Study on Stress Field and Security of Primary Support in High Rock Temperature Tunnel

-

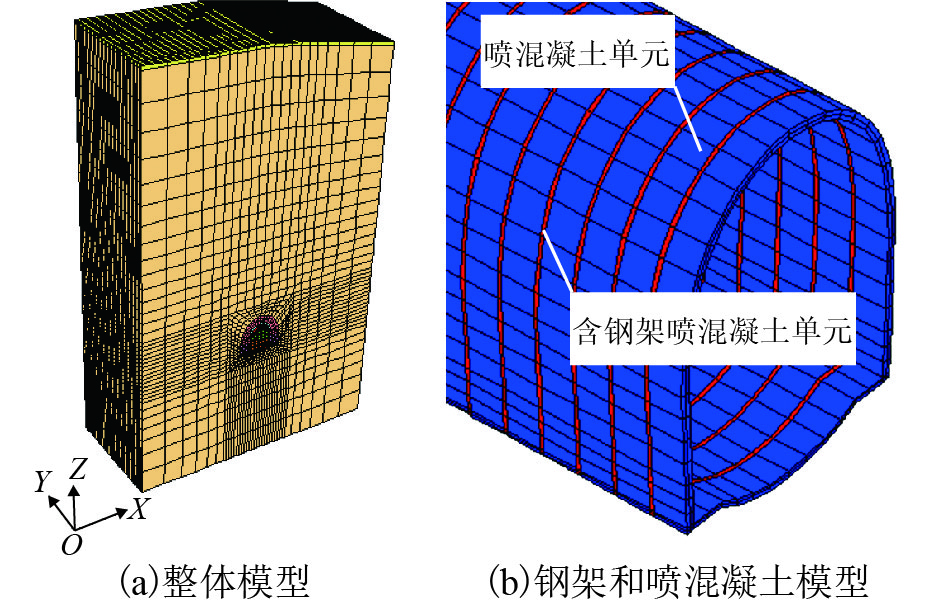

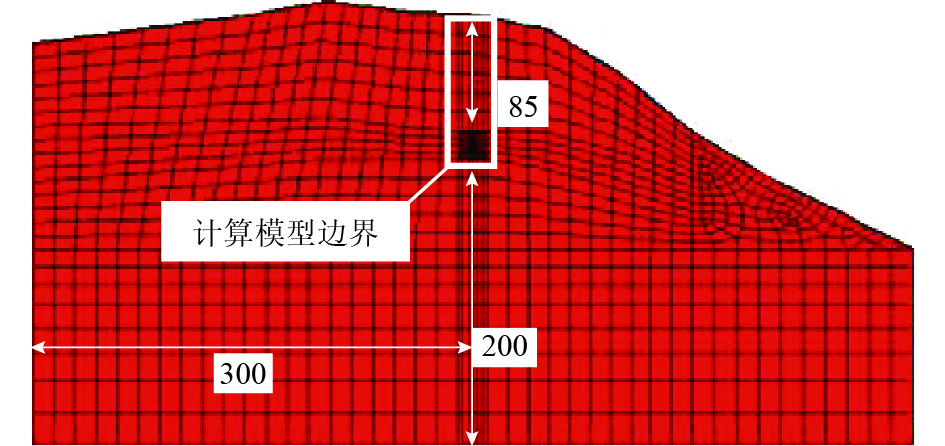

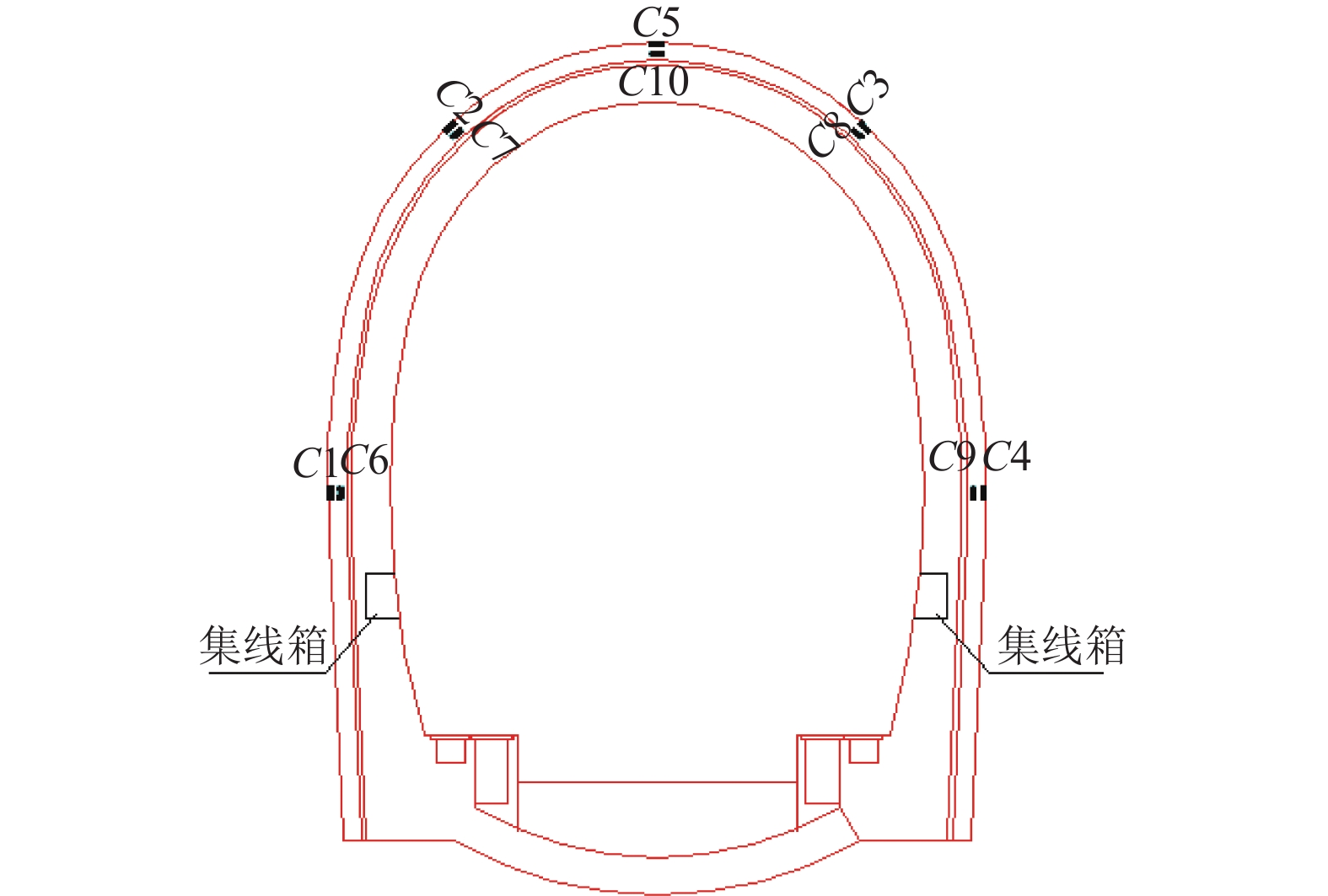

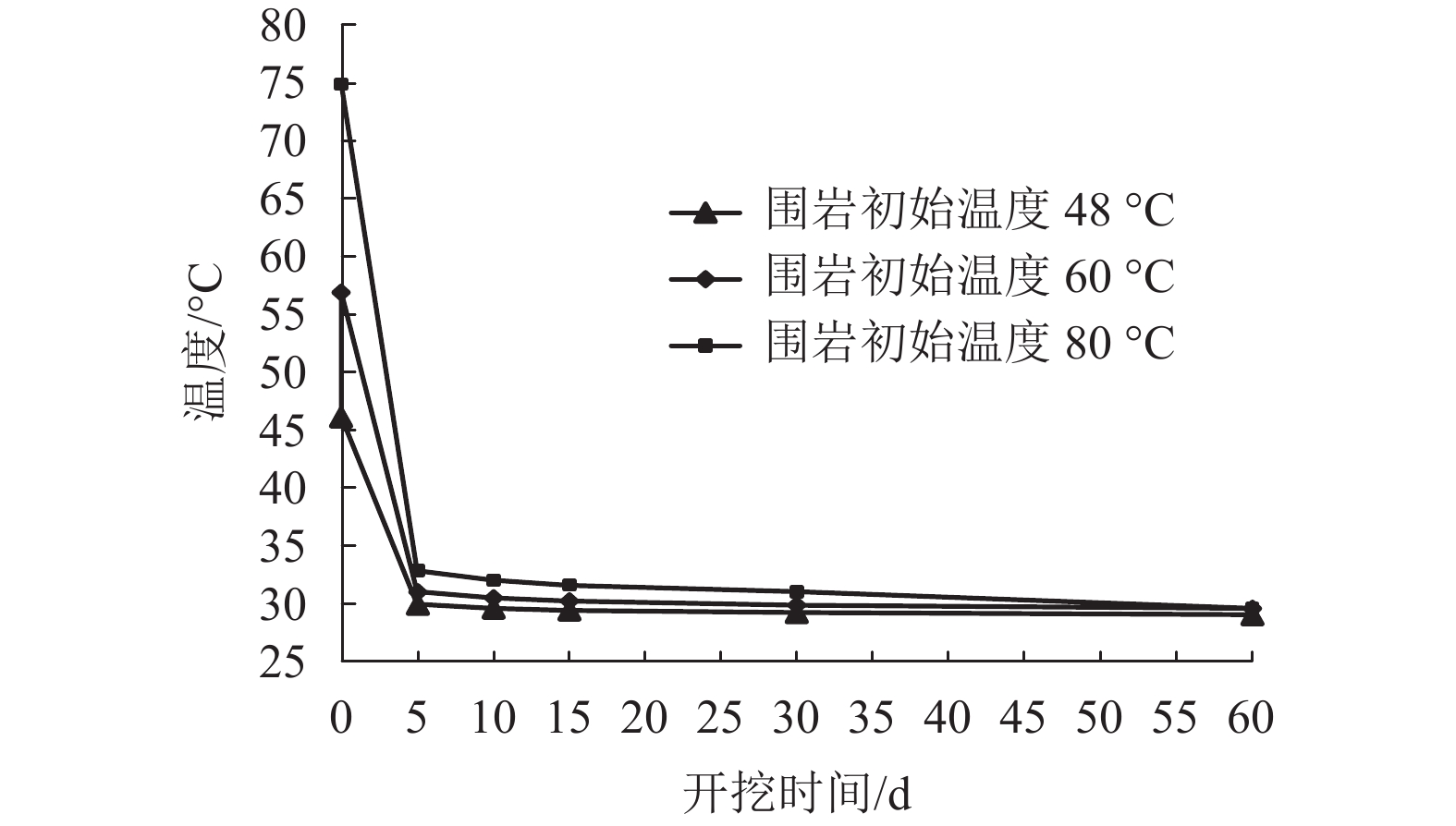

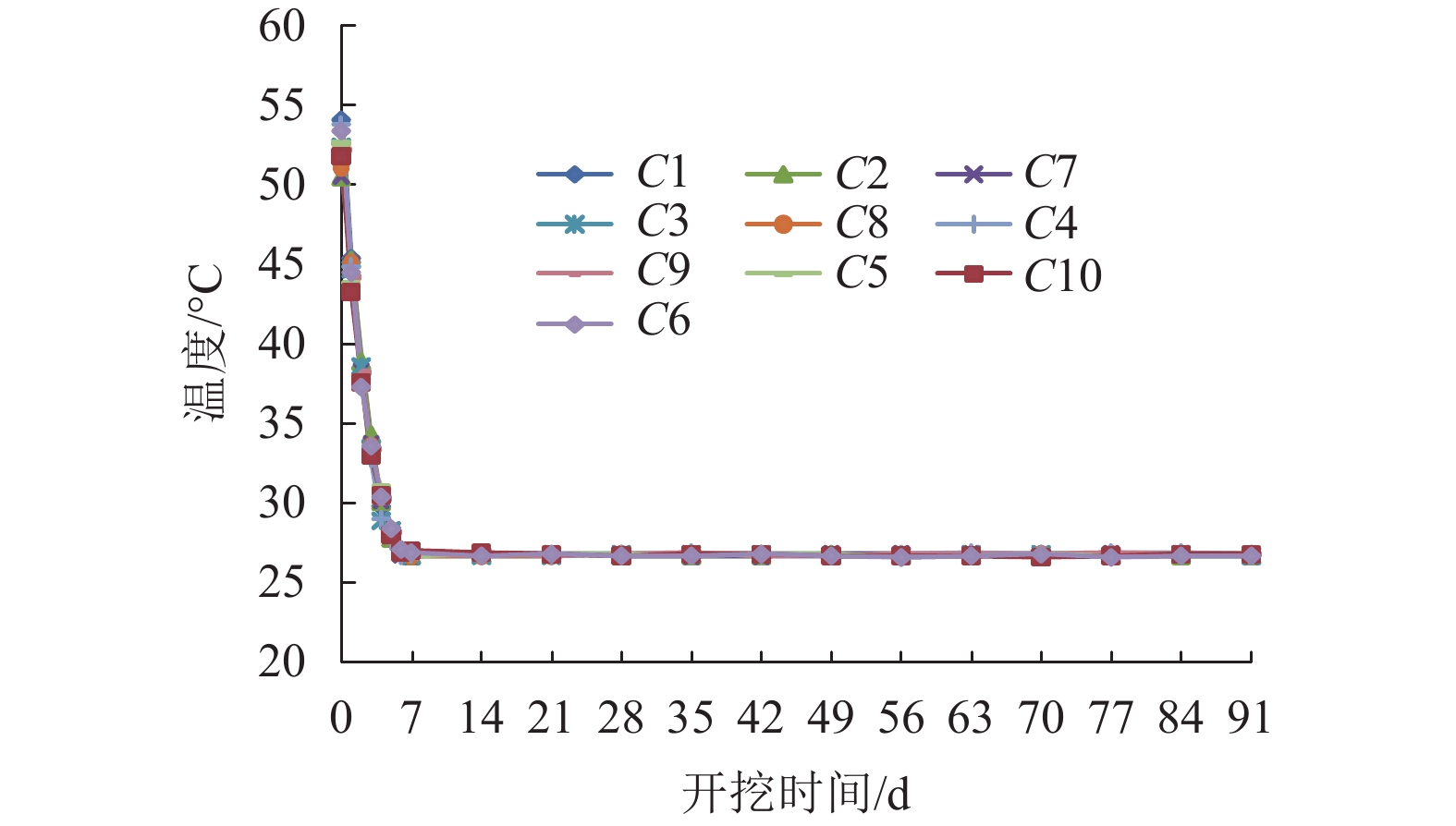

摘要: 为评价高岩温隧道施工过程中初期支护的安全性,研究了高岩温隧道初期支护温度场、应力场的施工期特征和演变规律. 首先通过热-应力耦合三维数值模拟和现场测试,研究了不同原始围岩温度场中,高岩温隧道开挖过程中初期支护温度场的变化规律;其次考虑围岩荷载和温度荷载共同作用,分析了高岩温隧道开挖过程中初期支护应力场的变化规律;最后基于初期支护应力值,评价了高岩温隧道初期支护的安全性. 研究结果表明:受施工通风影响,初期支护温度在隧道开挖后急剧降低,约5 d后基本与洞内气温一致;受施工工序影响,初期支护最大拉应力先增后减,最大压应力持续增加;随着围岩初始温度增大,在不同施工步序中,初期支护的最大拉应力和最大压应力均增大;初期支护安全性由喷射混凝土抗拉强度控制,当围岩初始温度大于60℃时,C25喷射混凝土将发生拉裂破坏.Abstract: The characteristics and changing behaviour of the initial support in high rock temperature tunnel were studied to evaluate security during the construction process. First, the temperature field of the initial support was analysed during the construction process of high rock temperature tunnel by using thermal-stress coupling numerical simulations and in-situ testing. Second, the stress field of the initial support, which bore the rock load and temperature load, was analysed over the construction process of high rock temperature tunnel. Finally, based on the stress of primary support, the security of primary support in high rock temperature tunnel was evaluated. The results show that the temperature of primary support sharply decreases after tunnel excavation and is equivalent to the air temperature in the tunnel after about 5 days. During the construction process, the maximum tensile stress of primary support first increases and then decreases. However, the maximum compressive stress always increases. With increased initial rock temperature, the maximum tensile and compressive stress of the primary support also increase. The security of the primary support depends on the tensile strength of shotcrete, and the C25 shotcrete will be damaged if the initial rock temperature exceeds 60℃.

