Influence of Temperature on Performance and Microporous Structure of Foamed Concrete during Pouring Period

-

摘要:

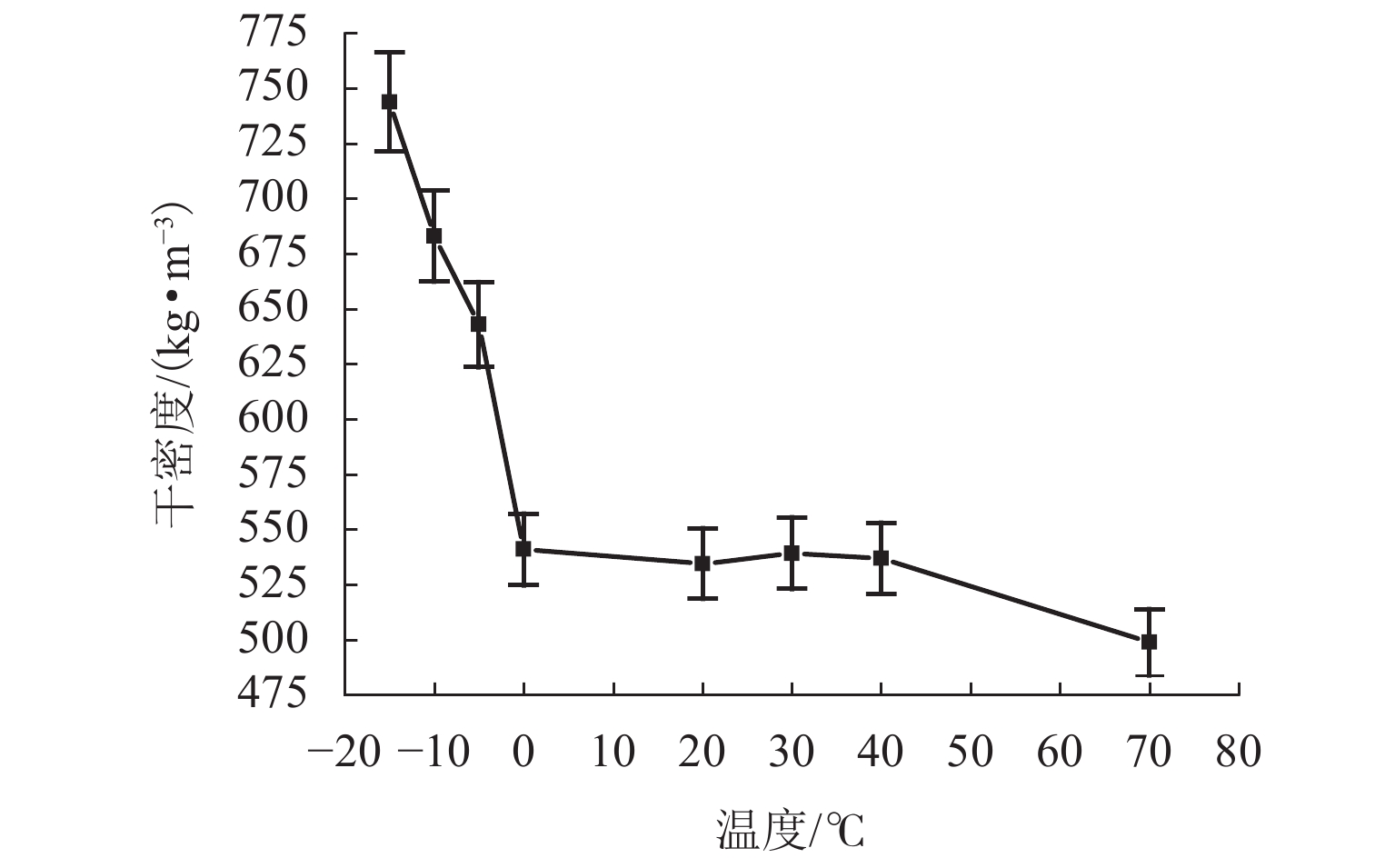

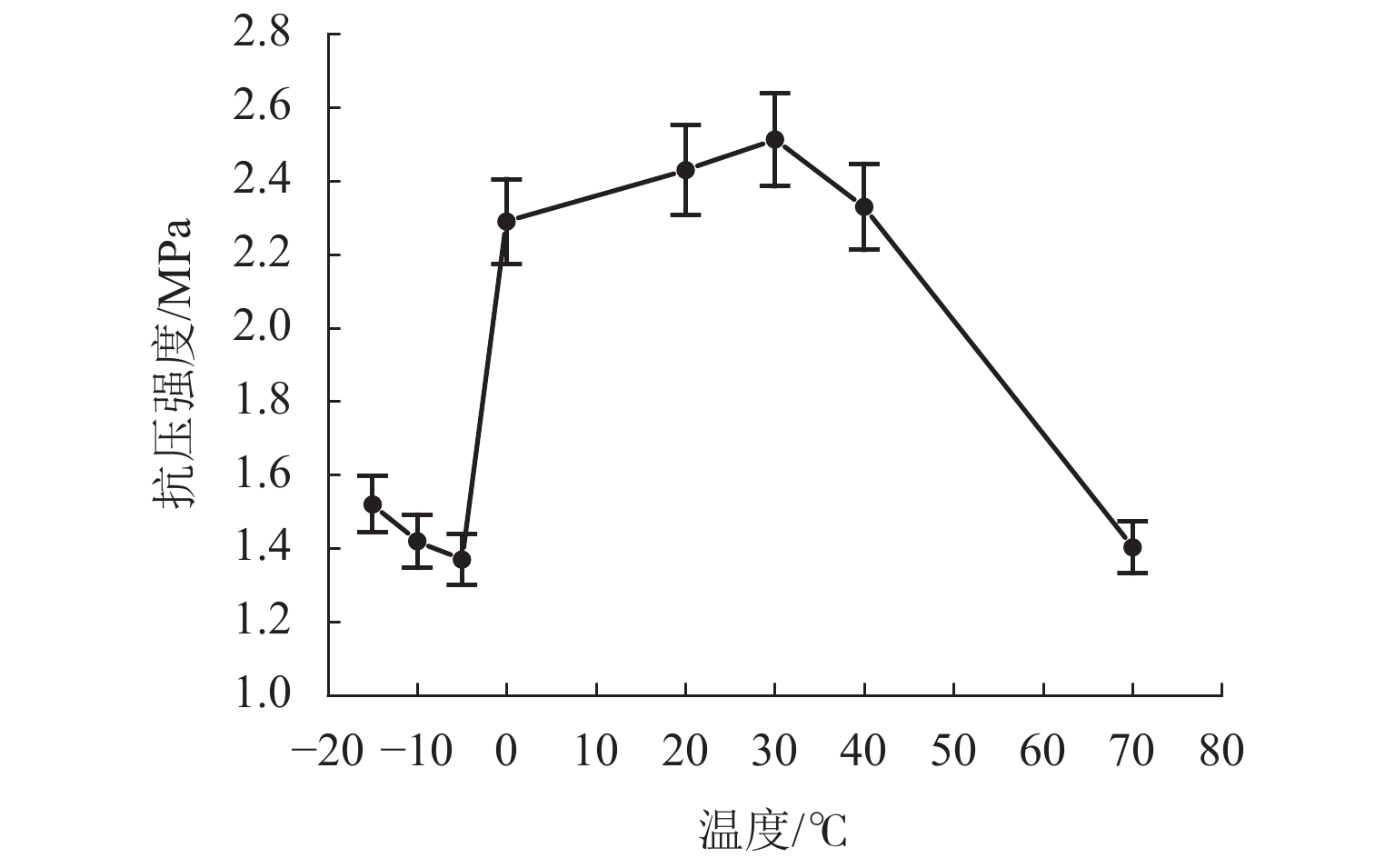

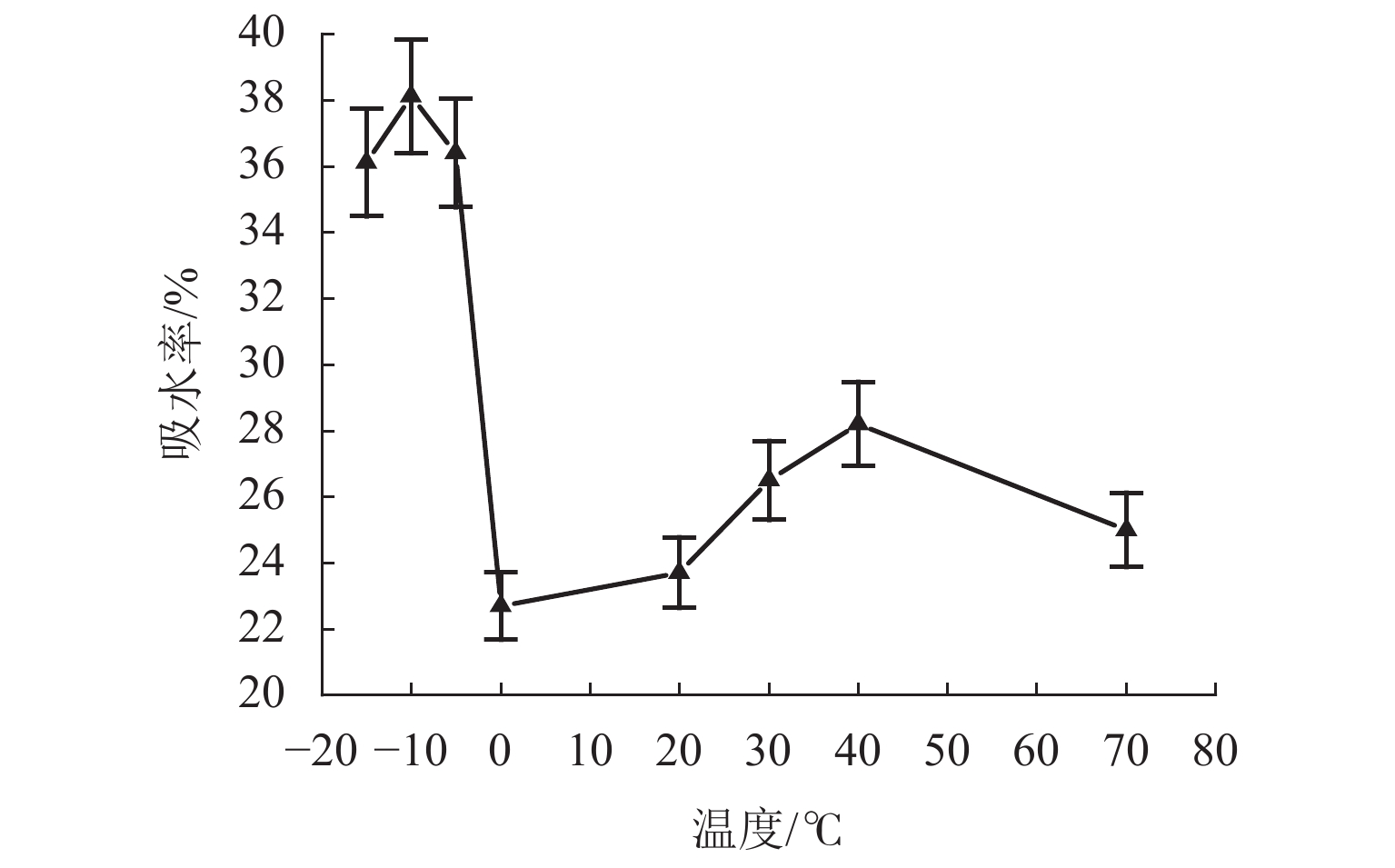

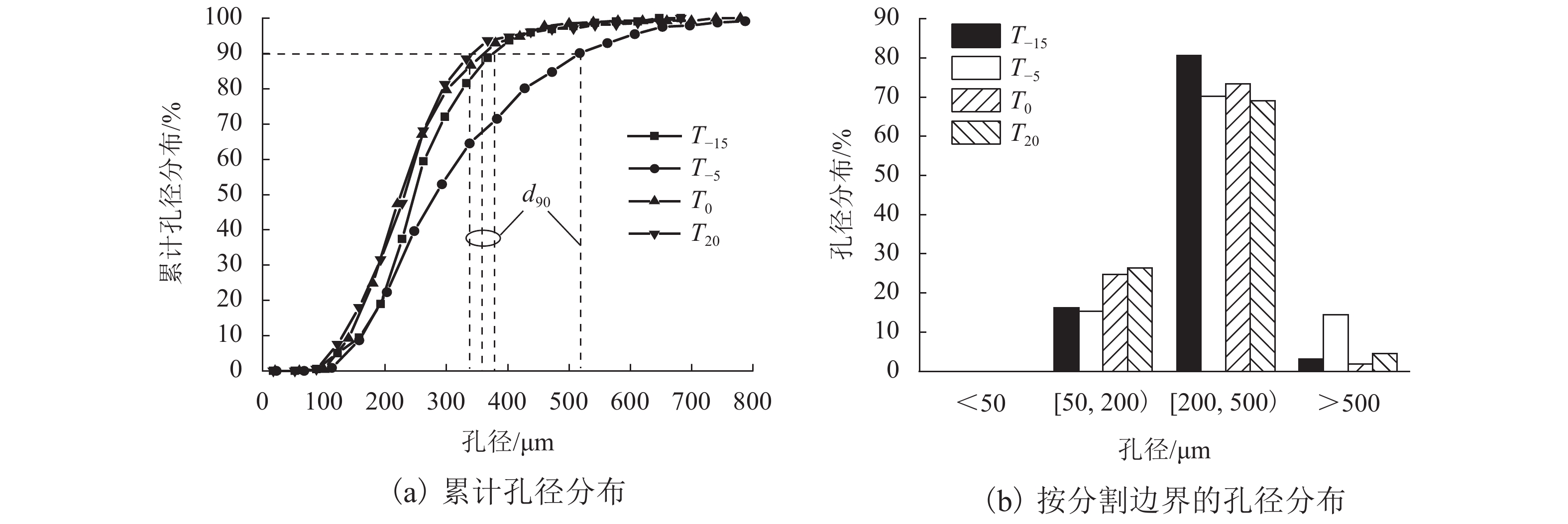

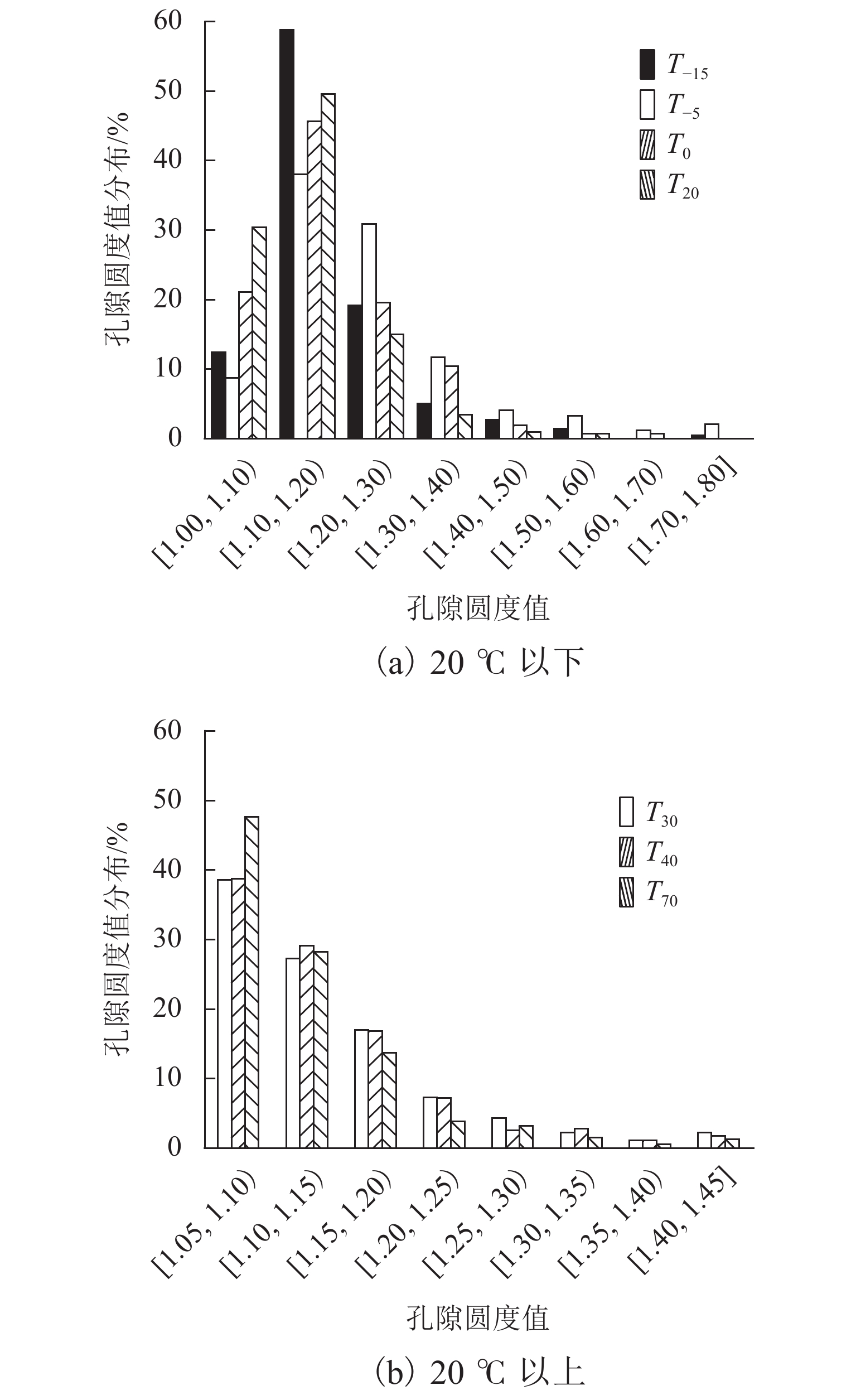

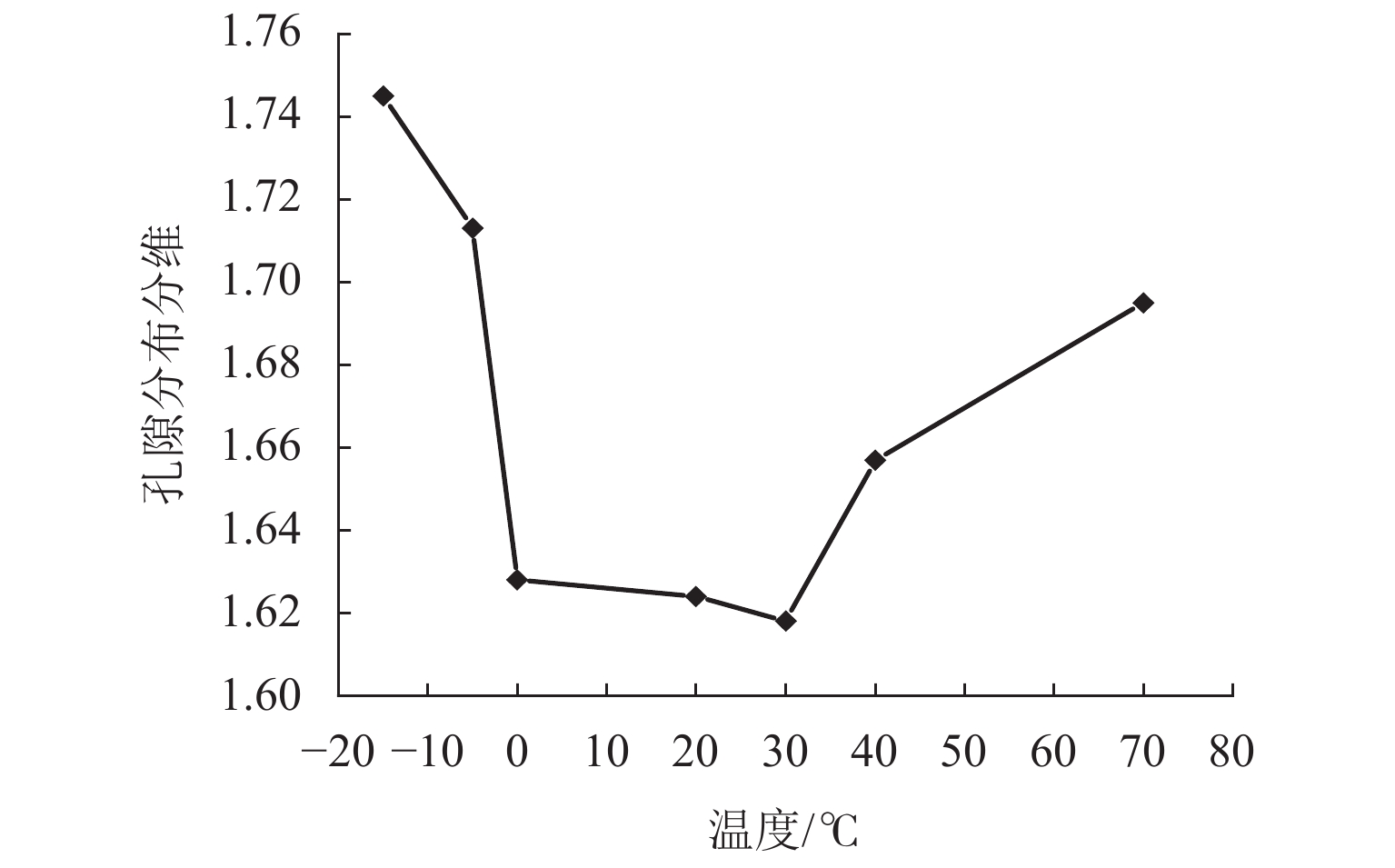

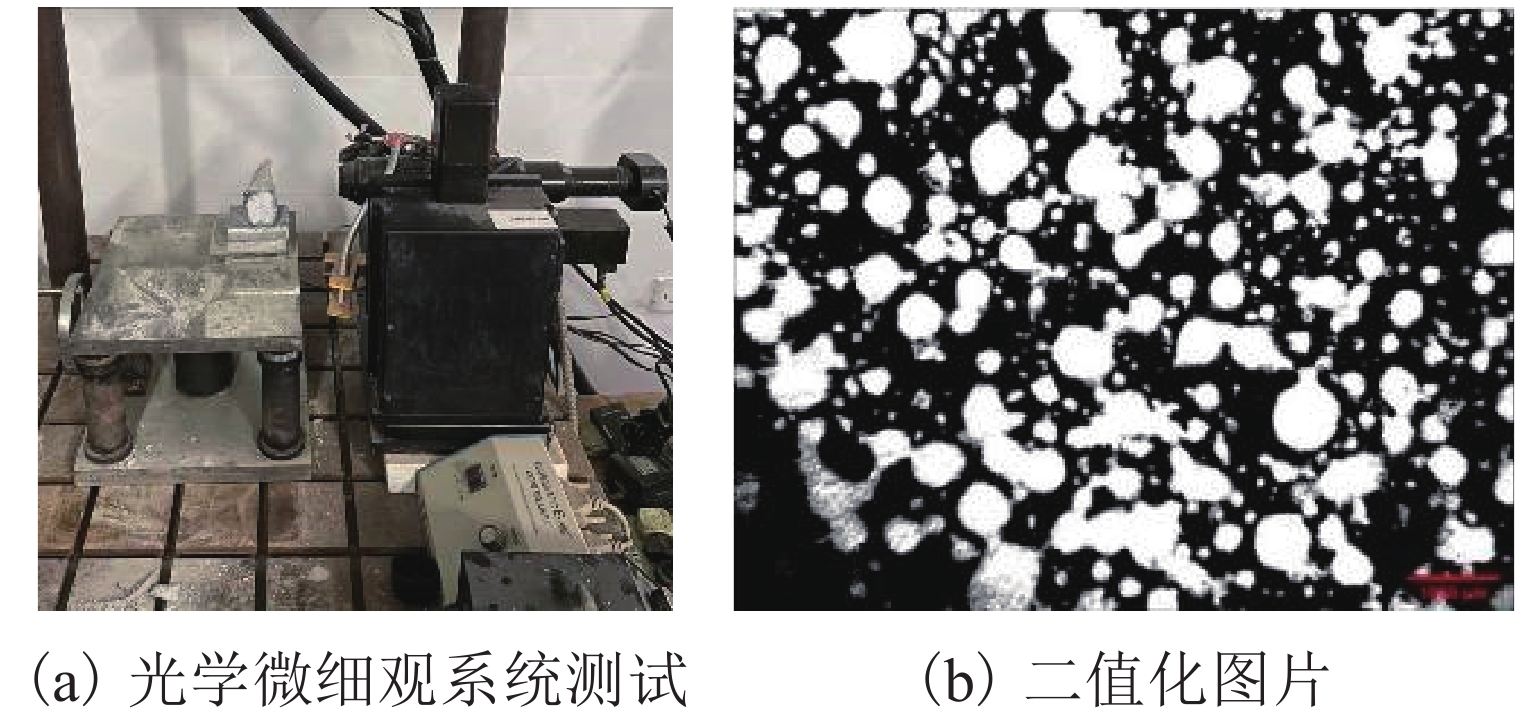

泡沫混凝土在浇筑至固化成型这段时期内,易受温度等环境因素影响,不利环境因素会导致固化成型后泡沫混凝土的性能退化和劣化. 为研究泡沫混凝土在浇筑期受温度(−15~70 ℃)影响后的性能和微孔结构,设计单因素室内试验方案,以干密度作为泡沫混凝土物理性质评价指标,抗压强度作为施工质量评价指标,吸水率用以评价泡沫混凝土的运营耐久性,并利用图像数据采集系统及Image J软件分析泡沫混凝土微孔结构的演变规律. 结果表明:随着温度上升,泡沫混凝土干密度总体呈阶梯式下降,抗压强度先减小后增大再减小,吸水率以0 ℃为分界点,温度降低或升高均呈先增大后减小趋势;等效孔径先增大后减小再增大,孔隙圆度值先增大后减小,孔隙分布分维先减小后变大;从混凝土宏观性能和微孔结构的演变规律建议泡沫混凝土浇筑期施工的温度范围为−5~40 ℃.

Abstract:Foamed concrete is susceptible to environmental factors such as temperature during the period from pouring to curing and molding, and adverse environmental factors can lead to performance degradation and deterioration of foamed concrete after curing and molding. In order to study the performance and microporous structure of foamed concrete affected by temperature (−15–70 ℃) during the pouring period, a single factor indoor test program was designed by using dry density, compressive strength, and water absorption to evaluate the physical property of foamed concrete, the construction quality, and the operational durability of foamed concrete, respectively. In addition, the evolution of the microporous structure of foamed concrete was analyzed by using an image data acquisition system and Image J software. The results show that the dry density of foamed concrete generally decreases in a stepwise manner as the temperature rises. The compressive strength first decreases, then increases, and finally decreases. The water absorption rate takes 0 ℃ as the cut-off point, and it tends to increase and then decrease when the temperature decreases or increases. The equivalent pore size shows a trend of increasing, decreasing, and increasing. The pore roundness value first increases and then decreases. The fractal dimension of pore distribution first decreases and then becomes larger. The results of macroscopic performance and microporous structure show that the recommended temperature range for the construction of foamed concrete during the pouring period is −5–40 ℃.

-

Key words:

- foamed concrete /

- pouring period /

- temperature /

- macroscopic performance /

- microporous structure

-

表 1 水泥的主要化合物含量

Table 1. Main compound content of cement

% 名称 SiO2 K2O SO3 CaO Al2O3 Fe2O3 MgO Na2O 含量 20.31 0.39 2.12 65.55 4.80 4.93 1.35 0.12 表 2 水泥的物理力学性能指标

Table 2. Physical and mechanical properties of cement

名称 细度80 μm/% 标准稠度用水量/% 初凝时间/min 终凝时间/min 抗压强度 3 d/MPa 28 d/MPa 取值 1.20 25.48 165 232 28.7 45.4 -

[1] 张磊,张静,张颖,等. 生物基发泡剂泡沫特征及其对泡沫混凝土性能的影响[J]. 建筑材料学报,2020,23(3): 589-595.ZHANG Lei, ZHANG Jing, ZHANG Ying, et al. Foam characteristics of biological based foaming agent and its effect on properties of foam concrete[J]. Journal of Building Materials, 2020, 23(3): 589-595. [2] 陈立延,杨安,洪芬,等. 不同粉煤灰掺量对泡沫混凝土性能及其孔径的影响[J]. 混凝土,2021(8): 137-140. doi: 10.3969/j.issn.1002-3550.2021.08.031CHEN Liyan, YANG An, HONG Fen, et al. Influence of different fly ash content on the performance and pore size of foamed concrete[J]. Concrete, 2021(8): 137-140. doi: 10.3969/j.issn.1002-3550.2021.08.031 [3] LARSSON R, RUDBERG M. Impact of weather conditions on in situ concrete wall operations using a simulation-based approach[J]. Journal of Construction Engineering and Management, 2019, 145(7): 05019009.1-05019009.15. doi: 10.1061/(ASCE)CO.1943-7862.0001662 [4] LIU X, ZHANG L Y, SHAO Z W, et al. Influence of construction-induced damage on the degradation of freeze—thawed lightweight cellular concrete[J]. Frontiers of Structural and Civil Engineering, 2021, 15(3): 781-792. doi: 10.1007/s11709-021-0733-9 [5] 胡晓鹏,彭刚,牛荻涛,等. 早期受冻环境对混凝土服役期性能的影响[J]. 建筑材料学报,2020,23(5): 1061-1070. doi: 10.3969/j.issn.1007-9629.2020.05.010HU Xiaopeng, PENG Gang, NIU Ditao, et al. Effect of early frost environment on service performance of concrete[J]. Journal of Building Materials, 2020, 23(5): 1061-1070. doi: 10.3969/j.issn.1007-9629.2020.05.010 [6] NASSIF A Y, PETROU M F. Influence of cold weather during casting and curing on the stiffness and strength of concrete[J]. Construction and Building Materials, 2013, 44: 161-167. doi: 10.1016/j.conbuildmat.2013.03.016 [7] CHOI H, ZHANG W Y, HAMA Y. Method for determining early-age frost damage of concrete by using air-permeability index and influence of early-age frost damage on concrete durability[J]. Construction and Building Materials, 2017, 153: 630-639. doi: 10.1016/j.conbuildmat.2017.07.140 [8] 崔玉理,贺鸿珠. 温度对泡沫混凝土性能影响[J]. 建筑材料学报,2015,18(5): 836-839,846. doi: 10.3969/j.issn.1007-9629.2015.05.021CUI Yuli, HE Hongzhu. Influence of temperature on performances of foam concrete[J]. Journal of Building Materials, 2015, 18(5): 836-839,846. doi: 10.3969/j.issn.1007-9629.2015.05.021 [9] KAMEI T, TAKASHIMA J I, SHIBI T. Temperature effects on unconfined compressive strength and microstructure of foamed mixture lightweight soil containing flaked polyethylene terephthalate (PET)[J]. Soils and Foundations, 2008, 48(6): 833-842. doi: 10.3208/sandf.48.833 [10] TAYEH B, ZEYAD A M, AGWA I S, et al. Effect of elevated temperatures on mechanical properties of lightweight geopolymer concrete[J]. Case Studies in Construction Materials, 2021, 15(5): e00673.1-e00673.15. [11] 中华人民共和国住房和城乡建设部. 泡沫混凝土: JG/T 266—2011[S]. 北京: 中国标准出版社, 2011. [12] 中国工程建设标准化协会. 现浇泡沫轻质土技术规程: CECS 249—2008[S]. 北京: 中国计划出版社, 2008. [13] 刘鑫,倪铖伟,孙东宁,等. 干湿循环下含初始损伤泡沫混凝土劣化机理研究[J]. 材料导报,2021,35(14): 14065-14071. doi: 10.11896/cldb.20030196LIU Xin, NI Chengwei, SUN Dongning, et al. Study on deterioration mechanism of lightweight cellular concrete with initial damage under wetting-drying cycles[J]. Materials Reports, 2021, 35(14): 14065-14071. doi: 10.11896/cldb.20030196 [14] LIU X, SUN D N, LIU D X, et al. Simulation of ultrasonic propagation in porous cellular concrete materials[J]. Construction and Building Materials, 2021, 285: 122852.1-122852.13. [15] KHOURY G A. Compressive strength of concrete at high temperatures: a reassessment[J]. Magazine of Concrete Research, 1992, 44(161): 291-309. doi: 10.1680/macr.1992.44.161.291 [16] 武艳文. 泡沫混凝土的制备及其气孔结构的研究[D]. 西安: 西安建筑科技大学, 2018. [17] 庞超明,王少华. 泡沫混凝土孔结构的表征及其对性能的影响[J]. 建筑材料学报,2017,20(1): 93-98. doi: 10.3969/j.issn.1007-9629.2017.01.017PANG Chaoming, WANG Shaohua. Void characterization and effect on properties of foam concrete[J]. Journal of Building Materials, 2017, 20(1): 93-98. doi: 10.3969/j.issn.1007-9629.2017.01.017 [18] KUNHANANDAN NAMBIAR E K, RAMAMURTHY K. Air-void characterisation of foam concrete[J]. Cement and Concrete Research, 2007, 37(2): 221-230. doi: 10.1016/j.cemconres.2006.10.009 [19] 李相国,刘敏,马保国,等. 孔结构对泡沫混凝土性能的影响与控制技术[J]. 材料导报,2012,26(7): 141-144,153. doi: 10.3969/j.issn.1005-023X.2012.07.030LI Xiangguo, LIU Min, MA Baoguo, et al. Influence of pore structure on foam concrete and controlling method[J]. Materials Reports, 2012, 26(7): 141-144,153. doi: 10.3969/j.issn.1005-023X.2012.07.030 -

下载:

下载: