Optimal Design of Corrugated Steel Deck Plate-UHPC Layer Composite Deck

-

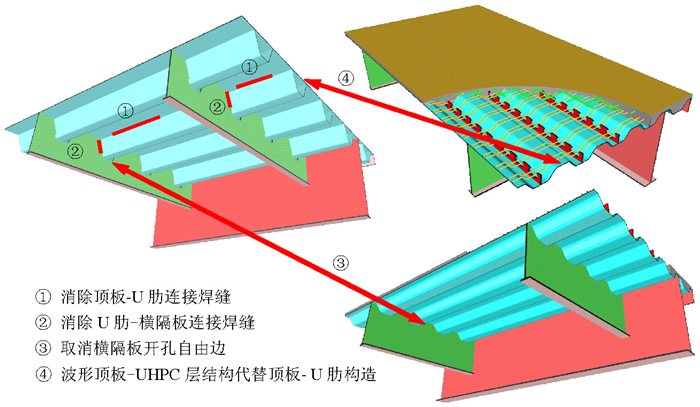

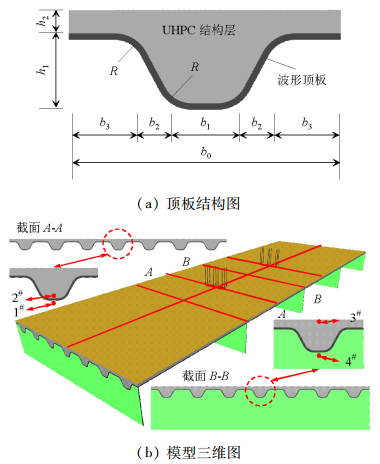

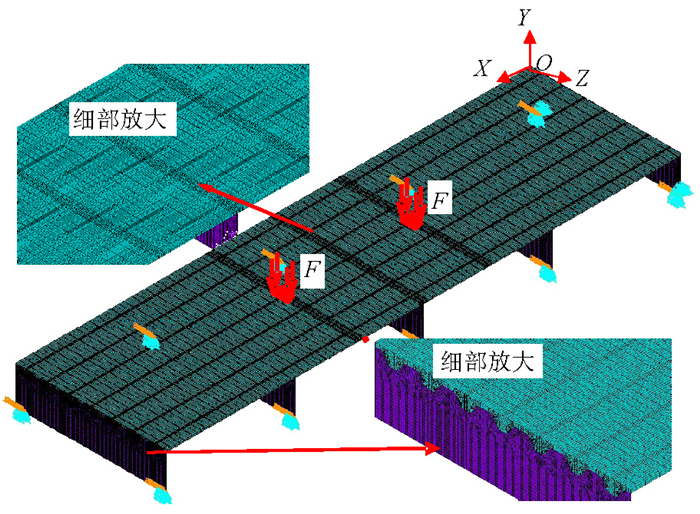

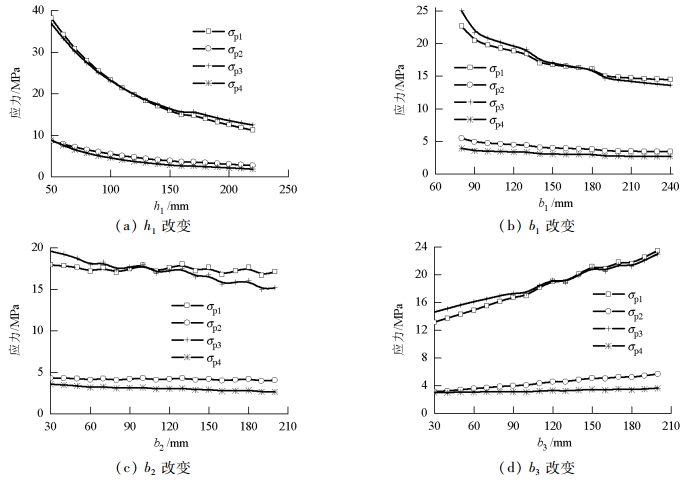

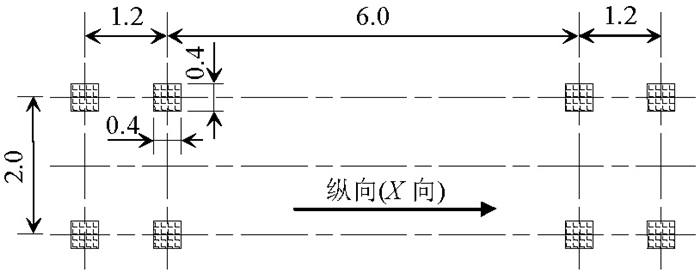

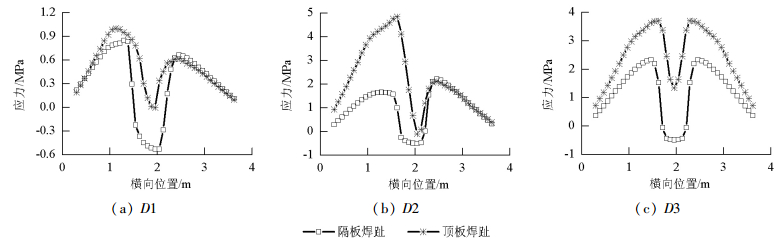

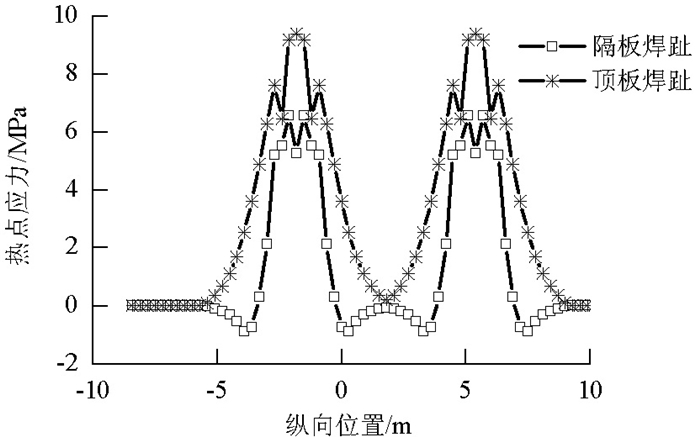

摘要: 为解决正交异性钢桥面板的疲劳问题,从其根本原因和提高其抗疲劳性能的基本途径出发,提出一种新型波形顶板-UHPC(超高性能混凝土)组合桥面板结构体系.确定影响新型桥面板受力特性的主要参数及其合理取值范围,使用基于BP(back propagation)神经网络的优化设计模型对结构进行优化设计,就所优化的结构尺寸进行疲劳性能测试.研究结果表明:该结构能大幅减少桥面板结构中的几何构型不连续部位数量和焊缝数量,显著提高顶板局部刚度;波形钢板高度、顶部和底部水平段宽度是结构受力性能的重要影响参数;基于BP神经网络的优化设计模型适用于该类桥面板结构的优化设计,最大误差为4.4%;新的结构体系具有良好的疲劳性能,疲劳寿命超过200 a,为正交异性钢桥面板的疲劳问题提供了较好的综合解决方案.

-

关键词:

- 正交异性钢桥面板 /

- 波形顶板-UHPC组合桥面板 /

- 优化设计模型 /

- BP神经网络 /

- 疲劳性能

Abstract: In order to solve the fatigue problem of orthotropic steel bridge decks, an innovative corrugated steel plate-UHPC (ultra-high performance concrete) layer composite deck structure is proposed based on the cause of the fatigue problems and the basic approaches used to improve the anti-fatigue performance. First, the major design parameters that significantly impact mechanical properties and the corresponding ranges of the parameter values were determined using parametric analysis. A model based on the BP artificial neural network was developed to determine the optimal design of the innovative structure system. Finally, the fatigue performance of the optimal structure was studied. The results show that the number of geometric discontinuity locations and weld joints are decreased, while the local stiffness of the deck plate is increased. According to the results of the parametric analysis, the height of the corrugated steel plate and the width of the top and bottom horizontal parts of the plate play important roles in structure mechanical characteristics. The proposed optimal design model based on the BP(back propagation) artificial neural network is suitable for the optimal design of innovative structure systems, and the maximum error is 4.4%. The innovative bridge deck has good fatigue performance, and its fatigue life is over 200 years, which provides a comprehensive solution to the fatigue problem and has good potential for further development and application. -

表 1 考察点位置汇总表

Table 1. Inspection positions in the structure

符号 位置含义描述 受力状态 σp1 位置1#处钢板的拉应力 纵向最大正弯矩 σp2 位置2#处混凝土的拉应力 纵向最大正弯矩 σp3 位置3#处混凝土的拉应力 纵向最大负弯矩 σp4 位置4#处钢板的压应力 纵向最大负弯矩 表 2 相邻指标相对重要程度rk赋值表

Table 2. Reference table of rk valuation

rk 说明 1.0 指标xk-1与指标xk具有同样重要性 1.2 指标xk-1比指标xk稍微重要 1.4 指标xk-1比指标xk明显重要 1.6 指标xk-1比指标xk强烈重要 1.8 指标xk-1比指标xk极端重要 表 3 单目标优化结果

Table 3. Single objective optimal results

序号 h1 b1 b2 b3 单目标函数值 1 90 140 80 130 0.256 7 2 90 140 80 140 0.257 1 3 90 140 80 120 0.258 4 ⋮ ⋮ ⋮ ⋮ ⋮ ⋮ 表 4 拟合值与有限元值误差对照

Table 4. Comparison between fitted and finite element values

序号 考察点 拟合值/MPa ANSYS值/MPa 误差/% 1 σp1 28.20 27.95 -0.89 σp2 6.60 6.58 -0.30 σp3 -27.39 -27.19 -0.73 σp4 5.42 5.25 -3.14 2 σp1 28.92 29.47 1.90 σp2 6.85 6.95 1.46 σp3 -28.12 -28.65 1.88 σp4 5.50 5.46 -0.75 3 σp1 27.50 28.26 2.76 σp2 6.37 6.65 4.40 σp3 -26.75 -27.78 3.85 σp4 5.36 5.44 1.59 表 5 疲劳寿命评估

Table 5. Evaluation on fatigue life

疲劳细节 ∑D Y/a D2顶板焊趾处 0.000 016 2 >200 D2横隔板焊趾处 0.000 005 7 >200 -

WOLCHUK R. Lessons from weld cracks in orthotropic decks on three European bridges[J]. Journal of Structural Engineering, 1990, 116(1):75-84. doi: 10.1061/(ASCE)0733-9445(1990)116:1(75) CONNOR R, FISHER J W, GATTI W, et al. Manual for design, construction, and maintenance of orthotropic steel deck bridges[J]. Integral Leadership Review, 2012(5):5-8. http://trid.trb.org/view/2012/M/1139894 《中国公路学报》编辑部.中国桥梁工程学术研究综述·2014[J].中国公路学报, 2014, 27(5):1-96. doi: 10.3969/j.issn.1001-7372.2014.05.001Editorial Department of China Journal of Highway and Transport. Review on China's bridge engineering research·2014[J]. China Journal of Highway and Transport, 2014, 27(5):1-96. doi: 10.3969/j.issn.1001-7372.2014.05.001 崔闯, 刘益铭, 廖贵星, 等.正交异性钢桥面板焊接接头疲劳评估方法[J].西南交通大学学报, 2015, 50(6):1011-1017. doi: 10.3969/j.issn.0258-2724.2015.06.006CUI Chuang, LIU Yiming, LIAO Guixing, et al. Fatigue evaluation approaches of welded joints on Orthotropic steel bridge deck[J]. Journal of Southwest Jiaotong University, 2015, 50(6):1011-1017. doi: 10.3969/j.issn.0258-2724.2015.06.006 卫星, 姜苏.基于断裂力学的钢桥面肋-板接头疲劳寿命预测[J].西南交通大学学报, 2017, 52(1):16-22. doi: 10.3969/j.issn.0258-2724.2017.01.003WEI Xing, JIANF Su. Fatigue life prediction on rib-to-deck welded joints of steel bridge deck based on LEFM[J]. Journal of Southwest Jiaotong University, 2017, 52(1):16-22. doi: 10.3969/j.issn.0258-2724.2017.01.003 张清华, 卜一之, 李乔.正交异性钢桥面板疲劳问题的研究进展[J].中国公路学报, 2017, 30(3):14-30. doi: 10.3969/j.issn.1001-7372.2017.03.002ZHANF Qinghua, BU Yizhi, LI Qiao. Review on fatigue problem of orthotropic steel bridge deck[J]. China Journal of Highway and Transport, 2017, 30(3):14-30. doi: 10.3969/j.issn.1001-7372.2017.03.002 孟凡超, 张清华, 谢红兵, 等.抗疲劳钢桥面板关键技术[M].北京:人民交通出版社, 2015:5-18. MIZUGUCHI K, YAMADA K, IWASAKI M, et al. Rationalized steel deck structure and large model test for developing new type of structure[C]//Proc. Int. Sacramento: Orthotropic Bridge Conf., ASCE, 2004: 675-688. WOLCHUK R. Prefabricating standard orthotropic steel decks[J]. Modern Steel Construction, 2006, 12:49-51. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ029974391/ 邓文中.正交异性板的一个新构思[J].桥梁, 2007, 4:43-50. http://www.ingentaconnect.com/content/iabse/report/2007/00000093/00000031/art00003DENG Wenzhong. A new idea of the orthotropic deck plate[J]. Bridge, 2007, 4:43-50. http://www.ingentaconnect.com/content/iabse/report/2007/00000093/00000031/art00003 葛耀君, 项海帆.桥梁工程可持续发展的理念与使命[C]//第十九届全国桥梁学术会议论文集.上海: [出版者不详], 2010: 15-31. 陈华婷, 迟啸起, 黄艳.正交异性板纵肋-盖板连接的疲劳应力对比分析[J].桥梁建设, 2012, 42(6):22-26. http://www.cqvip.com/QK/92467X/201206/44318071.htmlCHEN Huating, CHI Xiaoqi, HUANG Yan. Comparative analysis of fatigue stress in longitudinal rib and cover plate joints of orthotropic steel deck plate[J]. Bridge Construction, 2012, 42(6):22-26. http://www.cqvip.com/QK/92467X/201206/44318071.html JONG D. Renovation techniques for fatigue cracked orthotropic steel bridge decks[D]. Netherlands: Delft University of Technology, 2007. YA S, YAMADA K, ISHIKAWA T. Fatigue evaluation of rib-to-deck welded joints of orthotropic steel bridge deck[J]. Journal of Bridge Engineering, 2011, 16(4):492-499. doi: 10.1061/(ASCE)BE.1943-5592.0000181 MURAKOSHI J, YANADORI N, ISHⅡ H. Research on steel fiber reinforced concrete pavement for orthotropic steel deck as a countermeasure for fatigue[C]//Proc., 2nd Int. Sacramento: Orthotropic Bridge Conf., ASCE, 2008: 359-371. SHAO Xudong, YI Dutao, HUANG Zhenyu, et al. Basic performance of the composite deck system composed of orthotropic steel deck and ultrathin UHPC layer[J]. Journal of Bridge Engineering, 2013, 18(5):417-428. doi: 10.1061/(ASCE)BE.1943-5592.0000348 丁楠, 邵旭东.轻型组合桥面板的疲劳性能研究[J].土木工程学报, 2015, 48(1):74-81. http://d.old.wanfangdata.com.cn/Thesis/Y3206358DING Nan, SHAO Xudong. Study on fatigue performance of light-weighted composite bridge deck[J]. China Civil Engineering Journal, 2015, 48(1):74-8. http://d.old.wanfangdata.com.cn/Thesis/Y3206358 LORENC W, KOZ·CH M, ROWIN'KI S. The behaviour of puzzle-shaped composite dowels-part Ⅰ:experimental study[J]. Journal of Constructional Steel Research, 2014, 101(10):482-499. http://www.sciencedirect.com/science/article/pii/S0143974X14001540 LORENC W, KOZ·CH M, ROWIN'KI S. The behaviour of puzzle-shaped composite dowels-part Ⅱ:theoretical investigations[J]. Journal of Constructional Steel Research, 2014, 101(10):500-518. http://www.sciencedirect.com/science/article/pii/S0143974X14001540 宋随弟, 黄博, 祝兵, 等.预应力PBL剪力键的承载能力试验研究[J].西南交通大学学报, 2017, 52(4):647-654. doi: 10.3969/j.issn.0258-2724.2017.04.001SONG Suidi, HUANG Bo, ZHU Bing, et al. Analysis of the bearing capacity of PBL shear connector[J]. Journal of Southwest Jiaotong University, 2017, 52(4):647-654. doi: 10.3969/j.issn.0258-2724.2017.04.001 廖贵星.新型波形顶板正交异性钢板-UHPC组合桥面板疲劳性能研究[D].成都: 西南交通大学, 2016. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y3038981 KIM H Y, JEONG Y J. Ultimate strength of a steel-concrete composite bridge deck slab with profiled sheeting[J]. Engineering Structures, 2010, 32(2):534-546. doi: 10.1016/j.engstruct.2009.10.014 苏庆田, 田乐, 曾明根, 等.正交异性折形钢板-混凝土组合桥面板基本性能研究[J].工程力学, 2016, 33(增刊1):138-142. http://www.cnki.com.cn/Article/CJFDTotal-GCLX2016S1025.htmSU Qingtian, TIAN Le, ZENG Minggen, et al. Research on basic performance of composite bridge decks with orthotropic corrugated steel plates and concrete[J]. Engineering Mechanics, 2016, 33(sup.1):138-142. http://www.cnki.com.cn/Article/CJFDTotal-GCLX2016S1025.htm 郭亚军.综合评价理论、方法及应用[M].北京:科学出版社, 2007:45-48. 谢延敏, 何育军, 田银.基于RBF神经网络模型的板料成形变压边力优化[J].西南交通大学学报, 2016, 51(1):121-127. doi: 10.3969/j.issn.0258-2724.2016.01.018XIE Yanmin, HE Yujun, TIAN Yin. Optimization of variable blank holder forces in sheet metal forming based on RBF neural network model[J]. Journal of Southwest Jiaotong University, 2016, 51(1):121-127. doi: 10.3969/j.issn.0258-2724.2016.01.018 张德丰. MATLAB神经网络编程[M].北京:化学工业出版社, 2011:24-42. 期刊类型引用(20)

1. 徐晨,许琴东,孙旭霞,吴用贤,张玉彬,徐艺. 连续钢梁SFRC组合桥面板的优化设计. 华南理工大学学报(自然科学版). 2024(01): 26-37 .  百度学术

百度学术2. 阳霞,何俊杰,户东阳,肖柏军,王宁波. 波形钢-UHPC组合桥面板中栓钉-PBL连接件抗剪性能数值模拟研究. 铁道科学与工程学报. 2024(02): 697-708 .  百度学术

百度学术3. 刘素梅,丁汉山. 波形钢-混凝土组合桥面板力学性能研究综述. 混凝土. 2024(01): 180-185 .  百度学术

百度学术4. 刘聪,孙宏涛,段守辉,欧阳嵩,高莉莉. 新型大纵肋波折钢板–高性能混凝土组合桥面板疲劳性能研究. 工业建筑. 2024(03): 161-166 .  百度学术

百度学术5. 康志坚,李火星. 基于机器学习的UHPC抗压强度预测及配合比优化. 混凝土与水泥制品. 2024(07): 7-13 .  百度学术

百度学术6. 辛景舟,蒋黎明,王劼耘,马闻达,李双江. 基于反向传播神经网络的锈蚀RC柱抗压承载力预测. 混凝土. 2023(06): 19-25 .  百度学术

百度学术7. 史腾,朱劲松,王子挺,秦亚婷. 基于并行计算和遗传算法的钢-UHPC华夫板组合梁优化设计. 计算力学学报. 2023(03): 357-365 .  百度学术

百度学术8. 庞学冬,张德强,于长兴,刘传奇,孔凡磊. 波形钢组合桥面板受力性能分析. 河北工程大学学报(自然科学版). 2023(03): 70-76 .  百度学术

百度学术9. 张清华,程震宇,邓鹏昊,李明哲,魏川. 新型钢-UHPC组合桥面板抗弯承载力模型试验与理论分析方法. 土木工程学报. 2022(03): 47-64 .  百度学术

百度学术10. 吴丽丽,姚超,郑贺崇. 正交异性钢桥面板的研究进展. 公路与汽运. 2022(03): 112-117+121 .  百度学术

百度学术11. 张晓战. UHPC应用于大跨径柔性桥梁的组合优化研究. 成都工业学院学报. 2022(02): 58-63 .  百度学术

百度学术12. 程书剑,豆燚,李帅希,李成. 超高性能混凝土组合结构在屏蔽厂房中的应用及其对核岛结构楼面反应谱的影响研究. 工业建筑. 2022(S1): 158-162 .  百度学术

百度学术13. 赵毅,王恒,李力,易航宇. 正交异性钢桥面板裂纹成因分析及疲劳性能改善措施综述. 公路交通技术. 2022(06): 37-42 .  百度学术

百度学术14. 孔凡磊,黄平明,陆由付,夏建平,梅葵花. PBL和PZ组合销剪力连接件承载力试验研究. 公路交通科技. 2021(01): 79-86 .  百度学术

百度学术15. 史占崇,曾明辉,邱文东,苏庆田. 正交异性钢-混凝土组合桥面板纵桥向的压弯性能. 中国公路学报. 2021(06): 80-89 .  百度学术

百度学术16. 程震宇,张清华,邓鹏昊,魏川,李明哲,段跃超. UHPC中MCL形组合销的抗剪性能. 中国公路学报. 2021(08): 205-217 .  百度学术

百度学术17. 欧志攀. 正交异性组合桥面结构一体化协同设计方法. 四川建筑. 2021(05): 160-162 .  百度学术

百度学术18. 孙瑜,王焕然,王飞,朋茜. 波形钢板-UHPC组合桥面板结构截面优化. 宁波大学学报(理工版). 2020(03): 105-110 .  百度学术

百度学术19. 戴杜伟,刘扬,鲁乃唯. 全曲线波形板-UHPC组合桥面板优化设计. 交通科学与工程. 2020(02): 58-65 .  百度学术

百度学术20. 罗如登,屈植锋,王正阳,朱志辉,刘泽. 大纵肋正交异性-PBL剪力键桥面板疲劳性能分析. 铁道科学与工程学报. 2020(11): 2849-2856 .  百度学术

百度学术其他类型引用(19)

-

下载:

下载:

百度学术

百度学术