-

Key words:

- high rock temperature tunnel /

- initial support /

- tensile stress /

- compressive stress /

- security

-

表 1 初期支护设计参数

Table 1. Design parameters of primary support

围岩级别 喷层 系统锚杆 钢筋网 钢架 位置 厚度

/cm位置 长度

/m间距

(环/m × 纵/m)位置 直径

(环/mm × 纵/mm)间距

/cm位置 型号 间距

/(m•榀–1)Ⅳ 拱墙 12 拱墙 2.5 1.0 × 1.0 拱墙 8 × 6.5 20 × 20 Ⅳ加强 拱墙 20 拱墙 2.5 1.0 × 1.0 拱墙 8 × 6.5 20 × 20 拱墙 H125 1/1.2 Ⅴ加强 拱墙/

仰拱23/15 拱墙 3.0 1.0 × 1.0 拱墙 8 × 6.5 20 × 20 拱墙 工16 1/1 表 2 计算参数

Table 2. Calculation parameters

项目 容重γ

/(kN•m–3)弹模E

/GPa泊松比ν 黏聚力c/MPa 内摩擦角φ/(°) 导热系数λ

/(W•(m•℃)–1)线膨胀系数α

/(× 10–5 ℃–1)比热C

/(J•(kg•℃)–1)喷混凝土(C25) 22.0 23.0 0.20 2.94 1.00 960 含钢架喷混凝土(C25) 27.7 42.1 0.21 7.74 1.02 911 围岩(V级) 20.0 1.5 0.40 0.10 24.0 2.31 0.06 707 表 3 数值模型两侧边界温度梯度

Table 3. Thermal boundary condition on both sides of calculation model

路肩标高处围岩

初始温度/℃左边界/(℃•m–1) 右边界/(℃•m–1) 48.0 0.194 1 0.190 3 60.0 0.323 2 0.315 8 80.0 0.538 0 0.527 2 表 4 不同温度边界下的隧道路肩岩温

Table 4. Rock temperature at tunnel shoulder with various boundary conditions

下边界温度/℃ 路肩标高处围岩初始温度/℃ 60 36.1 80 42.2 100 46.9 120 52.1 表 5 各施工步序初期支护最大主应力最大值

Table 5. Maximum of major principal stress in primary support by various construction step

路肩标高处围岩

初始温度/℃上台阶施工 下台阶施工 仰拱施工 最值/MPa 位置 范围/m 最值/MPa 位置 范围/m 最值/MPa 位置 范围/m 常岩温 0.610 拱腰内侧 1.0 0.929 拱腰外侧 1.2 0.573 墙脚外侧 0~0.6 48℃ 0.992 拱腰内侧 1.0 1.374 墙脚内侧 5.0 0.901 墙脚外侧 0.6 60℃ 1.231 拱腰内侧 1.0 1.770 墙脚内侧 4.0 1.213 墙脚外侧 0.6 80℃ 1.513 拱腰内侧 1.0 2.011 墙脚内侧 4.0 1.502 墙脚外侧 0.6 表 6 各施工步序初期支护最小主应力最小值

Table 6. Minimum of minimum principal stress in primary support by various construction step

路肩标高处围岩

初始温度/℃上台阶施工 下台阶施工 仰拱施工 最值/MPa 位置 范围/m 最值/MPa 位置 范围/m 最值/MPa 位置 范围/m 常岩温 –3.433 拱顶外侧 3.0 –8.472 拱顶外侧 2.0 –11.771 边墙外侧 1.0 48℃ –3.442 拱腰外侧 1.0 –8.612 拱顶外侧 3.0 –12.367 边墙外侧 4.0 60℃ –3.510 拱腰/拱顶

外侧1/1 –8.744 拱顶外侧 4.0 –12.952 边墙外侧 4.0 80℃ –3.622 拱腰/拱顶

外侧2/3 –8.830 拱顶外侧 4.0 –13.283 边墙外侧 4.0 注:数据正负符号意义为拉正压负,余同. 表 7 初期支护应力试验结果

Table 7. Primary support stress by test

断面 左边墙 左拱腰 右拱腰 右边墙 拱顶 1 0.36 0.80 –5.37 –0.48 0.07 2 — — — –0.47 — 3 0.30 1.68 –5.12 –0.48 0.26 4 0.37 –0.74 –3.54 –0.53 0.34 注:“—”表示测试元件损坏. -

铁道部经济规划研究院. 铁路隧道工程施工技术指南: TZ204—2008[S]. 北京: 中国铁道出版社, 2008 中华人民共和国交通运输部. 公路隧道施工技术规范: JTG F60—2009[S]. 北京: 人民交通出版社, 2009 袁培国. 超高地温条件下引水隧洞施工关键技术探讨[J]. 水利水电技术,2014,45(4): 101-106 doi: 10.3969/j.issn.1000-0860.2014.04.027YUAN Peiguo. Discussion on key technologies for construction of water diversion tunnel under super-high ground temperature[J]. Water Resoures and Hydropower Engineering, 2014, 45(4): 101-106 doi: 10.3969/j.issn.1000-0860.2014.04.027 赵国斌,程向民,孙旭宁. 齐热哈塔尔水电站引水隧洞高地温表现与对策[J]. 资源环境与工程,2013,27(4): 566-567,591 doi: 10.3969/j.issn.1671-1211.2013.04.052ZHAO Guobin, CHENG Xiangmin, SUN Xuning. Manifestation and countermeasure of high geo-temperature of Qirihataer hydro-power station diversion tunnel[J]. Resources Environment & Engineering, 2013, 27(4): 566-567,591 doi: 10.3969/j.issn.1671-1211.2013.04.052 邵珠山, 乔汝佳, 王新宇. 高地温隧道温度与热应力场的弹性理论解[J]. 岩土力学, 2013, 34(增刊1): 1-8SHAO Zhushao, QIAO Rujia, WANG Xinyu. Elasticity solution for temperature and stress fields of tunnels with high geothermal temperature[J]. Rock and Soil Mechanics, 2013, 34(S1): 1-8 刘乃飞,李宁,余春海,等. 布仑口水电站高温引水发电隧洞受力特性研究[J]. 水利水运工程学报,2014(4): 14-21 doi: 10.3969/j.issn.1009-640X.2014.04.003LIU Naifei, LI Ning, YU Chunhai, et al. Analysis of mechanical characteristics for high-temperature diversion tunnel of Bulunkou hydropower station[J]. Hydro-science and Engineering, 2014(4): 14-21 doi: 10.3969/j.issn.1009-640X.2014.04.003 郭进伟,方焘,卢祝清. 高地温隧洞热-结构耦合分析[J]. 铁道建筑,2010(6): 77-79 doi: 10.3969/j.issn.1003-1995.2010.06.026GUO Jinwei, FANG Tao, LU Zhuqing. Thermal-stress analysis of high rock wall tunnel[J]. Railway Engineering, 2010(6): 77-79 doi: 10.3969/j.issn.1003-1995.2010.06.026 许富贵,蒋和洋,倪晓燕,等. 热-应力耦合作用下深部软岩隧洞大变形三维数值模拟分析[J]. 工程建设,2007,39(2): 5-9 doi: 10.3969/j.issn.1001-2206.2007.02.002XU Fugui, JIANG Heyang, NI Xiaoyan, et al. 3-Dimension numerical simulation analysis for large strain of deep soft rock twmel under thermo-mechanical coupling effect[J]. Engineering Construction, 2007, 39(2): 5-9 doi: 10.3969/j.issn.1001-2206.2007.02.002 王玉锁,叶跃忠,杨超,等. 高地热大埋深环境隧道支护结构受力分析[J]. 西南交通大学学报,2014,49(2): 260-267 doi: 10.3969/j.issn.0258-2724.2014.02.012WANG Yusuo, YE Yuezhong, YANG Chao, et al. Stress mechanism of lining structure of high geothermal and deep buried tunnel[J]. Journal of Southwest Jiaotong University, 2014, 49(2): 260-267 doi: 10.3969/j.issn.0258-2724.2014.02.012 周建军,彭浩,邓华. 反复温度-应力祸合作用下引水隧洞变形特征[J]. 人民黄河,2015,37(7): 133-137 doi: 10.3969/j.issn.1000-1379.2015.07.034ZHOU Jianjun, PENG Hao, DENG Hua. Deformation features of diversion tunnel under repeated action of coupled thermal-stress[J]. Yellow River, 2015, 37(7): 133-137 doi: 10.3969/j.issn.1000-1379.2015.07.034 李书杰. 高地温隧洞衬砌结构应力变形分析及降温措施[J]. 水利规划与设计,2016,1: 109-113 doi: 10.3969/j.issn.1672-2469.2016.09.033 中华人民共和国铁道部. 铁路隧道设计规范: TB10003—2005[S]. 北京: 中国铁道出版社, 2005 铁道部第二勘测设计院. 铁路工程设计技术手册(隧道)[M]. 北京: 中国铁道出版社, 1995: 25-43 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局. 混凝土结构设计规范: GB50010—2010[S]. 北京: 中国建筑工业出版社, 2010 程良奎. 喷射混凝土[M]. 北京: 中国建筑工业出版社, 1990: 29-34 杨林德. 公路施工手册: 隧道[M]. 北京: 人民交通出版社, 2011: 58-63 -

下载:

下载: