Axiomatic Design Based Logistics System Evaluation in Mass Customization Context

-

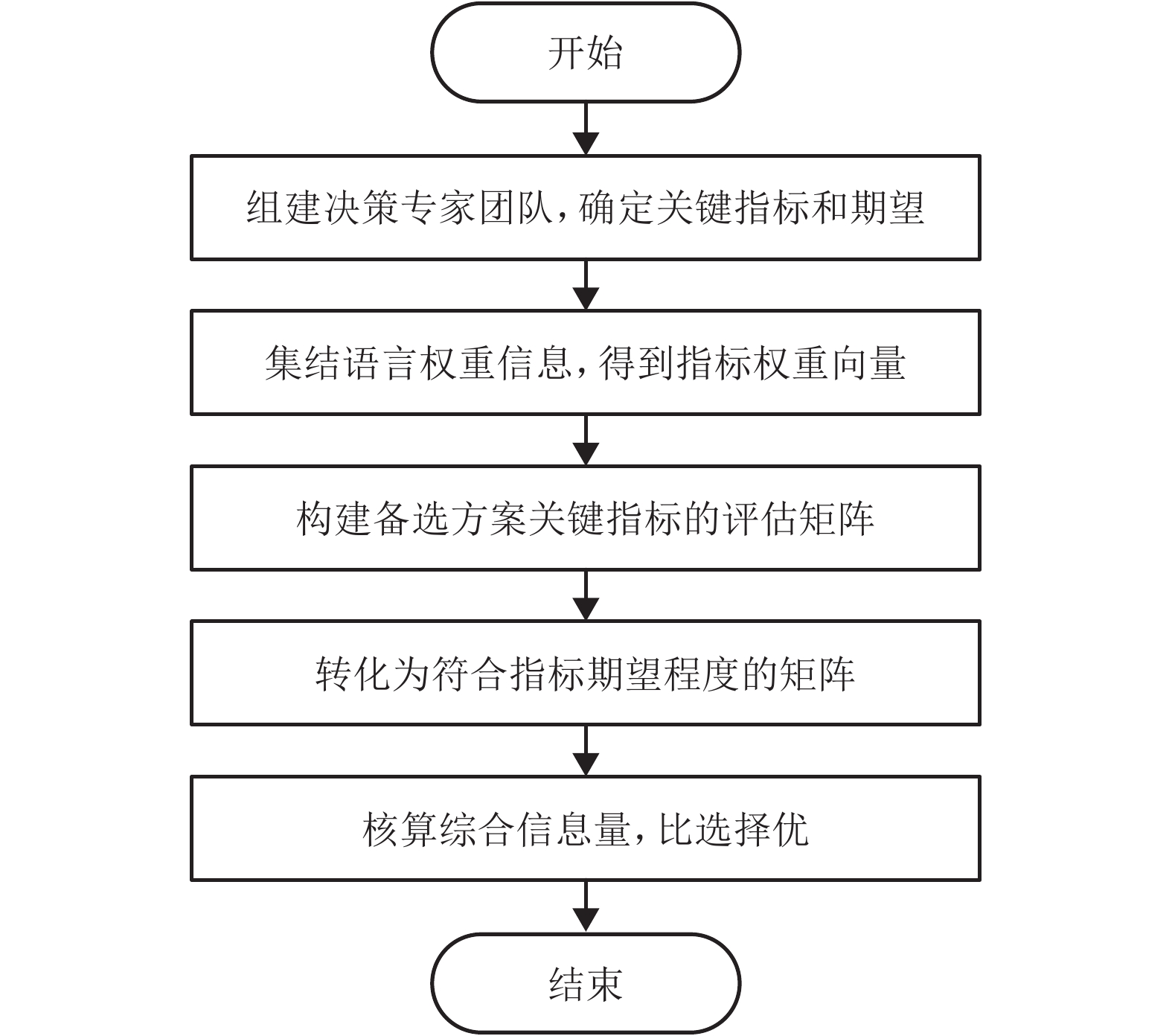

摘要: 针对大规模定制环境下物流系统评价的复杂性和不确定性、决策团队在选择物流系统时不能精确地量化评价指标而是直接给出语言短语,提出了基于语言信息和公理设计的物流系统评价方法. 首先,利用基于模糊评估标度的集成方法对语言短语处理获得规范化的权重向量,其次,决策团队明确各备选方案的期望符合程度,依据公理设计得到各方案的最终评价指数,最后对上述指数排序,以确定最合理方案. 本文所提方法集成了语言决策理论和公理设计的信息公理原理,应用于某电脑公司物流系统的选择,6位决策成员选择了物流系统评价的6项关键指标及其期望值,通过语言信息的处理得到指标权重向量,在此基础上确定了第三方物流企业设计的7个物流系统备选方案,针对服从3种分布的指标期望类型,使用相应的方法进行处理,得到的合理方案验证了方法的可行性和有效性.Abstract: Evaluating logistics systems in the context of mass customisation is uncertain and complex., As linguistic information is utilized in the evaluation of of logistics systems rather thanprecise and quantitative indexes, this paper presents a methodology based on the linguistic information and axiomatic design. In this methodology, firstly, an approach based on the integration of fuzzy scale evaluation is presented to obtain the normalised weight vector. Secondly, the expectation-outcome consistency for each alternative is determined by the executive team, followed by the calculation of the comprehensive evaluation indexes using axiomatic design. Finally, the most suitable logistics system can be identified by the ranking of the comprehensive appraisal indexes. The proposed method synthesized the linguistic-based decision-making theory and applied the information axiom in the axiomatic design for a computer company to select the logistics system. Six decision-makers determined six key indices of the logistics system and their expected values, and the index weight vector was calculated through linguistic information processing. Seven alternatives of logistic systems designed by the third-party logistics enterprises were determined, and the corresponding methods were employed to handle three types of index expectation. The obtained reasonable alternative has validated the feasibility and effectiveness of the proposed method.

-

Key words:

- logistics system /

- mass customization /

- linguistic information /

- axiomatic design

-

表 1 备选方案的评估矩阵

Table 1. Evaluation matrix of alternatives

方案 ${G_1}$ ${G_2}$ … ${G_M}$ $S_1$ ${r_{11}}$ ${r_{12}}$ … ${r_{1M}}$ $S_2$ ${r_{21}}$ ${r_{22}}$ … ${r_{2M}}$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $S_N$ ${r_{N1}}$ ${r_{N2}}$ … ${r_{NM}}$ 表 2 各项关键指标的期望值

Table 2. Expected values of key indices

指标 指标描述 指标期望 货物吞吐总量(任意数量) 反映系统每年输送和接收任意数量货物水平的指标 150万台以上 资金周转率 反映系统资金周转速度的指标 18圈以上 库存总时数 反映系统中产品流动速度的指标 2~6 d 订单响应时间 反映系统整体作业效率的指标 8 d以下 日处理订单数 反映系统处理订单效率的指标 180件以上 任意数量运输成本 反映系统节约开支能力的指标 订单价格的2%以下 表 3 决策成员给出的评估信息

Table 3. Evaluation information presented by decision makers

决策成员 ${G_1}$ ${G_2}$ ${G_3}$ ${G_4}$ ${G_5}$ ${G_6}$ ${D_1}$ 一般 一般 很高 极高 很高 高 ${D_2}$ 高 高 高 很高 一般 一般 ${D_3}$ 很高 高 高 很高 一般 一般 ${D_4}$ 一般 一般 高 高 高 较低 ${D_5}$ 较高 高 很高 极高 较高 高 ${D_6}$ 一般 高 较高 极高 高 高 表 4 备选方案的评估值

Table 4. Evaluation values of alternatives

方案 ${G_1}$ ${G_2}$ ${G_3}$ ${G_4}$ ${G_5}$ ${G_6}$/% ${S_1}$ [115,180] 19.8 [2.5,7.1] [3.5,7.5] 182 1.8 ${S_2}$ [151,192] 19.6 [1.6,6.8] [4.5,7.0] 199 1.9 ${S_3}$ [137,158] 18.2 [2.3,7.4] [4.5,8.0] 186 1.6 ${S_4}$ [132,181] 18.3 [2.5,6.7] [5.5,8.0] 194 1.7 ${S_5}$ [105,142] 17.5 [3.2,5.8] [5.0,7.5] 183 1.8 ${S_6}$ [117,179] 16.4 [3.7,6.8] [5.0,7.5] 179 1.6 ${S_7}$ [152,201] 20.5 [2.1,7.2] [5.0,7.5] 205 1.1 表 5 备选方案指标期望符合程度评估值

Table 5. Evaluation value for expectation-outcome consistency of alternative indexes

方案 ${G_1}$ ${G_2}$ ${G_3}$ ${G_4}$ ${G_5}$ ${G_6}$ ${S_1}$ 0.46 1.00 0.76 1.00 1.00 1.00 ${S_2}$ 1.00 1.00 0.77 1.00 1.00 1.00 ${S_3}$ 0.38 1.00 0.73 1.00 1.00 1.00 ${S_4}$ 0.63 1.00 0.83 1.00 1.00 1.00 ${S_5}$ 0 0 1.00 1.00 1.00 1.00 ${S_6}$ 0.47 0 0.74 1.00 0 1.00 ${S_7}$ 1.00 1.00 0.76 1.00 1.00 1.00 表 6 备选方案信息量

Table 6. Information content of alternatives

方案 ${G_1}$ ${G_2}$ ${G_3}$ ${G_4}$ ${G_5}$ ${G_6}$ ${S_1}$ 0.77 0 0.27 0 0 0 ${S_2}$ 0 0 0.26 0 0 0 ${S_3}$ 0.97 0 0.31 0 0 0 ${S_4}$ 0.46 0 0.19 0 0 0 ${S_5}$ $\infty $ $\infty $ 0 0 0 0 ${S_6}$ 0.76 $\infty $ 0.30 0 $\infty $ 0 ${S_7}$ 0 0 0.27 0 0 0 -

PINE B JⅡ. Mass customization–the new frontier in business competition[M]. Boston: Harvard Business Press, 1993: 3-5 TRENTIN A, PERIN E, FORZA C. Increasing the consumer-perceived benefits of a mass-customization experience through sales-configurator capabilities[J]. Computers in Industry, 2014, 65(4): 693-705. doi: 10.1016/j.compind.2014.02.004 KAY M J. Making mass customization happen:lessons for implementation[J]. Strategy & Leadership, 2013, 21(4): 14-18. 曾钟钟,江志斌,许淑君. 物流公司配送绩效评价模型研究[J]. 工业工程与管理,2003,9(3): 40-44. doi: 10.3969/j.issn.1007-5429.2003.03.010ZENG Zhongzhong, JIANG Zhibin, XU Shujun. Research on the performance evaluation model of logistic company’s distribution[J]. Industrial Engineering and Management, 2003, 9(3): 40-44. doi: 10.3969/j.issn.1007-5429.2003.03.010 彭禄斌,吴冰,刘仲英,等. 基于声誉的物流公共信息平台信任评价模型[J]. 工业工程与管理,2009,14(4): 78-83. doi: 10.3969/j.issn.1007-5429.2009.04.014PENG Lubin, WU Bing, LIU Zhongying, et al. A trust evaluation model based on reputation for logistics public information platform[J]. Industrial Engineering and Management, 2009, 14(4): 78-83. doi: 10.3969/j.issn.1007-5429.2009.04.014 丁斌,陈殿龙. 基于粗糙集与FAHP-FCE的地方政府应急物流预案评价[J]. 系统工程,2009,27(4): 7-11. doi: 10.3969/j.issn.1001-2362.2009.04.002DING Bin, CHEN Dianlong. The evaluation of emergency logistics plan of local government based on rough set and FAHP-FCE[J]. Systems Engineering, 2009, 27(4): 7-11. doi: 10.3969/j.issn.1001-2362.2009.04.002 GONG B, CHEN X, HU C. Fuzzy entropy clustering approach to evaluate the reliability of emergency logistics system[J]. Energy Procedia, 2012, 16(Part A): 278-283. THOMPSON M K. Improving the requirements process in axiomatic design theory[J]. CIRP Annals-Manufacturing Technology, 2013, 62(1): 115-118. doi: 10.1016/j.cirp.2013.03.114 HWANG H S. Design of supply-chain logistics system considering service level[J]. Computers & Industrial Engineering, 2002, 43(1/2): 283-297. BEDNAR S, MODRAK V. Mass customization and its impact on assembly process’ complexity[J]. International Journal for Quality Research, 2014, 8(3): 417-430. SILVA C A, SOUSAA J M C, RUNKLER T A. Optimization of logistic systems using fuzzy weighted aggregation[J]. Fuzzy Sets and Systems, 2007, 158(17): 1947-1960. doi: 10.1016/j.fss.2007.04.008 ROGHANIAN E, PAZHOHESHFAR P. An optimization model for reverse logistics network under stochastic environment by using genetic algorithm[J]. Journal of Manufacturing Systems, 2014, 33(3): 348-356. doi: 10.1016/j.jmsy.2014.02.007 WANG J, LI X, WANG G, et al. Modelling a remanufacturing reverse logistics system using fuzzy stochastic Petri net[J]. International Journal of Industrial & Systems Engineering, 2015, 19(3): 311. 佟士祺,王诺,谢春晓. 建设物流方案多目标均衡优化模型研究[J]. 计算机集成制造系统,2008,14(12): 2312-2316.TONG Shiqi, WANG Nuo, XIE Chunxiao. Multiobjective tradeoff optimization model of implementation scheme in project logistics[J]. Computer Integrated Manufacturing Systems, 2008, 14(12): 2312-2316. 董建华,肖田元,乔桂秀,等. 面向大规模定制的制造系统关键技术[J]. 计算机集成制造系统,2002,8(8): 579-592.DONG Jianhua, XIAO Tianyuan, QIAO Guixiu. Key technologies for mass customization manufacturing systems[J]. Computer Integrated Manufacturing Systems, 2002, 8(8): 579-592. BORDOGNA G, FEDRIZZI M, PASSI G. A linguistic modeling of consensus in group decision making based on OWA operator[J]. IEEE Transactions on Systems,Man,and Cybernetics, 1997, 27(1): 126-132. doi: 10.1109/3468.553232 樊治平, 冯博. 基于协同网络信息的多指标决策方法[M]. 北京: 科学出版社, 2009: 77-79 RAPPOLD J A, VAN ROO B D. Designing multi-echelon service parts networks with finite repair capacity[J]. European Journal of Operational Research, 2009, 199(3): 781-792. doi: 10.1016/j.ejor.2008.08.006 OPRICOVIC S, TZENG G H. Defuzzification within a multicriteria decision model[J]. International Journal of Uncertainty,Fuzziness and Knowledge based Systems, 2003, 11(5): 635-652. doi: 10.1142/S0218488503002387 BODILY S E. A delegation process for combining individual utility functions[J]. Management Sciences, 1979, 25(10): 1035-1041. doi: 10.1287/mnsc.25.10.1035 SUH N P. Axiomatic design: advances and applications[M]. New York: Oxford University Press, 2001: 12-16 KULAK O, KAHRAMAN C. Fuzzy multi-attribute selection among transportation companies using axiomatic design and analytic hierarchy process[J]. Information Sciences, 2005, 170(2/3/4): 191-210. doi: 10.1016/j.ins.2004.02.021 -

下载:

下载: