Experimental Investigation of Basic Mechanical Properties of Self-Compacting Recycled Aggregate Concrete

-

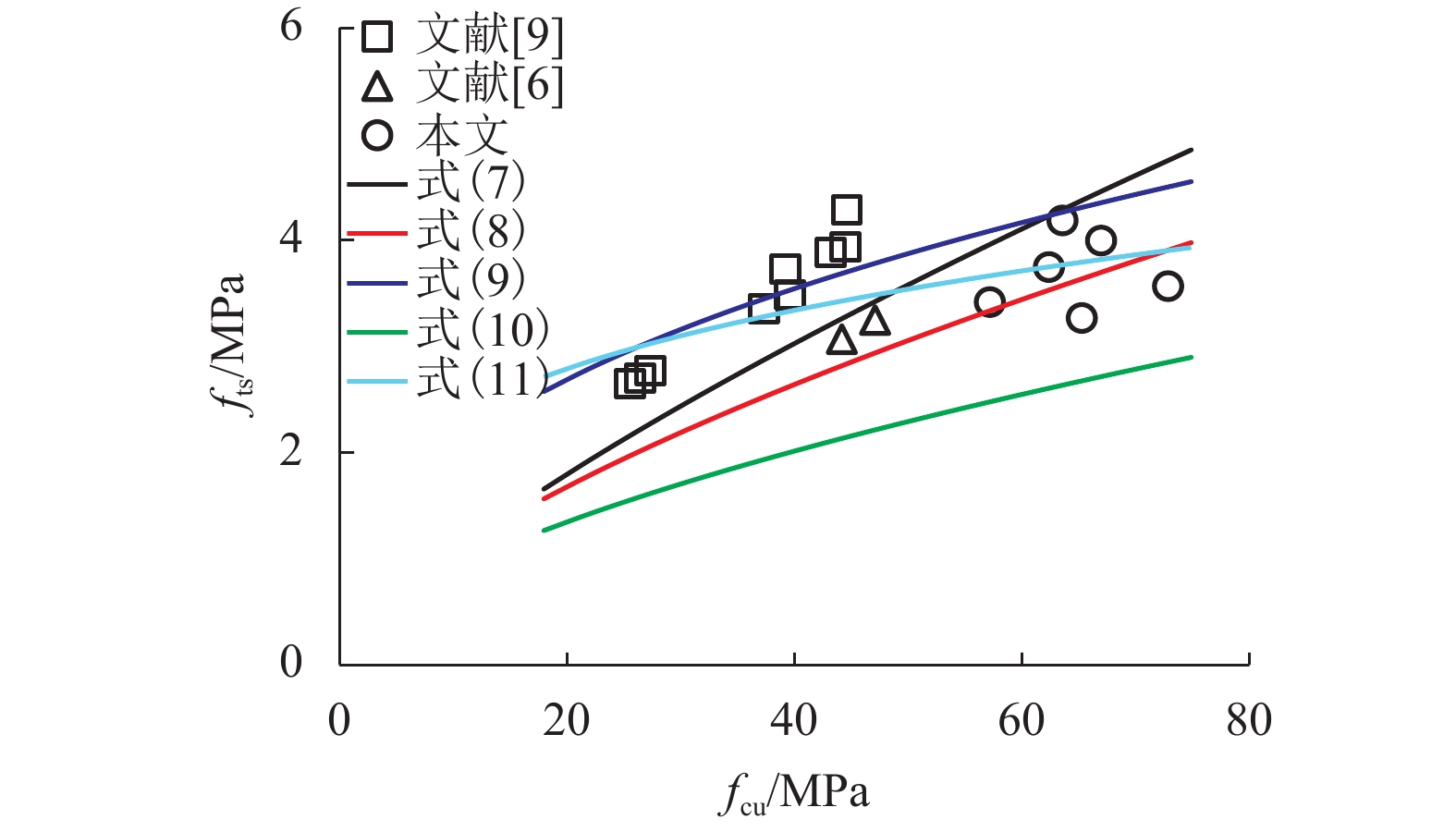

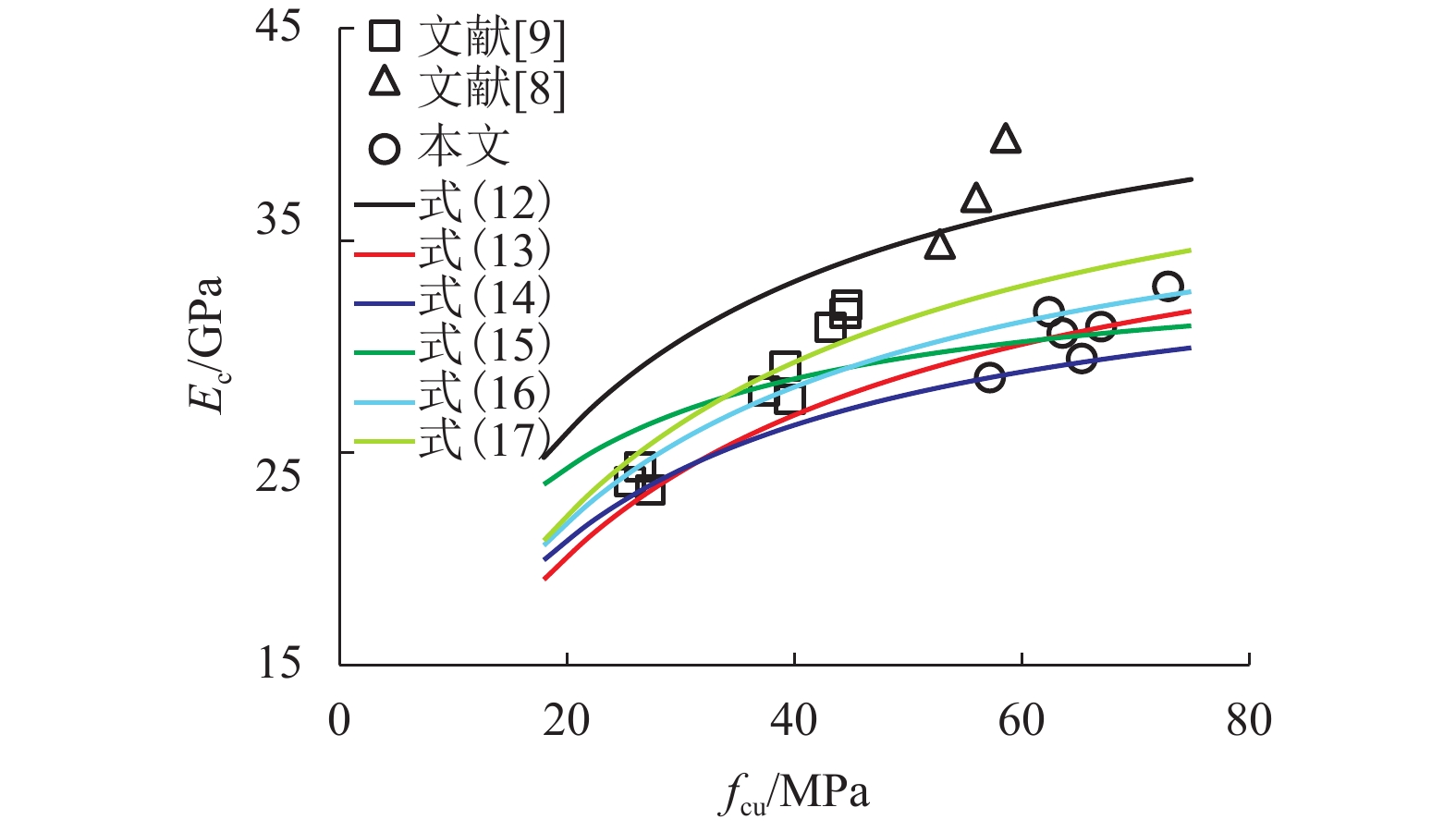

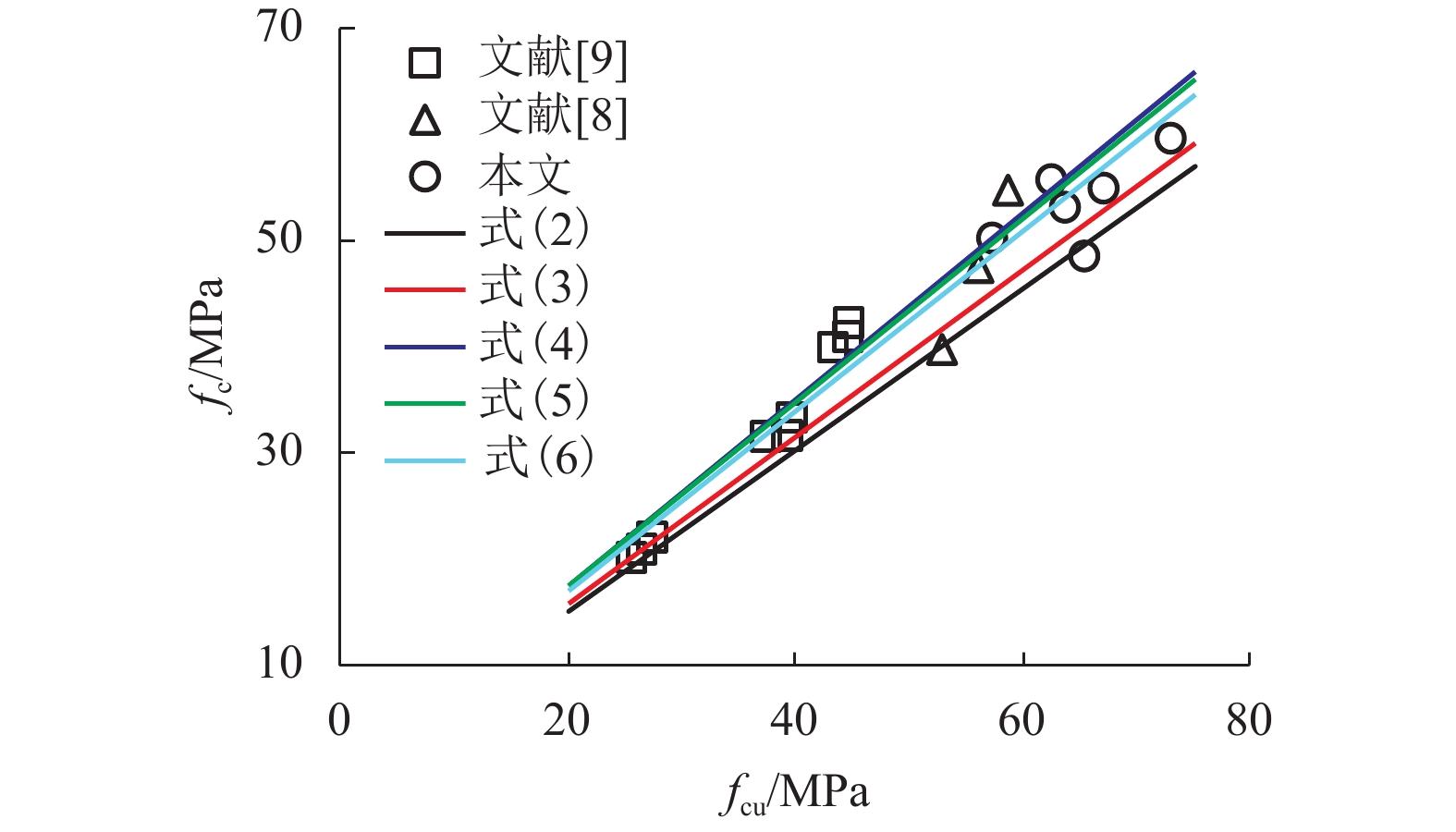

摘要: 为了研究自密实再生混凝土的基本力学性能,通过立方体抗压强度试验、轴心抗压强度试验、劈裂抗拉强度试验和弹性模量试验,观察了自密实再生混凝土的受压和受拉破坏过程和破坏形态,分析了再生粗骨料替代率对自密实再生混凝土基本力学性能的影响,探讨了普通混凝土和再生混凝土的各力学性能指标之间的换算关系对自密实再生混凝土的适用性. 结果表明:自密实再生混凝土受压和受拉的破坏形态与普通混凝土相似;当再生粗骨料替代率由0增加至100%时,自密实再生混凝土的立方体抗压强度、轴心抗压强度、劈裂抗拉强度和弹性模量分别降低了15.5%、12.7%、25.6%和11.5%,而自密实再生混凝土的峰值应变增大了19.8%;再生粗骨料替代率对自密实再生混凝土的泊松比无显著影响;普通混凝土和再生混凝土的各力学性能指标之间的换算关系不适用于自密实再生混凝土,提出的自密实再生混凝土的立方体抗压强度与其他力学性能指标之间的换算关系具有较高精度.Abstract: In order to study the basic mechanical properties of the self-compacting recycled aggregate concrete(SCRAC), the cubic compressive strength test, the axial compressive strength test, the splitting tensile strength test, and the elastic modulus test were carried out. The failure process and the failure mode of the SCRAC under compression and tension were observed. The effects of the recycled coarse aggregate(RCA)replacement ratio on the basic mechanical properties of the SCRAC were analyzed. The applicability of the conversion relationship between each mechanical property index of the ordinary concrete and the recycled aggregate concrete to the SCRAC was discussed. The test results show that the failure mode of the SCRAC under compression and tension is similar to that of the ordinary concrete. The test results also show that the cubic compressive strength, the axial compressive strength, the splitting tensile strength, and the elastic modulus of the SCRAC decrease by 15.5%, 12.7%, 25.6%, and 11.5%, respectively, and the peak strain of the SCRAC increases by 19.8%, when the RCA replacement ratio increases from 0 to 100%. The test results also demonstrate that RCA replacement ratio has no significant effect on the Poisson ratio of the SCRAC. The research findings indicate that the conversion relationship between each mechanical property index of the ordinary concrete and the recycled concrete is not applicable to the SCRAC, and the proposed conversion relationship between the cubic compressive strength and the other mechanical property indices of the SCRAC has high precision.

-

表 1 自密实再生混凝土的配合比

Table 1. Mix proportion of the self-compacting recycled aggregate concrete

编号 水泥 粉煤灰 粗骨料 砂 水 减水剂 膨胀剂 天然 再生 拌合水 附加水 SCRAC-0 378 135 856 0 816 173 5.1 41 SCRAC-1 378 135 428 428 816 173 7.6 6.2 41 SCRAC-2 378 135 0 856 816 173 15.2 7.1 41 表 2 自密实再生混凝土的基本力学性能

Table 2. Basic mechanical properties of the self-compacting recycled aggregate concrete

编号 ${f_{{\rm{cu}}}}$/MPa ${f_{\rm{c}}}$/MPa ${f_{{\rm{ts}}}}$/MPa ${E_{\rm{c}}}$/GPa ${\varepsilon _{\rm{c}}}$/×10-3 $\nu $ $\rho $/% 单值 平均值 单值 平均值 单值 平均值 单值 平均值 SCRAC-0-1 76.5 72.8 55.8 59.2 5.07 4.69 35.3 33.8 2.26 0.20 0 SCRAC-0-2 73.2 63.6 4.61 31.9 SCRAC-0-3 68.8 58.2 4.39 34.1 SCRAC-1-1 63.5 67.7 53.3 56.1 4.20 3.93 30.7 31.5 2.46 0.21 50 SCRAC-1-2 66.9 55.1 4.01 31.0 SCRAC-1-3 72.8 59.8 3.58 32.9 SCRAC-2-1 65.2 61.5 48.7 51.7 3.28 3.49 29.5 29.9 2.71 0.21 100 SCRAC-2-2 62.3 55.9 3.76 31.7 SCRAC-2-3 57.1 50.4 3.43 28.6 -

SONEBI M. Medium strength self-compacting concrete containing fly ash:modeling using factorial experimental plans[J]. Cement and Concrete research, 2004, 34(7): 1199-1208. doi: 10.1016/j.cemconres.2003.12.022 郑建军,盛毅生,孔德玉,等. 再生混凝土技术与发展[J]. 浙江工业大学学报,2006,34(1): 1-7. doi: 10.3969/j.issn.1006-4303.2006.01.001ZHENG Jianjun, SHENG Yisheng, KONG Deyu, et al. Technology and development of recycled concrete[J]. Journal of Zhejiang University of Technology, 2006, 34(1): 1-7. doi: 10.3969/j.issn.1006-4303.2006.01.001 CORINALDESI V. Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates[J]. Construction and Building Materials, 2010, 24(9): 1616-1620. doi: 10.1016/j.conbuildmat.2010.02.031 GESOGLU M, GÜNEYISI E, ÖZ H Ö, et al. Failure characteristics of self-compacting concretes made with recycled aggregates[J]. Construction and Building Materials, 2015, 98: 334-344. doi: 10.1016/j.conbuildmat.2015.08.036 TANG W C, RYAN P C, CUI H Z, et al. Properties of self-compacting concrete with recycled coarse aggregate[J]. Advances in Materials Science and Engineering, 2016, 2016: 1-11. 虞春龙,袁勇,水口裕之,等. 自密实再生混凝土试验研究[J]. 低温建筑技术,2011(6): 6-8. doi: 10.3969/j.issn.1001-6864.2011.06.003YU Chunlong, YUAN Yong, SHUIKOU Yuzhi. Experimental study on self-compacting recycled concrete[J]. Low Temperature Architecture Technology, 2011(6): 6-8. doi: 10.3969/j.issn.1001-6864.2011.06.003 贾艳东,王云洋,孙志屏,等. 自密实再生混凝土配合比设计及力学性能试验研究[J]. 四川建筑科学研究,2014,40(1): 241-244. doi: 10.3969/j.issn.1008-1933.2014.01.059JIA Yandong, WANG Yunyang, SUN Zhiping, et al. Mix design and experimental research on mechanical properties of self-compacting recycled concrete[J]. Sichuan Building Science, 2014, 40(1): 241-244. doi: 10.3969/j.issn.1008-1933.2014.01.059 郑惠珍. 再生粗骨料对自密实再生混凝土性能的影响[J]. 长春工程学院学报(自然科学版),2014,15(1): 33-37.ZHENG Huizhen. Impact of recycled coarse aggregate on the fundamental properties of recycled self-compacting concrete[J]. Journal of Changchun Institute of Technology (Natural Sciences Edition), 2014, 15(1): 33-37. 吴春杨,马剑,潘志宏,等. 非连续级配再生粗骨料自密实混凝土基本力学性能试验研究[J]. 建筑结构,2015,45(10): 69-73.WU Chunyang, MA Jian, PAN Zhihong, et al. Experimental study on basic mechanical properties of self-compacting recycled concrete with discontinuous graded recycled coarse aggregate[J]. Building Structure, 2015, 45(10): 69-73. 张学兵,邓寿昌. 再生混凝土单位体积用水量的实验研究[J]. 混凝土,2004(10): 38-40,64. doi: 10.3969/j.issn.1002-3550.2004.10.013ZHANG Xuebing, DENG Shouchang. Experimental research on unit water use in recycled concrete[J]. Concrete, 2004(10): 38-40,64. doi: 10.3969/j.issn.1002-3550.2004.10.013 过镇海. 钢筋混凝土原理和分析[M]. 北京: 清华大学出版社, 2003: 13-33 肖建庄. 再生混凝土[M]. 北京: 中国建筑工业出版社, 2008: 52-76 李旭平. 再生混凝土基本力学性能研究(Ⅰ)——单轴受压性能[J]. 建筑材料学报,2007,10(5): 598-603. doi: 10.3969/j.issn.1007-9629.2007.05.019LI Xuping. Study on mechanical properties of recycled aggregate concrete (Ⅰ) — behavior under uniaxial compression[J]. Journal of Building Materials, 2007, 10(5): 598-603. doi: 10.3969/j.issn.1007-9629.2007.05.019 金莉. 再生混凝土力学性能试验研究[J]. 新型建筑材料,2006(7): 11-13. doi: 10.3969/j.issn.1001-702X.2006.07.004JIN Li. Experimental study on mechanical behavior of recycled aggregate concrete[J]. New Building Materials, 2006(7): 11-13. doi: 10.3969/j.issn.1001-702X.2006.07.004 丁发兴,方常靖,龚永智,等. 再生混凝土单轴力学性能指标统一计算方法[J]. 建筑科学与工程学报,2014,31(4): 16-22. doi: 10.3969/j.issn.1673-2049.2014.04.004DING Faxing, FANG Changjing, GONG Yongzhi, et al. Unified calculation method of uniaxial mechanical performance index of recycled concrete[J]. Journal of Architecture and Civil Engineering, 2014, 31(4): 16-22. doi: 10.3969/j.issn.1673-2049.2014.04.004 胡波,柳炳康,王成刚. 再生混凝土基本力学性能研究[J]. 合肥工业大学学报,2014,37(1): 87-90. doi: 10.3969/j.issn.1003-5060.2014.01.019HU Bo, LIU Bingkang, WANG Chenggang. Investigation on basic mechanical properties of recycled aggregate concrete[J]. Journal of Hefei University of Technology, 2014, 37(1): 87-90. doi: 10.3969/j.issn.1003-5060.2014.01.019 陈宗平,徐金俊,郑华海,等. 再生混凝土基本力学性能试验及应力应变本构关系[J]. 建筑材料学报,2013,16(1): 24-32. doi: 10.3969/j.issn.1007-9629.2013.01.005CHEN Zongping, XU Jinjun, ZHENG Huahai, et al. Basic mechanical properties test and stress-strain constitutive relations of recycled coarse aggregate concrete[J]. Journal of Building Materials, 2013, 16(1): 24-32. doi: 10.3969/j.issn.1007-9629.2013.01.005 李旭平. 再生混凝土基本力学性能研究(Ⅱ)[J]. 建筑材料学报,2007,10(6): 699-704. doi: 10.3969/j.issn.1007-9629.2007.06.013LI Xuping. Study on mechanical properties of recycled aggregate concrete (Ⅱ)[J]. Journal of Building Materials, 2007, 10(6): 699-704. doi: 10.3969/j.issn.1007-9629.2007.06.013 金昌,王雪萍,AKINKUROLERE O O,等. 再生混凝土力学性能指标换算关系试验研究[J]. 混凝土,2008(11): 37-39. doi: 10.3969/j.issn.1002-3550.2008.11.012JIN Chang, WANG Xueping, AKINKUROLERE O O, et al. Experimental research on the conversion relationships between the mechanical performance indexes of recycled concrete[J]. Concrete, 2008(11): 37-39. doi: 10.3969/j.issn.1002-3550.2008.11.012 杨曦,吴瑾,梁继光. 再生混凝土抗拉强度与抗压强度关系的试验研究[J]. 四川建筑科学研究,2009,35(5): 190-192.YANG Xi, WU Jin, LIANG Jiguang. Experimental study on relationship between tensile strength and compressive strength of recycled aggregate concrete[J]. Sichuan Building Science, 2009, 35(5): 190-192. -

下载:

下载: