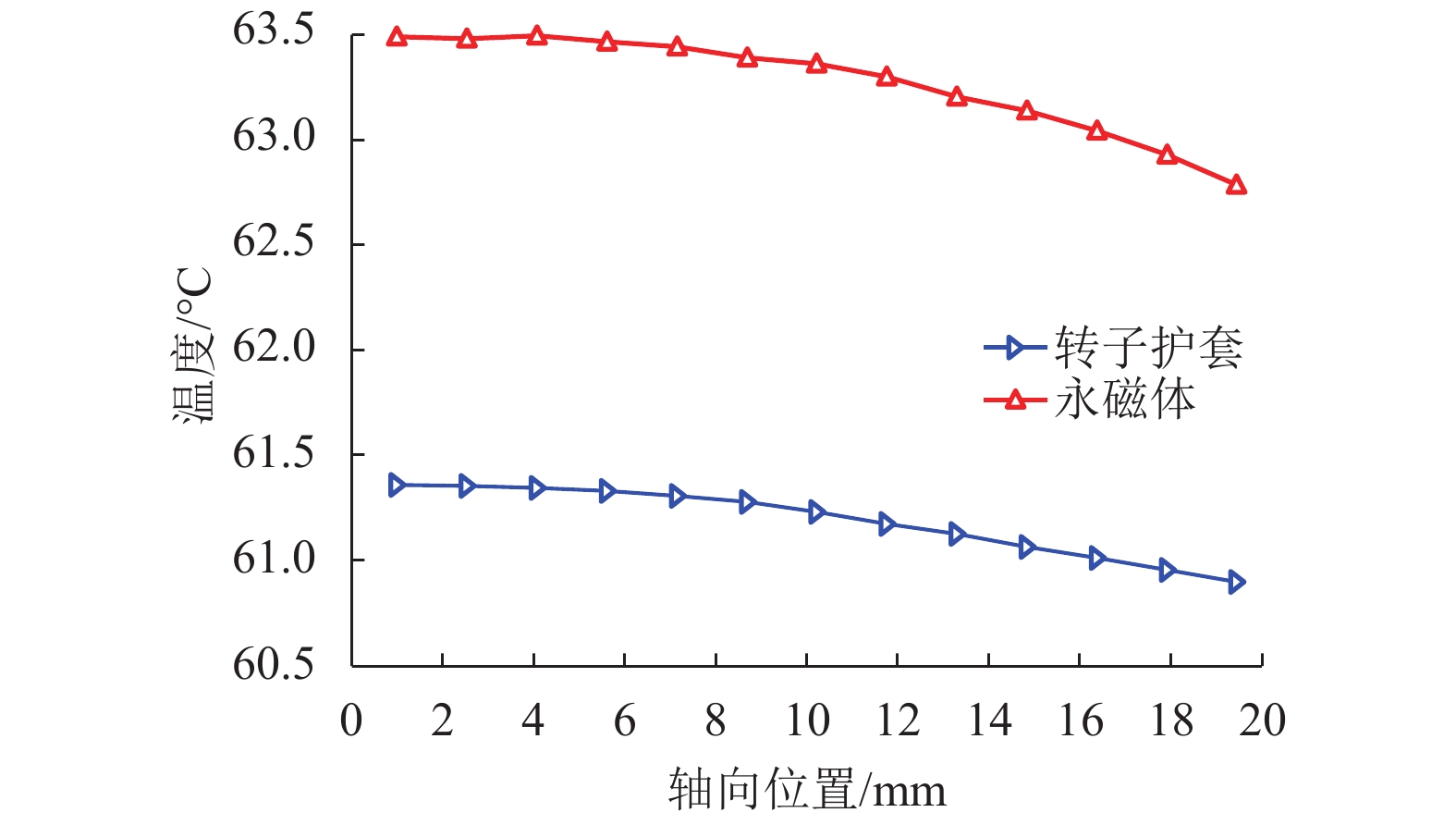

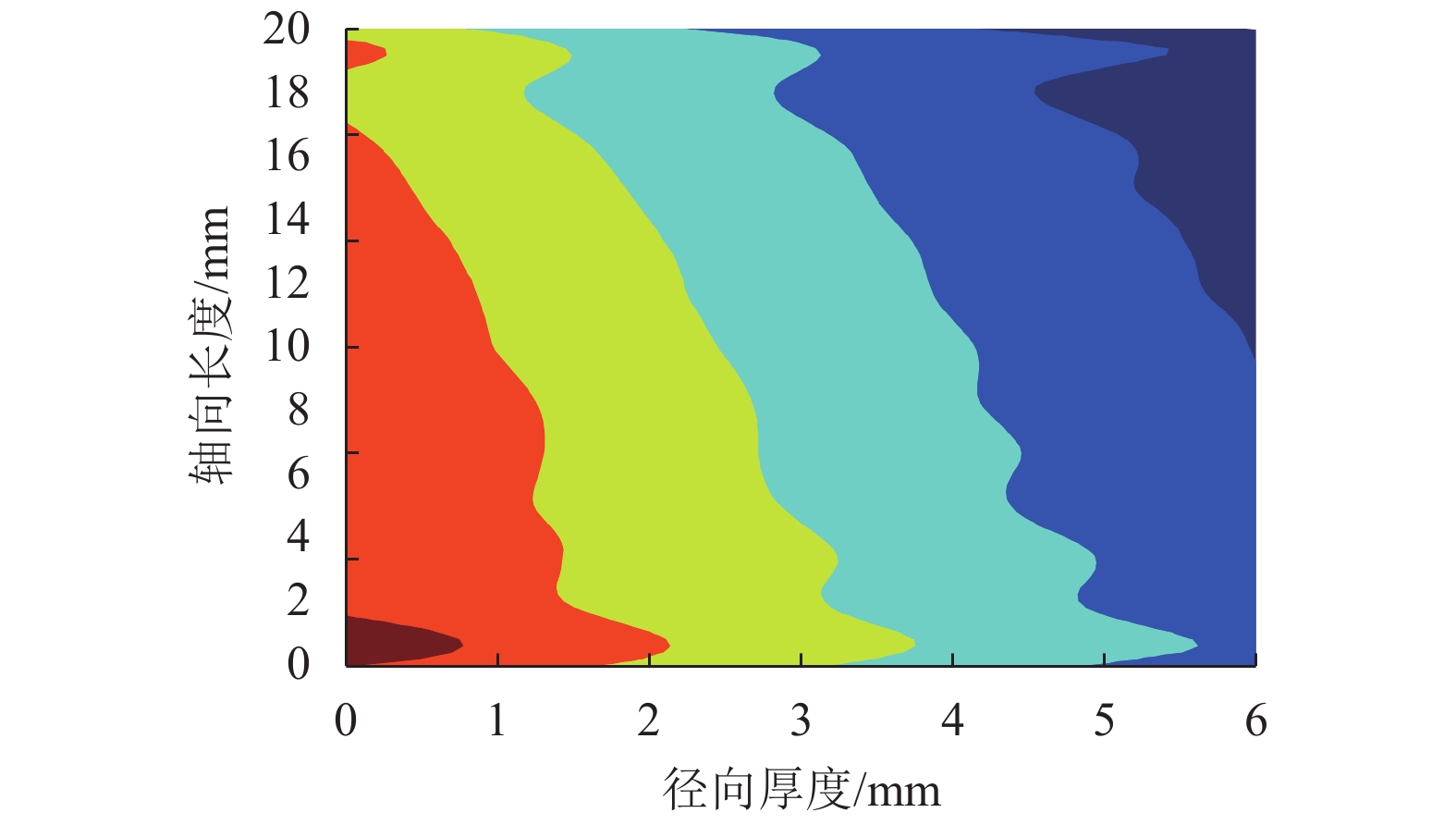

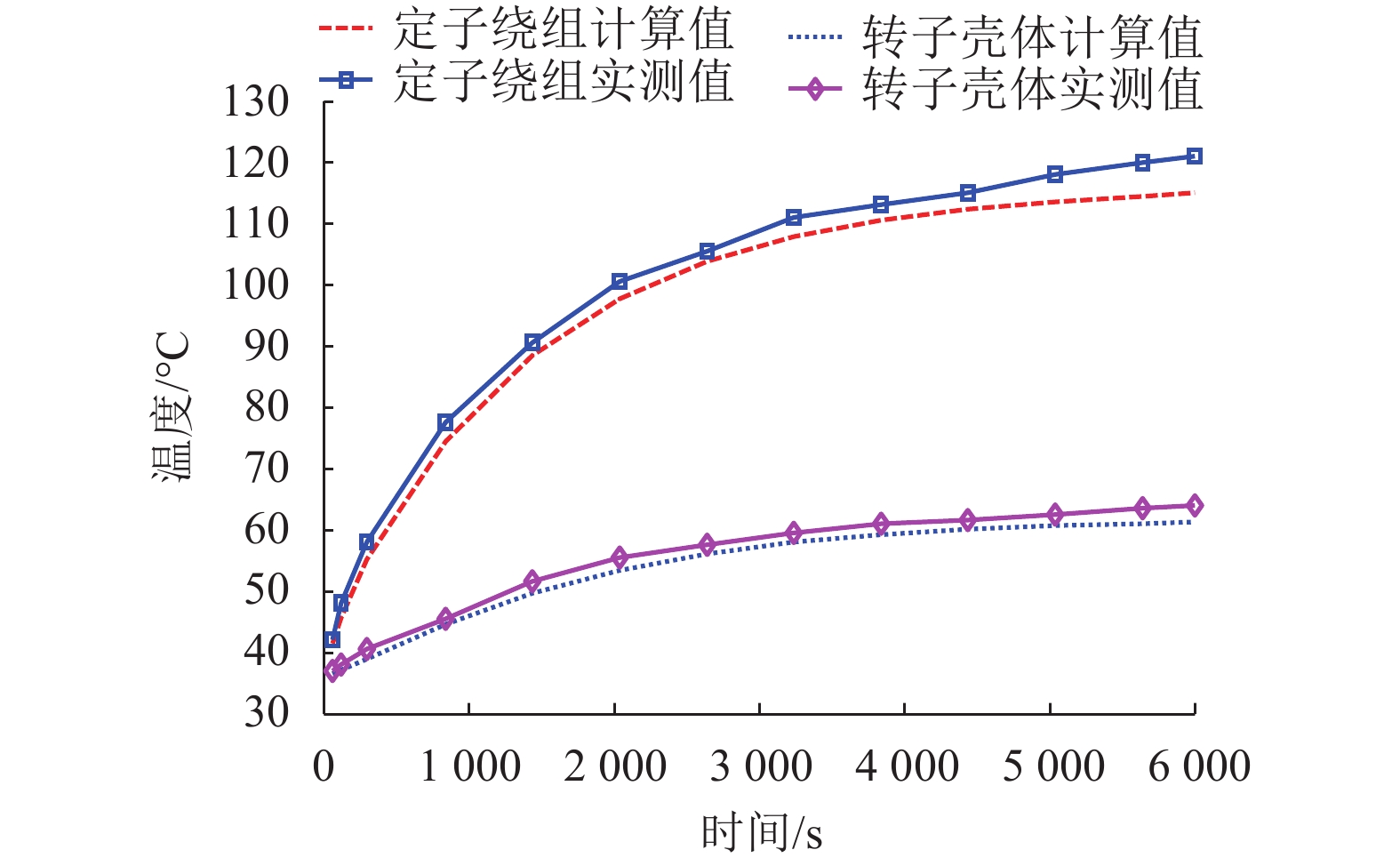

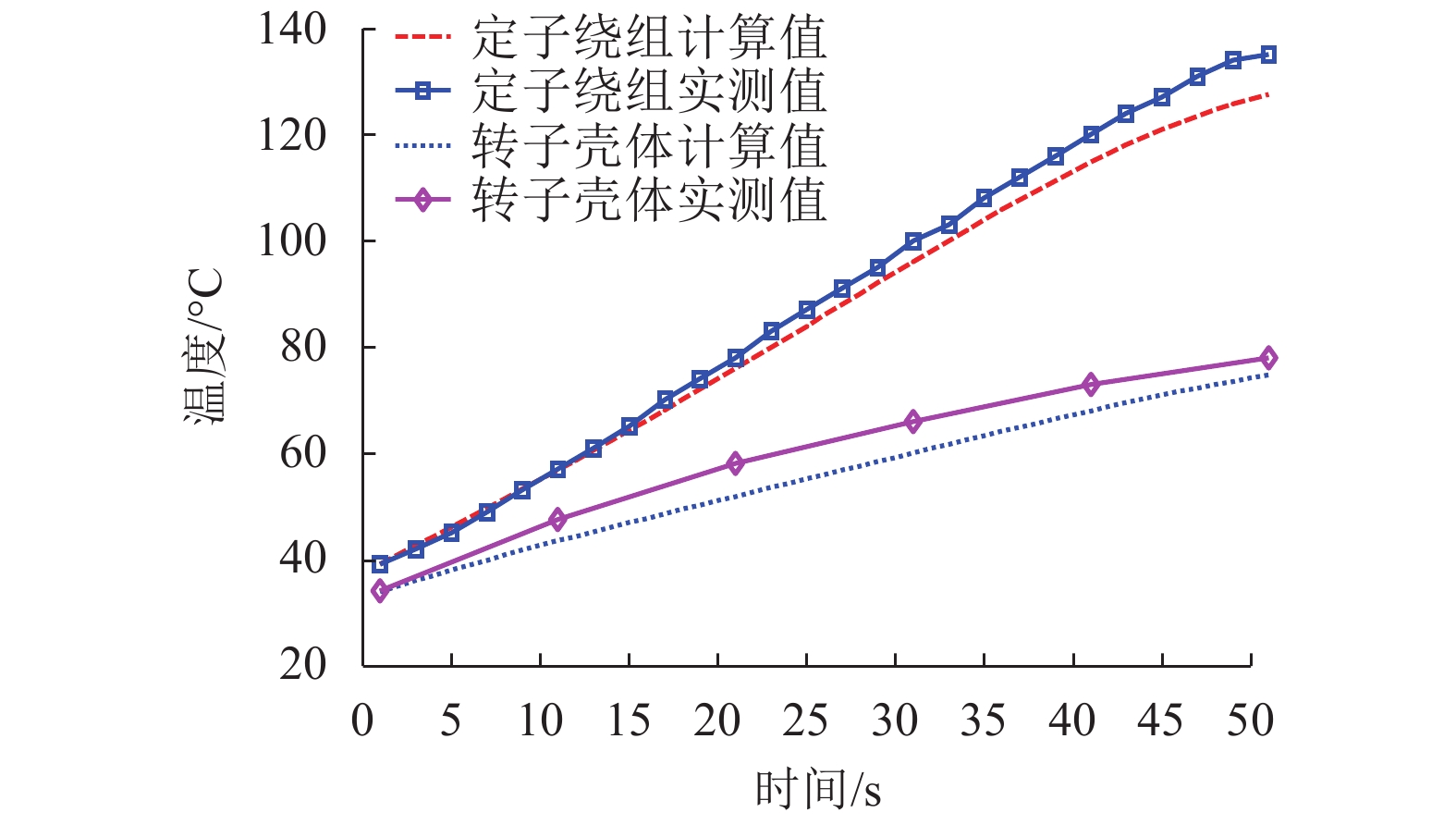

摘要: 为研究温度变化对电动汽车用轮毂电机的工作性能和使用寿命的影响,采用场路耦合法将轮毂电机有限元模型与外电路联合求解,建立了包含轮毂电机本体、外部驱动控制电路的联合仿真模型,充分考虑了外部激励中时间谐波电流对磁场的影响. 然后,将计算得到的绕组铜耗、定子铁芯损耗、永磁体涡流损耗以及杂散损耗等作为热源,采用磁热耦合法将其耦合到各部件进行瞬态温度场研究,综合考虑了电机工作过程中其损耗分布在时间和空间位置上的瞬态变化特性,热源损耗与温度场实时精确耦合. 详细研究了负载运行时轮毂电机各部件温度随时间的变化情况,以及温度的空间分布特性. 多物理域耦合法实现了电磁场与外电路的直接耦合,电磁场与温度场的顺序耦合. 最后,对轮毂电机进行台架试验. 研究结果表明:仿真计算结果与试验结果在额定工况下温度的最大误差为4.96%,峰值工况下最大误差为10.55%.Abstract: In order to study the influence of temperature change on the working performance and service life of in-wheel motor for electric vehicles, a coupled multi-physics analysis method is proposed. Firstly, the field-circuit coupling method is used to solve the finite element model of the in-wheel motor and the external circuit. A joint simulation model including the in-wheel motor and external drive control circuit is established, which takes into account the influence of the time harmonic current from external excitation on the magnetic field. Then, the calculated winding copper loss, stator core loss, permanent magnet (PM) eddy current loss and stray loss are used as heat sources, and they are coupled to each component by magneto-thermal coupling method to study the transient temperature field. The transient variation characteristics of the loss distribution in time and space are overall considered, and the thermal loss and temperature field are coupled accurately in real time. The temperature variation of each component over time and space is studied in detail. The direct coupling between electromagnetic field and external circuit, and the sequential coupling between electromagnetic field and temperature field are realized by the coupled multi-physics analysis method. Finally, the bench test of the in-wheel motor is carried out. The results show that the maximum temperature error between the simulation and tests is 4.96% under rated conditions, and the maximum error is 10.55% under peak conditions.

-

表 1 轮毂电机主要参数

Table 1. Main parameters of in-wheel motor

额定功率/kW 峰值功率/kW 直流母线

电压/V定子内径/mm 转子外径/mm 铁芯轴向长度/mm 额定转速/rpm 并联支路数 永磁体厚度/mm 定子

槽数极

对数绕组

节距10 23 355 182 314 40 600 16 6 48 16 1 表 2 轮毂电机各部件材料的热参数

Table 2. Thermal parameters of component material for in-wheel motor

部件 材料 密度/(kg•m−3) 导热系数/(W•m−2•℃−1) 比热容量/(J•kg−1•℃−1) 等效气隙 空气 1.161 4 0.047 8 1 012 定子绕组 铜 8 933 401 386 定子铁心 硅钢片 7 650 40.0(轴向),4.4(径向) 450 转子护套 铝合金 2 680 210 871 永磁体 钕铁硼 7 400 9 440 等效槽绝缘层 聚酰胺 1 200 0.13 1 300 槽楔 环氧树脂 980 0.3 847 -

余卓平,冯源,熊璐. 分布式驱动电动汽车动力学控制发展现状综述[J]. 机械工程学报,2013,49(8): 105-114.YU Zhuoping, FENG Yuan, XIONG Lu. Review on vehicle dynamics control of distributed drive electric vehicle[J]. Journal of Mechanical Engineering, 2013, 49(8): 105-114. 曹秉刚,张传伟,白志峰,等. 电动汽车技术进展和发展趋势[J]. 西安交通大学学报,2004,38(1): 1-5. doi: 10.3321/j.issn:0253-987X.2004.01.001CAO Binggang, ZHANG Chuanwei, BAI Zhifeng, et al. Technology progress and trends of electric vehicles[J]. Journal of Xi'an Jiaotong University, 2004, 38(1): 1-5. doi: 10.3321/j.issn:0253-987X.2004.01.001 WANG Q, JIANG B, LI B, et al. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles[J]. Renewable & Sustainable Energy Reviews, 2016, 64(10): 106-128. 沈启平. 车用高功率密度永磁同步电机的研究[D]. 沈阳: 沈阳工业大学, 2012. 邓尧强, 董江东. 用分段等效热路法计算电机的温升[J]. 电机技术,2016,10(4): 14-18.DENG Yaoqiang, DONG Jiangdong. Calculation on temperature-rise of motors by means of the equivalent heat-path subsection method[J]. Electrical Machinery Technology, 2016, 10(4): 14-18. 张建忠,姜永将. 基于等效热网络法的定频双转子永磁风力发电机的热分析[J]. 电工技术学报,2015,30(2): 87-97. doi: 10.3969/j.issn.1000-6753.2015.02.012ZHANG Jianzhong, JIANG Yongjiang. Thermal analysis of constant frequency double rotor permanent magnet generator based on equivalent thermal network method[J]. Transactions of China Electrotechnical Society, 2015, 30(2): 87-97. doi: 10.3969/j.issn.1000-6753.2015.02.012 GUO B, HUANG Y, GUO Y, et al. Thermal analysis of the conical rotor motor using LPTN with accurate heat transfer coefficients[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(7): 1-7. 王晓远,高鹏. 等效热网络法和有限元法在轮毂电机温度场计算中的应用[J]. 电工技术学报,2016,31(16): 26-33. doi: 10.3969/j.issn.1000-6753.2016.16.004WANG Xiaoyuan, GAO Peng. Application of equivalent thermal network method and finite element method in temperature calculation of in-wheel motor[J]. Transactions of China Electrotechnical Society, 2016, 31(16): 26-33. doi: 10.3969/j.issn.1000-6753.2016.16.004 LIU Y, LEE Y, JUNG H K, et al. 3D thermal stress analysis of the rotor of an induction motor[J]. IEEE Transactions on Magnetics, 2002, 36(4): 1394-1397. 周封,熊斌,李伟力,等. 大型电机定子三维流体场计算及其对温度场分布的影响[J]. 中国电机工程学报,2005,25(24): 128-132. doi: 10.3321/j.issn:0258-8013.2005.24.023ZHOU Feng, XIONG Bin, LI Weili, et al. Numerical calculation of 3D stator fluid field for large electrical machine as well as influences on thermal field distribution[J]. Proceedings of the Chinese Society for Electrical Engineering, 2005, 25(24): 128-132. doi: 10.3321/j.issn:0258-8013.2005.24.023 丁树业,郭保成,冯海军,等. 变频控制下永磁同步电机温度场分析[J]. 中国电机工程学报,2014,34(9): 1368-1375.DING Shuye, GUO Baocheng, FENG Haijun, et al. Temperature field investigation of permanent magnet synchronous motors controlled by the frequency conversion control system[J]. Proceedings of the CSEE, 2014, 34(9): 1368-1375. 陈齐平,舒红宇,庄深,等. 微型电动车轮毂电机的磁热耦合分析[J]. 汽车工程,2013,35(7): 593-598. doi: 10.3969/j.issn.1000-680X.2013.07.004CHEN Qiping, SHU Hongyu, ZHUANG Shen, et al. Magneto-thermal coupling analysis on the in-wheel motors of micro electric vehicles[J]. Automotive Engineering, 2013, 35(7): 593-598. doi: 10.3969/j.issn.1000-680X.2013.07.004 王晓远,贾珍珍,高鹏. 外转子轮毂电机电磁场-温度场的耦合求解分析[J]. 天津大学学报(自然科学与工程技术版),2014,47(10): 898-902.WANG Xiaoyuan, JIA Zhenzhen, GAO Peng. Coupled electromagnetic-thermal field analysis of out-rotor in-wheel motor[J]. Journal of Tianjin University (Science and Technology), 2014, 47(10): 898-902. 丁树业,孟繁东,葛云中. 核主泵屏蔽电机温度场研究[J]. 中国电机工程学报,2012,32(36): 149-155.DING Shuye, MENG Fandong, GE Yunzhong. Temperature field investigation of canned primary pump motors in nuclear power stations[J]. Proceedings of the Chinese Society for Electrical Engineering, 2012, 32(36): 149-155. 李伟力,陈婷婷,曲凤波,等. 高压永磁同步电动机实心转子三维温度场分析[J]. 中国电机工程学报,2011,31(18): 55-60.LI Weili, CHEN Tingting, QU Fengbo, et al. Analysis on solid rotor 3D temperature field in high voltage PMSM[J]. Proceedings of the Chinese Society for Electrical Engineering, 2011, 31(18): 55-60. 胡田,唐任远,李岩,等. 永磁风力发电机三维温度场计算及分析[J]. 电工技术学报,2013,28(3): 122-126. doi: 10.3969/j.issn.1000-6753.2013.03.017HU Tian, TANG Renyuan, LI Yan, et al. Thermal analysis and calculation of permanent magnet wind generators[J]. Transactions of China Electrotechnical Society, 2013, 28(3): 122-126. doi: 10.3969/j.issn.1000-6753.2013.03.017 邰永,刘赵淼. 感应电机全域三维瞬态温度场分析[J]. 中国电机工程学报,2010,30(30): 114-120.TAI Yong, LIU Zhaomiao. Analysis on three-dimensional transient temperature field of induction motor[J]. Proceedings of the CSEE, 2010, 30(30): 114-120. 鲍里先科, 丹特, 亚科夫列夫. 电机中的空气动力学与热传递[M]. 魏书慈, 邱建甫, 译. 北京: 机械工业出版社, 1985: 76-77. 魏永田, 孟大伟, 温嘉斌. 电机内热交换[M]. 北京: 机械工业出版社, 1998: 281-282. 江善林,邹继斌,张洪亮. 电梯曳引PMSM三维暂态温度场的数值计算与分析[J]. 电工技术学报,2007,22(10): 6-11. doi: 10.3321/j.issn:1000-6753.2007.10.002JIANG Shanlin, ZOU Jibin, ZHANG Hongliang. Numerical calculation and analysis of 3D transient temperature field in tractive PMSM for elavator[J]. Transactions of China Electrotechnical Society, 2007, 22(10): 6-11. doi: 10.3321/j.issn:1000-6753.2007.10.002 李立毅,黄旭珍,寇宝泉,等. 基于有限元法的圆筒型直线电机温度场数值计算[J]. 电工技术学报,2013,28(2): 132-138. doi: 10.3969/j.issn.1000-6753.2013.02.018LI Liyi, HUANG Xuzhen, KOU Baoquan, et al. Numerical calculation of temperature field for tubular linear motor based on finite element method[J]. Transactions of China Electrotechnical Society, 2013, 28(2): 132-138. doi: 10.3969/j.issn.1000-6753.2013.02.018 丁树业,孙兆琼,徐殿国,等. 3 MW双馈风力发电机传热特性数值研究[J]. 中国电机工程学报,2012,32(3): 137-143.DING Shuye, SUN Zhaoqiong, XU Dianguo, et al. Numerical investigation of heat transfer for 3 MW doubly-fed wind generators[J]. Proceedings of the CSEE, 2012, 32(3): 137-143. 张河山,邓兆祥,妥吉英,等. 基于改进人工蜂群算法的轮毂电机多目标优化[J]. 西南交通大学学报,2019,54(4): 671-678.ZHANG Heshan, DENG Zhaoxiang, TUO Jiying, et al. Multi-objective optimum design for in-wheel motor based on improved artificial bee colony algorithm[J]. Journal of Southwest Jiaotong University, 2019, 54(4): 671-678. -

下载:

下载: